Silicon Nitride Seal Ring is a precision-machined ceramic sealing component made from Si₃N₄ (silicon nitride), designed to serve as a rotating or stationary seal face in mechanical seals, pumps, compressors, and vacuum systems. Its function is to maintain a stable sealing interface under high pressure, temperature variation, and sliding velocity

Silicon Nitride Seal Ring Benefits

-

Stable Face Geometry

Tight control of flatness (≤ 2 μm) and parallelism (≤ 3 μm) ensures minimal face gap variation under fluctuating pressure or axial load. This geometric stability prevents micro-opening during rapid start-stop cycles, maintaining steady leakage rates even under 20–25 bar differential pressure. -

Low Rotating Mass

The thin-wall Si₃N₄ structure achieves approximately 40 % lower density than tungsten carbide, significantly reducing torque demand during acceleration. Lower inertia lessens bearing load and vibration amplitude at surface speeds exceeding 20 m/s, extending both seal and motor life. -

Edge-Chip Mitigation

Optimized chamfer, fillet, and corner radius libraries (0.2–0.5 mm typical) prevent edge stress concentration and micro-crack initiation during installation or thermal expansion mismatch. This design approach reduces chip-related leakage failures and simplifies alignment in tight seal cavities. -

Consistent Lapping Window

Repeatable Ra ≤ 0.02 μm and Waviness Wt ≤ 0.15 μm parameters provide predictable initial face contact and fluid-film formation. Uniform lapping quality shortens run-in time, stabilizes friction torque, and keeps sealing faces cooler during the first 100 hours of operation. -

Pairing Flexibility

The Si₃N₄ seal ring design is validated with standard counterpart materials—silicon carbide (SiC), tungsten carbide (TC), carbon graphite, and Si₃N₄-vs-Si₃N₄ combinations—each supported by recommended pressure-velocity (PV) limits up to 2.5 MPa·m/s. This enables engineers to match the ring precisely to media type, load, and duty cycle without requalifying the entire seal assembly.

Silicon Nitride Ceramic Seal Ring Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

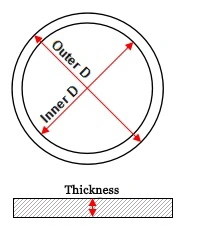

Specifications of Si3N4 Seal Ring

| Item | Outer Diameter (mm) | Inner Diameter (mm) | Thickness (mm) |

| AT-DHG-MF001 | 10.0 | 5.0 | 2.5 |

| AT-DHG-MF002 | 15.0 | 9.0 | 3.0 |

| AT-DHG-MF003 | 20.0 | 12.9 | 3.5 |

| AT-DHG-MF004 | 25.0 | 15.0 | 2.0 |

| AT-DHG-MF005 | 28.0 | 20.0 | 2.5 |

| AT-DHG-MF006 | 31.0 | 25.0 | 3.0 |

| AT-DHG-MF007 | 36.5 | 27.0 | 4.5 |

| AT-DHG-MF008 | 48.0 | 38.0 | 4.8 |

| AT-DHG-MF009 | 50.0 | 39.0 | 5.0 |

| AT-DHG-MF010 | 50.0 | 40.0 | 5.0 |

| AT-DHG-MF011 | 50.0 | 38.5 | 5.5 |

| AT-DHG-MF012 | 50.0 | 30.0 | 10.0 |

| AT-DHG-MF013 | 51.0 | 40.5 | 5.1 |

| AT-DHG-MF014 | 55.5 | 51.5 | 2.0 |

| AT-DHG-MF015 | 62.0 | 51.0 | 5.5 |

| AT-DHG-MF016 | 65.0 | 53.8 | 5.5 |

| AT-DHG-MF017 | 68.0 | 57.0 | 5.5 |

| AT-DHG-MF018 | 90.0 | 18.0 | 6.0 |

| AT-DHG-MF019 | 102.0 | 63.0 | 19.4 |

| AT-DHG-MF020 | 120.0 | 112.8 | 8.5 |

| AT-DHG-MF021 | 1-150 | 0.5-140 | 0.25-50 |

Si3N4 Seal Ring Packaging

- Clean room-grade pouch → anti-static tray → foam-lined carton. Single-piece separators prevent face rub.