ADCERAX® Square Silicon Carbide Crucible is engineered for flat-bed sintering environments where thin-layer powder spreading, surface temperature consistency, and high-frequency thermal cycling define production stability. Its square geometry enables uniform 2D heat transfer and precise powder distribution, supporting applications ranging from battery cathode and anode materials to ceramic sheets, glass frit, and AM metal powders. Because these workflows rely on predictable thermal behavior and efficient furnace loading, the Square Silicon Carbide Crucible provides a structurally stable, high-conductivity SiC platform that integrates naturally into tray-based continuous furnaces and advanced materials processing lines.

Engineered Performance Features of Square Silicon Carbide Crucible

-

Superior 2D Heat Distribution

Thin-layer powder sintering benefits from a planar heat field where center–edge deviation is maintained within ±5–15°C, improving grain growth predictability. This level of uniformity supports cathode and anode powders that show particle-size variation increases of 10–18% when using non-flat crucibles.

-

Increased Furnace Loading Efficiency

The square footprint increases useable furnace area by 15–35%, enabling tighter tray arrangements in push-plate and multi-layer furnaces. This gain directly increases batch throughput, often improving line output by 1.2–1.5× in high-frequency operations.

-

High Flexural Strength at Elevated Temperature

Flexural strength maintains 250–400 MPa between room temperature and 1200°C, preventing cracking under mechanical or thermal stress. Competing materials can lose 30–45% of their strength at similar temperatures, raising the risk of mid-process breakage.

Technical Specifications of Square Silicon Carbide Crucible

ADCERAX® Square Silicon Carbide Crucible is engineered with high-density silicon carbide microstructures designed for thermal stability, mechanical endurance, and chemical resistance in high-temperature sintering and flat-bed heat-treatment environments, enabling reliable performance across repeated thermal cycles and demanding process conditions.

| Property |

Specification |

| Material Composition |

RBSiC (SiC 80%, free Si 20%) / SSiC (SiC 99%) |

| Density |

3.02–3.10 g/cm³ |

| Porosity |

<0.1%, closed-pore structure |

| Continuous Use Temperature |

1200–1500°C (atmosphere dependent) |

| Peak Temperature |

1600°C short-term |

| Flexural Strength |

250–400 MPa (20–1200°C range) |

| Thermal Conductivity |

45–74 W/m·K at 1000°C |

| Thermal Expansion |

4.1–4.5×10⁻⁶ K⁻¹ |

| Elastic Modulus |

330–420 GPa (grade dependent) |

| Hardness |

2600–2800 kg/mm² |

| Oxidation Resistance |

Stable protective SiO₂ layer above 1200°C |

| Chemical Compatibility |

Resistant to acids, alkalis, oxide vapors, catalyst precursors |

| Thermal Shock Resistance |

Survives quenching cycles from 1000°C → RT |

| Atmosphere Suitability |

Air, inert gases, mild reducing atmospheres |

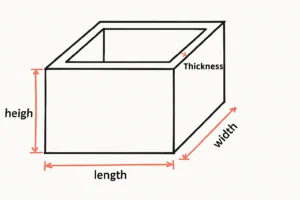

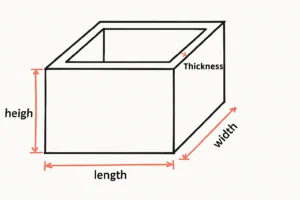

Dimensions of Square Silicon Carbide Crucible

Protective Export Packaging for the Square Silicon Carbide Crucible

Square Silicon Carbide Crucible shipments are secured through a multi-layer packaging workflow designed to prevent vibration, impact, and moisture intrusion during long-distance transport. Each unit is first stabilized with internal buffers, then consolidated in reinforced cartons and finally locked inside custom plywood crates suitable for ocean and air freight. This packaging structure ensures safe arrival at international industrial sites, even under high-load palletization conditions.

ADCERAX® Square Silicon Carbide Crucible Resolves Critical Processing Challenges in Flat-Bed Thermal Workflows

ADCERAX®Square Silicon Carbide Crucible is adopted in industrial environments where planar thermal fields, thin-layer material spreading, and predictable heat transfer directly determine production stability and batch yield. By integrating a monolithic flat-bed SiC structure with tight thermal gradients and durable cycle life, it addresses technical bottlenecks that traditional curved-wall or cylindrical vessels cannot resolve in tray-based sintering and layered material processing workflows.

-

Square Silicon Carbide Crucible for Layer-Spread High-Nickel Cathode Powder Conditioning

✅Key Advantages

1. Anti-Migration Flat Geometry

The square, planar cavity prevents powder convergence toward the center, maintaining a uniform layer profile across the full 2D surface. This stability avoids thickness deviations that commonly push particle-size variation into the 8–15% range in curved vessels.

2. Tight Thermal Gradient Control

The flat-bed SiC body sustains a center–edge ΔT within 5–15°C, stabilizing heat ramp behavior across high-nickel formulations. This consistent thermal field suppresses secondary agglomeration and supports predictable morphological evolution during pre-sintering.

3. High-Conductivity Activation Support

Thermal conductivity values of 45–74 W/m·K accelerate heat equalization under high-throughput continuous kiln loading. Faster stabilization reduces local overheating zones that distort BET uniformity in high-energy cathode powders.

✅ ️Problem Solved

High-nickel cathode lines often face inconsistent pre-conditioning when powders migrate toward the center of curved trays, producing measurable layer-thickness variation and elevating particle-size deviation by 8–15%. These shifts contribute to secondary agglomeration during ramp stages and destabilize BET-specific surface area across production lots. ADCERAX® Square Silicon Carbide Crucible eliminates the center-pull pattern through its planar bottom and right-angle perimeter, forcing powders to remain evenly distributed throughout the thermal cycle. The stable ΔT profile and high-conductivity SiC matrix ensure consistent powder activation, enabling more predictable coating behavior in downstream processes.

-

Square Silicon Carbide Crucible for Rectangular Ceramic Green-Tape Binder Burn-Out

✅Key Advantages

1. Flatness-Controlled Support Plane

The monolithic flat-bed SiC structure holds surface deviation within 0.05–0.10 mm, preventing green-tape bowing during binder decomposition. This rigidity mitigates the curvature that commonly drives 12–20% scrap rates in multilayer ceramic sheets.

2. Distortion-Resistant Thermal Behavior

Its low thermal expansion coefficient of 4.1–4.5×10⁻⁶ K⁻¹ ensures negligible base deformation throughout binder burn-out ramps. This stability preserves thickness uniformity and prevents early misalignment in stacked tape assemblies.

3. Uniform Heat Exposure for Sheet Integrity

High thermal conductivity maintains even heating across the rectangular sheet footprint, reducing edge-lift formation during volatile release. Balanced heat flow is essential for preventing delamination that propagates during final sintering.

✅ ️Problem Solved

Tape-casting operations frequently report bending, edge-lift, and geometric drift when green tapes are processed on curved or thermally unstable supports, yielding 12–20% scrap in multilayer production. Even minor curvature during binder burn-out propagates misalignment between stacked layers, weakening lamination reliability and downstream sintering integrity. ADCERAX® Square Silicon Carbide Crucible solves this by providing a rigid flat-bed surface with minimal thermal distortion and controlled flatness deviation. The uniform heat field protects tape geometry, enabling stable binder removal and consistent laminate alignment across production cycles.

-

Square Silicon Carbide Crucible for Component-Shaped Glass Frit Formulation and Depth-Controlled Melting

✅Key Advantages

1. Uniform Melt-Depth Control

The square planar melt surface eliminates the central pooling effect observed in round crucibles, maintaining consistent melt depth across the entire footprint. This improvement reduces melt uniformity variability from 20–30% to within a predictable test range.

2. High-Conductivity Melt Homogenization

Thermal conductivity of 45–74 W/m·K promotes rapid and even heat penetration into the shallow frit layer. This helps laboratories capture accurate compositional behavior by minimizing localized overheating that would otherwise distort fining and color reactions.

3. Predictable 2D Thermal Field for Comparative Trials

A consistent edge-to-center thermal profile allows formulation changes to be evaluated without thermal bias. This stability shortens iteration cycles by reducing repeat tests caused by divergent melt behavior across experimental runs.

✅ ️Problem Solved

Glass frit development often becomes inefficient when round crucibles create uneven melt depths and central pooling, producing 20–30% variation in sample uniformity and distorting comparative evaluations. Uneven temperature fields obscure early-stage reactions and delay qualification cycles by forcing repeat trials. ADCERAX® Square Silicon Carbide Crucible provides a controlled melt geometry with consistent 2D heat distribution and high-conductivity behavior, ensuring stable depth-controlled melting across all test regions. Its planar thermal field enables accurate assessment of formulation changes and reduces divergence between iterative trials.

ADCERAX® Square Silicon Carbide Crucible User Guide for Stable, Predictable Thermal Operations

The Square Silicon Carbide Crucible operates within precision-controlled thermal environments where powder uniformity, surface heating behavior, and multi-cycle durability directly affect production outcomes, making correct usage practices essential for long-term performance stability and safety.

-

Pre-Operation Handling Guidelines

1. Proper Pre-Heating Discipline

Pre-heating helps the crucible reach a balanced thermal state before loading, reducing stress concentration during rapid ramp stages. This step is especially important for powders requiring tight thermal uniformity. Controlled warm-up minimizes unnecessary thermal fatigue and preserves structural strength.

2. Clean Surface Preparation

Remove particulates, binder residue, or previous batch contaminants with a soft non-abrasive tool to avoid unintentional reaction points. Surface impurities can cause localized overheating and influence powder behavior. Maintaining a clean interior ensures consistent 2D heat distribution for thin-layer applications.

3. Safe Material Loading Practices

Spread materials as evenly as possible to maintain planned thermal patterns across the square geometry. Uneven distribution alters heat flow and may disrupt powder morphology development. Balanced loading supports repeatable process outputs in continuous furnaces.

-

In-Process Thermal Management Instructions

1. Avoid Extreme Thermal Shocks

Sudden temperature drops or accelerated cooling cycles create excessive stress even in high-conductivity SiC structures. Stable transition rates support predictable powder activation. Controlled heat cycling maintains microstructural stability over repeated use.

2. Maintain Furnace Loading Symmetry

Ensure trays, crucibles, or companion vessels are arranged without creating uneven heat pockets. Symmetry preserves a stable ΔT across the crucible’s 2D surface. Consistent loading contributes to dependable heating behavior in high-throughput lines.

3. Monitor Gas Flow and Atmosphere Conditions

Different materials respond variably to inert, oxidative, or reducing atmospheres, and crucible performance depends on compatible settings. Adjust furnace atmosphere based on the applied material. Correct gas control protects surface integrity and prevents vapor-phase corrosive reactions.

-

Post-Operation Cooling and Maintenance Practices

1. Gradual Cooling Protocol

Allow the crucible to cool inside a controlled environment to minimize internal stress. Abrupt exposure to ambient temperature creates contraction gradients. Slow cooling preserves dimensional stability and reduces microcrack formation.

2. Residue Removal After Each Cycle

Remove melted residues, frit remnants, or powder layers before next use to prevent contamination. Build-up affects thermal uniformity across the square surface. Clean cycles support repeatable material responses in sensitive formulations.

3. Record Usage Cycles

Track number of heating cycles, atmosphere type, and maximum temperatures encountered. This documentation helps predict wear progression. Cycle tracking improves maintenance planning for continuous production.

-

Storage, Transportation, and Long-Term Preservation Advice

1. Store in a Dry, Stable Environment

SiC is resistant to moisture but best preserved in controlled storage conditions. Humidity accumulation on companion materials may cause future contamination. Dry storage protects handling cleanliness and maintains surface quality.

2. Protect Against Mechanical Impact

Use padded shelving or compartmented crates to avoid corner impacts during handling. Square geometry features sharper edges requiring careful protection. Mechanical safeguarding prolongs service life and avoids microstructural stress.

3. Use Dedicated Placement Supports

Avoid stacking crucibles unless dedicated separators are used to distribute load evenly. Direct stacking introduces unnecessary pressure points. Proper support prevents edge deformation and maintains base flatness for precise heating.

![]()