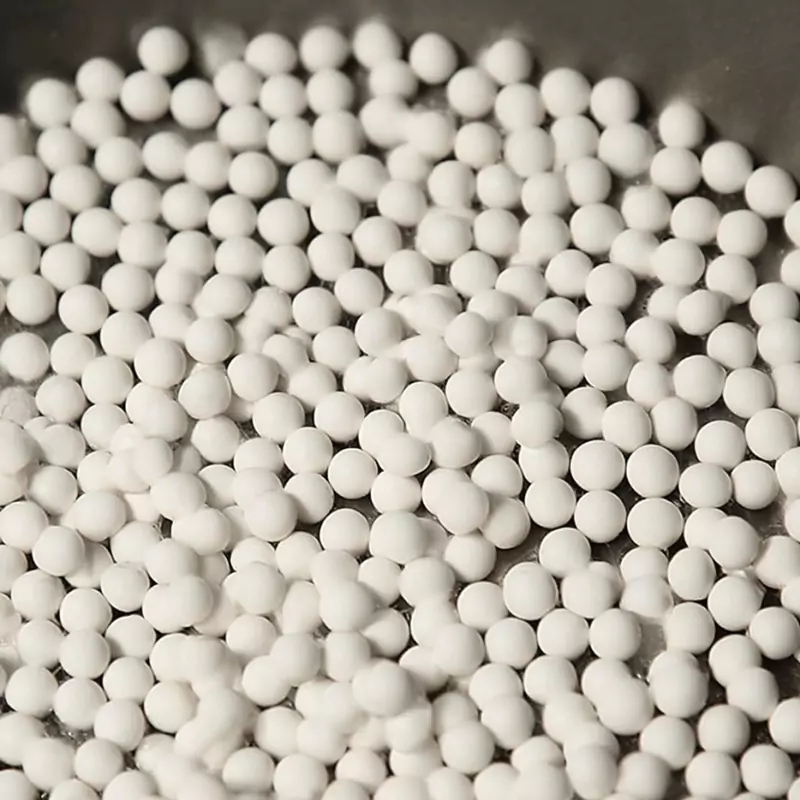

Yttrium Stabilized Zirconia Beads are engineered for high-precision grinding and dispersion, ideal for advanced ceramics, electronic materials, and pharmaceutical applications. Designed to maintain uniform particle distribution and surface quality, these beads enhance process efficiency and product consistency. Suitable for laboratories, research institutions, and industrial production, Zirconia Beads deliver reliable performance across demanding manufacturing and R&D processes.

Key Benefits of Yttrium Stabilized Zirconia Beads

- YSZ Beads achieve particle sizes down to sub-micron levels, ensuring even dispersion for sensitive nanomaterials. The controlled bead size allows for >95% uniform particle distribution, critical for functional coatings and advanced ceramics.

- These beads maintain high surface activity, resulting in 20% higher material homogeneity compared to standard ceramic beads. They enable fine-grinding processes without introducing aggregation or particle clumps.

- With a density of ≥6.0 g/cm³, Zirconia Beads maximize energy transfer during milling, enhancing grinding efficiency. This density contributes to 30% longer operational lifespan than conventional ceramic beads.

- Hardness of ≥11 GPa ensures minimal bead degradation, reducing contamination and maintaining product quality over repeated cycles.

- Their chemical stability supports neutral pH dispersion, preserving sensitive electronic slurries without altering material properties.

- Consistent performance ensures >98% reproducibility in high-precision applications such as piezoelectric ceramics and conductive nanomaterials.

Properties of Yttrium Stabilized Zirconia Beads

| Performance |

Unit |

Material |

| Component |

Wt% |

ZrO2 94.8±0.2%, Y2O3 5.2±0.2% |

| Filled Density |

Kg/l |

3.5(φ5mm) |

| Density |

g/cm3 |

6.04 |

| Hardness (HV) |

HV |

>1350 |

| Elasticity Modulus |

GPa |

200 |

| Thermal Conductivity |

W/m.k |

3 |

| Thermal Expansion Coefficient |

10x10⁻⁶/°C (20-400) |

9.6 |

| Crush Strength |

KN |

≥20(φ7mm) |

| Bending Toughness |

MPam1/2 |

8 |

| Grain Size |

Um |

≤0.5 |

Dimension of Yttrium Stabilized Zirconia Beads

|

Model |

Diameter(mm) |

|

AT-YHG-WZ1001 |

0.03 |

|

AT-YHG-WZ1002 |

0.05 |

|

AT-YHG-WZ1003 |

0.1 |

|

AT-YHG-WZ1004 |

0.2 |

|

AT-YHG-WZ1005 |

0.3 |

|

AT-YHG-WZ1006 |

0.4 |

|

AT-YHG-WZ1007 |

0.5 |

|

AT-YHG-WZ1008 |

0.6 |

|

AT-YHG-WZ1009 |

0.7 |

|

AT-YHG-WZ1010 |

0.8 |

|

AT-YHG-WZ1011 |

0.9 |

|

AT-YHG-WZ1012 |

0.9-1.0 |

|

AT-YHG-WZ1013 |

0.9-1.1 |

|

AT-YHG-WZ1014 |

1.0-1.2 |

|

AT-YHG-WZ1015 |

1.2-1.4 |

|

AT-YHG-WZ1016 |

1.4-1.6 |

|

AT-YHG-WZ1017 |

1.6-1.8 |

|

AT-YHG-WZ1018 |

1.8-2.0 |

|

AT-YHG-WZ1019 |

2.0-2.2 |

|

AT-YHG-WZ1020 |

2.2-2.5 |

|

AT-YHG-WZ1021 |

2.5-2.8 |

|

AT-YHG-WZ1022 |

2.8-3.2 |

Packaging of Yttrium Stabilized Zirconia Beads

ADCERAX® YSZ Beads are securely packaged in jumbo bags, metal barrels, plastic barrels, or paper barrels for bulk industrial applications. For smaller orders, they are supplied in paper boxes, aluminum foil vacuum bags, paper bags, or textile bags.

User Guide for Yttrium Stabilized Zirconia Beads

This user guide provides essential guidance for handling, milling, and storing YSZ Beads to ensure consistent particle uniformity, minimize contamination, and maximize performance across laboratory, research, and industrial applications. Following these recommendations will help maintain the integrity and efficiency of your processes while optimizing product longevity.

-

Handling and Storage Best Practices

1. Avoid Direct Contact: Always use appropriate tools when handling Zirconia Beads to prevent contamination and maintain particle integrity. Gloves and clean containers are recommended to preserve their high uniformity.

2. Proper Storage Conditions: Store Zirconia Beads in a dry, temperature-controlled environment to avoid moisture absorption and potential degradation. Regularly inspect containers for tight sealing and cleanliness.

3. Prevent Cross-Contamination: Do not mix Zirconia Beads with other milling media unless verified compatible. Always label and segregate batches to maintain process consistency.

-

Milling and Dispersion Guidelines

1. Optimal Milling Speed: Operate milling systems within the recommended speed range to maintain even particle dispersion and minimize bead wear. Excessive speed may reduce efficiency and increase contamination risk.

2. Loading Ratios: Use correct bead-to-material ratios to achieve uniform results and minimize energy consumption. Adjust ratios based on slurry viscosity and particle density for best outcomes.

3. Process Duration: Monitor milling duration closely; extended times can affect particle distribution consistency. Regular sampling is advised to ensure target uniformity is maintained.

-

Cleaning and Maintenance Instructions

1. Rinse Thoroughly After Use: Clean Zirconia Beads immediately after each milling cycle using deionized water or appropriate solvent to remove residual material. Proper rinsing preserves bead performance and prevents cross-batch contamination.

2. Inspect for Wear or Damage: Regularly check for surface defects or micro-cracks, as these can compromise product consistency. Replace beads showing visible wear to maintain process reliability.

3. Dry and Store Correctly: After cleaning, dry beads completely before returning to storage containers. Moisture retention can affect future milling performance and particle quality.

-

Safety and Operational Recommendations

1. Personal Protective Equipment: Always wear gloves, goggles, and protective clothing when handling Zirconia Beads or slurry mixtures. This ensures both operator safety and product integrity.

2. Avoid Contaminants: Prevent exposure to oils, dust, or other foreign substances that may interfere with bead performance. Clean work surfaces before introducing beads into the system.

3. System Compatibility Checks: Verify that milling equipment materials are compatible with Zirconia Beads to prevent unintended chemical reactions or mechanical damage. Conduct small-scale tests before full-scale production.