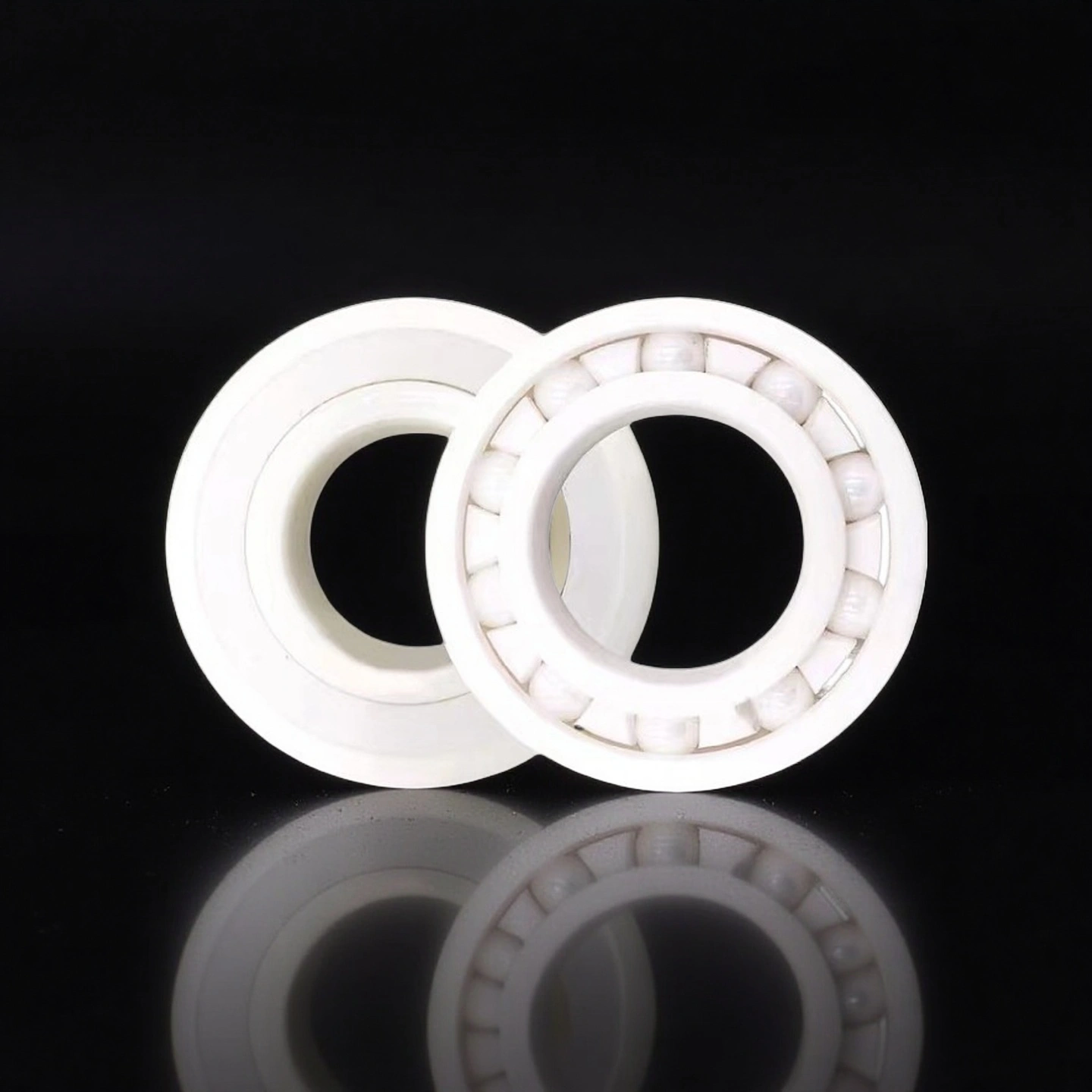

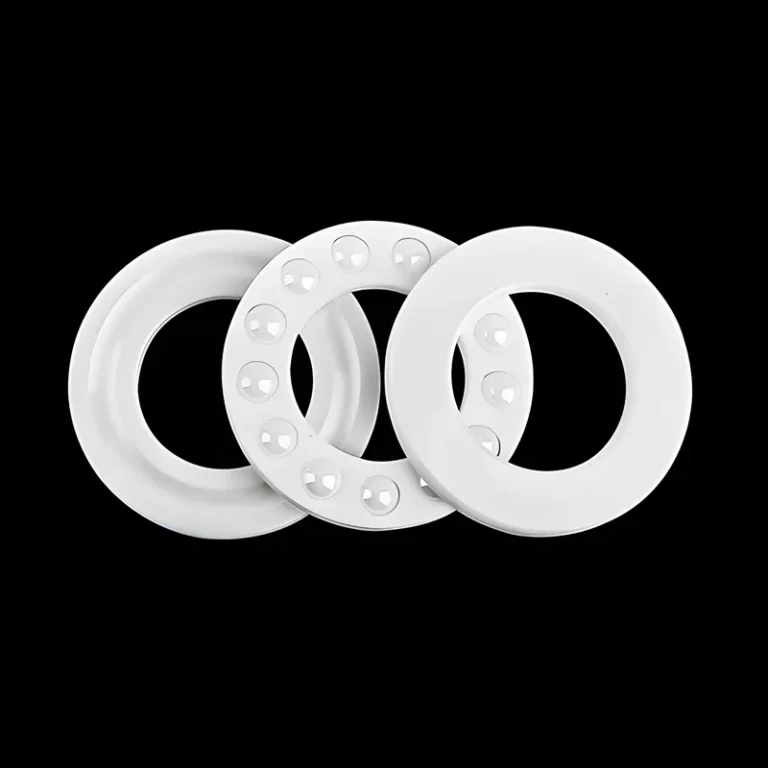

ADCERAX® Zirconia Bearing is engineered for use in demanding environments where metal bearings fail due to heat, corrosion, or electrical conductivity. With exceptional resistance to wear, chemicals, and magnetism, it provides stable operation in high-speed and high-temperature systems. Whether used with stainless steel cages or advanced PEEK/PTFE options, it performs reliably in continuous conditions up to 500 °C.

Key Performance Features of Zirconia Bearing in Demanding Industrial Conditions

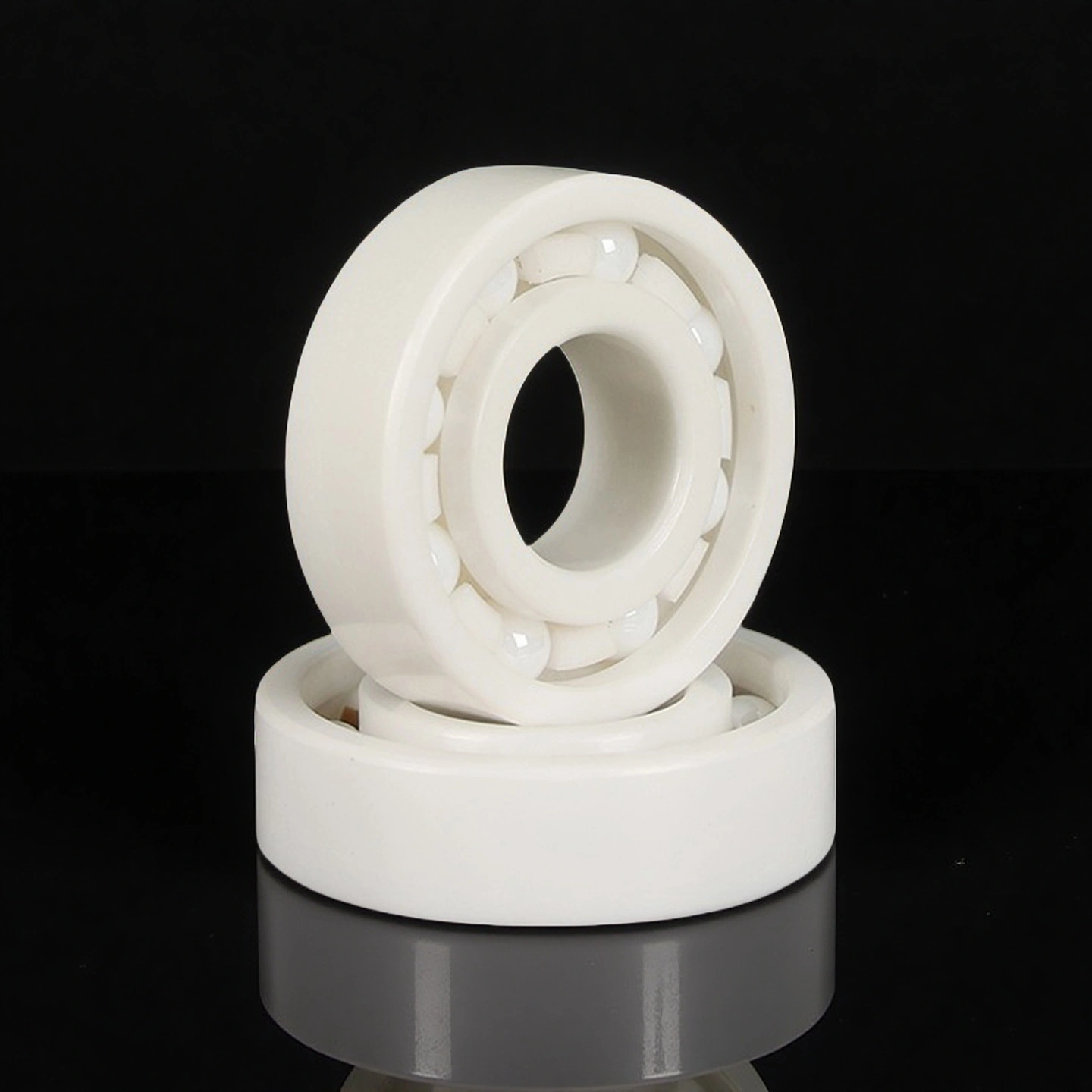

- Zirconia Bearing operates continuously at up to 500 °C with full-ball configuration. It maintains >90% mechanical strength at 400 °C and supports stable rotation in kilns, plastic extrusion, and steel forming equipment.

- Zirconia Bearing maintains structural integrity after 72 hours of immersion in NaOH and H₃PO₄. It resists degradation in acidic, alkaline, and saline environments, proving its suitability for chemical pumps, plating systems, and marine drives.

- Zirconia Bearing exhibits a hardness of 1,200–1,350 HV and withstands sustained mechanical loading above 900 MPa flexural strength. It retains wear resistance over 3× longer service life than hardened stainless steel bearings in dry and contaminated environments.

- Zirconia Bearing shows zero magnetic permeability (μ=0), eliminating particle attraction and enabling use in sensitive instruments. Its dielectric strength exceeds 15 kV/mm, ensuring reliable performance in electrically insulated motor housings and power modules.

- Zirconia Bearing enables dry operation with no added lubrication, maintaining rotation in vacuum and sterile environments. Friction coefficient remains below 0.25, reducing energy loss and startup torque in low-load systems.

Technical Properties of Zirconia Bearing

Zirconia Bearing delivers consistent mechanical, thermal, and electrical stability across high-load, high-speed, and chemically aggressive environments. The ceramic composition, microstructure, and performance metrics listed below are suitable for quality inspection, engineering validation, and material certification processes.

| Property | Specification |

|---|---|

| Material Composition | Yttria-Stabilized Zirconia (Y-TZP) |

| Zirconia Purity | ≥ 99.8% |

| Density | 6.05 g/cm³ |

| Vickers Hardness | 1,200–1,350 HV |

| Flexural Strength | > 900 MPa |

| Compressive Strength | > 2,000 MPa |

| Fracture Toughness | 6–8 MPa·m¹ᐟ² |

| Thermal Conductivity (25 °C) | 2.2 W/m·K |

| Thermal Expansion Coefficient | 10.5×10⁻⁶ /K |

| Maximum Operating Temperature | 500 °C (full-ball), 260 °C (PEEK cage) |

| Dielectric Strength | > 15 kV/mm |

| Electrical Resistivity | > 10¹² Ω·cm |

| Magnetic Permeability | ≈ 0 (Non-magnetic) |

| Surface Finish (Raceway) | Ra ≤ 0.05 µm |

| Water Absorption | 0% |

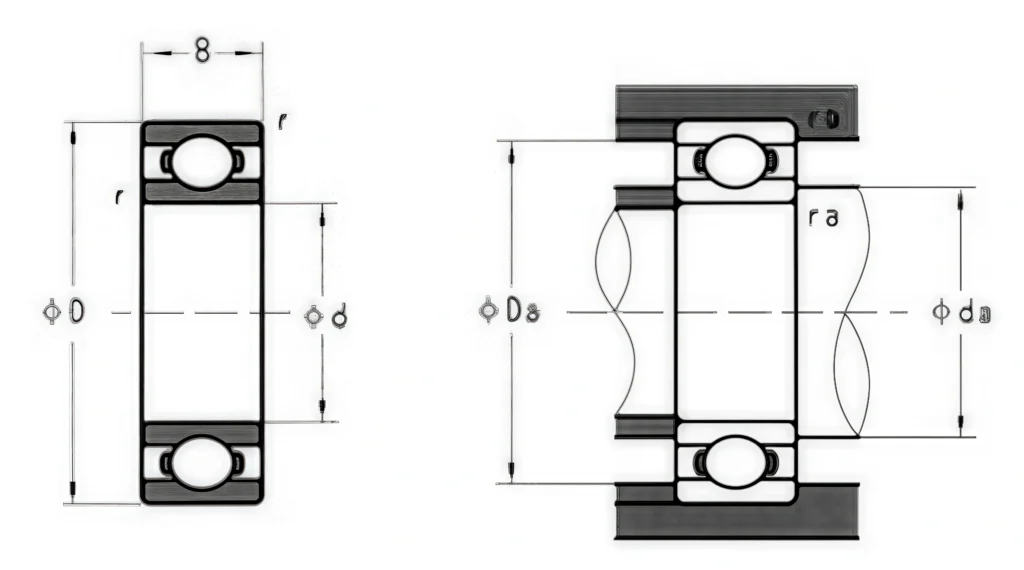

Specifications of Zirconia Bearing

| Zirconia Bearing | |||||||||

| Item NO. | Model | Product Size (mm) | r (Min) | Install Size (mm) | |||||

| d(Inner Dia) | D(Outer Dia) | B(Height) | da (Min) | Max | Max | Max | |||

| AT-YHG-ZC684CE | 684CE | 4 | 9 | 2.5 | 0.1 | 4.8 | / | 8.2 | 0.1 |

| AT-YHG-ZC694CE | 694CE | 4 | 11 | 4 | 0.15 | 5.2 | / | 9.8 | 0.15 |

| AT-YHG-ZC604CE | 604CE | 4 | 12 | 4 | 0.2 | 5.6 | / | 10.4 | 0.2 |

| AT-YHG-ZC624CE | 624CE | 4 | 13 | 5 | 0.2 | 5.6 | / | 11.4 | 0.2 |

| AT-YHG-ZC634CE | 634CE | 4 | 16 | 5 | 0.3 | 6 | / | 14 | 0.3 |

| AT-YHG-ZC685CE | 685CE | 5 | 11 | 3 | 0.15 | 6.2 | / | 9.8 | 0.15 |

| AT-YHG-ZC695CE | 695CE | 5 | 13 | 4 | 0.2 | 6.6 | / | 11.4 | 0.2 |

| AT-YHG-ZC605CE | 605CE | 5 | 14 | 5 | 0.2 | 6.6 | / | 12.4 | 0.2 |

| AT-YHG-ZC625CE | 625CE | 5 | 16 | 5 | 0.3 | 7 | / | 14 | 0.3 |

| AT-YHG-ZC635CE | 635CE | 5 | 19 | 6 | 0.3 | 7 | / | 17 | 0.3 |

| AT-YHG-ZC686CE | 686CE | 6 | 13 | 3.5 | 0.15 | 7.2 | / | 11.8 | 0.15 |

| AT-YHG-ZC696CE | 696CE | 7 | 15 | 5 | 0.2 | 7.6 | / | 13.4 | 0.2 |

| AT-YHG-ZC606CE | 606CE | 8 | 17 | 6 | 0.3 | 8 | / | 15 | 0.3 |

| AT-YHG-ZC626CE | 626CE | 9 | 19 | 6 | 0.3 | 8 | / | 17 | 0.3 |

| AT-YHG-ZC636CE | 636CE | 10 | 22 | 7 | 0.3 | 8 | / | 20 | 0.3 |

| AT-YHG-ZC687CE | 687CE | 7 | 14 | 3.5 | 0.15 | 8.2 | / | 12.8 | 0.15 |

| AT-YHG-ZC697CE | 697CE | 7 | 17 | 5 | 0.3 | 9 | / | 15 | 0.3 |

| AT-YHG-ZC607CE | 607CE | 7 | 19 | 6 | 0.3 | 9 | / | 17 | 0.3 |

| AT-YHG-ZC627CE | 627CE | 7 | 22 | 7 | 0.3 | 9 | / | 20 | 0.3 |

| AT-YHG-ZC637CE | 637CE | 7 | 26 | 9 | 0.3 | 9 | / | 24 | 0.3 |

| AT-YHG-ZC688CE | 688CE | 8 | 16 | 4 | 0.2 | 9.6 | / | 14.4 | 0.2 |

| AT-YHG-ZC698CE | 698CE | 8 | 19 | 6 | 0.3 | 10 | / | 17 | 0.3 |

| AT-YHG-ZC608CE | 608CE | 8 | 22 | 7 | 0.3 | 10 | / | 20 | 0.3 |

| AT-YHG-ZC628CE | 628CE | 8 | 24 | 8 | 0.3 | 10 | / | 22 | 0.3 |

| AT-YHG-ZC638CE | 638CE | 8 | 28 | 9 | 0.3 | 10 | / | 26 | 0.3 |

| AT-YHG-ZC689CE | 689CE | 9 | 17 | 4 | 0.2 | 10.6 | / | 15.4 | 0.2 |

| AT-YHG-ZC699CE | 699CE | 9 | 20 | 6 | 0.3 | 11 | / | 18 | 0.3 |

| AT-YHG-ZC609CE | 609CE | 9 | 24 | 7 | 0.3 | 11 | / | 22 | 0.3 |

| AT-YHG-ZC629CE | 629CE | 9 | 26 | 8 | 0.3 | 11 | / | 24 | 0.3 |

| AT-YHG-ZC639CE | 639CE | 9 | 30 | 10 | 0.6 | 13 | / | 26 | 0.6 |

| AT-YHG-ZC6800CE | 6800CE | 10 | 19 | 5 | 0.3 | 12 | 12 | 17 | 0.3 |

| AT-YHG-ZC6900CE | 6900CE | 10 | 22 | 6 | 0.3 | 12 | 12.5 | 20 | 0.3 |

| AT-YHG-ZC6000CE | 6000CE | 10 | 26 | 8 | 0.3 | 12 | 13 | 24 | 0.3 |

| AT-YHG-ZC6200CE | 6200CE | 10 | 30 | 9 | 0.6 | 14 | 16 | 26 | 0.6 |

| AT-YHG-ZC6300CE | 6300CE | 10 | 35 | 11 | 0.6 | 14 | 16.5 | 31 | 0.6 |

| AT-YHG-ZC6801CE | 6801CE | 12 | 21 | 5 | 0.3 | 14 | 14 | 19 | 0.3 |

| AT-YHG-ZC6901CE | 6901CE | 12 | 24 | 6 | 0.3 | 14 | 14.5 | 22 | 0.3 |

| AT-YHG-ZC16001CE | 16001CE | 12 | 28 | 7 | 0.3 | 14 | / | 26 | 0.3 |

| AT-YHG-ZC6001CE | 6001CE | 12 | 28 | 8 | 0.3 | 14 | 15.5 | 26 | 0.3 |

| AT-YHG-ZC6201CE | 6201CE | 12 | 32 | 10 | 0.6 | 16 | 17 | 28 | 0.6 |

| AT-YHG-ZC6301CE | 6301CE | 12 | 37 | 12 | 1 | 17 | 18 | 32 | 1 |

| AT-YHG-ZC6802CE | 6802CE | 15 | 24 | 5 | 0.3 | 17 | 17 | 22 | 0.3 |

| AT-YHG-ZC6902CE | 6902CE | 15 | 28 | 7 | 0.3 | 17 | 17 | 26 | 0.3 |

| AT-YHG-ZC16002CE | 16002CE | 15 | 32 | 8 | 0.3 | 17 | / | 30 | 0.3 |

| AT-YHG-ZC6002CE | 6002CE | 15 | 32 | 9 | 0.3 | 17 | 19 | 30 | 0.3 |

| AT-YHG-ZC6202CE | 6202CE | 15 | 35 | 11 | 0.6 | 19 | 20.5 | 31 | 0.3 |

| AT-YHG-ZC6302CE | 6302CE | 15 | 42 | 13 | 1 | 20 | 22.5 | 37 | 1 |

| AT-YHG-ZC6803CE | 6803CE | 17 | 26 | 5 | 0.3 | 19 | 19 | 24 | 0.3 |

| AT-YHG-ZC6903CE | 6903CE | 17 | 30 | 7 | 0.3 | 19 | 19.5 | 28 | 0.3 |

| AT-YHG-ZC16003CE | 16003CE | 17 | 35 | 8 | 0.3 | 19 | / | 33 | 0.3 |

| AT-YHG-ZC6003CE | 6003CE | 17 | 35 | 10 | 0.3 | 19 | 21.5 | 33 | 0.3 |

| AT-YHG-ZC6203CE | 6203CE | 17 | 40 | 12 | 0.6 | 21 | 23.5 | 36 | 0.6 |

| AT-YHG-ZC6303CE | 6303CE | 17 | 47 | 14 | 1 | 22 | 25.5 | 42 | 1 |

| AT-YHG-ZC6403CE | 6403CE | 17 | 62 | 17 | 1.1 | 23.5 | / | 55.5 | 1 |

| AT-YHG-ZC6804CE | 6804CE | 20 | 32 | 7 | 0.3 | 22 | 22.5 | 30 | 0.3 |

| AT-YHG-ZC6904CE | 6904CE | 20 | 37 | 9 | 0.3 | 22 | 24 | 35 | 0.3 |

| AT-YHG-ZC16004CE | 16004CE | 20 | 42 | 8 | 0.3 | 22 | / | 40 | 0.3 |

| AT-YHG-ZC6004CE | 6004CE | 20 | 42 | 12 | 0.6 | 24 | 25.5 | 38 | 0.6 |

| AT-YHG-ZC6204CE | 6204CE | 20 | 47 | 14 | 1 | 25 | 26.5 | 42 | 1 |

| AT-YHG-ZC6304CE | 6304CE | 20 | 52 | 15 | 1.1 | 26.5 | 28 | 45.5 | 1 |

| AT-YHG-ZC6404CE | 6404CE | 20 | 72 | 19 | 1.1 | 26.5 | / | 65.5 | 1 |

| AT-YHG-ZC6805CE | 6805CE | 25 | 37 | 7 | 0.3 | 27 | 27 | 35 | 0.3 |

| AT-YHG-ZC6905CE | 6905CE | 25 | 42 | 9 | 0.3 | 27 | 28.5 | 40 | 0.3 |

| AT-YHG-ZC16005CE | 16005CE | 25 | 47 | 8 | 0.3 | 27 | / | 45 | 0.3 |

| AT-YHG-ZC6005CE | 6005CE | 25 | 47 | 12 | 0.6 | 29 | 30 | 43 | 0.6 |

| AT-YHG-ZC6205CE | 6205CE | 25 | 52 | 15 | 1 | 30 | 32 | 47 | 1 |

| AT-YHG-ZC6305CE | 6305CE | 25 | 62 | 17 | 1.1 | 31.5 | 36 | 55.5 | 1 |

| AT-YHG-ZC6405CE | 6405CE | 25 | 80 | 21 | 1.5 | 33 | / | 72 | 1.5 |

| AT-YHG-ZC6806CE | 6806CE | 30 | 42 | 7 | 0.3 | 32 | 32 | 50 | 1 |

| AT-YHG-ZC6906CE | 6906CE | 30 | 47 | 9 | 0.3 | 32 | 34 | 57 | 1 |

| AT-YHG-ZC16006CE | 16006CE | 30 | 55 | 9 | 0.3 | 32 | 42.5 | 65.5 | 1 |

| AT-YHG-ZC6006CE | 6006CE | 30 | 55 | 13 | 1 | 35 | 36.5 | 53 | 1 |

| AT-YHG-ZC6206CE | 6206CE | 30 | 62 | 16 | 1 | 35 | 38.5 | 60 | 1 |

| AT-YHG-ZC6306CE | 6306CE | 30 | 72 | 19 | 1.1 | 36.5 | 42.5 | 68.5 | 1 |

| AT-YHG-ZC6406CE | 6406CE | 30 | 90 | 23 | 1.5 | 54 | / | 82 | 2 |

| AT-YHG-ZC6807CE | 6807CE | 35 | 47 | 7 | 0.3 | 37 | 37 | 45 | 0.3 |

| AT-YHG-ZC6907CE | 6907CE | 35 | 55 | 10 | 0.6 | 39 | 39 | 51 | 0.6 |

| AT-YHG-ZC16007CE | 16007CE | 35 | 62 | 9 | 0.3 | 37 | / | 60 | 0.3 |

| AT-YHG-ZC6007CE | 6007CE | 35 | 62 | 14 | 1 | 40 | 41.5 | 57 | 1 |

| AT-YHG-ZC6207CE | 6207CE | 35 | 72 | 17 | 1.1 | 41.5 | 44.5 | 65.5 | 1 |

| AT-YHG-ZC6307CE | 6307CE | 35 | 80 | 21 | 1.5 | 43 | 47 | 72 | 1.5 |

| AT-YHG-ZC6407CE | 6407CE | 35 | 100 | 25 | 1.5 | 43 | / | 92 | 1.5 |

| AT-YHG-ZC6808CE | 6808CE | 40 | 52 | 7 | 0.3 | 42 | 42 | 50 | 0.3 |

| AT-YHG-ZC6908CE | 6908CE | 40 | 62 | 12 | 0.6 | 44 | 46 | 58 | 0.6 |

| AT-YHG-ZC16008CE | 16008CE | 40 | 68 | 9 | 0.3 | 42 | / | 66 | 0.3 |

| AT-YHG-ZC6008CE | 6008CE | 40 | 68 | 15 | 1 | 45 | 47.5 | 63 | 1 |

| AT-YHG-ZC6208CE | 6208CE | 40 | 80 | 18 | 1.1 | 46.5 | 50.5 | 73.5 | 1 |

| AT-YHG-ZC6308CE | 6308CE | 40 | 90 | 23 | 1.5 | 48 | 53 | 80 | 1.5 |

| AT-YHG-ZC6408CE | 6408CE | 40 | 110 | 27 | 2 | 49 | / | 101 | 2 |

| AT-YHG-ZC6809CE | 6809CE | 45 | 58 | 7 | 0.3 | 47 | 47.5 | 56 | 0.3 |

| AT-YHG-ZC6909CE | 6909CE | 45 | 68 | 12 | 0.6 | 49 | 50 | 64 | 0.6 |

| AT-YHG-ZC16009CE | 16009CE | 45 | 75 | 10 | 0.6 | 49 | / | 71 | 0.6 |

| AT-YHG-ZC6009CE | 6009CE | 45 | 75 | 16 | 1 | 50 | 53.5 | 70 | 1 |

| AT-YHG-ZC6209CE | 6209CE | 45 | 85 | 19 | 1.1 | 51.5 | 55.5 | 78.5 | 1 |

| AT-YHG-ZC6309CE | 6309CE | 45 | 100 | 25 | 1.5 | 53 | 61.5 | 92 | 1.5 |

| AT-YHG-ZC6409CE | 6409CE | 45 | 120 | 29 | 2 | 54 | / | 111 | 2 |

| AT-YHG-ZC6810CE | 6810CE | 50 | 65 | 7 | 0.3 | 52 | 52.5 | 63 | 0.3 |

| AT-YHG-ZC6910CE | 6910CE | 50 | 72 | 12 | 0.6 | 54 | 55 | 68 | 0.6 |

| AT-YHG-ZC16010CE | 16010CE | 50 | 80 | 10 | 0.6 | 54 | / | 76 | 0.6 |

| AT-YHG-ZC6010CE | 6010CE | 50 | 80 | 16 | 1 | 55 | 58.5 | 75 | 1 |

| AT-YHG-ZC6210CE | 6210CE | 50 | 90 | 20 | 1.1 | 56.5 | 60 | 83.2 | 1 |

| AT-YHG-ZC6310CE | 6310CE | 50 | 110 | 27 | 2 | 59 | 68 | 101 | 2 |

| AT-YHG-ZC6410CE | 6410CE | 50 | 130 | 31 | 2.1 | 61 | / | 119 | 2 |

| AT-YHG-ZC6811CE | 6811CE | 55 | 72 | 9 | 0.3 | 57 | 59 | 70 | 0.3 |

| AT-YHG-ZC6911CE | 6911CE | 55 | 80 | 13 | 1 | 60 | 61.5 | 75 | 1 |

| AT-YHG-ZC16011CE | 16011CE | 55 | 90 | 11 | 0.6 | 59 | / | 86 | 0.6 |

| AT-YHG-ZC6011CE | 6011CE | 55 | 90 | 18 | 1.1 | 61.5 | 64 | 83.5 | 1 |

| AT-YHG-ZC6211CE | 6211CE | 55 | 100 | 21 | 1.5 | 63 | 66.5 | 92 | 1.5 |

| AT-YHG-ZC6311CE | 6311CE | 55 | 120 | 29 | 2 | 64 | 72.5 | 111 | 2 |

| AT-YHG-ZC6411CE | 6411CE | 55 | 140 | 33 | 2.1 | 66 | / | 129 | 2 |

| AT-YHG-ZC6812CE | 6812CE | 60 | 78 | 10 | 0.3 | 62 | 64 | 76 | 0.3 |

| AT-YHG-ZC6912CE | 6912CE | 60 | 85 | 13 | 1 | 65 | 66 | 80 | 1 |

| AT-YHG-ZC16012CE | 16012CE | 60 | 95 | 11 | 0.6 | 64 | / | 91 | 0.6 |

| AT-YHG-ZC6012CE | 6012CE | 60 | 95 | 18 | 1.1 | 66.5 | 69 | 88.5 | 1 |

| AT-YHG-ZC6212CE | 6212CE | 60 | 110 | 22 | 1.5 | 68 | 74.5 | 102 | 1.5 |

| AT-YHG-ZC6312CE | 6312CE | 60 | 130 | 31 | 2.1 | 71 | 79 | 119 | 2 |

| AT-YHG-ZC6412CE | 6412CE | 60 | 150 | 35 | 2.1 | 71 | 139 | 2 | |

| AT-YHG-ZC6813CE | 6813CE | 65 | 85 | 10 | 0.6 | 69 | 69 | 81 | 0.6 |

| AT-YHG-ZC6913CE | 6913CE | 65 | 90 | 13 | 1 | 70 | 71.5 | 85 | 1 |

| AT-YHG-ZC16013CE | 16013CE | 65 | 100 | 11 | 0.6 | 69 | / | 96 | 0.6 |

| AT-YHG-ZC6013CE | 6013CE | 65 | 100 | 18 | 1.1 | 71.5 | 73 | 93.5 | 1 |

| AT-YHG-ZC6213CE | 6213CE | 65 | 120 | 23 | 1.5 | 73 | 80 | 112 | 1.5 |

| AT-YHG-ZC6313CE | 6313CE | 65 | 140 | 33 | 2.1 | 76 | 85.5 | 129 | 2 |

| AT-YHG-ZC6814CE | 6814CE | 70 | 90 | 10 | 0.6 | 74 | 74.5 | 86 | 0.6 |

| AT-YHG-ZC6914CE | 6914CE | 70 | 100 | 16 | 1 | 75 | 77.5 | 95 | 1 |

| AT-YHG-ZC16014CE | 16014CE | 70 | 110 | 13 | 0.6 | 74 | / | 106 | 0.6 |

| AT-YHG-ZC6014CE | 6014CE | 70 | 110 | 20 | 1.1 | 76.5 | 80.5 | 103.5 | 1 |

| AT-YHG-ZC6214CE | 6214CE | 70 | 125 | 24 | 1.5 | 78 | 84 | 117 | 1.5 |

| AT-YHG-ZC6314CE | 6314CE | 70 | 150 | 35 | 2.1 | 81 | 92 | 139 | 2 |

| AT-YHG-ZC6815CE | 6815CE | 75 | 95 | 10 | 0.6 | 79 | 79.5 | 91 | 0.6 |

| AT-YHG-ZC6915CE | 6915CE | 75 | 105 | 16 | 1 | 80 | 82 | 100 | 1 |

| AT-YHG-ZC16015CE | 16015CE | 75 | 115 | 13 | 0.6 | 79 | / | 111 | 0.6 |

| AT-YHG-ZC6015CE | 6015CE | 75 | 115 | 20 | 1.1 | 81.5 | 85.5 | 108.5 | 1 |

| AT-YHG-ZC6215CE | 6215CE | 75 | 130 | 25 | 1.5 | 83 | 90 | 122 | 1.5 |

| AT-YHG-ZC6816CE | 6816CE | 80 | 100 | 10 | 0.6 | 84 | 84.5 | 96 | 0.6 |

| AT-YHG-ZC6916CE | 6916CE | 80 | 110 | 16 | 1 | 85 | 87.5 | 105 | 1 |

| AT-YHG-ZC16016CE | 16016CE | 80 | 125 | 14 | 0.6 | 84 | / | 121 | 0.6 |

| AT-YHG-ZC6016CE | 6016CE | 80 | 125 | 22 | 1.1 | 86.5 | 91 | 118.5 | 1 |

| AT-YHG-ZC6216CE | 6216CE | 80 | 140 | 26 | 2 | 89 | 95.5 | 131 | 2 |

| AT-YHG-ZC6817CE | 6817CE | 85 | 110 | 13 | 1 | 90 | 90.5 | 105 | 1 |

| AT-YHG-ZC6917CE | 6917CE | 85 | 120 | 18 | 1.1 | 91.5 | 94.5 | 113.5 | 1 |

| AT-YHG-ZC16017CE | 16017CE | 85 | 130 | 14 | 0.6 | 89 | / | 126 | 0.6 |

| AT-YHG-ZC6017CE | 6017CE | 85 | 130 | 22 | 1.1 | 91.5 | 96 | 123.5 | 1 |

| AT-YHG-ZC6217CE | 6217CE | 85 | 150 | 28 | 2 | 94 | 102 | 141 | 2 |

| AT-YHG-ZC6818CE | 6818CE | 90 | 115 | 13 | 1 | 95 | 95.5 | 110 | 1 |

| AT-YHG-ZC6918CE | 6918CE | 90 | 125 | 18 | 1.1 | 96.5 | 98.5 | 118.5 | 1 |

| AT-YHG-ZC16018CE | 16018CE | 90 | 140 | 16 | 1 | 95 | / | 135 | 1 |

| AT-YHG-ZC6018CE | 6018CE | 90 | 140 | 24 | 1.5 | 98 | 103 | 132 | 1.5 |

| AT-YHG-ZC6819CE | 6819CE | 95 | 120 | 13 | 1 | 100 | 102 | 115 | 1 |

| AT-YHG-ZC6919CE | 6919CE | 95 | 130 | 18 | 1.1 | 101.5 | 104 | 123.5 | 1 |

| AT-YHG-ZC16019CE | 16019CE | 95 | 145 | 16 | 1 | 100 | / | 140 | 1 |

| AT-YHG-ZC6019CE | 6019CE | 95 | 145 | 24 | 1.5 | 103 | 109 | 137 | 1.5 |

| AT-YHG-ZC6820CE | 6820CE | 100 | 125 | 13 | 1 | 105 | 106 | 120 | 1 |

| AT-YHG-ZC6920CE | 6920CE | 100 | 140 | 20 | 1.1 | 106.5 | 111 | 133.5 | 1 |

| AT-YHG-ZC16020CE | 16020CE | 100 | 150 | 16 | 1 | 105 | / | 145 | 1 |

| AT-YHG-ZC6020CE | 6020CE | 100 | 150 | 24 | 1.5 | 108 | 113 | 142 | 1.5 |

| AT-YHG-ZC6821CE | 6821CE | 105 | 130 | 13 | 1 | 110 | 111 | 125 | 1 |

| AT-YHG-ZC6921CE | 6921CE | 105 | 145 | 20 | 1.1 | 111.5 | 116 | 138.5 | 1 |

| AT-YHG-ZC6822CE | 6822CE | 110 | 140 | 16 | 1 | 115 | 117 | 135 | 1 |

| AT-YHG-ZC6922CE | 6922CE | 110 | 150 | 20 | 1.1 | 116.5 | 121 | 143.5 | 1 |

| AT-YHG-ZC6824CE | 6824CE | 120 | 150 | 16 | 1 | 125 | 127 | 145 | 1 |

| AT-YHG-ZC6924 | 6924 | 120 | 165 | 22 | 1.1 | / | / | / | / |

| AT-YHG-ZC16024 | 16024 | 120 | 180 | 19 | 1 | / | / | / | / |

| AT-YHG-ZC6024 | 6024 | 120 | 180 | 28 | 2 | / | / | / | / |

| AT-YHG-ZC6224 | 6224 | 120 | 215 | 40 | 2.1 | / | / | / | / |

| AT-YHG-ZC6324 | 6324 | 120 | 260 | 55 | 3 | / | / | / | / |

| AT-YHG-ZC6826 | 6826 | 130 | 165 | 18 | 1.1 | / | / | / | / |

| AT-YHG-ZC6926 | 6926 | 130 | 180 | 24 | 1.5 | / | / | / | / |

| AT-YHG-ZC16026 | 16026 | 130 | 200 | 22 | 1.1 | / | / | / | / |

| AT-YHG-ZC6026 | 6026 | 130 | 200 | 33 | 2 | / | / | / | / |

| AT-YHG-ZC6226 | 6226 | 130 | 230 | 40 | 3 | / | / | / | / |

| AT-YHG-ZC6326 | 6326 | 130 | 280 | 58 | 4 | / | / | / | / |

| AT-YHG-ZC6828 | 6828 | 140 | 175 | 18 | 1.1 | / | / | / | / |

| AT-YHG-ZC6928 | 6928 | 140 | 190 | 24 | 1.5 | / | / | / | / |

| AT-YHG-ZC16028 | 16028 | 140 | 210 | 22 | 1.1 | / | / | / | / |

| AT-YHG-ZC6028 | 6028 | 140 | 210 | 33 | 2 | / | / | / | / |

| AT-YHG-ZC6228 | 6228 | 140 | 250 | 42 | 3 | / | / | / | / |

| AT-YHG-ZC6328 | 6328 | 140 | 300 | 62 | 4 | / | / | / | / |

| AT-YHG-ZC6830 | 6830 | 150 | 190 | 20 | 1.1 | / | / | / | / |

| AT-YHG-ZC6930 | 6930 | 150 | 210 | 28 | 2 | / | / | / | / |

| AT-YHG-ZC16030 | 16030 | 150 | 225 | 24 | 1.1 | / | / | / | / |

| AT-YHG-ZC6030 | 6030 | 150 | 225 | 35 | 2.1 | / | / | / | / |

| AT-YHG-ZC6230 | 6230 | 150 | 270 | 45 | 3 | / | / | / | / |

| AT-YHG-ZC6330 | 6330 | 150 | 320 | 65 | 4 | / | / | / | / |

| AT-YHG-ZC60/22 | 60/22 | 22 | 44 | 12 | 0.6 | / | / | / | / |

| AT-YHG-ZC62/22 | 62/22 | 22 | 50 | 14 | 1 | / | / | / | / |

| AT-YHG-ZC63/22 | 63/22 | 22 | 56 | 16 | 1.1 | / | / | / | / |

| AT-YHG-ZC60/28 | 60/28 | 28 | 52 | 12 | 0.6 | / | / | / | / |

| AT-YHG-ZC62/28 | 62/28 | 28 | 58 | 16 | 1 | / | / | / | / |

| AT-YHG-ZC63/28 | 63/28 | 28 | 68 | 18 | 1.1 | / | / | / | / |

| AT-YHG-ZC60/32 | 60/32 | 33 | 58 | 13 | 1 | / | / | / | / |

| AT-YHG-ZC62/32 | 62/32 | 33 | 65 | 17 | 1 | / | / | / | / |

| AT-YHG-ZC63/32 | 63/32 | 33 | 75 | 20 | 1.1 | / | / | / | / |

| AT-YHG-ZC603CE | 603CE | 3 | 9 | 3 | / | / | / | / | / |

| AT-YHG-ZC606CE | 606CE | 6 | 17 | 6 | / | / | / | / | / |

| AT-YHG-ZCMR117 | MR117 | 7 | 11 | 3 | / | / | / | / | / |

| AT-YHG-ZCMR128 | MR128 | 8 | 12 | 3.5 | / | / | / | / | / |

| AT-YHG-ZCMR85 | MR85 | 5 | 8 | 2.5 | / | / | / | / | / |

| AT-YHG-ZCMR63-1 | MR63-1 | 3 | 6 | 2.5 | / | / | / | / | / |

| AT-YHG-ZCMR85-1 | MR85-1 | 5 | 8 | 2 | / | / | / | / | / |

| AT-YHG-ZCMR148 | MR148 | 8 | 14 | 4 | / | / | / | / | / |

| AT-YHG-ZCMR84 | MR84 | 4 | 8 | 2 | / | / | / | / | / |

| AT-YHG-ZCMR126 | MR126 | 6 | 12 | 4 | / | / | / | / | / |

| AT-YHG-ZCMR74-1 | MR74-1 | 4 | 7 | 2 | / | / | / | / | / |

| AT-YHG-ZCMR84-1 | MR84-1 | 4 | 8 | 3 | / | / | / | / | / |

| AT-YHG-ZCMR74 | MR74 | 4 | 7 | 2.5 | / | / | / | / | / |

| AT-YHG-ZCMR148 | MR148 | 8 | 14 | 3.5 | / | / | / | / | / |

| AT-YHG-ZCMR63 | MR63 | 3 | 6 | 2 | / | / | / | / | / |

| AT-YHG-ZCMR103 | MR103 | 3 | 10 | 4 | / | / | / | / | / |

| AT-YHG-ZCMR104 | MR104 | 4 | 10 | 4 | / | / | / | / | / |

| AT-YHG-ZCMR105 | MR105 | 5 | 10 | 3 | / | / | / | / | / |

| AT-YHG-ZCMR105-1 | MR105-1 | 5 | 10 | 4 | / | / | / | / | / |

| AT-YHG-ZCMR106 | MR106 | 6 | 10 | 2.5 | / | / | / | / | / |

| AT-YHG-ZCMR106-1 | MR106-1 | 6 | 10 | 3 | / | / | / | / | / |

| AT-YHG-ZCMR115 | MR115 | 5 | 11 | 4 | / | / | / | / | / |

| AT-YHG-ZCMR52 | MR52 | 2 | 5 | 2.5 | / | / | / | / | / |

| AT-YHG-ZCMR62 | MR62 | 2 | 6 | 2.5 | / | / | / | / | / |

| AT-YHG-ZCMR94 | MR94 | 4 | 9 | 3 | / | / | / | / | / |

| AT-YHG-ZCMR95 | MR95 | 5 | 9 | 3 | / | / | / | / | / |

| AT-YHG-ZCR188 | R188 | 6.35 | 12.7 | 4.763 | / | / | / | / | / |

| AT-YHG-ZCR6 | R6 | 9.525 | 22.225 | 5.556 | / | / | / | / | / |

Packaging of Zirconia Bearing

Zirconia Bearing components are individually cushioned in multi-layer protective wraps and packed in segmented cartons to prevent movement during transit. All boxes are barcode-tracked and stored in humidity-controlled shelves prior to shipment. Final dispatch uses reinforced export-grade cartons loaded securely for bulk transport.