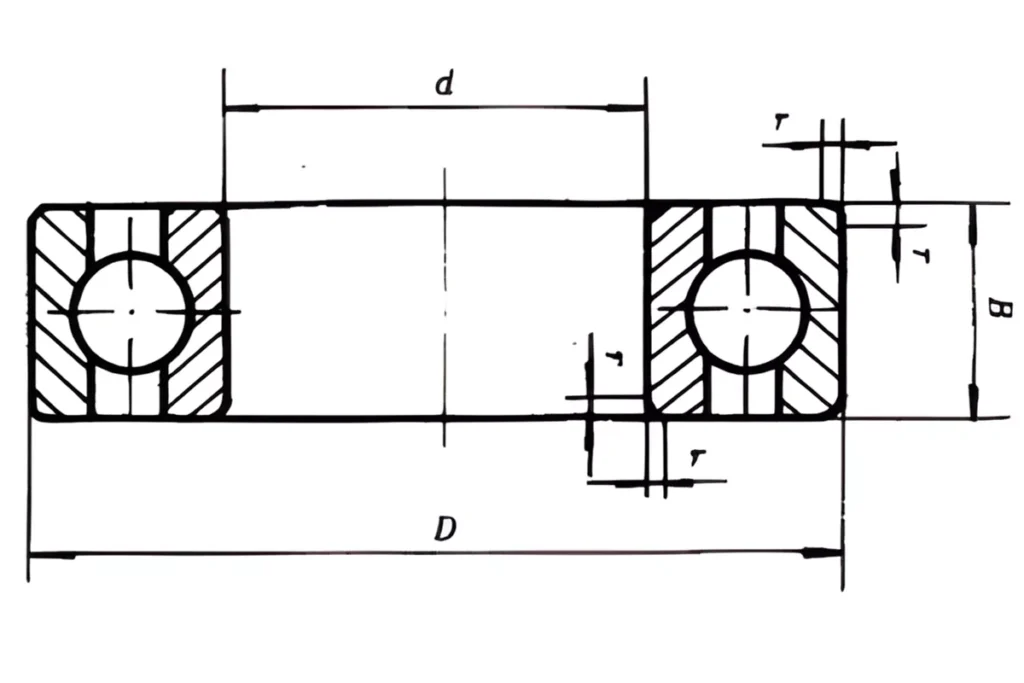

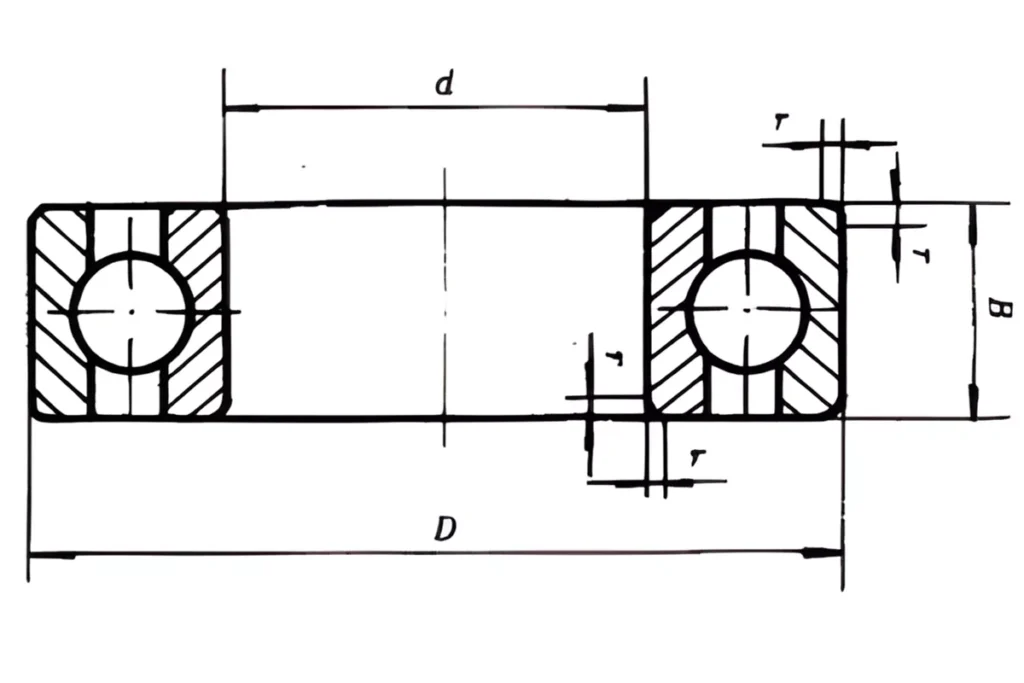

ADCERAX® Zirconia Ceramic Deep Groove Ball Bearing is designed for stable radial load operation in high-speed and chemically aggressive environments. Its structure features uninterrupted raceways optimized for continuous rotation under dry, cleanroom, or high-temperature conditions where angular misalignment is not a factor. This bearing type is uniquely suited for electric insulation and non-magnetic performance in axial-force-isolated, precision rotary systems.

Features of Zirconia Ceramic Deep Groove Ball Bearing

- Supports speeds up to 60,000 rpm under radial load.

The uninterrupted deep groove design enables smooth rotation in precision systems without axial deflection.

Performance remains consistent even under radial forces exceeding 1200 MPa, minimizing vibration and noise.

- No axial misalignment tolerance by design.

The bearing is structurally optimized for machines where shaft alignment is fixed and axial shifting is minimal.

This eliminates the need for angular adjustment present in self-aligning or angular contact bearings.

- High cycle reliability in rotary systems.

Tested bearings show >20,000 hours of operation under radial load at 300 °C, outperforming metallic equivalents by over 4× lifespan.

Zirconia surface finish at Ra ≤ 0.05 µm ensures consistent wear profile during full-cycle rotation.

- Corrosion resistance verified in acidic and alkaline media.

Zirconia material is inert in HCl, NaOH, H₂SO₄, and other process chemicals with zero degradation after 72-hour immersion.

This property enables use in chemical pumps and reactors where metal bearings fail prematurely.

- Stable operation up to 600 °C short-term.

Under high thermal environments, the bearing maintains dimensional stability due to CTE ≈ 10.5×10⁻⁶/K, avoiding deformation.

This makes it suitable for furnaces, motors, and sterilization equipment requiring long thermal exposure.

- Zero lubrication required in clean or vacuum settings.

Dry-running capability has been validated in 10⁻³ Pa vacuum chambers, where oil contamination must be avoided.

Friction coefficient remains below 0.001 under ceramic–ceramic contact without external lubrication.

Technical Properties of Zirconia Ceramic Deep Groove Ball Bearing

Designed for continuous radial motion under high temperature, corrosive, and electrically sensitive environments, the Zirconia Ceramic Deep Groove Ball Bearing maintains long-cycle dimensional stability, low friction, and structural integrity where axial misalignment and thrust loading are not present. Its material behavior and mechanical profile are engineered to meet the operational demands of high-speed, non-magnetic, and lubricant-free systems with strict thermal and chemical exposure requirements.

| Property |

Specification |

| Material Composition |

Y-TZP (5 mol% Y₂O₃ stabilized) |

| Density |

6.05 g/cm³ |

| Flexural Strength |

1200–1500 MPa |

| Fracture Toughness |

8–10 MPa·m¹ᐟ² |

| Elastic Modulus |

200 GPa |

| Surface Hardness |

≥ 1200 HV10 |

| Thermal Conductivity |

~2.0 W/m·K |

| Thermal Expansion (20–400 °C) |

10.5 × 10⁻⁶ /K |

| Service Temperature (Continuous) |

Up to 400 °C |

| Peak Exposure Temperature |

Up to 600 °C |

| Electrical Resistivity |

>10¹² Ω·cm |

| Magnetism |

Non-magnetic (<0.005 emu/g) |

| Surface Roughness (Ra) |

≤ 0.05 µm |

| Operating Environment |

Dry, vacuum, or inert gas |

| Lubrication Requirement |

None required |

| Clearance Range |

ISO 492 C0 / C2 / C3 |

Specifications of Zirconia Ceramic Deep Groove Ball Bearing

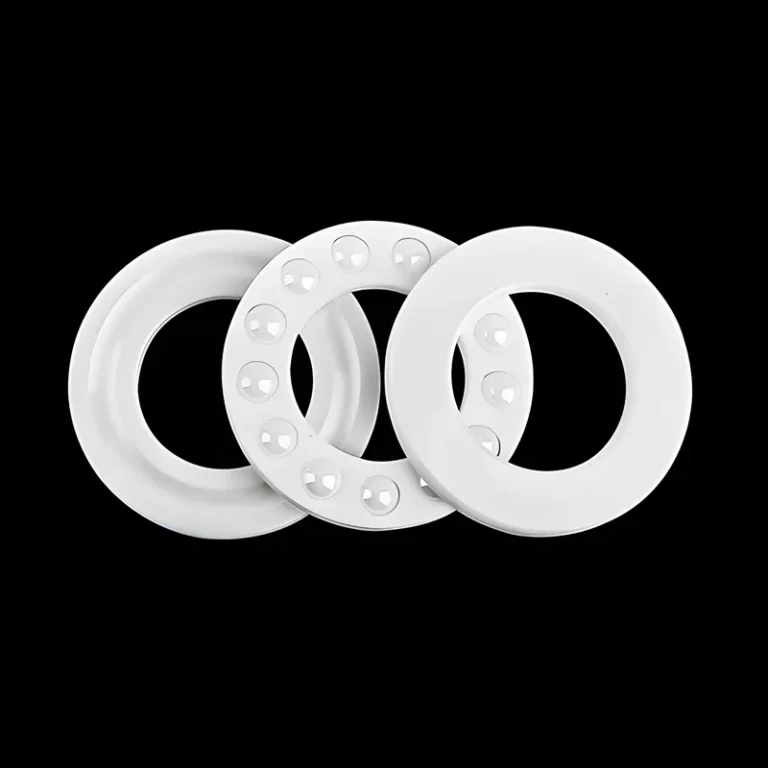

Packaging of Zirconia Ceramic Deep Groove Ball Bearing

Zirconia Ceramic Deep Groove Ball Bearing is individually protected using multi-layer anti-contact sleeves to prevent surface abrasion during transit. Each batch is stored in controlled warehouse conditions to maintain cleanliness and avoid moisture exposure before shipment. Final packing uses reinforced export-grade cartons and palletized loading to ensure stable transport for long-distance international delivery.

Why ADCERAX® Zirconia Ceramic Deep Groove Ball Bearing Excels in Fully Radial, High-Speed, and Chemically Hostile Systems

Zirconia Ceramic Deep Groove Ball Bearing is designed specifically for systems with sustained radial loads and no axial misalignment tolerance, where conventional bearings fail due to chemical attack, temperature-induced expansion, or stray electrical discharge. ADCERAX® provides a sealed raceway solution built for non-lubricated, precision-controlled motion across aggressive industrial environments.

-

Deployment in Vertical Magnetic Stirring Systems for Chemical Reactors

✅Key Advantages

1. Non‑Magnetic Motion Stability

The bearing maintains rotational performance with <0.005 emu/g magnetic susceptibility, preventing field distortion in magnetically driven stirrer couplings.

This ensures stable torque transfer and eliminates magnetic drag even during continuous vortex formation cycles.

2. Chemical Inertness Under Reactive Vapor Exposure

The zirconia raceways remain fully stable after 72+ hours of exposure to HCl/H₂SO₄ vapor, showing no surface etching.

This prevents particle introduction into closed reactor chambers where contamination directly affects reaction yield.

3. Radial Accuracy During High‑Speed Agitation

Inner and outer race concentricity holds within ±0.01 mm, maintaining consistent shaft centerline under 12,000–18,000 rpm agitation.

This stabilizes vortex formation and prevents oscillation‑induced shear inconsistencies in fluid mixing.

✅ ️Problem Solved

In a European specialty chemical reactor line, stainless steel bearings used in magnetic stirring mechanisms experienced visible corrosion within 3–6 weeks due to continuous acid vapor exposure, resulting in torque drift and contamination of batch processes valued at €40,000+ per batch. After integrating ADCERAX® Zirconia Ceramic Deep Groove Ball Bearings, the reactor has operated for over 14 months without measurable wear. No magnetic interference, no lubrication requirement, and no particulate contamination were detected during quality assurance sampling.

-

Implementation in Brushless Direct‑Drive Indexing Tables for CNC Automation

✅Key Advantages

1. Thermal Expansion Stability Near Servo Drives

With a thermal expansion coefficient of ~10.5 × 10⁻⁶/K, the bearing preserves radial clearance near high‑heat motor housings.

This prevents preload shift and torque fluctuation common in metallic bearings under CNC duty cycles.

2. Electrical Insulation for Motor‑Adjacent Rotational Zones

Volume resistivity > 10¹² Ω·cm prevents parasitic grounding through the rotating shaft.

This protects encoder feedback channels and eliminates arc‑pitting failures at high duty frequencies.

3. Low‑Friction Start‑Up for High‑Cycle Rotational Indexing

Dry‑run friction coefficient stays <0.001, allowing consistent restart accuracy across tens of thousands of indexing cycles.

This ensures precise angular alignment without lubrication maintenance interruptions.

✅ ️Problem Solved

A North American automation integrator reported indexing repeatability drift of 0.08–0.12 mm when using hybrid ceramic/steel bearings in servo‑driven rotary tables. Thermal mismatch and electrical grounding noise caused encoder instability, resulting in ~6% output scrap rate. After switching to ADCERAX® Zirconia Ceramic Deep Groove Ball Bearings, repeatability stabilized to ≤0.01 mm deviation over 50,000+ cycles, eliminating drift and enabling continuous unattended machining shifts.

-

Usage in Ultra‑Pure Liquid Chromatography (UPLC) Pump Drive Modules

✅Key Advantages

1. Zero Lubricant Migration into Analytical Fluid Paths

The bearing is engineered for fully dry operation, eliminating lubricant carryover into solvent channels.

This maintains signal fidelity in chromatographic separation, particularly in ppm‑sensitive detection ranges.

2. Ultra‑Low Particle Generation Under Mechanical Load

Surface finish of Ra ≤ 0.05 μm minimizes frictional particulate release during pump cycling.

This prevents baseline drift and protects detector sensitivity in precision assay workflows.

3. Corrosion‑Stable Under Organic Solvent Cycling

Zirconia resists degradation in acetonitrile, methanol, phosphate buffers, and mixed‑phase eluents.

This enables consistent performance across extended continuous‑duty chromatography runs.

✅ ️Problem Solved

A pharmaceutical analytical lab observed chromatogram baseline instability caused by micro‑wear particulates from metal bearings over 90‑day continuous UPLC operation. Trace contamination resulted in false peak readings and QC batch rejections. After transitioning to ADCERAX® Zirconia Ceramic Deep Groove Ball Bearings, baseline noise was reduced by >35%, particulate counts returned to instrument floor background, and pump drive systems achieved over 9 months of uninterrupted service without internal cleaning cycles.

ADCERAX® Zirconia Ceramic Deep Groove Ball Bearing – Operational Guidelines for Safe and Long-Term Use

To ensure consistent radial performance and extended bearing lifespan, users of Zirconia Ceramic Deep Groove Ball Bearing must follow precise handling, installation, and application protocols.

-

Proper Handling Before Installation

1. Avoid contact with metal tools or hard surfaces during unpacking.

The ceramic structure, while highly durable under load, is vulnerable to point impact damage during dry handling.

Use non-metallic gloves or soft grips to avoid micro-cracking of raceways or contact points.

2. Inspect bearing channels and balls under cleanroom lighting.

Prior to use, check for foreign particle inclusion, particularly when installed in optical or metrology-grade systems.

Visual inspection should confirm uninterrupted groove symmetry across both inner and outer rings.

3. Do not pre-lubricate or wash with industrial solvents.

Zirconia bearings are designed to operate dry or in ultra-clean fluid environments; harsh pre-cleaning agents may compromise material integrity.

If absolutely necessary, rinse only with lab-grade isopropyl alcohol and allow natural evaporation.

-

Mounting and Alignment Precautions

1. Align shafts axially with zero tolerance for misalignment.

This bearing is not self-aligning and must be mounted into precision-bored housings without forcing tilt or offset.

Misalignment induces non-uniform radial load and accelerates wear at the raceway–ball interface.

2. Avoid impact-based installation methods.

Press-fitting must be done uniformly with low force, using a parallel support fixture or a bearing arbor press.

Never use hammers, even with plastic tips, as this causes hidden fractures that reduce lifecycle reliability.

3. Confirm preload values are not applied unless specified.

Preload is not standard for deep groove bearings, and forced compression leads to internal stress buildup.

Follow technical drawings strictly when installed into precision robotic or metrology modules.

-

Operational Environment Optimization

1. Maintain controlled temperature environments for extended use.

While designed to operate up to 400 °C, consistent long-term use above 300 °C should include cooling management if rotational speed exceeds 30,000 rpm.

This prevents localized thermal expansion and dimensional distortion.

2. Do not apply axial or off-center thrust during operation.

This bearing does not absorb axial loads, and any off-axis force must be transferred to secondary components or thrust-bearing pairs.

Repeated axial pressure leads to outer race deformation and groove cracking.

3. Avoid magnetic and electric field exposure near steel contact parts.

In EMI-sensitive equipment, shield surrounding components, especially when integrated near servo amplifiers or RF coils.

Though zirconia is non-magnetic, adjacent metallic fixtures may compromise performance.

-

Cleaning, Storage, and Maintenance Practices

1. Clean only with non-abrasive, lint-free cloths.

Avoid compressed air with moisture, which can introduce particles or condensates.

For lab-grade applications, ultrasonic cleaning is acceptable with deionized water only.

2. Store in humidity-controlled environments with original packaging.

Long-term storage is best in 25–60% RH at 10–30 °C, within closed cell foam trays provided by ADCERAX®.

Cardboard box stacks must be placed horizontally to avoid load on one side of the bearing surface.

3. Plan service intervals based on usage temperature and speed.

For example, operation at 250 °C and 20,000 rpm in dry air suggests revalidation every 12–18 months.

ADCERAX® offers periodic lifecycle diagnostic support upon request.