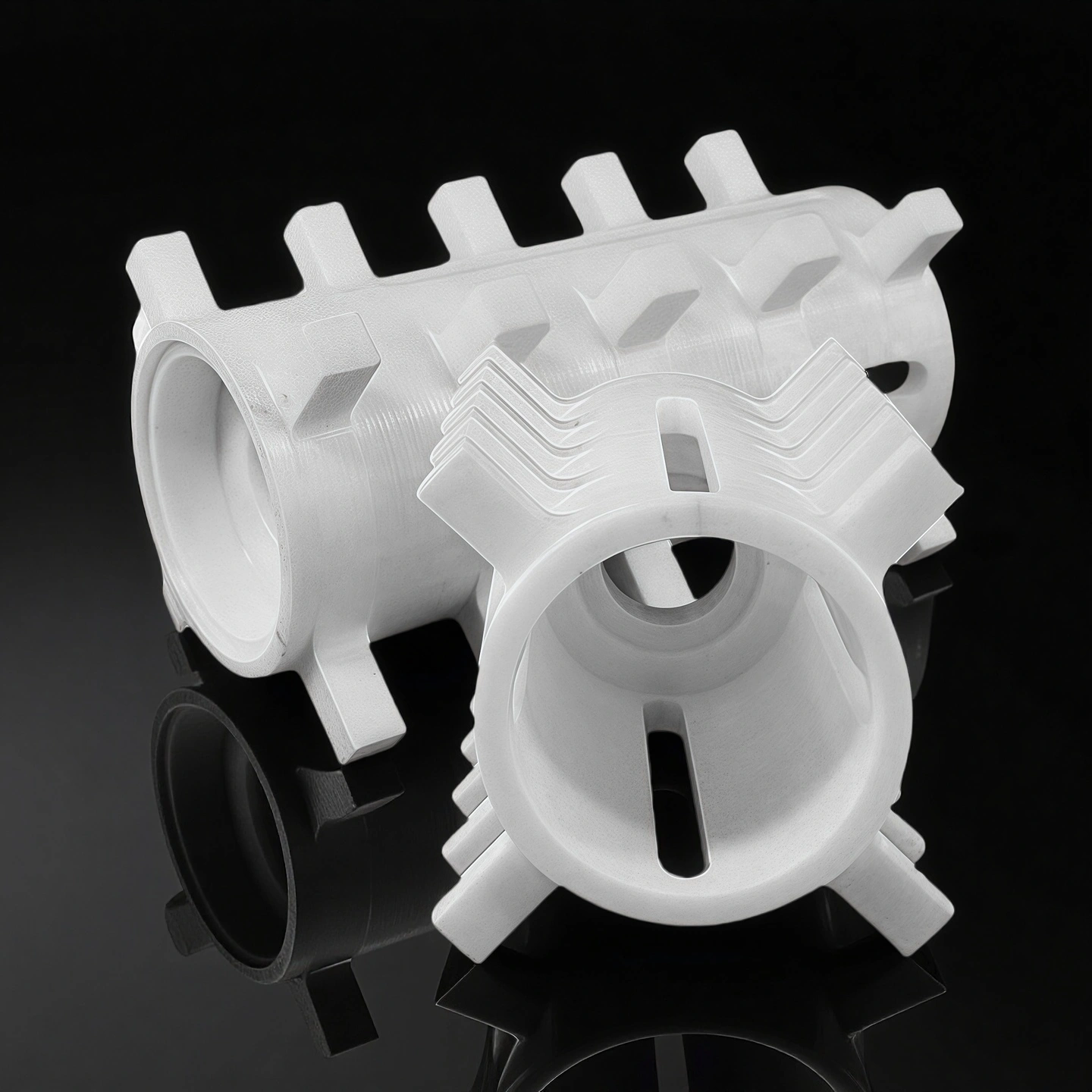

ADCERAX® Zirconia Ceramic Dispersion Rotor operates as the central rotating component in modern bead mill systems, where its multi-pin surface structure generates strong centrifugal forces for precise material dispersion. Through high-speed rotation, it transfers kinetic energy to zirconia grinding beads, achieving uniform particle reduction and stable viscosity control across demanding formulations. This advanced YSZ-based rotor design ensures reliable performance, extended wear life, and chemical stability in continuous dispersion of lithium slurries, electronic pastes, coatings, and fine chemicals.

Performance Features of Zirconia Ceramic Dispersion Rotor

- Surface Roughness ≤ Ra 0.2 μm

The polished rotor surface minimizes particle adhesion, reducing cross-contamination during material changeover.

- Bead Circulation Efficiency ≥ 93%

Smooth pin transitions support stable turbulent flow of grinding media, ensuring uniform dispersion within 10–30 μm distribution window.

- Clean-in-Place (CIP) Compatible

The non-porous structure and smooth geometry support automated cleaning protocols and reduce manual maintenance time by over 35%.

- Material Purity ≥ 99.8% YSZ

This high-purity ceramic resists chemical leaching, eliminating the risk of metal ion contamination during wet dispersion.

- Stable in pH 1–14 environments

Its inert matrix structure permits direct exposure to acids, bases, and organic solvents without degradation or corrosion.

- Thermal Stability up to 1000°C

This enables processing of formulations that involve elevated temperature pre-conditioning or continuous heat buildup.

- Hardness ≥ 1200 Hv

This level of hardness protects the rotor from abrasive wear caused by continuous high-speed bead impact. It significantly reduces dimensional degradation over long cycles.

- Flexural Strength ≥ 1000 MPa

This high flexural threshold allows the rotor to maintain integrity under torsional load during rapid acceleration and deceleration. It minimizes fracture risk under dynamic conditions.

- Compressive Strength ≥ 2000 MPa

With excellent load-bearing capacity, the rotor remains dimensionally stable even in closed-chamber high-pressure grinding operations.

Technical Properties of Zirconia Ceramic Dispersion Rotor

The Zirconia Ceramic Dispersion Rotor is manufactured from high-density yttria-stabilized zirconia and optimized for rotational stability, chemical durability, and prolonged wear resistance under intensive bead mill conditions. Its mechanical integrity and corrosion performance make it suitable for use in advanced material processing environments including battery slurry, electronics paste, and pigment dispersion lines.

| Property |

Specification |

| Material Composition |

≥ 99.8% Yttria-Stabilized ZrO₂ |

| Bulk Density |

6.0 ± 0.05 g/cm³ |

| Vickers Hardness |

≥ 1200 Hv |

| Flexural Strength |

≥ 1000 MPa |

| Compressive Strength |

≥ 2000 MPa |

| Fracture Toughness (KIC) |

8–10 MPa·m½ |

| Surface Roughness (Ra) |

≤ 0.2 μm |

| Thermal Conductivity |

2.5 W/m·K (at 20 °C) |

| Thermal Expansion Coefficient |

10.5 × 10⁻⁶ /K |

| Maximum Service Temperature |

1000 °C (air) |

| Acid/Base Resistance |

Stable from pH 1 to pH 14 |

| Electrical Resistivity |

> 10¹² Ω·cm (at 20 °C) |

| Pin Configuration Compatibility |

Multi-row / Spiral array |

| Balance Grade |

ISO 1940 G2.5 or better |

| Surface Porosity |

Non-porous (0%) |

Specifications of Zirconia Ceramic Dispersion Rotor

|

Sand Mill Zirconia Ceramic Dispersion Rotor |

|

Item No. |

Outer Diameter (mm) |

Inner Diameter (mm) |

Height (mm) |

|

AT-YHG-SM012 |

45 |

28 |

400 |

|

AT-YHG-SM013 |

60 |

40 |

400 |

|

AT-YHG-SM014 |

84 |

64 |

400 |

|

AT-YHG-SM015 |

95 |

75 |

500 |

|

AT-YHG-SM016 |

125 |

100 |

630 |

|

AT-YHG-SM017 |

155 |

130 |

700 |

|

AT-YHG-SM018 |

160 |

140 |

750 |

|

AT-YHG-SM019 |

180 |

150 |

800 |

Packaging of Zirconia Ceramic Dispersion Rotor

Zirconia Ceramic Dispersion Rotor is packaged using a multi-layer protection system to ensure safe handling and transport. Each unit is first individually boxed, then securely arranged in lined wooden crates with foam cushioning. The crates are sealed and reinforced with outer plywood and steel straps to prevent impact during international shipping.

Solving Process Reliability and Dispersion Precision with ADCERAX® Zirconia Ceramic Dispersion Rotor

ADCERAX® Zirconia Ceramic Dispersion Rotor plays a critical role in high-load bead mill systems by enabling precise energy transfer and uniform particle breakdown. Its material purity, mechanical stability, and surface finish are engineered to solve key operational and product quality challenges faced in industrial-scale dispersion lines. This section explores three specific use cases where performance consistency, contamination control, and mechanical endurance are essential.

-

Zirconia Ceramic Dispersion Rotor in Battery Slurry Preparation for LFP and NCM

✅Key Advantages

1. Minimal Ion Release Surface

The YSZ matrix exhibits <0.001 ppm ionic leaching in acidic electrolytes, preventing contamination of lithium slurries and preserving electrochemical integrity over 1000+ batch cycles. Its inert surface supports stable formulation consistency.

2. High Torque Load Stability

Rotor bodies are stress-verified to tolerate up to 200 N·m of cyclic torque, maintaining mechanical integrity throughout continuous 16-hour/day operations in multi-shift battery lines without deformation or cracking.

3. Dynamic Shear Uniformity

Multi-pin spiral geometry ensures turbulence consistency across the chamber, achieving D90 ≤ 450 nm with <8% batch deviation during NCM slurry dispersion verified in-line via laser diffraction analyzers.

✅ ️Problem Solved

A European LFP battery slurry processor previously faced ±15% variation in electrode coating density due to rotor imbalance and inconsistent bead acceleration. After integrating the ADCERAX® Zirconia Ceramic Dispersion Rotor, their D90 distribution narrowed by 42%, achieving sub-500 nm dispersion across 1800 hours with no mechanical failure or cleaning interruption.

-

Zirconia Ceramic Dispersion Rotor in Inkjet Pigment Mill Systems

✅Key Advantages

1. Ultra-Low Surface Roughness

Each rotor achieves Ra ≤ 0.2 μm surface finish, minimizing pigment residue adhesion and reducing the frequency of pigment flushing cycles by over 30% in continuous mill operation.

2. Turbulence-Optimized Pin Design

Precision-spaced pin rows create consistent bead flow rates >92%, preventing dead zones that typically cause particle agglomeration or oversized tails in pigment dispersion curves.

3. Color Fidelity Retention

YSZ’s non-reactive surface prevents pigment oxidation or hue drift; testing in magenta and cyan dispersions showed <2% Lab shift* across 60 batches, ensuring end-product optical stability.

✅ ️Problem Solved

An industrial ink manufacturer in Japan reported elevated nozzle blockage and pigment settling in DOD inkjet inks. After adopting the ADCERAX® Zirconia Ceramic Dispersion Rotor, their D90 dropped from 380 nm to 260 nm, clogging frequency fell by 60%, and inline Lab* deviations were kept under ±1.2 units across four pigments.

-

Zirconia Ceramic Dispersion Rotor in Ceramic Electronic Paste Production

✅Key Advantages

1. Non-Porous Grain Interface

Rotor microstructure is fully dense (porosity ≈ 0%) and polished, ensuring ceramic powders like BaTiO₃ or Al₂O₃ do not embed or shed during circulation, protecting downstream film integrity.

2. Anti-Vibration Structural Balance

Balanced to ISO 1940 G2.5, each rotor runs below 0.02 mm vibration amplitude, reducing print-line-induced paste shear variation and maintaining ±5% viscosity stability in screen printing lines.

3. Rapid Cleanout Compatibility

Rotor smoothness and CIP compatibility reduce paste residue carryover, shortening full batch transition and cleanout cycles to <18 minutes, improving production line changeover rates by 35%.

✅ ️Problem Solved

A Korean hybrid circuit manufacturer encountered dielectric layer inconsistencies due to fine oxide residue in ceramic paste dispersions. After upgrading to ADCERAX® rotors, sintered film rejection rates dropped from 7.8% to 1.4%, and batch cleaning time per shift was reduced by 42%, with zero visible surface degradation over 6 months.

User Guidelines for Zirconia Ceramic Dispersion Rotor

To ensure stable operation, extended lifespan, and optimal dispersion outcomes, Zirconia Ceramic Dispersion Rotor should be used and maintained under specific process parameters and handling precautions. This section provides guidance for installation, operation, cleaning, and lifecycle management based on real-world application feedback and engineering validation.

-

Rotor Installation Best Practices

1. Align rotor pin configuration with bead mill chamber layout.

Incorrect alignment can create uneven bead flow and increase localized wear. Always verify rotor orientation and axial centering before securing the coupling.

2. Use balanced fastening torque during rotor mounting.

Over-tightening can induce micro-cracks in the ceramic; under-tightening may lead to vibration during operation. Follow equipment manufacturer's torque settings strictly.

3. Conduct dynamic balance verification after rotor replacement.

Each Zirconia Ceramic Dispersion Rotor is balanced to ISO G2.5, but on-site alignment with shafts should be confirmed to avoid operational resonance.

-

Operation Parameters and Warnings

1. Avoid dry-starting the bead mill with no media or slurry.

Running the rotor dry causes surface overheating and can initiate microstructure degradation. Pre-fill the chamber to designed slurry levels before startup.

2. Monitor bead loading and avoid overpacking.

Excess media can lead to accelerated rotor wear and reduced energy efficiency. Maintain media filling ratio as specified by the mill's design guidelines.

3. Control rotational speed according to slurry viscosity.

Operating above 12,000 rpm in high-viscosity systems may induce cavitation or reduce shear effectiveness. Match speed to material rheology profile.

-

Cleaning and Maintenance Procedures

1. Flush rotor surfaces immediately after batch completion.

Delayed cleaning leads to solid residue buildup, particularly with ceramic pastes or pigment dispersions. Use compatible solvents or CIP systems where available.

2. Inspect pin and edge wear regularly (every 300 hours recommended).

Excessive wear alters shear geometry and affects dispersion uniformity. Replace when wear exceeds 0.3 mm on any pin or rotor edge.

3. Avoid abrasive brushes or metallic tools during manual cleaning.

Such tools can scratch the rotor surface (Ra increase >0.05 μm), increasing pigment adhesion and cross-contamination risk in the next batch.

-

Storage and Handling Recommendations

1. Store rotors in padded crates or foam-lined compartments.

Direct contact with hard surfaces can induce edge chipping or hairline cracks not visible to the eye. Use original packaging when possible.

2. Avoid exposure to thermal shock during storage or transfer.

Do not move rotors from sub-zero storage to humid high-temperature areas without acclimation time, to prevent material stress.

3. Record rotor usage history to predict lifecycle.

Maintaining a usage log (hours, material type, media size) allows predictive replacement before failure, reducing unplanned downtime.