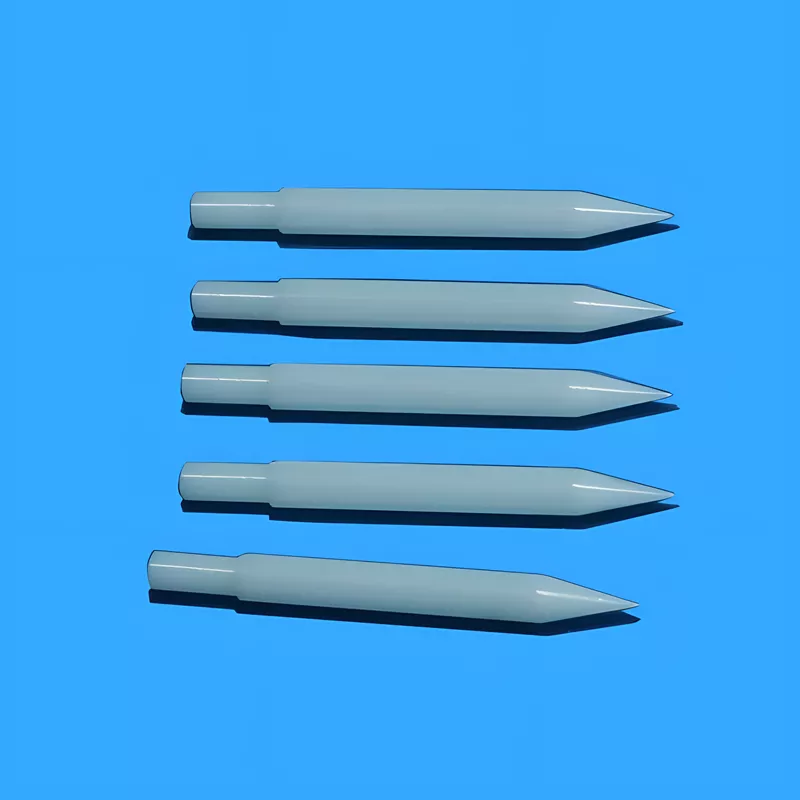

ADCERAX® Zirconia Ceramic Dowel Pin is engineered for high-precision positioning in demanding mechanical, welding, and assembly applications. With outstanding hardness, wear resistance, and thermal stability, it delivers consistent performance in environments exposed to heat, friction, and corrosion. This makes it a reliable choice for fixture alignment tasks where material durability and electrical insulation are critical.

Performance Features of Zirconia Ceramic Dowel Pin

-

Hardness Value

The material achieves a Vickers hardness of 12.5–13.5 GPa, which is over 8 times harder than stainless steel, making it highly resistant to surface wear during continuous contact.

-

Flexural Strength

With a minimum flexural strength of 950 MPa, it resists deformation and cracking even under repeated mechanical loads in fixture assemblies.

-

Compressive Performance

The compressive strength exceeds 2000 MPa, enabling the dowel pin to maintain positional accuracy in high-force clamping systems.

-

Thermal Stability

Zirconia ceramic supports continuous use at 1000–1200 °C, with short-term resilience up to 1500 °C, making it suitable for projection welding and furnace-side operations.

-

Oxidation Resistance

It shows no mass loss or surface degradation after 500-hour exposure to oxidizing conditions in thermal cycling tests.

-

Chemical Inertness

It remains stable in acidic and alkaline environments, with zero reaction observed in HCl (1 mol/L) and NaOH (1 mol/L) immersion tests.

-

Volume Resistivity

The pin offers a volume resistivity greater than 10¹² Ω·cm, ensuring complete insulation in high-voltage welding or robotic circuits.

-

Dielectric Behavior

Zirconia maintains dielectric integrity with no dielectric breakdown at standard operating voltages up to 20 kV/cm.

-

Electrochemical Stability

It prevents galvanic reactions and electrical leakage that commonly occur with metallic positioning components, especially in flux-contaminated assembly environments.

Technical Properties of Zirconia Ceramic Dowel Pin

The Zirconia Ceramic Dowel Pin is produced using high-density yttria‑stabilized zirconia and processed through precision post‑sinter grinding to ensure stability under mechanical load, thermal cycling, and corrosive operation environments.

| Property |

Specification |

| Material Composition |

ZrO₂ + 3 mol% Y₂O₃ (Y‑TZP) |

| Density |

≥ 6.05 g/cm³ |

| Hardness (HV10) |

12.5–13.5 GPa |

| Flexural Strength |

≥ 950 MPa |

| Compressive Strength |

≥ 2000 MPa |

| Fracture Toughness (K₁c) |

6.5–8.0 MPa·m¹/² |

| Thermal Expansion Coefficient |

10.3 × 10⁻⁶ /K (25–400°C) |

| Thermal Conductivity |

≈ 2.5 W/m·K |

| Maximum Continuous Service Temperature |

1000–1200°C |

| Short‑Term Peak Temperature Resistance |

Up to 1500°C |

| Volume Resistivity |

> 1×10¹² Ω·cm |

| Chemical Stability |

Inert in acids, alkalis, solvents |

| Surface Finish (as‑polished) |

Ra ≤ 0.2 µm |

| Phase Stability |

Tetragonal phase retention verified |

Specifications of Zirconia Ceramic Dowel Pin

|

Zirconia Ceramic Dowel Pin |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-YHG-Z1001 |

Customize |

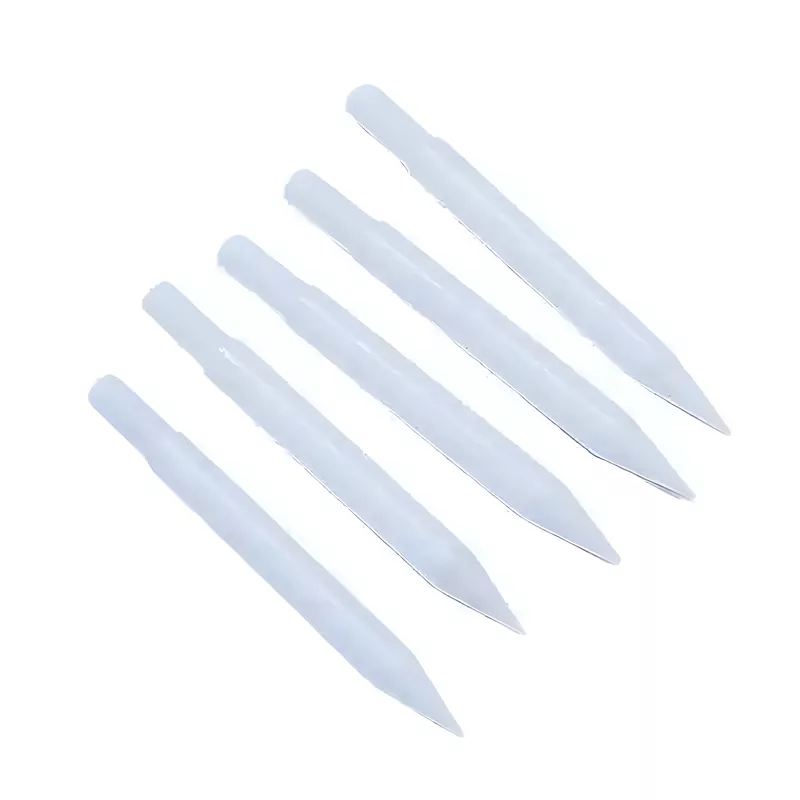

Packaging of Zirconia Ceramic Dowel Pin

Zirconia Ceramic Dowel Pin is individually slotted into high-density foam trays and sealed in anti-static clamshell boxes to prevent micro-fracture during transit. Each unit is then placed in a shock-absorbing polyurethane-insulated crate for secondary containment. Final outer packaging uses fumigation-free plywood cases to ensure secure export handling.

ADCERAX® Zirconia Ceramic Dowel Pin Enhances Process Accuracy Across High-Stress Industrial Positioning Systems

The Zirconia Ceramic Dowel Pin by ADCERAX® addresses core challenges faced in precision alignment tasks across metal welding, CNC fixture engineering, and robotic guidance mechanisms. By integrating this advanced ceramic pin into specific tooling configurations, manufacturers reduce misalignment, increase tool life, and ensure insulation where metallic pins fall short.

-

Resistance Welding Fixture Alignment in Automotive BIW Systems

✅Key Advantages

1. Arc‑Erosion Resistance in High‑Current Zones

The Zirconia Ceramic Dowel Pin surface does not bond with molten spatter, avoiding the arc-erosion wear that causes dimensional loss in alloy pins. In BIW welding tests, zirconia pins retained >98% of their original contact geometry after 10,000+ weld cycles, while hardened steel pins showed visible pitting and rounding.

2. Electrical Isolation in Multi‑Robot Cells

With volume resistivity > 1×10¹² Ω·cm, the pin prevents unintended current paths between electrodes or grounded fixtures. This eliminates micro‑shorting events, a common cause of heat concentration and weld nugget variation in high-density electrode arrays.

3. Stability Under Thermal Cycling

The tetragonal zirconia structure maintains integrity through rapid ΔT up to 600°C, preventing surface micro‑crack formation. This enables alignment consistency over extended production schedules, without requiring weekly fixture re‑shimming.

✅ ️Problem Solved

A Tier‑1 automotive supplier operating multi‑robot BIW lines reported alignment drift every 6–8 days when using alloy steel pins due to arc erosion and spatter buildup. Weld rejection rates increased by 3–5%, requiring fixture teardown and recalibration. After switching to ADCERAX® Zirconia Ceramic Dowel Pins, the fixture maintained alignment for >4 weeks without downtime, and weld defect rates stabilized at baseline target levels. The reduction in recalibration cycles directly improved equipment uptime and labor efficiency.

-

High‑Precision Jig Assembly in Multi‑Axis CNC Fixture Blocks

✅Key Advantages

1. Deflection‑Resistant Under Repeat Clamping

With flexural strength ≥ 950 MPa, the pin resists bending and edge bruising under continuous part loading. This ensures zero‑point reference retention, even in fixtures where clamping pressures exceed typical shop‑floor norms.

2. Thermal Expansion Matching to Tool Steel

The 10.3×10⁻⁶ /K thermal expansion coefficient aligns closely with common jig base steels (e.g., SKD11, H13). This prevents progressive hole‑to‑pin clearance variation during continuous machining cycles and temperature rise.

3. Ultra‑Smooth Contact Surface Integrity

A Ra ≤ 0.2 µm polished surface prevents micro‑galling between pin and bore interfaces. This reduces tolerance stack‑up during repositioning and extends fixture accuracy life across multi‑shift CNC operations.

✅ ️Problem Solved

A machining center producing precision aluminum housings experienced gradual hole‑alignment drift because coated steel pins expanded unevenly during repeated hot‑start machining. The result was 0.01–0.04 mm cumulative deviation across multi‑fixture assemblies, causing scrap escalation. After implementing ADCERAX® Zirconia Ceramic Dowel Pins, zero‑point alignment remained stable over three full production cycles, eliminating re-fixturing downtime and restoring consistent dimensional repeatability.

-

Guide Pin Systems in Robotic End Effectors and Automated Tool Transfer Units

✅Key Advantages

1. Wear Stability Across High‑Frequency Docking Cycles

Zirconia shows wear resistance >8× hardened steel, allowing the pin to maintain geometric fidelity across >5,000 robot tool‑change insertions. This prevents progressive fit looseness that leads to angular misalignment and connector damage.

2. Non‑Conductive Structure for Sensor‑Rich EOAT Systems

The non‑conductive ceramic body avoids electromagnetic interference near proximity sensors and servo feedback loops. This reduces signal noise variance, maintaining robotic path accuracy and smooth docking behavior.

3. Particle‑Free Surface for Clean‑Aligned Motion

Because zirconia does not shed metallic debris during sliding contact, it prevents contamination on optical sensors and critical precision interfaces. This improves uptime in vision‑assisted robotic workflows.

✅ ️Problem Solved

An automation integrator reported accumulating micro‑backlash in robotic end‑effector docking stations due to steel pin wear, causing insertion misalignment and occasional connector damage. Additionally, electrical interference from conductive pins disrupted positional sensors during high-speed sequences. After transitioning to ADCERAX® Zirconia Ceramic Dowel Pins, backlash was eliminated and tool docking remained repeatable across thousands of cycles, while sensor stability improved with no further EMI-related errors.

Practical Guidelines for Maximizing ADCERAX® Zirconia Ceramic Dowel Pin Performance

To ensure optimal long-term function, ADCERAX® Zirconia Ceramic Dowel Pin must be handled, installed, and maintained with consideration of its mechanical, thermal, and dimensional characteristics.

-

Handling and Installation Best Practices

1. Use Soft-Grip Tools Only

Avoid metal pliers or hammers during installation. Tool-induced microcracks may compromise strength.

2. Ensure Chamfered Hole Entry

Receiving components must be pre-chamfered to avoid press-fit jamming. Edge contact increases fracture risk.

3. Avoid Lateral Load Introduction

Dowels are optimized for vertical load alignment. Side force application causes structural stress.

-

Fitment Tolerances and System Compatibility

1. Follow ISO H7/g6 Guidelines

Tolerance matching ensures consistent interference or clearance fits. Deviations lead to alignment loss.

2. Thermal Expansion Differential Must Be Managed

When used with metals, CTE mismatch can cause binding or free play.

3. Avoid Mixed-Material Locating Systems

Maintain all-ceramic or matched-inertia pin sets to reduce dynamic mismatch effects.

-

Cleaning and Maintenance Protocols

1. Use Non-Abrasive Cleaning Fluids

Avoid acids or alkalis that can degrade surface polish. Neutral pH agents are recommended.

2. Implement Scheduled Visual Inspection

Check for chipping, surface erosion, or discoloration. Early wear indicators prevent failure propagation.

3. Refrain from Ultrasonic Cleaning

High-frequency resonance may introduce microcracks. Use static soaking instead.

-

Storage and Replacement Scheduling

1. Store in Padded, Dust-Free Containers

Use original packaging for re-storage. Hard surface contact risks hairline damage.

2. Apply Lifecycle Tracking per Batch ID

Maintain pin tracking by operational cycles or time-in-use. Prevents overextension of usage limits.

3. Replace After Mechanical Shock Events

Any accidental drop or collision mandates immediate replacement. Undetectable fractures may exist.