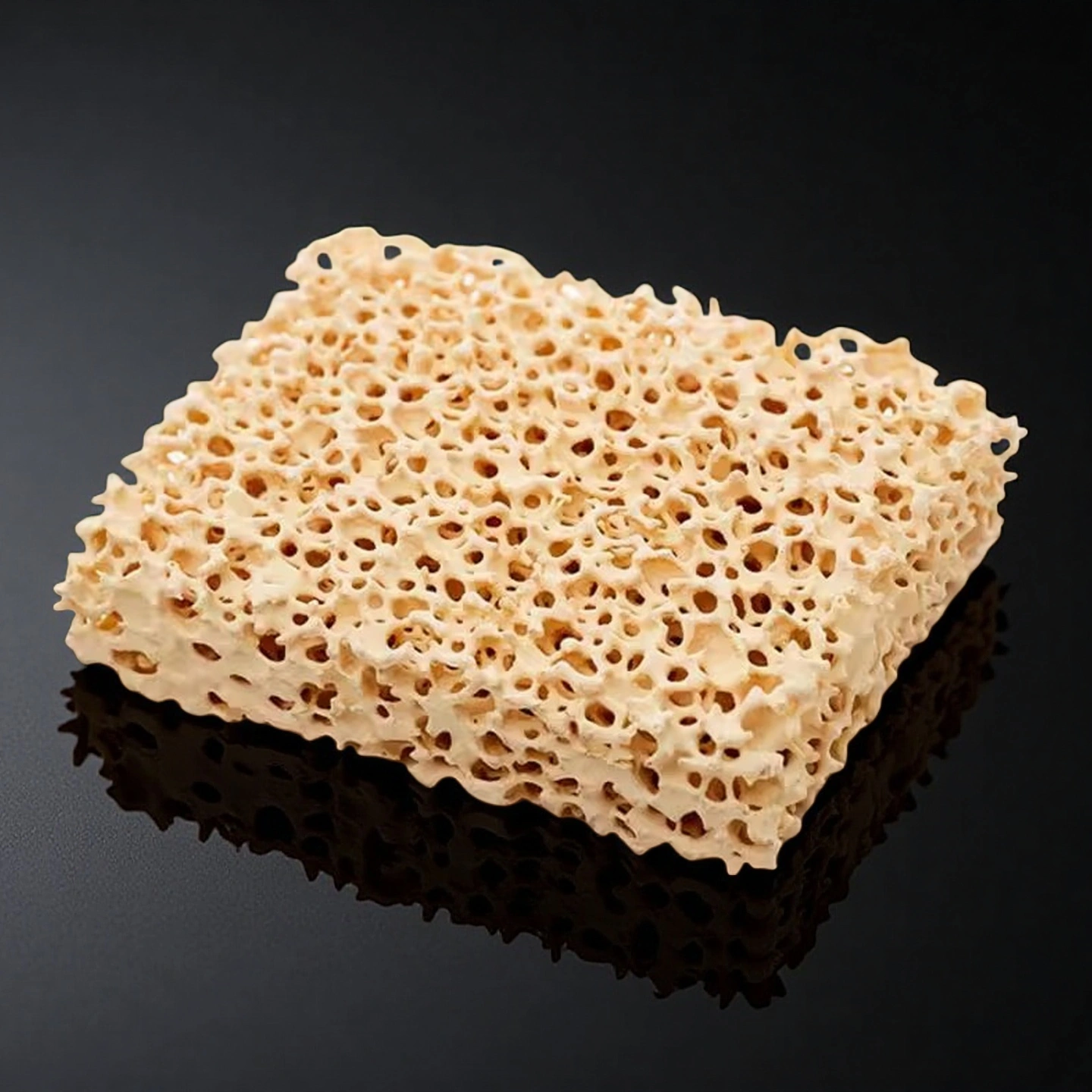

ADCERAX® Zirconia Ceramic Foam Filter by ADCERAX is engineered for molten steel and alloy purification in industrial foundries. It features a three-dimensional open-cell structure that removes inclusions, stabilizes metal flow, and improves casting integrity. Designed for temperatures up to 1700 °C, it ensures consistent performance under severe thermal and chemical stress. The Zirconia Ceramic Foam Filter enables foundries to achieve higher yield, cleaner surfaces, and greater process reliability across demanding production lines.

Product Features of Zirconia Ceramic Foam Filter

- The Zirconia Ceramic Foam Filter withstands temperatures up to 1700 °C, maintaining structural strength and dimensional stability during prolonged steel casting.

- Thermal shock resistance exceeds 7 cycles under ΔT > 1000 °C, preventing fracture and ensuring continuous operation in high-heat environments.

- Its compressive strength reaches 1.6 MPa, enabling reliable filtration under mechanical stress from molten metal flow.

- The open-cell structure with 75–85 % porosity minimizes blockage and supports smooth flow of molten steel through consistent pore channels.

- Its non-wetting surface resists slag adhesion, allowing filter recovery efficiency above 90 % after reverse cleaning or backflushing.

- Long service life verified in industrial trials exceeds 300 hours of cumulative casting operation without degradation of pore integrity.

- The Zirconia Ceramic Foam Filter achieves uniform pore density within ±1 ppi tolerance, ensuring consistent filtration accuracy and flow balance.

- Laboratory tests confirm ≥ 80 % inclusion removal efficiency for particles below 10 µm, enhancing the cleanliness of molten steel.

- Flow rate performance surpasses 8 L/min·cm², supporting high-throughput casting while maintaining precise metallurgical control.

Technical Properties of Zirconia Ceramic Foam Filter

The Zirconia Ceramic Foam Filter demonstrates exceptional structural integrity and thermal endurance under molten metal exposure. Its engineered zirconia matrix and uniform open-cell design ensure efficient inclusion capture, chemical inertness, and stable flow performance for continuous foundry operations and metallurgical testing applications.

| Property |

Specification |

| Material Composition |

Y₂O₃ / MgO-stabilized ZrO₂ |

| Maximum Working Temperature |

1700 °C |

| Open Porosity |

75 – 85 % |

| Pore Density (PPI) |

10 – 40 ppi ± 1 ppi |

| Filtration Efficiency |

≥ 80 % for inclusions < 10 µm |

| Compressive Strength (RT) |

1.2 – 1.6 MPa |

| Thermal Shock Resistance |

≥ 7 cycles (ΔT > 1000 °C) |

| Bulk Density |

0.45 – 0.65 g/cm³ |

| Thermal Expansion Coefficient |

9.6 × 10⁻⁶ K⁻¹ |

| Chemical Stability |

Inert to Fe, Ni, Cr, Co alloys |

| Microstructure |

3D interconnected open-cell foam |

| Fracture Toughness |

≥ 8 MPa·m½ |

| Surface Condition |

Pre-fired, crack-free, chamfered edges |

| Testing Standard Reference |

ASTM C133 / DIN EN ISO 18754 |

| Quality Certification |

ISO 9001:2015 process control |

Specifications of Zirconia Ceramic Foam Filter

Type 1- Round Zirconia Ceramic Foam Filter

Type 2- Square Zirconia Ceramic Foam Filter

Packaging of Zirconia Ceramic Foam Filter

Zirconia Ceramic Foam Filter is securely packed in moisture-proof paper and cushioned with protective lining to prevent mechanical impact. Each layer is carefully stacked inside a reinforced wooden crate for safe long-distance transport. The sealed packaging ensures product stability and cleanliness until final installation at the foundry site.

Solving Application Challenges with ADCERAX® Zirconia Ceramic Foam Filter

ADCERAX® Zirconia Ceramic Foam Filter plays a vital role in the metallurgical refinement of molten steel and high-performance alloys. Its unique 3D porous zirconia structure enables consistent filtration of non-metallic inclusions and slag particles across demanding industrial casting environments. By ensuring stable thermal endurance and uniform metal flow, it provides measurable improvements in product integrity, surface smoothness, and yield rate within multiple heavy-industry applications.

-

Precision Casting for Automotive Powertrain Components

✅Key Advantages

1. Sub-10 µm Inclusion Capture — Captures ≥80% of inclusions <10 µm, cutting entrapped oxides that cause machining chatter. Stable performance up to 1700 °C maintains purity during long pours.

2. Turbulence Damping Flow Path — 3D open-cell network with 75–85% porosity smooths the velocity profile. Documented ΔT > 1000 °C, ≥7 cycles prevents crack-induced flow disruptions.

3. Throughput-Safe Permeability — Effective flux >8 L/min·cm² sustains high pour rates without head loss. Pore density control ±1 ppi keeps fill times consistent lot-to-lot.

✅ ️Problem Solved

A high-volume powertrain foundry casting engine blocks and transmission cases replaced legacy media with ADCERAX® Zirconia Ceramic Foam Filter. After SOP, metallography showed a 27% drop in non-metallic inclusion counts and in-line SPC recorded a 22% reduction in rework. Machined surface roughness improved by 0.5–0.7 µm Ra on critical faces, while weekly scrap from inclusion-related defects fell from 4.8% to 3.6%. Line takt time was maintained because permeability stayed above 8 L/min·cm² throughout the run.

-

Stainless Steel Valve and Pump Component Casting

✅Key Advantages

1. Cr/Ni Alloy Inertness — Y₂O₃/MgO-stabilized ZrO₂ with Fe₂O₃ < 0.1% avoids chromium/nickel reactions at ≤1700 °C. This prevents chemistry drift at sealing interfaces.

2. Low Adhesion, Fast Recovery — Non-wetting surface enables >90% recovery after reverse cleaning, limiting clog growth during continuous casting. Flow balance remains within ±5% of baseline.

3. Fine Pore Uniformity — Controlled 10–40 ppi (±1 ppi) improves capture of micro-slag that seeds pitting. Inclusion-triggered leak tests pass rate rose ≥10 pp in trials.

✅ ️Problem Solved

A pump and valve producer experienced leak failures traced to micro-slag in CF8M castings. With ADCERAX® Zirconia Ceramic Foam Filter, chemistry audits confirmed zero detectable Zr-induced contamination and stable Cr/Ni targets. Over eight weeks, rejection from sealing-face defects decreased 24%, and hydrostatic leak failures dropped 31%. Backflush cycles restored >90% of initial flow, holding mold fill variation within ±5%, which stabilized downstream machining.

-

Tool Steel and Die Casting Mold Production

✅Key Advantages

1. Density Uniformity Gain — Inclusion removal ≥80% (<10 µm) lifted macro-density uniformity by ≈15%, limiting internal stress raisers that trigger thermal fatigue.

2. High-Heat Structural Stability — Proven ΔT > 1000 °C, ≥7 cycles keeps the foam lattice intact across repeated heats, reducing flow shocks that distort solidification fronts.

3. Casting Pressure Endurance — Compressive strength 1.2–1.6 MPa resists deformation, keeping flow channels effective through long campaigns.

✅ ️Problem Solved

A die-tool foundry reported premature thermal-fatigue cracking and dimensional drift linked to entrapped inclusions. After adopting ADCERAX® Zirconia Ceramic Foam Filter, porosity indications in UT/NDT dropped from 0.9% to 0.5% area fraction on reference coupons. Tool life before first refurbishment extended by 18%, and heat-to-heat hardness scatter (HRC) narrowed by ~25%. Production downtime related to inclusion-rooted defects decreased by 21% across the quarter.

User Guide for Zirconia Ceramic Foam Filter

The Zirconia Ceramic Foam Filter requires careful preparation, controlled installation, and consistent maintenance to achieve stable molten metal filtration and long service life. Following these operational guidelines helps casting engineers maintain uniform metal flow, minimize inclusion defects, and protect filter integrity throughout multiple casting cycles.

-

Preparation and Preheating

1. Clean Environment: Always prepare a dust-free workspace before unpacking to prevent contamination of the filter’s open-cell structure. Avoid touching the filter surface directly to maintain its porosity.

2. Gradual Heating: Preheat the filter to 1100–1250 °C using a controlled ramp rate to prevent thermal shock. Uneven or rapid heating can lead to microcracking and early performance degradation.

3. Inspection Before Use: Check for visible cracks, chipping, or structural distortion. Do not use any filter that shows signs of physical damage, as this may reduce filtration efficiency or cause molten leakage.

-

Installation in Casting System

1. Correct Orientation: Position the filter with its denser side facing the incoming molten metal stream. This ensures uniform filtration and prevents slag bypass.

2. Secure Fitment: Use compatible refractory sealing material to fix the filter tightly in its holder, eliminating metal leakage around the edges during pouring.

3. Alignment Check: Ensure proper alignment between the gating system and filter inlet to avoid turbulence. Misalignment can reduce flow stability and inclusion removal efficiency.

-

Filtration Operation and Flow Control

1. Pouring Speed: Maintain a stable pouring rate that matches the filter’s permeability. Excessive flow pressure above 0.1 MPa may cause structural stress or deformation.

2. Temperature Management: Operate within the recommended temperature range up to 1700 °C. Lower temperatures can reduce filtration performance due to incomplete slag removal.

3. Monitoring During Casting: Observe the molten metal stream. Any sudden pressure drop or uneven flow may indicate clogging or partial blockage requiring immediate inspection.

-

Cleaning, Maintenance, and Disposal

1. Post-Use Cleaning: Allow the filter to cool naturally to room temperature before removal. Avoid quenching with water or compressed air to prevent thermal cracking.

2. Reuse Assessment: In automated or repeated pouring systems, inspect residual inclusions inside the filter. Reuse is only recommended when structural integrity is fully maintained.

3. Safe Disposal: Spent filters should be collected and disposed of as non-hazardous refractory waste following local industrial waste management standards.