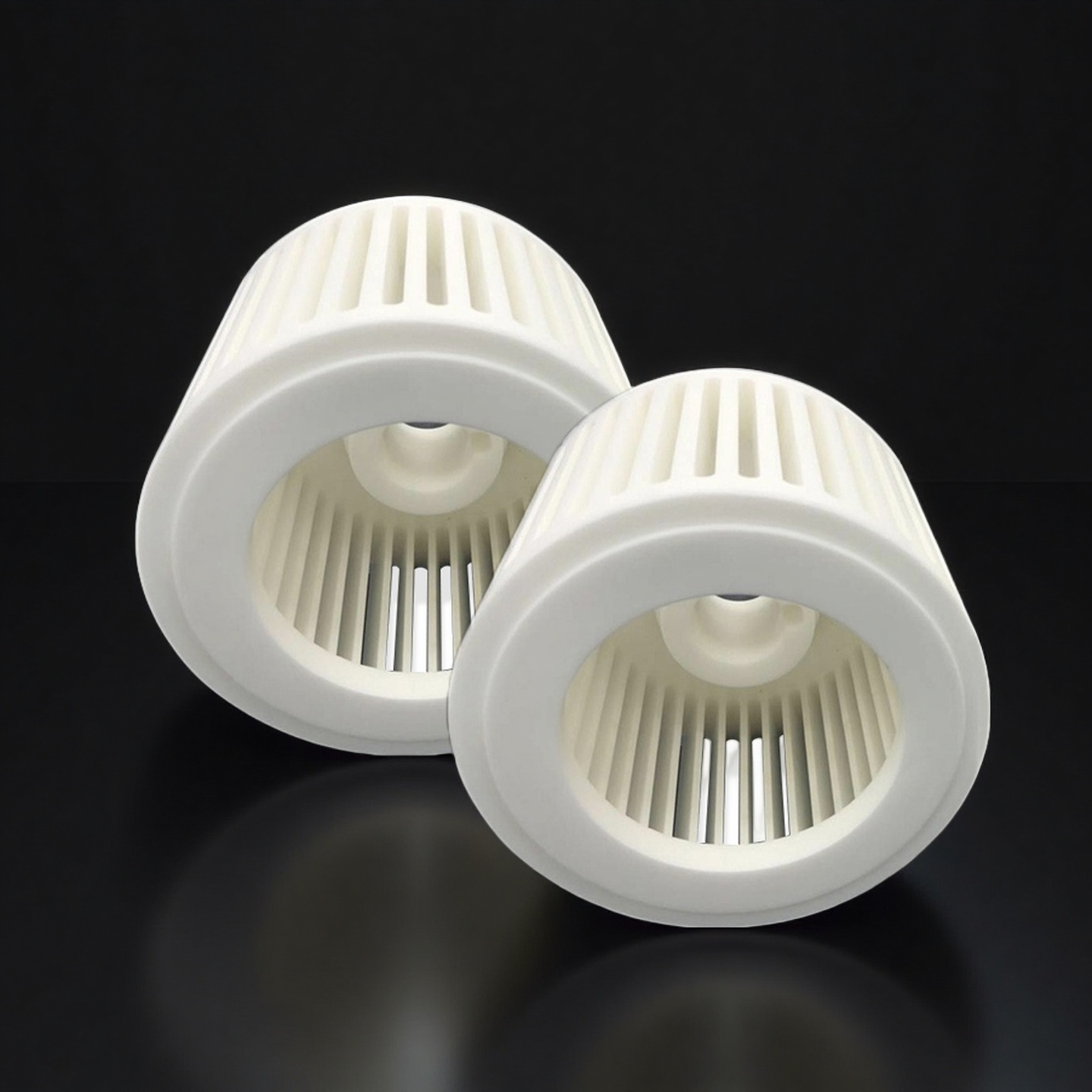

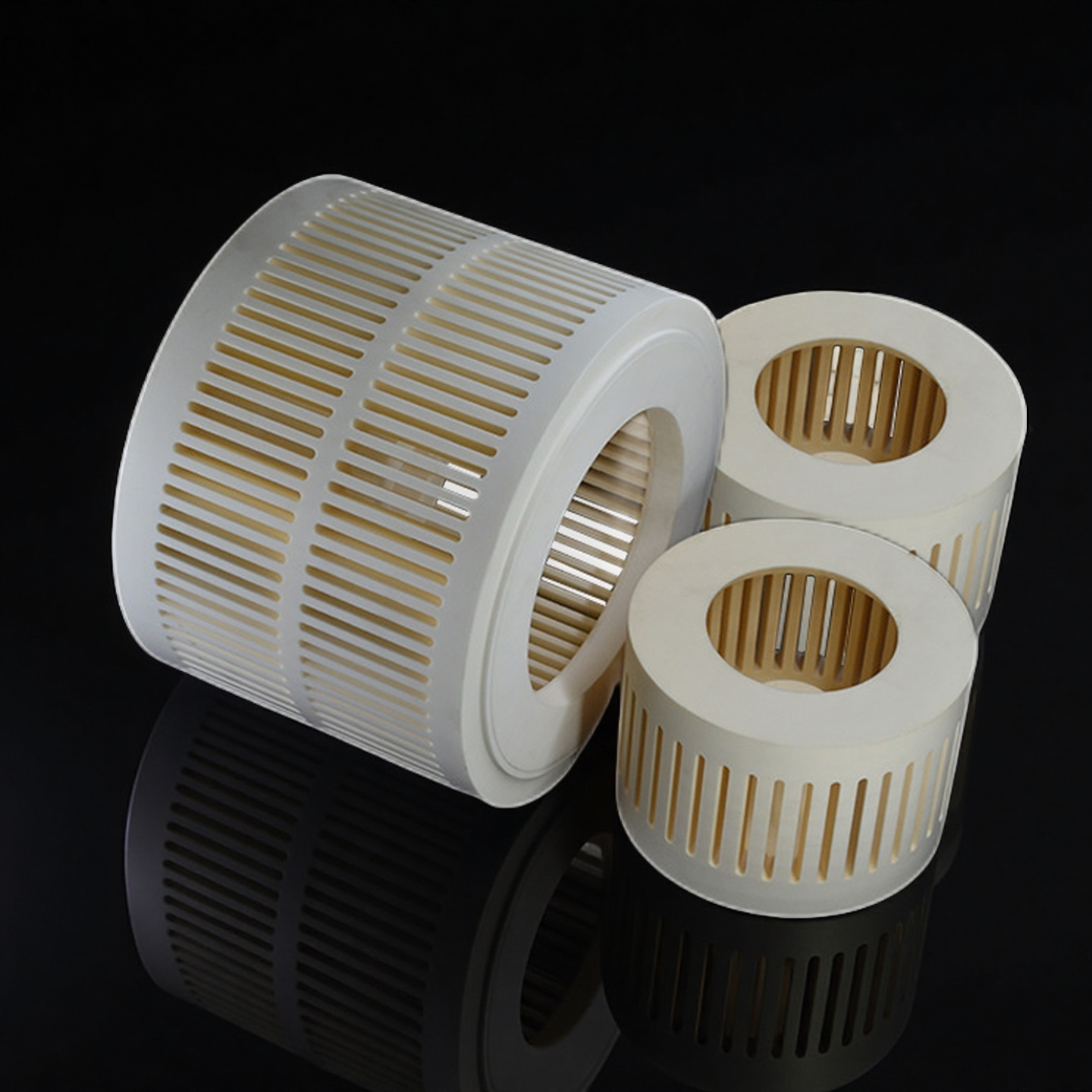

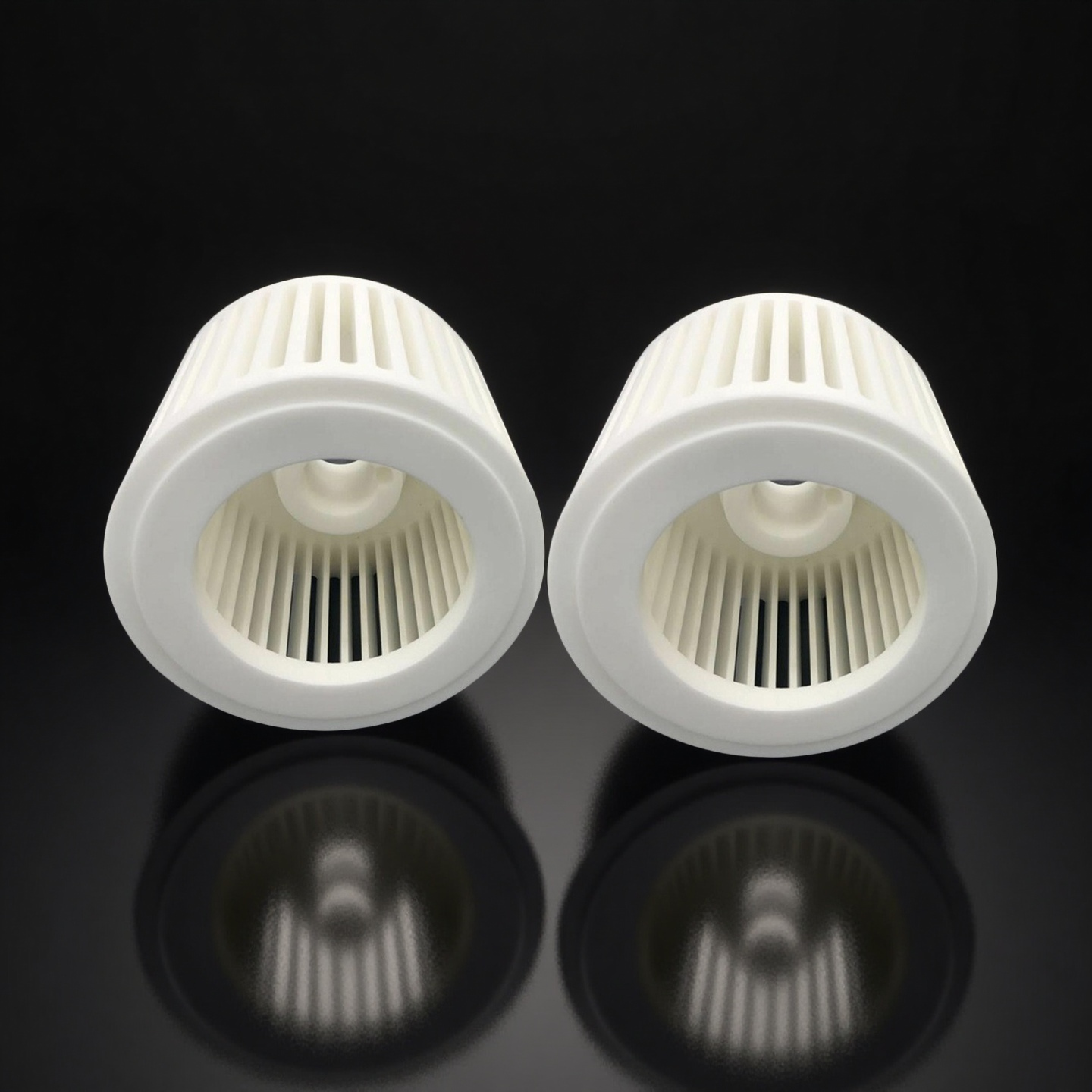

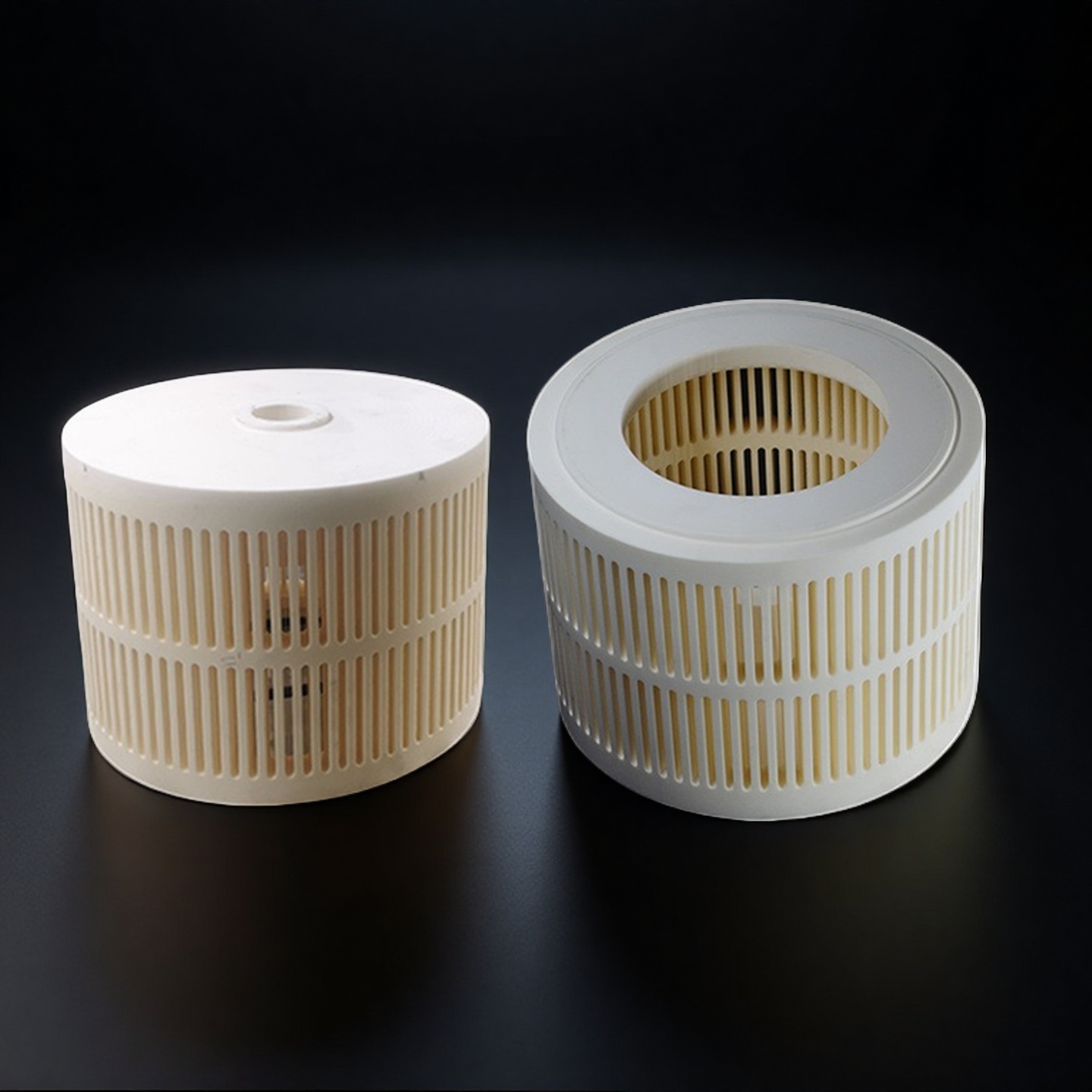

ADCERAX® Zirconia Ceramic Grading Wheel is a critical component in sand mill and air classifier systems, designed to precisely regulate airflow and separate particles by size. Its high hardness, wear resistance, and chemical inertness ensure long-term stability in abrasive and corrosive environments. With excellent thermal performance and structural toughness, it supports consistent powder classification across demanding industrial applications.

Performance Features of Zirconia Ceramic Grading Wheel

- No phase transformation under thermal stress

The 3Y-TZP zirconia structure ensures phase stability across temperature gradients, preventing material degradation or structural failure in continuous operation.

- Validated ΔT ≥ 400 °C thermal shock resistance

Lab tests confirm that the material resists thermal cracking when rapidly cycled from 20 °C to 420 °C, making it suitable for environments with fluctuating process conditions.

- Zero metal ion contamination

Material analysis confirms <0.005% leach rate under corrosive conditions, eliminating risks of metallic impurity migration into process media.

- Stable in acidic and alkaline media

The wheel shows no visible degradation after 72 hours in 10% HCl and 10% NaOH exposure, supporting long-term use in chemically aggressive systems.

- Flexural strength ≥ 1000 MPa

The zirconia wheel maintains its geometry under centrifugal forces and particle impact, enabling high-speed classification without fracture.

- Hardness > 1200 HV (Vickers)

Its ultra-high hardness ensures longer wear life—up to 10× compared to stainless steel, reducing maintenance frequency.

- Fracture toughness 8–10 MPa·m½

The microstructure offers strong resistance to chipping and crack propagation, even in systems with fluctuating loads or abrasive feedstock.

- Surface roughness ≤ 0.2 µm

Mirror-polished finish minimizes material buildup and dust adhesion, improving operational cleanliness and airflow consistency.

- Improved separation efficiency

Field results show up to 18% increase in fine particle recovery, driven by smoother flow paths and reduced clogging.

Technical Properties of Zirconia Ceramic Grading Wheel

The Zirconia Ceramic Grading Wheel delivers high mechanical integrity, chemical inertness, and thermal resilience required in advanced powder separation systems. Its dense microstructure, surface precision, and stable ceramic phase composition ensure optimal performance under continuous industrial stress.

| Property |

Specification |

| Material Composition |

Yttria-Stabilized Zirconia (3Y-TZP) |

| Bulk Density |

6.0 ± 0.05 g/cm³ |

| Vickers Hardness |

> 1200 HV |

| Flexural Strength |

≥ 1000 MPa |

| Fracture Toughness |

8–10 MPa·m¹ᐟ² |

| Thermal Conductivity (25 °C) |

2.5 W/m·K |

| Maximum Service Temperature |

≤ 1500 °C |

| Thermal Expansion Coefficient |

10.3 × 10⁻⁶ /K (25–1000 °C) |

| Surface Roughness (Ra) |

≤ 0.2 µm |

| Electrical Conductivity |

Insulating |

| Magnetic Behavior |

Non-magnetic |

| Acid/Alkali Corrosion Resistance |

No degradation in 10% HCl / NaOH (72 h) |

| Thermal Shock Resistance |

ΔT ≥ 400 °C |

| Microstructure Grain Size |

< 0.4 µm |

Specifications of Zirconia Ceramic Grading Wheel

|

Sand Mill Zirconia Ceramic Grading Wheel |

|

Item No. |

Outer Diameter (mm) |

Inner Diameter (mm) |

Height (mm) |

|

AT-YHG-SM006 |

50 |

30 |

70 |

|

AT-YHG-SM007 |

80 |

65 |

90 |

|

AT-YHG-SM008 |

100 |

75 |

80 |

|

AT-YHG-SM009 |

155 |

135 |

95 |

|

AT-YHG-SM010 |

250 |

220 |

100 |

|

AT-YHG-SM011 |

260 |

240 |

120 |

Packaging of Zirconia Ceramic Grading Wheel

Zirconia Ceramic Grading Wheel is first wrapped in protective cartons and arranged in a shock-absorbing foam-lined crate. Each unit is securely sealed to prevent moisture ingress and minimize vibration impact. The entire assembly is reinforced with a strapped plywood case for safe international transit.

Solving Application Challenges with ADCERAX® Zirconia Ceramic Grading Wheel

ADCERAX® Zirconia Ceramic Grading Wheel plays a pivotal role in material separation and particle refinement across high-demand sectors. By leveraging its resistance to heat, corrosion, and abrasion, it enhances throughput quality and process reliability in environments where conventional metal components fail. The following use cases illustrate how it directly addresses key pain points in precision grinding and classification processes.

-

Fine Particle Dispersion in Water-Based Automotive Coatings

✅Key Advantages

1. Non-Metallic Structure Prevents Ion Migration

The fully ceramic matrix ensures zero Fe/Ni/Cr leaching under high-pH dispersions, maintaining <0.005% trace metal presence throughout extended wet-milling cycles.

2. Stable Surface Gloss Across 3000 RPM Operation

Dynamic balance rated ≤ G2.5 per ISO 1940-1 supports consistent airflow and pigment orientation, leading to gloss deviation <2.3 GU across automotive topcoat applications.

3. Anti-Adhesion Finish Reduces Cycle Downtime

Polished Ra ≤ 0.2 µm surface limits binder and pigment build-up, extending maintenance intervals by 3× versus alumina or SS alloy blades in waterborne environments.

✅ ️Problem Solved

A Tier-1 paint manufacturer producing water-based metallic coatings reported particle agglomeration and gloss variation of ±6 GU across batches using stainless steel classification wheels. After replacing with ADCERAX® Zirconia Ceramic Grading Wheel, pigment dispersion uniformity improved by 22%, gloss deviation stabilized within ±2 GU, and rework rate dropped by 17% over a 60-day production cycle.

-

High-Purity Grinding in Lithium Iron Phosphate (LFP) Battery Powder Production

✅Key Advantages

1. Contamination-Free Ceramic Matrix

Certified <0.0001 ppm Fe/Ni/Cr ion release after 72h phosphate slurry exposure ensures compatibility with LFP purity standards and eliminates batch-level rejection risks.

2. Microstructure Maintains D90 < 10 µm

The wheel enables consistent classification of LFP particles with D90 tolerance below ±0.8 µm, verified by SEM image grading across 12 parallel production batches.

3. Extended Operation Under pH >11 Slurries

Thermal shock resistance of ΔT ≥ 400 °C and inertness to high-pH electrolytic media allow continuous 24/7 wet-milling without delamination or geometry distortion.

✅ ️Problem Solved

A battery materials producer reported over 8% monthly rejection rate due to Fe contamination and D90 overshoot in cathode powder lots. Switching to ADCERAX® Zirconia Ceramic Grading Wheel eliminated detectable Fe/Ni migration, reduced D90 variance to ±0.5 µm, and improved product acceptance rate to 98.6% across a 3-month scale-up phase.

-

Slurry Classification in Electronic Glass Paste Processing for Touch Panels

✅Key Advantages

1. Low-Shear Precision at High Flow Rates

Rotational consistency at >3000 rpm supports paste stability with deviation in screen-printed track width <±2.5 µm, critical for high-resolution ITO or Ag-grid layouts.

2. Electrochemically Inert Surface

Zirconia’s non-conductive and non-magnetic properties avoid disturbance of sensitive Ag and dielectric pastes, meeting display grade uniformity thresholds of <1.5% film thickness deviation.

3. Reduced Paste Dry-Out & Blockage Risk

Polished Ra ≤ 0.2 µm minimizes dead zones and flow path turbulence, extending nozzle/pump uptime by >40%, lowering maintenance frequency in paste transfer systems.

✅ ️Problem Solved

A panel manufacturer supplying high-resolution touch modules faced recurring defects linked to uneven paste line formation and excessive screen clogging. Post-integration of ADCERAX® Zirconia Ceramic Grading Wheel, the average paste viscosity deviation dropped by 12%, printing resolution stabilized across 1500 panels/day, and nozzle blockages reduced by 41% over one fiscal quarter.

Operational Recommendations for Zirconia Ceramic Grading Wheel

Zirconia Ceramic Grading Wheel is engineered for high-precision classification environments, but proper usage and handling are essential to ensure consistent performance and extended service life.

-

Installation and Setup Best Practices

1. Alignment Accuracy

Ensure shaft and wheel axis alignment within ±0.02 mm. Misalignment may cause uneven loading and vibration.

2. Torque Control

Use calibrated torque tools for fasteners to avoid structural stress. Over-tightening can result in surface microcracks.

3. Housing Clearance

Maintain at least 1.5 mm clearance between wheel edge and housing. Thermal expansion or material buildup may cause friction without it.

-

Operation Parameters and Process Compatibility

1. pH Range Monitoring

Operate within slurry pH range of 3–11. Extreme pH conditions may gradually weaken the ceramic matrix.

2. Temperature Stability

Maintain working fluid temperature below 120 °C. Prolonged exposure beyond threshold can affect binder phases.

3. Rotation Speed Control

Restrict rotational speed to system-rated maximum RPM. Overspeed leads to mechanical resonance and efficiency loss.

-

Cleaning and Maintenance Instructions

1. Non-Abrasive Cleaning

Use only soft brushes or ultrasonic baths with neutral detergents. Abrasive tools degrade functional surfaces.

2. Residue Inspection

Inspect after each shift for hardened slurry deposits. Early removal prevents structural surface pitting.

3. Drying Method

Air dry at ambient conditions only. Forced drying above 100 °C may induce microstructural tension.

-

Handling and Storage Requirements

1. Edge Contact Avoidance

Avoid direct contact with hard surfaces during movement. Use protective gloves and padded holders.

2. Vertical Storage Orientation

Store upright on padded shelves with full surface support. Horizontal stacking induces stress along unsupported arcs.

3. Humidity Control

Keep in a humidity-controlled environment below 60%. Absorbed moisture may affect surface condition on restart.