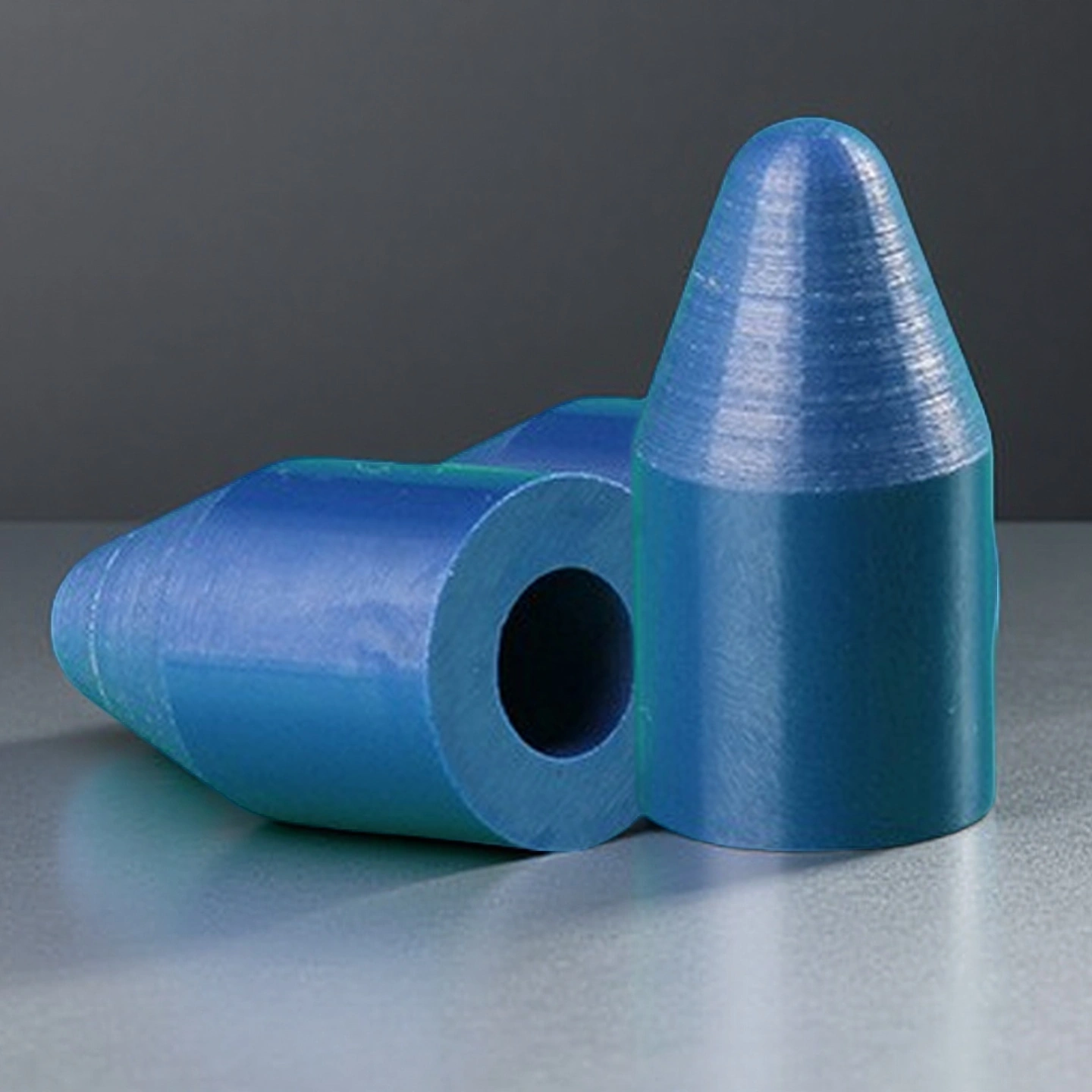

ADCERAX® Zirconia Ceramic Positioning Pin by ADCERAX® is designed for industrial environments that demand precision alignment, mechanical durability, and stability under heat and corrosion. It delivers consistent locating accuracy in automotive welding fixtures, electronic assembly systems, and chemical processing equipment. Engineered from yttria‑stabilized zirconia, this positioning pin ensures long service life, wear resistance, and reliable performance where metal or polymer components fail. Its strength and chemical inertness make it ideal for continuous operation in high‑temperature and high‑purity applications.

Key Performance Features of Zirconia Ceramic Positioning Pin

- Broad chemical stability: The pin maintains structural integrity in exposure to strong acids, alkalis, and saline solutions, making it ideal for chemical reactors and offshore processing equipment.

- Low thermal conductivity: With a thermal conductivity of only 2.0–2.5 W/m·K, it reduces heat transfer to surrounding components, protecting fixture structures from thermal fatigue.

- Stable expansion profile: Its thermal expansion coefficient of 10.5 × 10⁻⁶/K aligns with many tool steels, maintaining alignment in hybrid metal–ceramic setups.

- Surface inertness: Unlike metal pins, it experiences no oxidation or corrosion under H₂SO₄, HCl, or NaOH, verified by immersion testing over 72-hour cycles.

- No ion leaching: The inert ceramic matrix ensures 0% contamination risk in sensitive food-grade and pharmaceutical systems.

- Extreme surface hardness: With a Vickers hardness of 12–13 GPa, the Zirconia Ceramic Positioning Pin resists scratches, impact abrasion, and cyclic frictional wear.

- Durable under stress: It achieves a flexural strength of 900–1200 MPa, extending service life under repeated clamping or mechanical contact.

- Tested for longevity: In fatigue trials simulating 100,000 fixture cycles, dimensional stability remained within ±0.005 mm tolerance across all samples.

- Non-toxic and non-reactive: The ceramic composition is 100% inert and metal-free, preventing allergic reactions or chemical migration in biological environments.

Technical Properties of Zirconia Ceramic Positioning Pin

The Zirconia Ceramic Positioning Pin is engineered for dimensional stability, fracture resistance, and environmental durability across high-load and high-temperature operations. Its dense microstructure and thermomechanical properties enable consistent performance in welding fixtures, test jigs, and corrosive processing environments.

| Property |

Specification |

| Material Composition |

Yttria-Stabilized Zirconia (Y‑TZP) |

| Density |

6.0 g/cm³ |

| Flexural Strength |

900–1200 MPa |

| Compressive Strength |

≥ 2000 MPa |

| Fracture Toughness |

8–10 MPa·m¹ᐟ² |

| Vickers Hardness |

12–13 GPa |

| Maximum Working Temperature |

1000 °C continuous / 1200 °C peak |

| Thermal Conductivity |

2.0–2.5 W/m·K |

| Coefficient of Thermal Expansion |

10.5 × 10⁻⁶ /K |

| Electrical Resistivity |

> 10¹² Ω·cm at 25 °C |

| Dielectric Strength |

12–15 kV/mm |

| Acid/Alkali Resistance |

Stable in HCl, H₂SO₄, NaOH |

| Water Absorption |

0% (fully dense) |

| Color Options |

White / Black zirconia |

Specifications of Zirconia Ceramic Positioning Pin

Packaging of Zirconia Ceramic Positioning Pin

Zirconia Ceramic Positioning Pin is securely packed in individual grid compartments to prevent surface contact and chipping. Inner boxes are sealed and buffered with plastic liners before being placed in reinforced cartons. All cartons are finally palletized with shrink wrap and strapping for safe international transit.

Supporting Industrial Precision Systems with ADCERAX® Zirconia Ceramic Positioning Pin

ADCERAX® Zirconia Ceramic Positioning Pin plays a critical role in maintaining dimensional consistency and structural alignment across automated industrial systems. It is used as a fixed reference point in clamping jigs, inspection tooling, and modular fixtures that must withstand repeated contact, elevated temperatures, and corrosive environments. Its performance ensures downstream accuracy in machining, welding, and measurement processes

-

Zirconia Ceramic Positioning Pin in Sheet Metal Forming Fixture Systems

✅Key Advantages

1. High Compressive Strength Under Press Load

With a compressive strength ≥ 2000 MPa, the ADCERAX® Zirconia Ceramic Positioning Pin endures repetitive clamping and forming pressure without plastic deformation. It sustains consistent locating accuracy even after tens of thousands of stamping cycles in automated die stations.

2. Resistance to Vibration‑Induced Wear

The material’s Vickers hardness of 12–13 GPa and fine‑grain microstructure prevent micro‑pitting caused by high‑frequency vibration in progressive dies. This eliminates clearance growth that typically occurs in metal locator pins after long‑term operation.

3. Stable Geometry Under Cyclic Stress

The flexural strength range of 900–1200 MPa ensures reliable shape retention under lateral shear loads. The pin preserves its reference point precision, avoiding cumulative deviation in die‑to‑punch alignment during multi‑stage forming.

✅ ️Problem Solved

Misalignment and Scrap in Progressive Stamping Lines

A Tier‑2 automotive supplier reported dimensional drift of 0.04 mm on steel locator pins after 45,000 press cycles, leading to a 15 % increase in rejected parts and unplanned die re‑calibration. After replacement with ADCERAX® Zirconia Ceramic Positioning Pins, no measurable locator wear was detected after 120,000 cycles. The fixture maintained consistent blank alignment, reducing downtime by 40 % and stabilizing overall part geometry tolerance.

-

Zirconia Ceramic Positioning Pin in Heavy‑Duty Welding Positioners for Steel Assemblies

✅Key Advantages

1. Thermal Shock Resistance in Welding Environments

The pin tolerates temperature spikes up to 1000 °C and rapid cooling without structural degradation. It resists micro‑cracking from repeated pre‑heat and cooling cycles in robotic welding fixtures.

2. Non‑Adhesive Surface to Molten Slag

With a dense, non‑metallic surface finish (Ra ≤ 0.2 µm), spatter and slag do not adhere to the zirconia pin, keeping the locating point clean. This reduces post‑weld fixture maintenance and regrinding operations.

3. Anti‑Oxidation and Dimensional Retention

The inert ceramic composition shows zero oxidation scale formation even after 72 h exposure at 900 °C, maintaining the locating geometry of the jig throughout continuous production.

✅ ️Problem Solved

Locator Damage and Weld Gap Variability

In a heavy‑fabrication facility, steel locator pins oxidized and fused with slag, causing weld gap variance up to 0.25 mm after only two weeks of use. By implementing ADCERAX® Zirconia Ceramic Positioning Pins, the fixture maintained stable geometry over 8,000 welded parts with no measurable oxidation or buildup. Maintenance frequency was reduced from every 14 days to every 60 days, improving line availability by 28 %.

-

Zirconia Ceramic Positioning Pin in Precision Coordinate Measuring Fixtures

✅Key Advantages

1. High Modulus for Geometric Stability

The Young’s modulus of 200–210 GPa minimizes elastic deflection under part loading. This maintains micrometer‑level consistency in repeat measurements on coordinate measuring machines.

2. Micro‑Wear Resistance for Contact Probing

The zirconia surface shows no wear marks after 100,000 contact probes, verified under CMM fatigue testing. It sustains the same datum reference over extended inspection cycles, preserving calibration accuracy.

3. Thermal Neutrality and Measurement Repeatability

Low thermal conductivity (2.0–2.5 W/m·K) prevents local expansion from ambient temperature changes. Measurement repeatability is retained even during long inspection sequences.

✅ ️Problem Solved

Measurement Drift and False Non‑Conformance Reports

An industrial metrology lab observed progressive dimensional drift of 0.008 mm in fixtures using hardened steel pins after six months. The drift led to false out‑of‑tolerance readings in CMM reports. After integrating ADCERAX® Zirconia Ceramic Positioning Pins, thermal drift was eliminated, and measurement repeatability improved by over 95 %, verified through three independent gauge repeatability and reproducibility (GR&R) audits.

Operational Best Practices for Zirconia Ceramic Positioning Pin

Zirconia Ceramic Positioning Pin must be used with attention to mechanical compatibility, thermal behavior, and fixture integration to ensure optimal performance. This guide outlines critical user-side precautions and handling recommendations to support product longevity, repeatability, and safety across industrial applications.

-

Proper Installation into Fixtures

1. Verify alignment: Always ensure the mating bore or bushing has matching axis alignment with the Zirconia Ceramic Positioning Pin. Misalignment beyond ±0.02 mm can generate torsional stress.

2. Use interference-free fits: Avoid press-fitting or over-tightening. A slip or clearance fit with anti-vibration retention is recommended.

3. Support axial load properly: Pins used in vertical jigs must have a flat shoulder stop to prevent creep under long-term load.

-

Thermal and Environmental Considerations

1. Avoid thermal shock: Do not subject the pin to sudden temperature jumps exceeding 200 °C/min to prevent microcracks.

2. Monitor ambient acidity: Although corrosion-resistant, prolonged exposure to pH < 2 or > 12 conditions may weaken the material over time.

3. Ensure cooling compatibility: When used near heat sources, design uniform cooling paths around the pin to avoid hot spots.

-

Handling and Maintenance Precautions

1. Avoid point contact impacts: Do not drop or allow hard tool collision against the pin; local fracture strength can degrade with even microscopic edge damage.

2. Inspect contact surfaces regularly: Clean debris from seat interfaces and confirm no visible erosion or color change from heat.

3. Do not reuse fractured pins: Partial chipping or cracks below 0.2 mm depth can lead to complete breakage under load.

-

Storage and Transport Recommendations

1. Use padded compartment trays: Store pins individually with non-abrasive inserts to prevent edge-to-edge contact.

2. Control humidity levels: Keep stock in environments below 60% RH to avoid indirect corrosion in long-term storage.

3. Secure in multi-layer cartons: For shipping, follow double-box and pallet strapping protocols as shown in the packaging section.