ADCERAX® Zirconia Ceramic Screws & Bolts are advanced fastening components engineered for long-term reliability in corrosive, high-temperature, and electrically sensitive industrial environments. Made from yttria-stabilized zirconia, they provide outstanding mechanical strength, wear resistance, and chemical inertness. These fasteners maintain stability under thermal cycling and exposure to harsh media, offering a durable alternative to metal bolts. Used across chemical equipment, electrical systems, and laboratory instruments, Zirconia Ceramic Screws & Bolts ensure secure, non-magnetic, and maintenance-free connections.

Key Performance Features of Zirconia Ceramic Screws & Bolts

- Zirconia Ceramic Screws & Bolts withstand flexural forces up to 1200 MPa, outperforming conventional fasteners in structural integrity. This high strength enables use in high-load assemblies and dynamic mechanical joints.

- Fracture toughness values between 8–10 MPa·m¹ᐟ² provide resistance to crack propagation under torsional stress and prevent brittle failure.

- Elastic modulus of ~200 GPa ensures minimal elastic deformation under tightening loads, reducing torque loss over time.

- Surface hardness ≥ 1200 HV provides abrasion resistance over 200× greater than manganese steel, ideal for friction or particle-prone environments.

- Volumetric density of 6.0 g/cm³ delivers structural compactness, enhancing thread wear resistance in repeated assembly cycles.

- Surface roughness of Ra < 0.2 μm minimizes micro-crack formation and ensures consistent torque transfer during tightening.

- Thermal expansion coefficient of ~10×10⁻⁶/K allows compatibility with most engineering substrates, reducing joint stress under temperature fluctuation.

- No observable degradation in 5% NaOH or 10% H₂SO₄ for over 72 hours, based on immersion resistance tests.

- Dielectric strength >15 kV/mm supports use in insulation-critical applications across electrical distribution and instrumentation.

Technical Properties of Zirconia Ceramic Screws & Bolts

Zirconia Ceramic Screws & Bolts exhibit a combination of mechanical strength, thermal resilience, chemical durability, and electrical insulation, making them suitable for demanding industrial fastening tasks under harsh conditions.

| Property | Specification |

|---|---|

| Material Composition | 3 mol% Y₂O₃-stabilized ZrO₂ (3Y-TZP) |

| Density | 6.0 ± 0.1 g/cm³ |

| Flexural Strength | 800 – 1200 MPa |

| Compressive Strength | > 2000 MPa |

| Vickers Hardness (HV1) | ≥ 1200 HV |

| Fracture Toughness | 8 – 10 MPa·m¹ᐟ² |

| Elastic Modulus | ~200 GPa |

| Thermal Conductivity | 2.5 W/m·K |

| Maximum Working Temperature | 1000 °C (continuous) |

| Thermal Expansion Coefficient | ~10 × 10⁻⁶ /K |

| Volume Resistivity | > 10¹² Ω·cm |

| Dielectric Strength | > 15 kV/mm |

| Magnetic Susceptibility | Non-magnetic |

| Corrosion Resistance | Excellent in acids, bases, salts |

| Water Absorption | 0% |

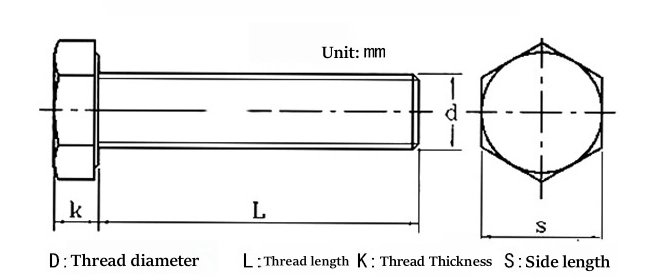

Specifications of Zirconia Ceramic Screws & Bolts

| M2 Zirconia Ceramic Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHG-LS001 | Flat Head with Single Slot Half-thread | 22 | 1.4 | 3.8 |

| AT-YHG-LS002 | Internal Hexagon | 14 | 1.9 | 3.8 |

| AT-YHG-LS003 | Flat Head with Single Slot | 10 | 1.4 | 3.8 |

| AT-YHG-LS004 | Cross-head Self-tapping Thread | 8 | 1.6 | 3.5 |

| AT-YHG-LS005 | Round Head with Cross-slot | 8 | 1.5 | 3.5 |

| AT-YHG-LS006 | External hHexagon | 6 | 1.6 | 3.9 |

| AT-YHG-LS007 | Countersunk Head with Cross-slot | 6 | / | 4.2 |

| M3 Zirconia Ceramic Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHG-LS008 | External hHexagon | 10 | 3 | 5.5 |

| AT-YHG-LS009 | Internal Hexagon | 330 | 3 | 5.4 |

| AT-YHG-LS010 | Internal Hexagon | 20/25 | 3 | 5.4 |

| AT-YHG-LS011 | Internal Hexagon | 15 | 3 | 5.4 |

| AT-YHG-LS012 | Internal Hexagon | 10 | 3 | 5.4 |

| AT-YHG-LS013 | Internal Hexagon | 8 | 3 | 5.4 |

| AT-YHG-LS014 | Countersunk Head with Cross-slot | 15 | / | 5.2 |

| AT-YHG-LS015 | Countersunk Head with Cross-slot | 6 | / | 5.6 |

| AT-YHG-LS016 | Round Head with Cross-slot | 6.5 | 2.7 | 5.5 |

| M4 Zirconia Ceramic Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHG-LS017 | External hHexagon | 20 | 3.2 | 6.8 |

| AT-YHG-LS018 | External hHexagon | 15 | 3.3 | 6.8 |

| AT-YHG-LS019 | External hHexagon | 10 | 3.2 | 6.8 |

| AT-YHG-LS020 | Internal Hexagon | 30/40/50 | / | / |

| AT-YHG-LS021 | Internal Hexagon | 25 | 4 | 7 |

| AT-YHG-LS022 | Internal Hexagon | 20 | 4.1 | 6.9 |

| AT-YHG-LS023 | Internal Hexagon | 15 | 4.1 | 6.8 |

| AT-YHG-LS024 | Internal Hexagon | 10 | 3.2 | 6.8 |

| AT-YHG-LS025 | Countersunk Head with Internal Hexagon | 25 | / | 8.5 |

| AT-YHG-LS026 | Countersunk Head with Cross-slot | 12 | / | 8.4 |

| AT-YHG-LS027 | Round Head with Cross-slot | 8 | 2.9 | 7 |

| AT-YHG-LS028 | Round Head with Cross-slot | 5 | 2.1 | 9.3 |

| AT-YHG-LS029 | Round Head with Single Slot and Hole | 3 | 4.5 | 8.9 |

| M5 Zirconia Ceramic Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHG-LS029 | External hHexagon | 25 | 3.5 | 8 |

| AT-YHG-LS030 | External hHexagon | 20 | 3.6 | 8 |

| AT-YHG-LS031 | External hHexagon | 15 | 3.6 | 8 |

| AT-YHG-LS032 | External hHexagon | 10/12 | 3.6 | 7.6 |

| AT-YHG-LS033 | External hHexagon | 5 | 3.6 | 8 |

| AT-YHG-LS034 | Internal Hexagon | 35 | 4.7 | 7.8 |

| AT-YHG-LS035 | Internal Hexagon | 25 | 4.9 | 8.1 |

| AT-YHG-LS036 | Internal Hexagon | 20 | 4.9 | 8.1 |

| AT-YHG-LS037 | Internal Hexagon | 15 | 4.9 | 8.1 |

| AT-YHG-LS038 | Internal Hexagon | 10/12 | 4.9 | 8.1 |

| AT-YHG-LS039 | Internal Hexagon | 5 | 4.9 | 8.1 |

| AT-YHG-LS040 | Round Head with Cross-slot | 25 | / | 8.6 |

| AT-YHG-LS041 | Round Head with Cross-slot | 20 | / | 8.5 |

| AT-YHG-LS042 | Round Head with Cross-slot | 12 | / | 8.5 |

| AT-YHG-LS043 | Round Head with Internal Hexagon | 25 | 2.6 | 9.3 |

| AT-YHG-LS044 | Round Head with Internal Hexagon | 20 | 2.8 | 9.4 |

| AT-YHG-LS045 | Round Head with Internal Hexagon | 12 | 2.8 | 8.6 |

| AT-YHG-LS046 | Round Head with Single Slot | 10 | 3.4 | 7.9 |

| AT-YHG-LS047 | Countersunk Head with Cross-slot | 10 | / | 8.9 |

| AT-YHG-LS048 | Round Head with Single Slot and Hole | 6/15 | 3 | 10 |

| AT-YHG-LS049 | Blind Head with Internal Hexagon | 10 | / | / |

| AT-YHG-LS050 | Blind Head with Internal Hexagon | 6 | / | / |

| M6 Zirconia Ceramic Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHG-LS051 | External hHexagon | 55 | 5.2 | 9.7 |

| AT-YHG-LS052 | External hHexagon | 40 | 4.3 | 9.6 |

| AT-YHG-LS053 | Internal Hexagon | 40 | 5.8 | 9.8 |

| AT-YHG-LS054 | Internal Hexagon | 25 | 5.9 | 10 |

| AT-YHG-LS055 | Internal Hexagon | 16 | 5.9 | 10 |

| AT-YHG-LS056 | Countersunk Head with Cross-slot | 40 | / | 12 |

| AT-YHG-LS057 | External Hexagon with Single Slot | 25 | 3.9 | 9.8 |

| AT-YHG-LS058 | Round Head with Single Slot and Hole | 20 | 4.8 | 10 |

| AT-YHG-LS059 | Countersunk Head with Internal Hexagon | 15 | / | 9.8 |

| M8 Zirconia Ceramic Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHG-LS060 | External hHexagon | 70 | 5.6 | 14 |

| AT-YHG-LS061 | External hHexagon | 50 | 4.5 | 11.7 |

| AT-YHG-LS062 | External hHexagon | 35 | 5.3 | 12.9 |

| AT-YHG-LS063 | External hHexagon | 25 | 5.3 | 12.9 |

| AT-YHG-LS064 | Internal Hexagon | 50 | 7.6 | 12.3 |

| AT-YHG-LS065 | Internal Hexagon | 35 | 7.9 | 12.3 |

| AT-YHG-LS066 | Flat Head with Internal Hexagon | 30 | / | 13.8 |

| AT-YHG-LS067 | Countersunk Head with Cross-slot | 20 | / | 14.2 |

| M10 Zirconia Ceramic Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHG-LS068 | External hHexagon | 70 | 7 | 16.8 |

| AT-YHG-LS069 | External hHexagon | 35 | 6.6 | 16.6 |

| AT-YHG-LS070 | Internal Hexagon | 50 | 9 | 14.8 |

| AT-YHG-LS071 | Internal Hexagon | 35 | 9.1 | 14.8 |

| M12 Zirconia Ceramic Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHG-LS072 | External hHexagon | 75 | 8.1 | 18.8 |

| AT-YHG-LS073 | External hHexagon | 50 | 10.2 | 18.8 |

| AT-YHG-LS074 | External hHexagon | 35 | 10.1 | 18.4 |

| AT-YHG-LS075 | External hHexagon | 25 | 10.3 | 18.4 |

| AT-YHG-LS076 | External hHexagon | 15 | 10 | 21.2 |

| AT-YHG-LS077 | Internal Hexagon | 50 | 10.5 | 17.2 |

| AT-YHG-LS078 | Internal Hexagon | 35/25 | 10.4 | 17.1 |

| AT-YHG-LS079 | Internal Hexagon | 15 | 12.2 | 18.1 |

| AT-YHG-LS080 | Internal Hexagon | 14 | 12.2 | 18 |

Packaging of Zirconia Ceramic Screws & Bolts

Zirconia Ceramic Screws & Bolts are first sorted into protective foam trays and sealed in compact inner cartons to prevent chipping. These units are then grouped in moisture-resistant outer boxes with plastic liners for added barrier protection. Finally, the cartons are stacked on reinforced pallets and wrapped for stability during long-distance export transit.