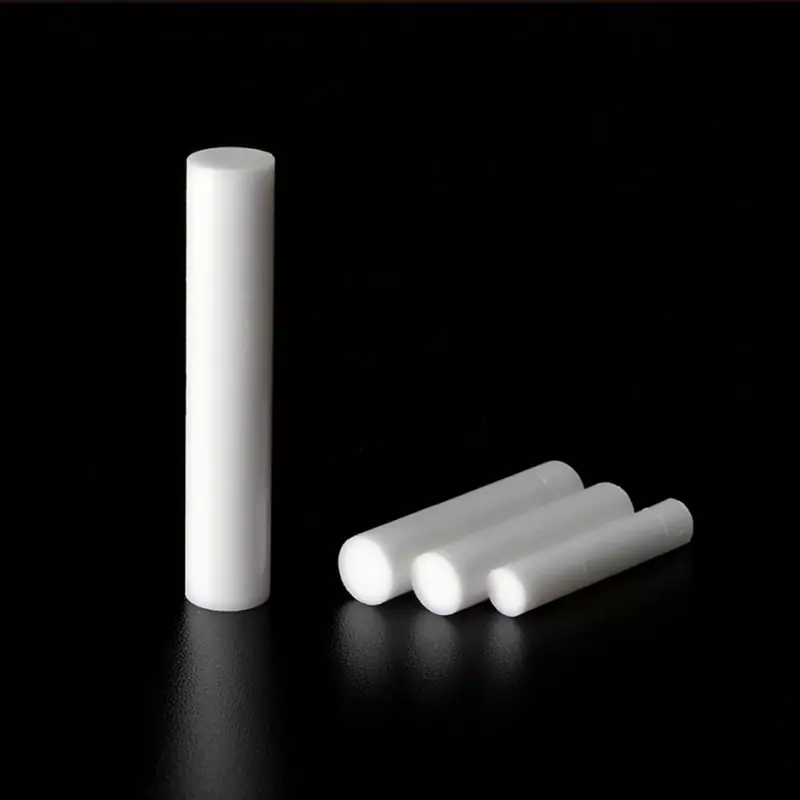

ADCERAX® Zirconia Ceramic Shaft Rod is engineered for demanding industrial applications where durability and reliability are critical. Its yttria-stabilised zirconia composition delivers high hardness, strong wear resistance, and excellent corrosion stability across harsh environments. This material remains stable under high temperatures and aggressive chemicals, ensuring consistent performance in pumps, motors, and chemical processing equipment. By choosing Zirconia Ceramic Shaft Rod, manufacturers reduce downtime, extend equipment service life, and secure dependable operation in challenging conditions.

Features of Zirconia Ceramic Shaft Rod

- The shaft rod reaches ≥1200 HV Vickers hardness, preventing surface wear in abrasive fluid handling. It maintains structural strength under long-term load conditions.

- With density ≥6.0 g/cm³, the rod delivers a compact and uniform structure. This density improves resistance to cracks during continuous rotation.

- Comparative tests show zirconia rods last 2–3 times longer than steel shafts. This reduces replacement frequency and overall lifecycle costs.

- The Zirconia Ceramic Shaft Rod remains stable at working temperatures up to 1400°C. This ensures continuous use in heat-intensive processes.

- Its thermal shock resistance allows safe operation during sudden heating and cooling. This protects pumps and motors from unplanned downtime.

- Industry studies show zirconia ceramics withstand >200 rapid thermal cycles without failure. This reliability exceeds typical metal shaft performance.

Properties for Zirconia Ceramic Shaft Rod

The Zirconia Ceramic Shaft Rod is engineered with advanced Y-TZP zirconia material properties. This section provides a clear overview of its technical parameters, including physical, mechanical, and chemical performance, along with specifications that support engineering evaluation and dimension planning.

| Property |

Specification |

| Density |

≥ 6.0 g/cm³ |

| Flexural Strength |

900–1200 MPa |

| Compressive Strength |

≥ 2000 MPa |

|

|

7–10 MPa·m¹ᐟ² |

|

|

|

|

|

Up to 1400°C |

|

|

|

|

|

|

|

|

Excellent vs acids, alkalis, salts

|

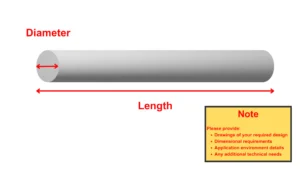

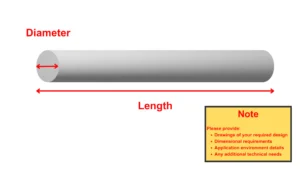

Custom Dimensions for Zirconia Ceramic Shaft Rod

Custom Dimensions for Zirconia Ceramic Shaft Rod

|

Model |

Diameter(mm) |

Length(mm) |

|

AT-YHG-ZZ001 |

2 |

100 |

|

AT-YHG-ZZ002 |

4 |

100 |

|

AT-YHG-ZZ003 |

6 |

100 |

|

AT-YHG-ZZ004 |

10 |

100 |

|

AT-YHG-ZZ005 |

12 |

100 |

|

AT-YHG-ZZ006 |

17 |

100-500 |

|

AT-YHG-ZZ007 |

20 |

100-500 |

|

AT-YHG-ZZ008 |

23 |

100-500 |

|

AT-YHG-ZZ009 |

30 |

150-500 |

|

AT-YHG-ZZ010 |

40 |

200-500 |

|

AT-YHG-ZZ011 |

50 |

200-500 |

|

AT-YHG-ZZ012 |

60 |

200-1000 |

|

AT-YHG-ZZ013 |

80 |

300-1000 |

|

AT-YHG-ZZ014 |

100 |

300-1000 |

Packaging for Zirconia Ceramic Shaft Rod

The Zirconia Ceramic Shaft Rod is securely packed using foam-protected cartons and reinforced wooden cases. Each Zirconia Ceramic Shaft Rod is individually cushioned to prevent vibration or impact damage during transport. Strong palletized crates ensure the Zirconia Ceramic Shaft Rod arrives safely to global customers.

Addressing Industry Challenges with ADCERAX® Zirconia Ceramic Shaft Rod

The Zirconia Ceramic Shaft Rod is designed to overcome specific failures that occur in critical industrial applications. Its material properties provide solutions where metals or polymers cannot sustain performance, reducing downtime and extending operational lifetimes.

-

Precision Dosing Pumps in Chemical Plants

✅Key Advantages

1. Acid/Base Endurance at Process Strengths — Verified stability in 35% HCl at 25 °C (good), 20% H₂SO₄ at 25 °C (excellent), and 50% NaOH at boiling (excellent) supports continuous dosing without shaft degradation.

2. High Wear Barrier (≥1200 HV) — Vickers hardness ≥1200 HV lowers abrasive wear from particulates in dosing streams, maintaining metering accuracy over long service.

3. Low Contamination Risk — Dense Y-TZP (≥6.0 g/cm³) microstructure minimizes leachables, protecting purity in acid/alkali dosing lines for sustained process control.

✅ ️Problem Solved

A chemical plant operating acid and caustic dosing skids saw metal shafts corrode within weeks, causing leaks and batch contamination. After switching to ADCERAX® Zirconia Ceramic Shaft Rod, shafts ran continuously in 35% HCl at 25 °C and 50% NaOH at boiling, conditions rated good/excellent in corrosion testing. Unplanned stoppages dropped after the changeover, and leak incidents were eliminated during the review period. Dosing accuracy stabilized, allowing maintenance to move from reactive replacement to scheduled inspection aligned with production cycles.

-

High-Speed Spindles in Precision Machine Tools

✅Key Advantages

1. High Flexural Strength (900–1200 MPa) — Resists bending under high rpm loads, preserving spindle geometry during continuous runs.

2. Low Thermal Growth (~10 × 10⁻⁶/K) — Limits heat-induced shaft expansion, reducing vibration drift at elevated operating temperatures.

3. Low-Friction Finish (Ra ≤0.4 µm) — Smooth surface lowers frictional heating, sustaining stable rotation at high speeds.

✅ ️Problem Solved

A precision machining cell experienced thermal growth and vibration with metal shafts during extended high-rpm cycles, degrading surface finish and throughput. Replacing the spindle shaft with ADCERAX® Zirconia Ceramic Shaft Rod maintained dimensional stability thanks to ~10 × 10⁻⁶/K expansion and Ra ≤0.4 µm finish. Cut quality held steady across long runs, and vibration-related stoppages were removed from the maintenance log. The cell maintained consistent accuracy over prolonged operating windows without shaft-related variability.

-

Circulating Shafts in Medical Sterilization Equipment

✅Key Advantages

1. Autoclave Cycle Endurance (>200 cycles) — Withstands repeated 121–134 °C steam cycles without structural loss, supporting continuous sterilization duty.

2. Cleaner Compatibility — Rated excellent in HNO₃ 83% at 25 °C and NaOH 50% at boiling, enabling resistance to common decon chemistries.

3. Electrical Insulation (>10¹² Ω·cm) — High resistivity limits stray-current pathways that can accelerate corrosion in wet, conductive environments.

✅ ️Problem Solved

A hospital CSSD reported frequent shaft pitting and thermal cracking in steam sterilizers, disrupting schedules and raising service costs. After adopting ADCERAX® Zirconia Ceramic Shaft Rod, units endured >200 autoclave cycles at 121–134 °C with no shaft degradation and remained compatible with aggressive cleaners (HNO₃ 83%, NaOH 50% boiling). Sterilization uptime improved, and shaft replacement was removed from the quarterly maintenance plan. Compliance and scheduling reliability were maintained across peak operating periods.

User Guide for Zirconia Ceramic Shaft Rod

The Zirconia Ceramic Shaft Rod requires correct handling and maintenance to achieve its full performance potential. This guide provides clear recommendations to help customers use the product safely, reduce operational risks, and extend service life across different industries.

-

Operating Conditions

1. The Zirconia Ceramic Shaft Rod is stable up to 1400°C but should not be subjected to sudden thermal shocks. Gradual heating and cooling cycles protect material strength.

2. Avoid exposing the shaft to hydrofluoric acid, as it significantly reduces ceramic integrity. For other acids and alkalis, refer to corrosion resistance test data.

3. Ensure proper lubrication where required by the system design. Even with self-lubricating properties, controlled environments improve operational efficiency.

-

Cleaning and Maintenance

1. Clean the shaft with neutral cleaning agents or deionized water to avoid chemical attack. Regular inspection prevents buildup of deposits on the surface.

2. After extended operation, inspect for surface wear or minor fractures. Early detection helps prevent catastrophic failure in pumps or motors.

3. Document maintenance cycles and performance logs. A structured record allows comparison of shaft longevity against metal alternatives.

-

Storage and Shelf Life

1. Store the Zirconia Ceramic Shaft Rod in dry and vibration-free conditions. Excess humidity may introduce surface micro-defects over time.

2. Keep rods separated by soft padding to avoid accidental impact damage. Direct ceramic-to-ceramic contact should always be prevented.

3. Maintain a controlled storage temperature between 15°C and 30°C. Stable environments ensure that shafts remain ready for immediate industrial deployment.

-

Handling and Installation

1. Always transport the shafts in cushioned containers to prevent chipping during transit. Ensure lifting tools support the rod evenly to avoid stress concentration.

2. During installation, align the shaft precisely with mating components to prevent side loads. Misalignment increases vibration and reduces operating stability.

3. Use torque-limiting tools when fastening connected parts. Excessive force can cause microcracks that shorten the shaft’s lifetime.