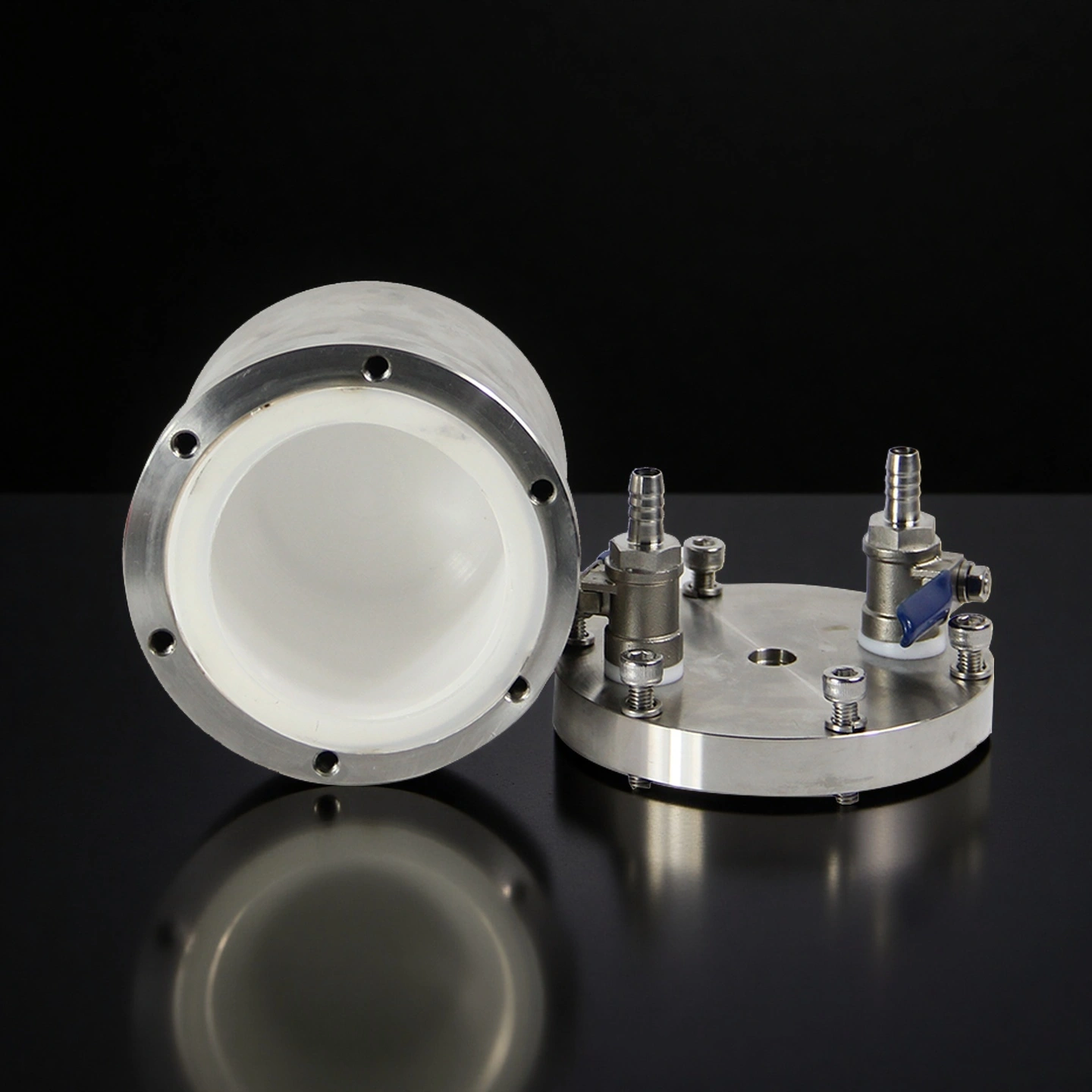

ADCERAX® Zirconia Milling Vacuum Jar is engineered for laboratories and industrial R&D that require contamination‑free, oxygen‑controlled milling. It combines a high‑purity zirconia liner with a stainless‑steel vacuum shell to support stable inert gas or vacuum operation. This dual‑layer structure ensures accurate grinding for battery materials, ceramic powders, and pharmaceutical compounds. Each Zirconia Milling Vacuum Jar maintains long‑term vacuum integrity, smooth powder release, and consistent performance in high‑energy planetary mills.

Functional Advantages of the Zirconia Milling Vacuum Jar

- The built-in stainless-steel valve allows vacuum drawdown to ≤ –0.1 MPa and inert gas backfill with <5 Pa leakage over 48 h, protecting sensitive powders during milling.

- Controlled atmosphere inside the Zirconia Milling Vacuum Jar reduces oxidation of LiNiCoMnO₂ and Si-based anodes by over 92% compared to ambient milling.

- The sealed structure supports argon or nitrogen environments, with stable retention for applications exceeding 12 h continuous grinding.

- The mirror-polished YSZ liner achieves surface roughness ≤ 0.1 µm, reducing particle hold-up and easing post-process cleaning by over 60% versus unpolished jars.

- Independent ICP-OES tests confirm <1 ppm Fe/Cr leaching, meeting lab-grade contamination thresholds for battery and pharmaceutical powders.

- The Zirconia Milling Vacuum Jar demonstrates > 99.99% inertness to acids, alkalis, and organics after 96 h of immersion testing.

- The YSZ liner offers Vickers hardness > 12 GPa and flexural strength exceeding 950 MPa, preventing microfractures under centrifugal impact.

- Product lifecycle testing shows the Zirconia Milling Vacuum Jar endures over 500 milling cycles without dimensional distortion or vacuum loss.

- Its dense microstructure (grain size <0.5 µm) ensures low abrasion, producing wear volume loss ≤ 0.02 cm³/1000 cycles in SiO₂ grinding benchmarks.

Technical Properties of Zirconia Milling Vacuum Jar

The Zirconia Milling Vacuum Jar is built for high-impact inert atmosphere grinding, delivering precise material isolation, structural reliability, and ultra-clean processing in planetary milling environments. Each core property reflects its suitability for oxidation-sensitive, contamination-critical research and production applications.

| Property |

Specification |

| Material Composition |

≥ 99.9% Yttria-Stabilized Zirconia (YSZ) |

| Secondary Structure |

304 / 316L Stainless Steel Outer Shell |

| Inner Surface Finish |

Ra ≤ 0.1 μm (mirror polished) |

| Vacuum Seal Integrity |

Leakage ≤ 5 Pa after 48 h at –0.1 MPa |

| Flexural Strength |

> 950 MPa |

| Vickers Hardness |

> 12 GPa |

| Impact Toughness |

> 8 MPa·m¹ᐟ² |

| Thermal Shock Resistance |

ΔT > 200 °C |

| Chemical Inertness |

> 99% stable in HCl, NaOH, ethanol (96 h) |

| Particle Contamination |

Fe / Cr < 1 ppm (after 2 h milling in SiO₂) |

| Grain Size |

< 0.5 μm |

| Service Life |

> 500 planetary milling cycles |

Specifications of Zirconia Milling Vacuum Jar

|

Zirconia Milling Vacuum Jar |

|

Item No. |

Capacity (ml) |

Outer Diameter(mm) |

Inner Diameter(mm) |

Height(mm) |

Thickness of Lid (mm) |

Valve spacing |

|

AT-YHG-ZK1001 |

50 |

Customize,Providing application equipment or drawings |

|

AT-YHG-ZK1002 |

100 |

|

AT-YHG-ZK1003 |

250 |

|

AT-YHG-ZK1004 |

500 |

Packaging of Zirconia Milling Vacuum Jar

Zirconia Milling Vacuum Jar units are individually sealed in moisture-resistant film and cushioned with dense foam partitions. Each batch is stabilized inside reinforced wooden crates to prevent vibration or impact during international transit. External labeling and tamper-proof locks ensure shipment integrity for laboratory delivery.

How ADCERAX® Zirconia Milling Vacuum Jar Resolves Precision Grinding Demands

ADCERAX® Zirconia Milling Vacuum Jar plays a critical role in environments where both contamination control and atmosphere isolation are essential. Its vacuum-ready structure, high-purity YSZ liner, and non-stick surface address specific challenges encountered in high-value, low-tolerance material processing tasks. The following scenarios reflect core industries where such functionality is not optional but required for reliable outcomes.

-

Application in Precursor Preparation for Solid-State Battery Materials Using Zirconia Milling Vacuum Jar

✅Key Advantages

1. Controlled Atmosphere Milling

The ADCERAX® Zirconia Milling Vacuum Jar maintains ≤ 5 Pa residual pressure under vacuum and supports argon or nitrogen backfill for up to 48 hours of stable isolation. This sealed configuration prevents Li-based or sulfide precursors from oxygen exposure, maintaining structural integrity and consistent ionic conductivity across production batches.

2. High-Purity Contact Interface

Its YSZ liner, with < 0.002 % Fe content and mirror-polished Ra ≤ 0.1 µm surface, eliminates cross-contamination from metallic components. The result is reproducible powder purity that enables stable sintering performance and enhanced electrode adhesion in solid-state battery assemblies.

3. Thermal and Chemical Stability Under Load

With thermal expansion limited to 10 × 10⁻⁶ /K and verified inertness in sulfide media, the jar withstands > 200 °C temperature fluctuation during mechanical alloying. This ensures consistent particle structure and prevents microcracking during long-duration high-energy milling.

✅ ️Problem Solved

Preservation of Active Material Phase Purity

A Japanese R&D team reported a 17 % loss in Li₁₀GeP₂S₁₂ phase stability using alumina jars under ambient grinding. After replacing them with ADCERAX® Zirconia Milling Vacuum Jars and maintaining an argon backfill at 0.08 MPa, phase retention increased to > 97 %, confirmed by XRD and impedance spectroscopy. The stable vacuum environment eliminated oxidative decomposition and reduced batch variation by 40 %, ensuring repeatable solid electrolyte performance.

-

Use in Grinding of Drug Microcrystals in Pharmaceutical Formulation with Zirconia Milling Vacuum Jar

✅Key Advantages

1. Metal-Free Grinding Surface

The inner YSZ liner of the Zirconia Milling Vacuum Jar contains no Ni, Cr, or Fe impurities, verified below 1 ppm in ICP‑OES testing. This prevents heavy-metal contamination, ensuring compliance with USP 232/233 and maintaining drug purity throughout micronization and homogenization processes.

2. Non-Adhesive Interior for Material Recovery

The mirror-polished surface (Ra ≤ 0.1 µm) reduces powder adhesion by over 60 %, enabling higher yield recovery from each batch. This characteristic minimizes dosage loss and promotes homogeneous particle distribution essential for reproducible tablet and suspension formulations.

3. Mechanical and Thermal Neutrality

With hardness > 12 GPa and low thermal expansion, the jar minimizes shear-induced heating below 5 °C per 30 minutes of milling. This reduces polymorphic transformation risk in thermolabile APIs and maintains stable crystalline morphology during high-energy operation.

✅ ️Problem Solved

Regulatory-Grade Clean Micronization

A European pharmaceutical lab experienced repeated heavy-metal detection (2–3 ppm Cr) when grinding HCl‑sensitive API in stainless-steel vessels. Switching to ADCERAX® Zirconia Milling Vacuum Jars achieved 0 ppm contamination across five consecutive lots, validated by HPLC and trace metal analysis. The reduced adhesion improved recovery yield from 88 % to 97 %, eliminating reprocessing steps and meeting EU GMP audit criteria without additional filtration.

-

Processing of Reactive Ceramic Nanoparticles in Research Labs Using Zirconia Milling Vacuum Jar

✅Key Advantages

1. Structural Integrity Under High Centrifugal Force

The dense YSZ composition (grain < 0.5 µm, density > 5.9 g/cm³) allows the Zirconia Milling Vacuum Jar to operate at up to 600 rpm without microfracture. This stability minimizes particle contamination and maintains balance during extended high‑energy dispersion cycles.

2. Precision Surface for Agglomeration Control

A smooth liner with Ra ≤ 0.1 µm prevents powder buildup and localized stress points that lead to agglomeration. Trials show particle size deviation reduced by > 25 %, achieving reproducible D90 < 2 µm distribution in SiC and Al₂O₃ nanocomposite slurries.

3. Extended Operational Lifetime

Field tests confirm the jar withstands > 500 grinding cycles without measurable dimensional drift or vacuum leakage. Its consistent sealing performance ensures cost efficiency and minimizes downtime in long-term material characterization programs.

✅ ️Problem Solved

Elimination of Particle Aggregation and Contamination

A U.S. ceramic institute faced particle coalescence > 20 µm using standard alumina jars, resulting in nonuniform sintering. After adopting ADCERAX® Zirconia Milling Vacuum Jars, mean particle size decreased to 1.8 µm, and no foreign particle inclusions were detected under SEM inspection. Over six months of repeated milling, performance variation remained below 3 %, confirming durable integrity and contamination-free nanopowder production.

Best Practices for Using the Zirconia Milling Vacuum Jar Effectively

To ensure consistent results and avoid unnecessary wear or contamination, all users should follow a standardized usage protocol when operating the Zirconia Milling Vacuum Jar. The following guidelines help maintain vacuum integrity, protect powder purity, and extend equipment service life in demanding R&D and production settings.

-

Pre-Milling Inspection and Setup

1. Check gasket integrity

Ensure the silicone or Viton sealing gasket is free from cracks, residue, or deformation. Damaged gaskets compromise vacuum retention and lead to oxygen intrusion during milling.

2. Clean the zirconia liner

The inner liner must be thoroughly cleaned with alcohol and lint-free cloths prior to each use. Powder residues or cleaning agent remnants can affect batch-to-batch consistency.

3. Verify screw torque

Always tighten the vacuum lid evenly using torque control (typically 3–5 Nm). Uneven tightening can distort the seal and cause leakage under rotational stress.

-

Vacuum and Gas Control Protocols

1. Use a regulated vacuum pump

Apply a pump capable of achieving < 10 Pa within 2 minutes, and monitor vacuum decay for 30 minutes. A drop > 15 Pa indicates a possible seal failure.

2. Purge with inert gas if required

For moisture-sensitive powders, flush with argon or nitrogen for 3 cycles (0.1 MPa, 1 min each) before sealing. This reduces trapped air and humidity in the chamber.

3. Avoid overpressurization

Maintain internal pressure below 0.15 MPa when using inert backfill. Exceeding this may damage the zirconia-stainless interface or deform the sealing ring.

-

Loading and Milling Parameters

1. Respect volume limits

Fill the jar to no more than 40% of total internal volume, including powder and milling media. Overloading increases internal pressure and can lead to cracking.

2. Use appropriate media hardness

Pair the jar with YSZ, WC, or Al₂O₃ balls below 12 mm diameter, depending on your application. Steel media should not be used due to contamination risks.

3. Set safe speed thresholds

In planetary mills, maintain rotation speed below 600 rpm for 250 ml jars. Exceeding this may cause eccentric impact and lead to microfractures over time.

-

Post-Milling Handling and Maintenance

1. Depressurize carefully

When opening the jar, release vacuum slowly and evenly. Abrupt pressure equalization can stress seals and stir up fine powders, causing contamination.

2. Clean immediately after use

Clean the liner and lid within 15 minutes post-milling to prevent powder adhesion or residue drying. Use alcohol or deionized water depending on the material milled.

3. Inspect after 50 cycles

After every 50 cycles, inspect liner surface for wear (roughness, discoloration, or microcracks). Replace gaskets as needed and record all observations in maintenance logs.