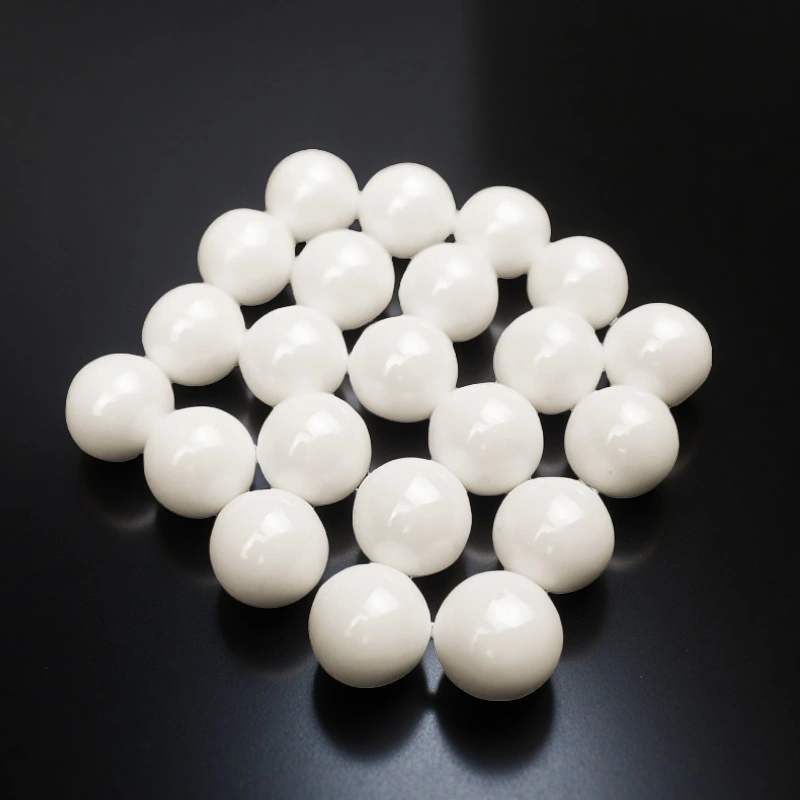

Zirconia toughened alumina balls are ceramic spheres made from an alumina (Al₂O₃) matrix that is reinforced with fine zirconia (ZrO₂) particles. The zirconia phase undergoes transformation toughening under stress, which significantly improves impact resistance and crack-growth suppression compared with alumina-only balls—while keeping high hardness, chemical inertness, and cleanliness for grinding, milling, bearing, and valve applications.

Zirconia-toughened Alumina Balls Benefits

- Enhanced Toughness — Up to 3× higher fracture strength compared to alumina-only balls.

- Low Contamination — Minimal metal or silica leaching, ideal for high-purity grinding.

- Stable Performance — Maintains density and integrity in both wet and dry milling.

- Wide Compatibility — Suitable for planetary, attrition, and horizontal ball mills.

- Extended Service Life — Reduced ball loss and maintenance frequency under continuous duty.

ZTA Ceramic Balls Properties

|

Property |

Unit |

Alumina (99%) |

ZTA (Zirconia Toughened Alumina) |

Y-TZP Zirconia |

|

Fracture Toughness (KIC) |

MPa·m¹⁄² |

5 |

7 – 9 |

6 – 10 |

|

Hardness (HV10) |

GPa |

8.9 |

9 – 10 (≈ 90 HV) |

12 – 14 |

|

Flexural Strength |

MPa |

400 |

650 – 800 |

800 – 1200 |

|

Density |

g/cm³ |

3.9 |

4.0 – 4.3 |

6.0 |

|

Relative Wear Rate |

— |

1.0 |

0.45 – 0.55 |

0.2 |

|

Thermal Expansion Coefficient (RT – 800 °C) |

×10⁻⁶ /K |

8.0 |

8.5 – 9.0 |

10 – 11 |

|

Thermal Conductivity (RT) |

W/m·K |

25 |

22 – 24 |

2 – 3 |

|

Maximum Working Temperature |

°C |

1600 |

1450 – 1500 |

1000 – 1200 |

|

Dielectric Strength |

kV/mm |

12 |

11 – 13 |

9 – 11 |

|

Surface Roughness (Ground face) |

µm Ra |

0.4 – 1.2 |

0.3 – 0.8 |

0.2 – 0.6 |

|

Flatness (after grinding) |

mm/300 mm |

≤ 0.4 |

≤ 0.3 |

≤ 0.2 |

Zirconia Alumina Ceramic Ball Specifications

|

Item |

Diameter (mm) |

Purity (AI203%) |

Tolerance |

|

AT-YM-H001 |

0.5 |

93 |

±0.2 |

|

AT-YM-H002 |

1 |

93 |

±0.5 |

|

AT-YM-H003 |

2 |

93 |

|

AT-YM-H004 |

3 |

93 |

±1.0 |

|

AT-YM-H005 |

4 |

93 |

|

AT-YM-H006 |

5 |

93 |

|

AT-YM-H007 |

6 |

93 |

|

AT-YM-H008 |

7 |

93 |

|

AT-YM-H009 |

8 |

93 |

|

AT-YM-H010 |

9 |

93 |

|

AT-YM-H011 |

10 |

93 |

±1.5 |

|

AT-YM-H012 |

11 |

93 |

|

AT-YM-H013 |

12 |

93 |

|

AT-YM-H014 |

13 |

93 |

|

AT-YM-H015 |

14 |

93 |

Zirconia Alumina Ceramic Balls Packing

- Each seal ring is individually packed in dust-proof polyester bags, with foam protection layers.

Zirconia Toughened Alumina Balls Applications

Zirconia Toughened Alumina (ZTA) balls are engineered for high-performance industrial grinding, precision motion components, and chemical flow systems where both durability and purity are essential. Below are the three key industries where ZTA balls deliver measurable performance advantages.

-

Advanced Powder Grinding & Milling Industry

✅Key Advantages

1. Extended Service Life — ZTA media lasts 2–4× longer than standard alumina balls in high-energy mills.

2. High Efficiency Grinding — Optimized density (3.8–4.1 g/cm³) enhances impact force, improving particle uniformity and throughput.

3. Low Contamination — Wear loss < 0.01 % prevents metal or silica impurities in fine powders.

✅ Problem Solved

In a U.S. lithium battery cathode factory, switching from 95 % alumina to ZTA balls cut slurry contamination by 72 % and improved mill throughput by 28 %, extending media replacement cycles from 3 months to 8 months. This translated into significant cost and downtime savings.

-

Precision Mechanical & Bearing Components

✅Key Advantages

1. Tight Dimensional Control — Diameter tolerance ≤ ± 0.02 mm with roundness < 0.2 µm for friction-sensitive bearings.

2. High Load & Temperature Endurance — Operates continuously at 300–500 °C without deformation or corrosion.

3. Non-magnetic & Electrically Insulating — Suitable for cleanrooms and magnetic-sensitive systems.

✅ Problem Solved

A German robotics bearing manufacturer reported 20 % longer component life and reduced surface noise by 15 % after replacing steel bearings with ZTA precision balls, achieving smoother motion and lower maintenance frequency.

-

Chemical, Petrochemical & Valve Systems

✅Key Advantages

1. Chemical Stability — Resistant to acids, alkalis, and solvents in high-temperature or corrosive pipelines.

2. High Hardness & Sealing Integrity — 1300 HV surface hardness ensures durable, leak-free valve performance.

3. Thermal Shock Resistance — Reliable under frequent heating/cooling cycles (up to 1700 °C).

✅ Problem Solved

In a Japanese petrochemical valve plant, stainless-steel valve balls were replaced with ZTA ceramics, eliminating corrosion-related shutdowns and reducing annual maintenance downtime by over 35 hours per line, while maintaining flow accuracy over 18 months of continuous use.

Zirconia Toughened Alumina Balls Usage Instructions

Proper installation and maintenance of Zirconia Toughened Alumina (ZTA) balls ensure long-term stability, low wear rates, and contamination-free operation in industrial milling or precision applications. Follow these steps to maximize performance and extend service life.

-

Installation

1. Verify ball specifications: Check diameter, density, and batch consistency before loading. Even small size deviations can cause uneven impact distribution.

2. Optimal loading ratio: Fill 60–70 % of mill volume with ZTA balls for efficient energy transfer and minimal void spaces.

3. Layer distribution: For mixed-size configurations, use larger balls at the bottom and smaller ones on top to improve cascading efficiency.

4. Avoid metal-to-ceramic impact: Use polymer or ceramic scoops instead of metal tools to prevent surface microcracks.

5. Pre-wash before first use: Rinse balls with ethanol or deionized water to remove surface dust from packaging.

-

Usage

1. pH & chemical compatibility: Recommended pH 3–11, suitable for both aqueous and solvent-based milling. Avoid strong fluorides or molten alkalis that attack alumina.

2. Rotational speed tuning: Adjust mill speed according to ball density (~3.9–4.1 g/cm³) for balanced kinetic energy.

3. Temperature range: Stable mechanical properties up to 1700 °C; no structural change below 1500 °C.

4. Operational check: Inspect wear pattern and mass loss every 200–300 hours; replace balls showing > 0.5 % weight deviation.

5. Performance tip: Combine ZTA balls with ZTA liners for consistent wear balance and extended mill lifespan.

-

Storage

1. Environment: Store in a dry, vibration-free and temperature-stable area. Avoid rapid temperature fluctuation > ± 50 °C to prevent microstructural stress.

2. Packaging integrity: Keep products in sealed PE or vacuum bags to prevent moisture or dust adsorption.

3. Stacking guidance: Do not exceed 1 m stacking height to prevent deformation of lower layers in bulk packages.

4. Long-term storage: For > 12 months, inspect moisture level and reseal if humidity > 60 % RH.

-

Cleaning

1. Routine cleaning: Use ultrasonic bath or ethanol rinsing between milling cycles.

2. Drying: Air-dry or bake at ≤ 120 °C for 1–2 hours to remove residual liquid.

3. Avoid corrosion sources: Never use acidic, alkaline, or chlorine-based detergents, as they may erode micro-pores.

4. For precision-grade balls: Handle with nitrile gloves; avoid contact with metal trays that can leave microscopic scratches.

5. Reuse protocol: For high-purity applications, limit reuse cycles to 5–8 rounds before performance verification.

-

Cautions

1. Thermal exposure: Do not exceed 1700 °C; above this point zirconia toughening effect declines.

2. Thermal ramping: Avoid heating or cooling faster than 10 °C/min to reduce thermal shock cracking.

3. Mechanical stress: Do not drop containers or strike balls against hard surfaces; internal microcracks shorten lifespan.

4. Chemical disposal: Follow local ceramic waste regulations; ZTA materials are inert but should be processed separately from metals.

5. Operational mismatch: Do not mix ZTA balls with steel or glass media—different densities cause imbalance and reduce efficiency.