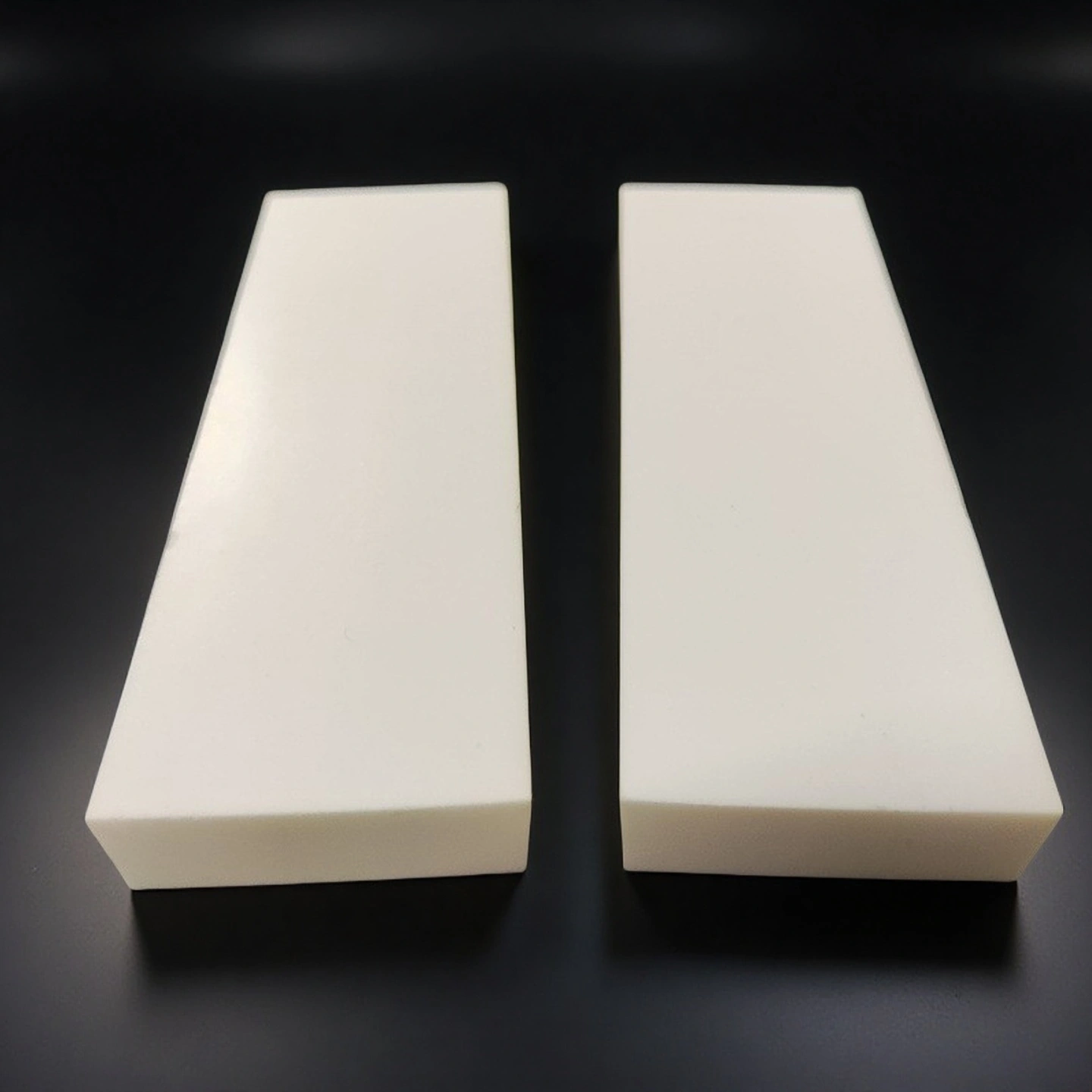

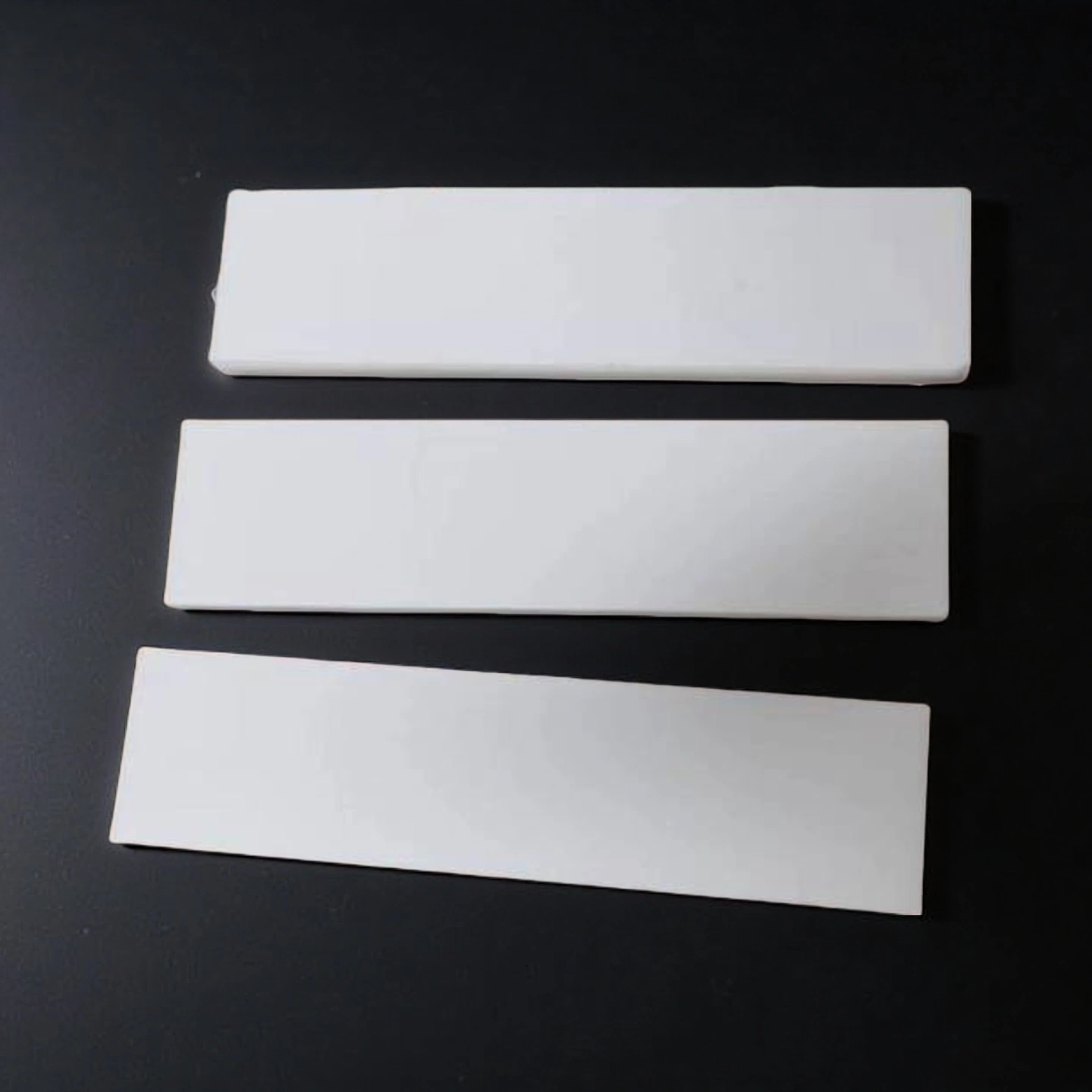

Zirconia Toughened Alumina (ZTA) lining Board is a modular wear lining made from zirconia-toughened alumina. It is engineered for bulk-handling equipment where sliding abrasion and particle impact occur together, such as chutes, hoppers, transfer points, elbows, and splitter boxes. By dispersing zirconia within an alumina matrix.

ZTA Ceramic Liner Board Advantages

- Mixed-wear stability in impact-abrasion zones; ZTA composition reduces edge chipping vs. alumina-only tiles.

- Module integrity with optimized grain size and zirconia dispersion to limit micro-crack growth at bolt holes.

- Low-seam surface via tight thickness tolerance to reduce turbulence and carryback at panel joints.

- Retention flexibility: bolt-on pattern or dovetail; compatible with composite backings for energy absorption.

- Curved section capability: radius-matched ZTA boards for elbows and cones reduce on-site grinding.

Zirconia Toughened Alumina Ceramic Lining Boards Properties

| Property | Unit | Alumina (99%) | ZTA (Zirconia Toughened Alumina) | Y-TZP Zirconia |

| Fracture Toughness (KIC) | MPa·m¹⁄² | 5 | 7 – 9 | 6 – 10 |

| Hardness (HV10) | GPa | 8.9 | 9 – 10 (≈ 90 HV) | 12 – 14 |

| Flexural Strength | MPa | 400 | 650 – 800 | 800 – 1200 |

| Density | g/cm³ | 3.9 | 4.0 – 4.3 | 6.0 |

| Relative Wear Rate | — | 1.0 | 0.45 – 0.55 | 0.2 |

| Thermal Expansion Coefficient (RT – 800 °C) | ×10⁻⁶ /K | 8.0 | 8.5 – 9.0 | 10 – 11 |

| Thermal Conductivity (RT) | W/m·K | 25 | 22 – 24 | 2 – 3 |

| Maximum Working Temperature | °C | 1600 | 1450 – 1500 | 1000 – 1200 |

| Dielectric Strength | kV/mm | 12 | 11 – 13 | 9 – 11 |

| Surface Roughness (Ground face) | µm Ra | 0.4 – 1.2 | 0.3 – 0.8 | 0.2 – 0.6 |

| Flatness (after grinding) | mm/300 mm | ≤ 0.4 | ≤ 0.3 | ≤ 0.2 |

ZTA Ceramic Lining Board Specifications

| ZTA Ceramic Lining Board | |||

| Item No. | Length (mm) | Width (mm) | Thickness (mm) |

| AT-ZR-CB001 | 50 | 25 | 5-12 |

| AT-ZR-CB002 | 50 | 50 | 5-20 |

| AT-ZR-CB003 | 100 | 100 | 6-30 |

| AT-ZR-CB004 | 120 | 80 | 8-30 |

| AT-ZR-CB005 | 150 | 100 | 6-50 |

| AT-ZR-CB006 | 100 | 25 | 5-15 |

| AT-ZR-CB007 | 100 | 50 | 6-30 |

| AT-ZR-CB008 | 100 | 75 | 12-50 |

| AT-ZR-CB009 | 150 | 50 | 6-50 |

| AT-ZR-CB010 | 70 | 70 | 10-25 |

| AT-ZR-CB011 | 75 | 50 | 6-15 |

| AT-ZR-CB012 | 120 | 100 | 6-25 |

| AT-ZR-CB013 | 120 | 50 | 6-25 |

| AT-ZR-CB014 | 100 | 80 | 6-25 |

| AT-ZR-CB015 | 150 | 75 | 6-50 |

| AT-ZR-CB016 | 27 | 27 | 5-18 |

| AT-ZR-CB017 | 37.5 | 37.5 | 5-18 |

| AT-ZR-CB018 | 39.2 | 39.2 | 6-18 |

| AT-ZR-CB019 | 50 | 30 | 5-15 |

ZTA Ceramic Lining Plate Packaging

- Panel Protection: foam-separated layers, edge guards, shrink-wrap per module set.