Custom Quartz Ceramic Manufactured for Industrial Performance

ADCERAX is a quartz ceramic manufacturer in China delivering standard and custom-engineered fused quartz ceramic tubes, plates, discs, crucibles and application-specific components for global OEM customers. Our factory supports both standard items and drawing-based fabrication to meet the needs of UV disinfection systems, high-temperature furnaces, infrared heating modules, analytical instruments and chemical process applications.

With engineered production and controlled fused quartz quality, we ensure stable tolerances, reliable thermal performance and flexible customization with safe global shipping.

🤝Send your drawing or specifications and our engineers will prepare a tailored quartz ceramic solution for your application.

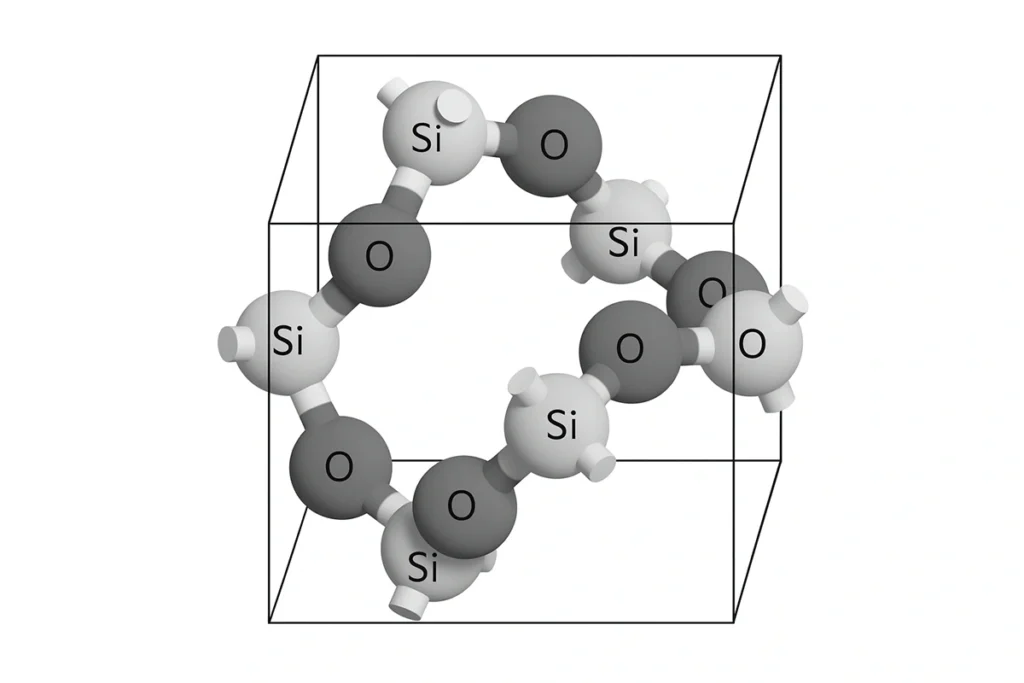

What Is Quartz Ceramic?

Ceramic Quartz Definition

Quartz ceramic is a family of inorganic, non-metallic materials based on high-purity silicon dioxide. In industrial components it is usually supplied as fused quartz or fused silica that has been formed, machined and sometimes sintered into precise shapes such as tubes, plates, crucibles and porous blocks. Because of its purity, low thermal expansion, excellent thermal shock resistance and optical transmission, quartz ceramic is widely used wherever metal or conventional glass cannot meet process requirements.

Is Quartz a Ceramic Material?

Quartz is not a traditional ceramic in its natural crystalline form, but once melted and processed into fused quartz or fused silica components, it is classified as a ceramic-type engineering material in industrial practice. This classification is based on how the material behaves, how it is formed and how it is used in equipment design—not on its geological origin.

Below is a clear comparison showing why fused quartz is grouped with technical ceramics rather than with ordinary glass materials:

Difference Between Quartz and Ceramic

Quartz and technical ceramics are both inorganic, non-metallic materials used in high-temperature and chemically demanding environments, but they serve different engineering purposes. The key difference lies in their optical behavior, thermal response and processing method, which directly affects how they perform in furnaces, UV systems, analytical instruments and electrical assemblies.

| Criteria | Fused Quartz / Fused Silica | Technical Ceramics (Alumina / Si₃N₄ / SiC etc.) |

|---|---|---|

| Material Nature | Amorphous SiO₂, transparent or opaque | Crystalline oxide / nitride / carbide ceramics |

| Thermal Shock Resistance | Excellent(low thermal expansion) | Good to very good(depending on composition) |

| Continuous Working Temperature | ~1000–1100°C | 800–1700°C(material dependent) |

| Transparency / Optical Use | UV/IR transparent(unique advantage) | Opaque(not suitable for optical paths) |

| Electrical Insulation | Very high | High to extremely high |

| Chemical Resistance | Excellent to acids, high purity | Excellent to acids/alkalis(varies by material) |

| Mechanical Strength | Moderate(brittle) | High(stronger structural materials) |

| Manufacturing Method | Melting → forming → machining | Powder sintering → machining |

| Typical Applications | UV sleeves, furnace tubes, IR covers, analytical tubes, windows | Insulators, substrates, wear parts, fixtures, supports |

| When It’s Preferred | Needs optical transmission, low expansion, high purity | Needs strength, wear resistance, electrical/mechanical load |

- When to Choose Quartz

Select quartz when the application requires UV/IR transmission, very low thermal expansion, high purity, or the part will be used in optical paths, high-temperature thermal cycling or corrosive environments.

- When to Choose Technical Ceramics

Choose ceramics when the part must withstand mechanical load, abrasion, structural stress, or when operating temperatures exceed the safe continuous range of fused quartz.

Quartz Ceramics Properties

Quartz ceramic is valued for its predictable thermal behavior, high-purity SiO₂ structure and stable insulating performance under continuous high-temperature load. A typical fused-quartz ceramic part offers low thermal expansion, strong thermal-shock tolerance, chemical inertness and consistent translucency, enabling reliable operation in UV systems, industrial furnaces, analytical equipment and other performance-critical assemblies.

✅ Chemical Composition

High-purity fused quartz formulated for stable high-temperature and UV-related applications.

| Item | Value |

|---|---|

| SiO₂ (wt%) | ≥ 99.8% |

| Al₂O₃ | ≤ 0.10% |

| Fe₂O₃ | ≤ 0.02% |

| TiO₂ | ≤ 0.01% |

| MgO | ≤ 0.02% |

| Na₂O | ≤ 0.01% |

| CaO | ≤ 0.007% |

| K₂O | ≤ 0.004% |

✅ Physical Properties

Derived from high-purity fused quartz to provide stable structural performance and consistent behavior under thermal and mechanical load.

| Item | Value |

|---|---|

| Bulk Density | ≥ 1.90–1.95 g/cm³ |

| Apparent Porosity | ≤ 15% |

| Cold Crushing Strength | ≥ 50 MPa |

| Flexural Strength (Room Temperature) | ≥ 25 MPa |

| Flexural Strength (High Temperature) | ≥ 28 MPa |

| Crystal Phase Content | ≤ 1% |

| Water Absorption | ≤ 0.5% |

| True Density | 2.20 g/cm³ |

✅ Thermal Properties

Engineered from high-purity fused quartz to deliver stable thermal expansion and strong resistance to thermal shock.

| Item | Value |

|---|---|

| Thermal Shock Resistance (1100°C → water quench) | ≥ 10 cycles |

| Thermal Conductivity @ 20°C | 0.64 W/m·K |

| Thermal Conductivity @ 500°C | 0.81 W/m·K |

| Thermal Conductivity @ 1100°C | 0.83 W/m·K |

| Thermal Expansion Coefficient (20–1100°C) | ≤ 0.9 × 10⁻⁶ /°C |

| Maximum Service Temperature | 1650°C |

✅Mechanical Properties

Developed from fused quartz with stable elastic behavior and predictable mechanical response suitable for low-strain, high-temperature applications.

| Item | Value |

|---|---|

| Shear Modulus (G) | ~31 GPa |

| Tensile Strength | ~50 MPa |

| Fracture Strain | 0.1–0.2% |

| Elastic Recovery | ≥ 98% after unloading |

| Microhardness (Knoop Hardness HK0.1) | ~520 HK |

| Brittleness Index (BI) | ~700–900 μm⁻¹/² |

Quartz Ceramic Products from ADCERAX

ADCERAX supplies fused-quartz ceramic components in multiple forms, including crucibles, nozzles, rollers, tubes, plates and custom-shaped parts for high-temperature and contamination-sensitive processes. Each product is made from high-purity quartz to deliver clean heating, stable thermal behavior and reliable performance, with both standard sizes and fully customized geometries available according to drawings and operating requirements.

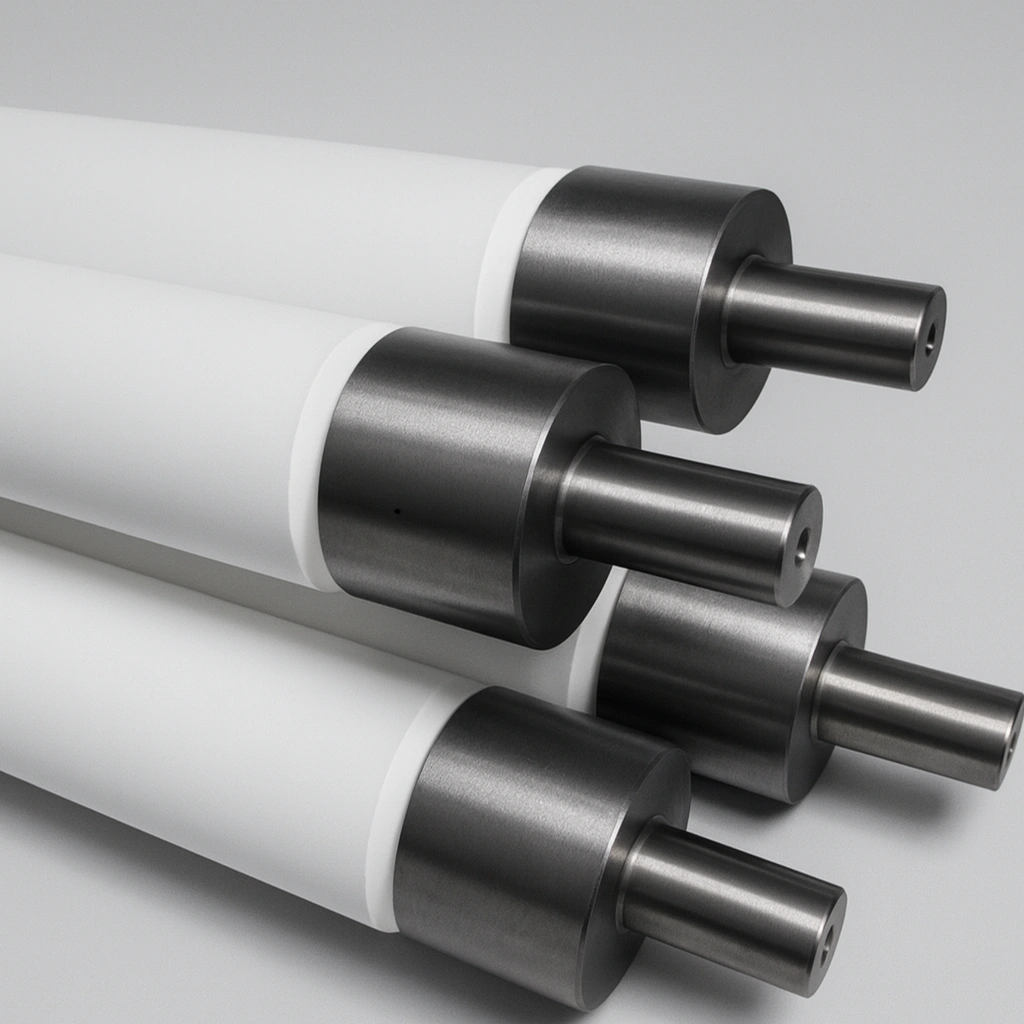

Fused quartz ceramic rollers enable high-temperature conveying and clean material handling in glass, metal and furnace systems, providing smooth rotation under continuous heat.

- Ensures smooth rotation with uniform fused-quartz geometry.

- Maintains stable dimensions for consistent thermal profiles.

- Provides clean, non-reactive handling in high-temperature processes.

Fused quartz ceramic crucibles are used for high-temperature melting, purification and thermal processing in glass, metal and laboratory workflows, offering clean heating and stable thermal cycling.

- Ensures clean melting and processing without introducing impurities.

- Maintains uniform wall thickness for consistent heating behavior.

- Delivers stable performance across repeated thermal-shock cycles and high-temperature ramps.

Fused quartz ceramic nozzles provide controlled molten flow and high-temperature dispensing in glass, metal and laboratory systems, ensuring clean transfer and stable performance.

- Provides stable flow paths with high-purity fused-quartz geometry.

- Suitable for custom inlet and outlet designs across different process lines.

- Maintains consistent dimensions for reliable thermal and flow behavior.

💡Get quartz ceramic parts that improve stability, cut downtime and fit your exact operating conditions.

ADCERAX manufactures fused-quartz ceramic components built for clean heating, predictable thermal performance and long service life. Share your drawing and receive engineered parts, fast sampling and a lead time you can count on.

Typical Applications of Quartz Ceramic

Quartz ceramics are used across glass melting lines, metal refining systems, semiconductor processing tools and analytical instruments where high-temperature stability, low contamination and precise dimensional behavior are required. Their fused-quartz structure enables clean thermal transfer, chemical durability and consistent performance in demanding industrial and laboratory environments.

Glass Manufacturing & High-Temperature Processing

🧩 Advantages:

- Low Thermal Deformation Under 700°C Line Loads

Quartz ceramic rollers retain <0.15 mm run-out after 24 h at 650°C, keeping float-glass sheet deviation within process specification. - High Melt Purity with <10 ppm Metallic Contamination

Fused-quartz crucibles introduce <10 ppm metallic impurities into specialty glass melts, improving clarity and reducing defect density. - Stable Flow Geometry at 1100–1250°C

Quartz ceramic nozzles maintain orifice dimensional change under ±0.05 mm after prolonged molten-glass exposure, ensuring consistent throughput.

🔹Case Study: A European speciality-glass line faced 1.0–1.4 mm sheet deviation caused by roller deformation during 650°C annealing. After switching to fused quartz ceramic rollers with <0.15 mm run-out, flatness defects fell by 48% and thermal-stress breakage dropped 32% in 3 months. Quartz crucibles also reduced melt contamination from 22 ppm to <8 ppm, improving clarity and cutting polishing time by 18%. The line achieved more stable throughput with fewer intervention stops.

Metal Refining & Metallurgical Processing

🧩Advantages:

- Minimal Metal–Surface Reaction at >1200°C

Quartz ceramic nozzles show <0.02 mm erosion after 10 h molten-metal exposure, maintaining stable casting throughput. - Ultra-Low Impurity Transfer (<5 ppm)

Quartz crucibles keep metallic contamination under 5 ppm during alloy melts, improving composition accuracy for small-batch metallurgy. - High-Dimensional Stability Under Repeated Heating

Orifice and tube geometry shift remains within ±0.05 mm after 50 thermal cycles between 200–1200°C, improving process predictability.

🔹Case Study: A U.S. precision casting foundry reported inconsistent metal flow and ±0.12 mm orifice erosion using alumina nozzles at 1250°C. After switching to fused quartz ceramic nozzles with erosion controlled to <0.02 mm, casting flow variation decreased by 41% and scrap rate dropped 27% over two production cycles. Quartz crucibles also reduced melt contamination from 14 ppm to <4 ppm, improving alloy consistency and reducing rework time by 22%. The foundry achieved more predictable pouring behavior and higher yield stability.

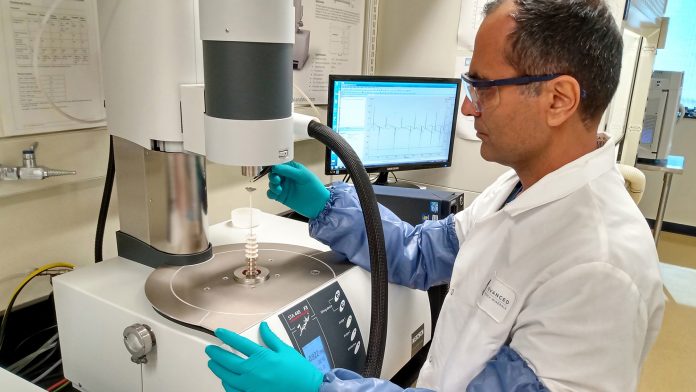

Laboratory & Analytical Instruments

🧩Advantages:

- Ultra-low background contamination for trace analysis

Quartz ceramic surfaces introduce <5–10 µg/L leachable impurities after 900–1000°C conditioning, reducing baseline drift in CHN/O and ICP workflows. - Stable geometry and low devitrification under repeated thermal cycling

Combustion tubes maintain dimensional change <0.2% after 100+ heating cycles between room temperature and 1000°C, improving analyzer calibration stability. - High UV transmission for optical detection accuracy

Quartz windows provide >85–92% transmittance at 200–260 nm, supporting sensitive UV/Vis and fluorescence measurements without spectral distortion.

🔹Case Study: A U.S. analytical-instrument OEM reported inconsistent CHN baselines due to aluminosilicate tubes releasing 25–40 µg/L impurities during high-temperature oxidation. After switching to fused quartz ceramic combustion tubes with <8 µg/L extractables and <0.2% thermal-cycle deformation, baseline variability decreased by 41% and recalibration frequency dropped from every 300 samples to every 520 samples. Quartz windows further improved UV signal stability, reducing optical noise by 22% in low-concentration assays.

Semiconductor & Optical Systems

🧩Advantages:

- Low particle generation for contamination-sensitive processes

Fused quartz ceramic components contribute <0.5 particles/cm² ≥0.3 µm after standard cleaning, supporting defect-controlled wafer environments. - High UV/DUV optical stability for optical modules

Quartz windows maintain >88–94% transmission at 200–280 nm after 100 hours of UV exposure, ensuring stable optical power delivery in lithography and inspection systems. - Minimal dopant diffusion and chemical interaction

Quartz process tubes exhibit <0.1% dimensional drift and negligible alkali ion release up to 1000–1050°C, reducing dopant cross-contamination in oxidation and annealing steps.

🔹Case Study: A European semiconductor equipment builder found persistent particle contamination (1.4–1.8 particles/cm² ≥0.3 µm) inside an oxidation module using borosilicate liners, causing wafer defect rates to rise by 12%. After switching to fused quartz ceramic tubes with <0.5 particles/cm² and <0.1% thermal drift at 1000°C, wafer defect levels dropped to 4%, chamber cleaning cycles extended from every 160 wafers to every 310 wafers, and UV optical window transmission remained >90% after extended exposure.

Custom quartz ceramic Supplier

We provide custom fused-quartz ceramic parts manufactured according to customer drawings, samples or target outlines. Dimensions, wall thickness, hole patterns, cutouts and surface conditions can be tailored to match specific thermal or process requirements. Custom quartz ceramic components typically require 3–9 weeks depending on geometry complexity and machining needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – quartz ceramic manufacturers

ADCERAX is a quartz ceramic manufacturer in China producing fused-quartz components in both standard and custom formats for high-temperature and contamination-sensitive applications. As a quartz ceramic supplier, we focus on stable material quality, precise machining capability and flexible customization suitable for sampling, prototyping and volume production.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX provides integrated manufacturing for fused quartz ceramic components, covering forming, sintering, precision machining and finished-part preparation in a streamlined workflow. We produce quartz ceramic crucibles, nozzles, rollers, tubes, plates and custom-shaped parts according to drawings or sample requirements. Prototype and volume orders are both supported.

-

Precision Machining & Dimensional Control:

Quartz ceramic parts are machined with controlled wall thickness, flatness and outline accuracy. CNC processing ensures clean edges, smooth surfaces and tight tolerances suitable for direct integration into thermal, analytical and industrial assemblies. -

Batch Consistency & Production Reliability

Each batch of quartz ceramic components is inspected for geometry repeatability and uniform fused-quartz density. Stable forming and thermal treatment processes help maintain predictable behavior and long-term performance across multiple production runs. -

Customization Based on Drawings

We provide drawing-based customization for outline dimensions, wall thickness, holes, slots, cutouts and surface finishes. Custom quartz ceramic parts can be produced to match specific heating paths, flow channels or assembly layouts with engineering support throughout fabrication.

ADCERAX specializes in producing fused-quartz ceramic components through controlled forming, high-temperature treatment and precision CNC machining. Our process maintains consistent wall thickness, flatness and outline accuracy to ensure stable performance in thermal, analytical and industrial systems. Each batch is inspected for geometry repeatability and surface uniformity, ensuring clean, defect-free quartz ceramic parts suitable for both prototype and volume production. These manufacturing strengths allow us to deliver quartz ceramic components with reliable dimensional control, smooth surfaces and flexible customization based on customer drawings.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Fused quartz ceramic material produced through controlled melting and forming to achieve uniform SiO₂ purity, smooth surfaces and stable structural integrity suitable for high-temperature and contamination-sensitive applications. | ||

| Precision Machining | CNC and diamond-tool machining used to deliver stable wall thickness, clean edges and outline tolerances typically held within ±0.05–0.10 mm for customer-defined quartz geometries. | ||

| Forming & Shaping | Supports custom quartz ceramic formats including tubes, crucibles, plates, rollers and non-standard outlines, with optional holes, slots, cutouts and surface finishing according to drawings. | ||

| Flatness & Dimensional Control | Stabilized thermal treatment ensures low warpage and predictable flatness across batches, with uniform dimensions maintained for repeatable performance under high-temperature or optical-sensitive conditions. | ||

| Inspection & Quality Control | Full inspection of thickness, flatness, edge condition and surface cleanliness to ensure consistent quartz geometry, material purity and readiness for downstream machining or assembly. | ||

FAQs About Quartz Ceramic

Quartz ceramic and fused quartz glass share the same base chemistry but are processed and used differently. Fused quartz glass is typically supplied as tubing or plates with high transparency, while quartz ceramic includes both fused and sintered forms machined into functional components such as tubes, crucibles and porous filters.

For a precise quotation, we need the drawing or a clear sketch with dimensions, tolerances, material grade or optical requirements, expected quantity, target temperature and atmosphere, and any special notes on surface finish or porosity. This allows us to recommend a suitable quartz ceramic design and provide realistic pricing and lead time.

Yes, quartz ceramic parts are designed for high-temperature service within their specified limits. When operated within the recommended temperature range and with reasonable heating and cooling rates, they offer long service life in furnaces, UV systems and analytical instruments.

In applications where transparency, very high purity or low thermal expansion is essential, quartz ceramic can replace other materials. In applications requiring maximum mechanical strength or wear resistance, materials such as alumina or silicon nitride may still be preferred. Our engineers can review your process and advise on the most appropriate combination.

Quartz is one specific material within the broader family of ceramics and glasses. Not all ceramics are quartz, and not all quartz components behave like other ceramic materials. Selection should be based on temperature, mechanical load, purity and optical needs.

No. “quartz 3.0 ceramic” is usually used in consumer care or coating products, for example in automotive detailing. ADCERAX focuses on industrial quartz ceramic parts such as tubes, sleeves, plates and crucibles used inside equipment, not on consumer coatings.

Yes. We regularly supply prototype and pilot-scale batches so that OEMs can validate design and performance before committing to volume orders. Once the design is frozen, we can convert to stable serial production with agreed quality and delivery terms.

Quartz is a ceramic material, not a metal or polymer. It is composed of high-purity crystalline or fused SiO₂ and behaves as an inorganic, non-metallic ceramic with excellent thermal stability, chemical inertness and low thermal expansion. These characteristics place quartz in the ceramic family, specifically within oxide-based ceramics rather than metallic or polymeric materials.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours