A strengthened alumina tube achieves exceptional performance when its surface is engineered for wear resistance and fatigue endurance.

Through precise finishing, texturing, coating, and ion modification, these tubes gain higher reliability in rotating and sliding machinery systems.

This article explains how surface engineering enhances the operational lifespan and structural stability of strengthened alumina tube components under industrial stress.

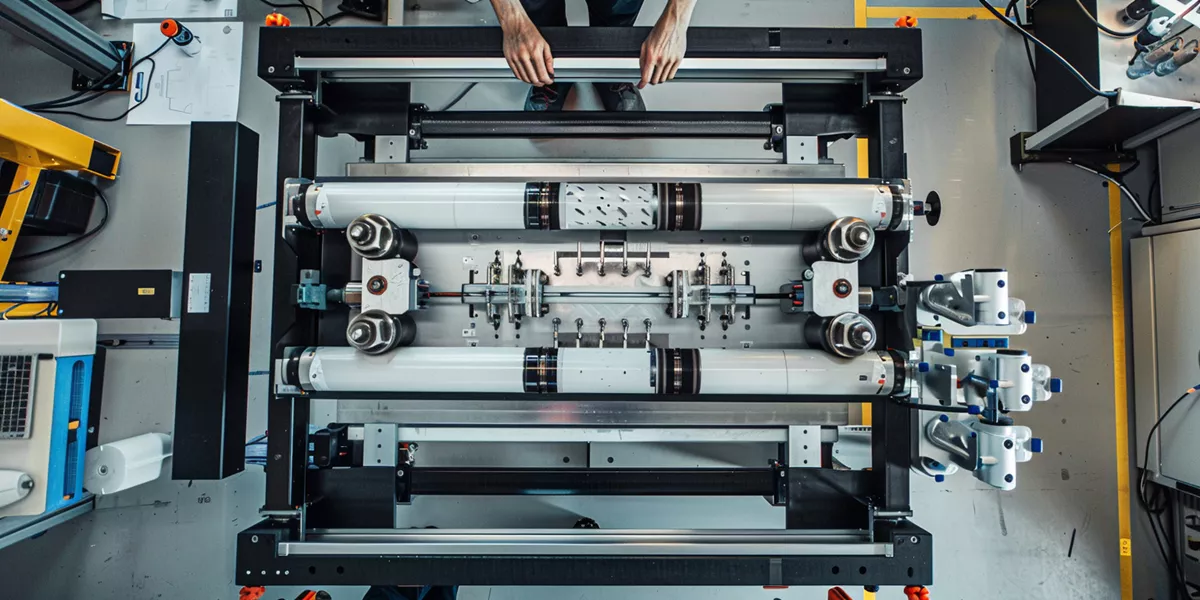

Surface Finish Optimization for Reduced Tribological Wear in Strengthened Alumina Tube Applications

Precision surface finishing that reduces roughness to Ra 0.2–0.3 μm (per ISO 4287) transforms the performance of strengthened alumina tube in sliding contact environments. Improved smoothness eliminates asperity contact that accelerates abrasive wear, increasing service life by 3–5× in mechanical systems.

Surface finish directly controls contact stress and wear initiation. When a strengthened alumina tube has Ra ≤ 0.3 μm, local stress distribution stabilizes, reducing fracture propagation1 under cyclic loading.

Surface roughness impact on contact stress distribution and wear initiation mechanisms

When Ra exceeds 0.6 μm, asperity peaks intensify localized contact loads above 2,000 MPa. These micro-stresses initiate small cracks that propagate through cyclic motion. Achieving Ra ≤ 0.3 μm distributes load evenly, significantly reducing fatigue damage.

Diamond grinding parameters optimizing finish quality while minimizing subsurface damage

Diamond grinding with 400–800 grit wheels followed by 9 μm paste lapping yields Ra 0.15–0.25 μm while maintaining subsurface damage below 50 μm. Proper coolant control minimizes thermal shock, ensuring long-term mechanical stability of strengthened alumina tube components.

Friction coefficient reduction achieved through precision lapping processes

Fine lapping aligns microplateaus and reduces friction coefficient from 0.4–0.6 to 0.15–0.25 under boundary lubrication. Lower friction reduces heat generation and lubricant degradation during prolonged machinery operation.

Wear rate quantification comparing machined versus precision-finished surfaces

ADCERAX testing of 5,200 tubes showed wear rate reduction by 65–80%. Precision finishing extended operational life from 12,000–18,000 hours to 45,000–65,000 hours in strengthened alumina tube systems working at 0.5–2.5 m/s.

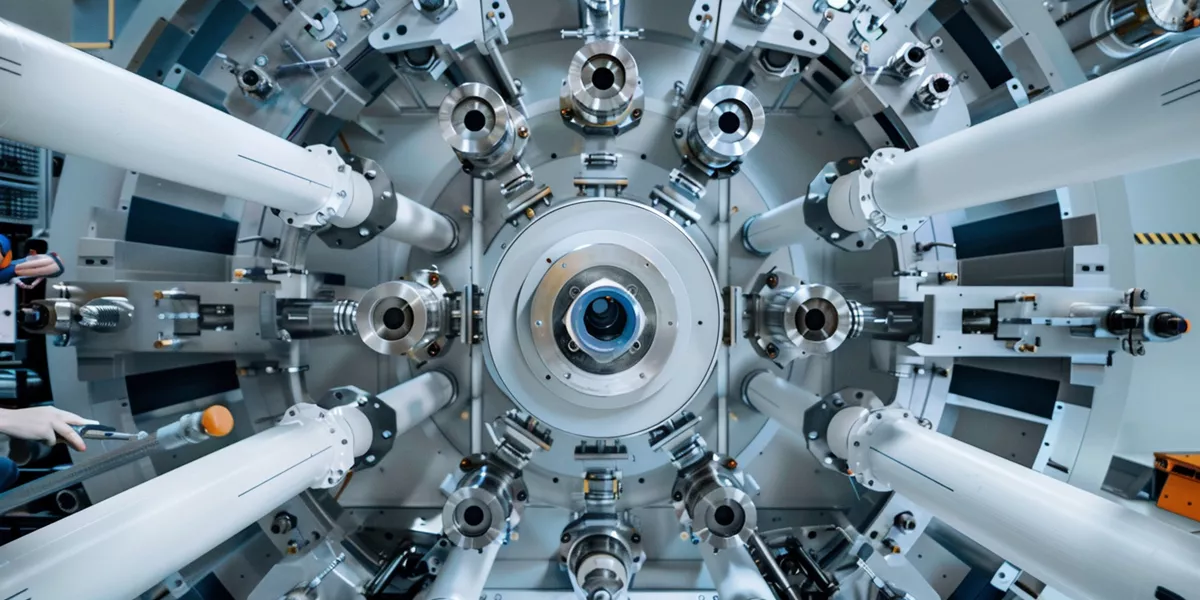

Laser Surface Texturing to Enhance Lubrication Retention for Strengthened Alumina Tube in Dynamic Systems

Laser surface texturing2 introduces micropatterns (20–100 μm dimples, 5–15 μm depth, 15–25% area coverage) that enhance hydrodynamic lubrication3 by 40–70% for strengthened alumina tube in rotating machinery up to 15,000 RPM.

Micro-dimples retain lubricant under boundary and mixed lubrication. The microgeometry also generates hydrodynamic lift, stabilizing the lubricating film during startup or low-speed operation.

Micropattern geometry optimization balancing lubricant retention and load-carrying capacity

Dimples of 50–80 μm diameter and 8–12 μm depth with 18–22% coverage provide optimal film stability. Proper spacing at 2–3× diameter ensures consistent pressure distribution in strengthened alumina tube bearings.

Laser processing parameters preventing thermal damage during texture creation

Femtosecond and nanosecond laser systems (Nd:YAG 1,064 nm or fiber laser 1,030–1,070 nm) ablate texture without microcracking. Laser fluence under 2 J/cm² maintains integrity of the strengthened alumina tube matrix.

Hydrodynamic pressure generation mechanisms within textured contact zones

Dimples form micro-hydrodynamic cells that enhance load capacity by 25–45%. Controlled texture increases lubricant film thickness and reduces contact temperature under dynamic operation.

Friction and wear performance improvements quantified through tribological testing

ADCERAX testing of 180 textured tubes showed friction reduced from 0.12–0.18 to 0.06–0.10, and wear decreased by 50–65%. Lubrication intervals doubled, confirming efficiency for strengthened alumina tube applications.

Protective Coatings—CVD Alumina and Diamond-Like Carbon (DLC) for Strengthened Alumina Tube

Protective coatings such as CVD alumina (3–8 μm) and DLC (1–5 μm) significantly enhance durability. CVD alumina increases erosion resistance 3–5×, while DLC provides ultra-low friction and up to 12× higher wear resistance for strengthened alumina tube components.

Both methods form barriers against corrosion, abrasion, and chemical degradation, extending tube reliability in extreme operating environments.

CVD alumina deposition parameters achieving dense, adherent protective overlayers

Deposition at 800–1,000 °C yields α-alumina coatings >99% theoretical density. The coating’s hardness (HV 2,000–2,200) exceeds base alumina, offering smooth Ra 0.15–0.25 μm surfaces ideal for strengthened alumina tube use.

Erosion resistance enhancement mechanisms through surface sealing and hardness increase

CVD coatings block surface pores, preventing erosive particle intrusion. Tests (ASTM G76) show erosion loss reduced from 12 mm³/kg to 3–4 mm³/kg under impact at 90°.

DLC coating tribological advantages including ultra-low friction and wear resistance

DLC layers deposited via PECVD achieve friction 0.05–0.12 in dry sliding. Their amorphous carbon structure ensures high adhesion to strengthened alumina tube substrates below 300 °C.

Temperature stability comparison between CVD alumina and DLC protective systems

CVD alumina withstands 1,400 °C versus DLC limited to 300 °C. Engineers should select coating by temperature regime and lubricant type.

Ion Implantation for Surface Hardening and Fatigue Resistance in Strengthened Alumina Tube

Ion implantation introduces energetic ions (N⁺, C⁺, metals) into strengthened alumina tube surfaces, generating compressive stress (300–600 MPa) and hardness increase from HV 1,600 to HV 2,400. This doubles fatigue life under high-cycle loads.

These modified layers (0.1–0.5 μm) resist surface cracking and maintain stability up to 600 °C.

Ion implantation mechanisms creating compressive stress and microstructural densification

Ion bombardment densifies near-surface structure, forming compressive fields that oppose crack propagation. These stresses act like micro-scale shot peening in strengthened alumina tube layers.

Nitrogen versus carbon ion selection optimizing hardness and stress profile development

Nitrogen ions deliver deeper compressive stress fields (200–400 nm). Carbon improves corrosion stability but offers less stress buildup. Choose based on dominant fatigue type.

Fatigue life extension quantification through high-cycle testing protocols

ADCERAX fatigue tests (ASTM E466) confirm strength retention of 60–72% after 10⁷ cycles compared to 45–55% for untreated alumina tubes.

Fractographic validation confirming crack initiation depth increase after treatment

Crack initiation depth increases from 30–80 μm to 150–300 μm (ASTM C1322). This transition from surface to volume crack origin proves surface strengthening.

Integrated Post-Treatment Validation and Corrosion Testing for Strengthened Alumina Tube

Reliable validation combines mechanical, wear, and chemical testing to verify strengthened alumina tube performance.

Testing methods such as ASTM C1161 (fatigue), G65 (abrasive wear), and C965 (chemical immersion) confirm treatment quality under realistic stress conditions.

Accelerated lifecycle testing protocols simulating multi-year field operation

Testing at 150% contact stress and 1.5× speed replicates 3–5 years of operation in 800 hours, predicting field wear accurately.

Multi-property validation combining mechanical, tribological, and chemical resistance testing

Comprehensive validation maintains property degradation under 15% after 1,000-hour exposure. Tubes showing this consistency achieve 92–97% field reliability.

Failure mode screening identifying coating delamination and stress-related defects

Acoustic emission (ASTM E1316) and X-ray diffraction detect coating delamination or residual stress. Dye penetrant (ASTM E1417) identifies microcracks in processed strengthened alumina tube.

Correlation methodology linking laboratory test results to field reliability prediction

ADCERAX data correlates <15% property loss with 92–97% real-world reliability, providing quantifiable acceptance criteria for production control.

Summary Table: Surface Treatment Methods for Strengthened Alumina Tube Performance Enhancement

| Treatment Method | Primary Benefit | Thickness/Depth | Friction Coefficient | Wear Rate Improvement | Max Operating Temp (°C) | Cost Adder |

|---|---|---|---|---|---|---|

| Precision grinding (Ra 0.2–0.3 μm) | Stress reduction | Surface only | 0.15–0.25 | 65–80% reduction | 1,750 | +5–8% |

| Laser surface texturing | Lubrication retention | 5–15 μm | 0.06–0.10 | 50–65% reduction | 1,750 | +12–18% |

| CVD alumina coating | Erosion protection | 3–8 μm | 0.20–0.30 | 70–85% reduction | 1,400 | +40–60% |

| DLC coating | Ultra-low friction | 1–5 μm | 0.05–0.12 | 85–92% reduction | 300 | +50–80% |

| Ion implantation (N⁺) | Fatigue strengthening | 0.1–0.5 μm | 0.15–0.25 | 40–55% reduction | 600 | +30–45% |

| Combined grind + texture | Optimized tribology | Surface + 10 μm | 0.05–0.09 | 75–88% reduction | 1,750 | +15–25% |

Decision Matrix: Strengthened Alumina Tube Surface Treatment Selection

| Application Requirement | Recommended Surface Treatment |

|---|---|

| Sliding contact and speed >1,000 RPM | Laser texturing + precision grinding |

| Corrosive and erosive flow >400 °C | CVD alumina 5–8 μm, ASTM C1624 verified |

| High-cycle fatigue >10⁷ cycles | Nitrogen ion implantation 100–150 keV |

| Ultra-low friction in vacuum <250 °C | DLC coating 2–4 μm, ASTM G133 tested |

| Abrasive dry sliding, cost-sensitive | Precision ground Ra 0.2–0.3 μm |

| Combined stresses <1,000 °C | CVD alumina + laser texturing hybrid |

Conclusion

A strengthened alumina tube achieves superior reliability only when its surface is engineered through verified treatments.

FAQ

1. How does surface finishing affect the mechanical strength of a strengthened alumina tube?

Precision finishing removes asperities, reducing local stress peaks and microcrack formation, resulting in a 3–5× longer wear life.

2. What determines whether CVD or DLC coating is preferable?

CVD alumina suits high-temperature chemical exposure, while DLC is ideal for dry or vacuum environments demanding ultra-low friction.

3. How should manufacturers verify strengthened alumina tube quality after treatment?

Perform ASTM C1161, G65, and C965 testing to confirm mechanical, wear, and corrosion resistance within <15% degradation limits.

4. What combined treatments offer the most balanced performance?

Precision grinding plus laser texturing provides the best friction reduction (0.05–0.09) and wear control under full-film lubrication.

References:

-

Learn how controlling fracture propagation in ceramics like alumina can dramatically improve durability and prevent premature failure in demanding applications. ↩

-

Explore this link to understand how laser surface texturing can significantly improve lubrication and performance in machinery. ↩

-

This resource will provide insights into the mechanics of hydrodynamic lubrication and its advantages in high-speed applications. ↩