Alumina Substrate selection often determines whether a PCB can withstand heat, electrical stress, and long-term operation. However, many electronic failures still originate from an incomplete understanding of ceramic substrate behavior. Therefore, a clear engineering definition is essential.

An Alumina Substrate is a ceramic-based PCB material primarily composed of aluminum oxide (Al₂O₃), engineered to provide electrical insulation, thermal dissipation, and mechanical stability within a single rigid platform. It is widely used in electronic assemblies where organic laminates struggle to maintain reliability under elevated temperature, power density, or environmental stress.

Before examining detailed properties, applications, and manufacturing considerations, it is necessary to establish a precise technical context for how alumina substrates function at the PCB and system level. This foundation clarifies why alumina ceramics remain a preferred substrate choice in demanding electronic designs.

Before evaluating performance metrics or application limits, a clear functional definition is required. Accordingly, this section explains what an Alumina Substrate represents specifically within PCB and electronic system design contexts.

What Is an Alumina Substrate in PCB and Electronic Applications

An Alumina Substrate is a ceramic-based circuit carrier manufactured primarily from aluminum oxide (Al₂O₃) and used as a rigid platform for electronic circuits. Unlike organic laminates, it simultaneously provides electrical insulation, thermal conduction, and mechanical rigidity, which are critical in high-power and high-temperature electronics.

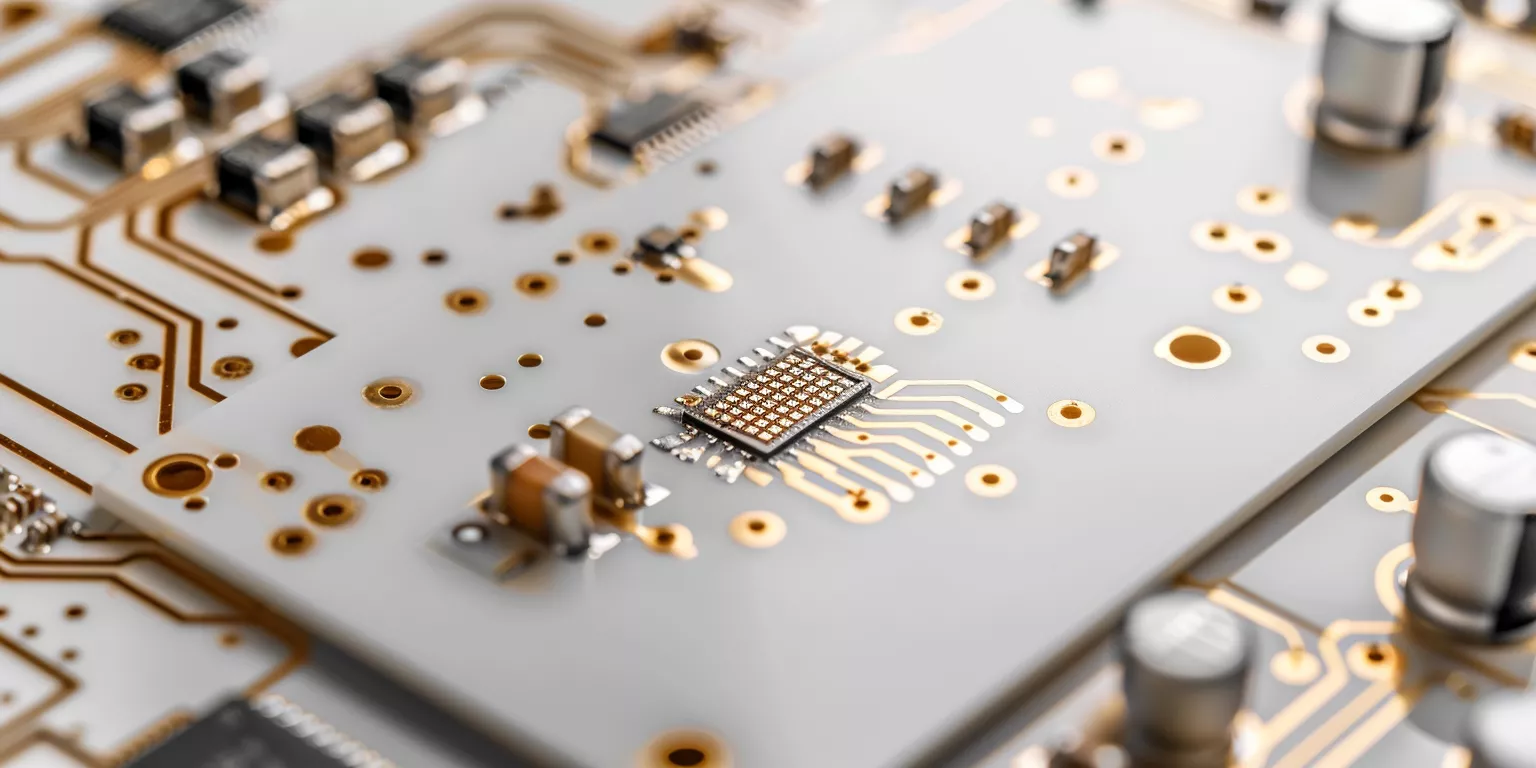

In practical PCB and hybrid circuit applications, alumina substrates support copper traces, thick-film resistors, thin-film conductors, and power semiconductor components. Consequently, stable circuit operation is enabled in environments where polymer-based substrates would suffer from thermal deformation, dielectric breakdown, or accelerated aging.

More importantly, alumina substrates maintain predictable physical and electrical behavior across wide temperature ranges and extended service lifetimes. Therefore, they are commonly specified in power electronics, industrial control modules, LED assemblies, and other systems where reliability cannot be compromised.

As electronic assemblies continue to operate at higher power densities, substrate limitations become more visible. Consequently, alumina substrates have emerged as a practical solution because thermal control, electrical safety, and mechanical durability are balanced within one ceramic platform.

Why Alumina Substrate Became a Preferred Ceramic PCB Material

Alumina substrates gained widespread adoption because multiple PCB failure modes are addressed simultaneously rather than optimizing a single property. Specifically, structural strength, heat dissipation capability, and insulation reliability are combined in operating environments where organic materials degrade rapidly.

Moreover, alumina substrates remain dimensionally stable under thermal cycling, which supports consistent electrical performance over long service periods. Therefore, alumina ceramics are increasingly specified for applications that demand predictable behavior rather than minimum upfront cost.

Mechanical Strength Under Shock, Stress, and Vibration

Mechanical strength in alumina substrates originates from dense ceramic grain bonding achieved during sintering. In standardized flexural testing, flexural strength values between 300 and 400 MPa are typically observed, depending on purity and density.

In real-world qualification testing, alumina-based PCBs have been shown to endure continuous vibration levels above 10 g RMS without microcracking, even when mounted near motors or switching power devices. This performance contrasts with polymer substrates, which often exhibit fatigue-induced delamination under similar conditions.

As a result, alumina substrates are frequently selected for environments involving mechanical shock, repetitive vibration, or rigid mounting constraints.

Thermal Conductivity and Heat Dissipation Capability

Thermal performance is a defining advantage of Alumina Substrate materials. Standard 96% alumina ceramics typically provide thermal conductivity of approximately 22 W/m·K, while higher-purity grades approach 30 W/m·K.

During power module evaluations, junction temperature reductions of 15–30°C are commonly observed when FR-4 substrates are replaced with alumina under identical load conditions. This temperature reduction directly improves component reliability and slows solder joint fatigue.

Therefore, alumina substrates support higher power density designs without relying exclusively on external heat sinks.

Electrical Insulation and Operational Safety

Electrical insulation performance remains equally critical. Alumina substrates commonly exhibit dielectric strength exceeding 15 kV/mm, maintaining isolation even at elevated operating temperatures.

In high-voltage endurance testing, stable insulation resistance with minimal surface leakage has been demonstrated over thousands of operating hours. This stability is particularly valuable in power electronics where insulation failure can propagate system-wide damage.

Consequently, alumina substrates provide a reliable electrical barrier in demanding circuit architectures.

Summary Table: Reasons Alumina Substrates Are Preferred

| Performance Aspect | Typical Value | Engineering Benefit |

|---|---|---|

| Flexural strength (MPa) | 300–400 | Shock and vibration resistance |

| Thermal conductivity (W/m·K) | 22–30 | Efficient heat spreading |

| Dielectric strength (kV/mm) | ≥15 | Electrical safety margin |

| Thermal stability (°C) | >300 | High-temperature reliability |

Once the selection rationale is clear, attention naturally shifts toward quantifiable performance limits. Accordingly, this section examines the physical and electrical properties that define how alumina ceramic substrates behave inside real PCB assemblies.

Key Physical and Electrical Properties of Alumina Ceramic Substrates

Alumina ceramic substrates are not defined by a single outstanding parameter; instead, reliability emerges from the coupling of thermal, electrical, and surface-related properties. Moreover, these properties remain stable across wide temperature and operating ranges, which is essential for long-term PCB performance.

From an engineering perspective, understanding these parameters allows heat flow, signal behavior, and mechanical response to be predicted under realistic loading conditions. Therefore, each property must be evaluated in the context of actual circuit operation rather than isolated datasheet values.

Thermal Properties Relevant to PCB Heat Management

Thermal conductivity is the most frequently cited property of alumina substrates because it directly affects heat dissipation from active components. In practice, 96% alumina substrates typically exhibit thermal conductivity between 20 and 24 W/m·K, while high-purity grades can reach 28–30 W/m·K.

During power PCB prototyping, localized hot spots beneath MOSFETs1 and power ICs are significantly reduced by this conductivity. Instead of relying solely on copper planes or external heat sinks, the substrate itself participates in lateral heat spreading.

Consequently, alumina substrates enable more compact thermal designs while maintaining acceptable junction temperatures.

Electrical Insulation and Dielectric Behavior

Electrical insulation performance ensures safe separation between conductive features. Alumina substrates commonly provide dielectric strength above 15 kV/mm and maintain insulation resistance even as temperatures exceed 200°C.

In high-frequency measurements, the dielectric constant of alumina remains relatively stable, typically between 9 and 10 at 1 MHz. This stability allows impedance behavior to be predicted with greater confidence than with organic substrates.

As a result, alumina ceramics support both power delivery and signal integrity requirements in mixed-signal PCBs.

Surface Smoothness and Metallization Compatibility

Surface condition strongly influences metallization quality. Well-processed alumina substrates achieve average surface roughness (Ra) values below 0.5 μm, supporting reliable adhesion of thick-film and thin-film conductors.

In production environments, smoother surfaces translate into fewer conductor discontinuities and improved yield during screen printing2 or sputtering processes3. Meanwhile, controlled porosity prevents excessive absorption of conductive pastes.

Therefore, surface quality plays a direct role in both manufacturability and long-term circuit reliability.

Summary Table: Physical and Electrical Properties of Alumina Substrates

| Property | Typical Range | PCB-Level Impact |

|---|---|---|

| Thermal conductivity (W/m·K) | 20–30 | Heat dissipation efficiency |

| Dielectric constant (1 MHz) | 9–10 | Predictable signal behavior |

| Dielectric strength (kV/mm) | ≥15 | Electrical insulation safety |

| Surface roughness Ra (μm) | ≤0.5 | Metallization adhesion |

| Continuous operating temperature (°C) | >300 | Thermal stability |

After evaluating core physical and electrical parameters, dimensional behavior becomes the next critical concern. Consequently, this section focuses on how dimensional stability and breaking strength influence alumina substrate reliability during PCB fabrication and long-term operation.

Dimensional Stability and Breaking Strength in Alumina Substrates

Dimensional stability in alumina substrates ensures that circuit layouts remain accurate from fabrication through service life. Moreover, consistent breaking strength minimizes the risk of hidden damage during handling, assembly, and thermal cycling.

From an engineering standpoint, alumina substrates outperform organic materials because ceramic microstructure resists creep, softening, and warpage under elevated temperatures. Therefore, geometry remains predictable even in power-dense or high-temperature environments.

Dimensional Consistency Under Thermal Cycling

Thermal cycling imposes repeated expansion and contraction on PCB materials. Alumina substrates typically exhibit a coefficient of thermal expansion (CTE) around 6–7 ×10⁻⁶ /°C, closely matching many metallization systems.

In accelerated thermal cycling tests, dimensional variation below ±0.1% is commonly maintained across repeated cycles between room temperature and 200–250°C. This consistency prevents trace misalignment and solder joint stress accumulation.

As a result, alumina substrates support tight tolerances in multilayer and hybrid circuit assemblies.

Breaking Strength and Handling Reliability

Breaking strength reflects a substrate’s resistance to fracture under applied load. High-density alumina substrates typically demonstrate modulus of rupture values exceeding 300 MPa, depending on purity and sintering conditions.

During assembly trials, alumina substrates have been shown to withstand manual handling, fixture clamping, and component mounting without edge chipping when proper thickness is selected. Conversely, lower-strength materials often fail at corners or mounting holes.

Therefore, stable breaking strength directly reduces scrap rates and assembly-induced failures.

Flatness and Warpage Control

Flatness influences both component placement and thermal contact. Alumina substrates generally achieve warpage values below 0.3 mm per 100 mm length after sintering and finishing.

In practical PCB layouts, this flatness ensures uniform solder thickness and reliable heat transfer to attached heat spreaders. Additionally, controlled warpage improves screen printing accuracy during metallization.

Thus, dimensional flatness contributes to both electrical reliability and manufacturing yield.

Summary Table: Dimensional Stability and Mechanical Integrity

| Parameter | Typical Value | Engineering Significance |

|---|---|---|

| CTE (×10⁻⁶ /°C) | 6–7 | Thermal compatibility |

| Dimensional variation (%) | ≤0.1 | Layout accuracy |

| Modulus of rupture (MPa) | ≥300 | Fracture resistance |

| Warpage (mm/100 mm) | ≤0.3 | Assembly flatness |

Beyond strength and dimensional control, secondary performance characteristics strongly influence real-world reliability. Accordingly, this section examines additional material behaviors that determine how alumina substrates perform under electrical, chemical, and environmental stress.

Additional Performance Characteristics of Alumina Substrate Materials

Alumina substrates exhibit a combination of surface, chemical, and dielectric characteristics that support long-term stability. Furthermore, these properties often become decisive in harsh or safety-critical electronic environments.

From field evaluations, these secondary characteristics frequently explain why alumina substrates remain stable where alternative materials gradually degrade. Therefore, focused engineering evaluation is required.

Electrical Insulation and Dielectric Stability

Electrical insulation defines the substrate’s ability to isolate conductive paths. Alumina substrates typically show a volume resistivity above 10¹⁴ Ω·cm and a dielectric strength exceeding 10 kV/mm.

In high-voltage layouts, consistent insulation behavior is maintained even after prolonged exposure to elevated temperatures. By contrast, polymer substrates may experience insulation drift or partial discharge.

Consequently, alumina substrates provide predictable electrical isolation in power electronics and high-density circuits.

Surface Smoothness and Metallization Adhesion

Surface smoothness influences metallization quality and adhesion strength. High-purity alumina substrates often achieve average surface roughness (Ra) below 0.5 μm after finishing.

During thick-film and thin-film processing, smoother alumina surfaces consistently improve conductor adhesion and line definition. Moreover, reduced porosity limits void formation beneath metallized layers.

As a result, circuit reliability improves through stronger metallization interfaces.

Chemical and Environmental Resistance

Chemical resistance allows alumina substrates to operate in corrosive or contaminated environments. Alumina is inherently resistant to oils, solvents, and many acidic or alkaline agents.

In industrial control boards, surface integrity has been shown to remain stable after exposure to flux residues and cleaning chemicals. This resistance prevents surface degradation that could otherwise compromise insulation.

Therefore, chemical stability extends usable life in demanding applications.

Fire Resistance and Safety Behavior

Fire resistance is a critical safety attribute. Alumina substrates are non-flammable and remain structurally stable at temperatures exceeding 1,000°C.

In thermal abuse testing, toxic fumes are not emitted and combustion is not sustained. This behavior significantly reduces fire risk in high-power assemblies.

Hence, alumina substrates support compliance with stringent safety requirements.

Summary Table: Additional Performance Characteristics

| Characteristic | Typical Value | Practical Impact |

|---|---|---|

| Volume resistivity (Ω·cm) | >10¹⁴ | Electrical isolation |

| Dielectric strength (kV/mm) | ≥10 | High-voltage safety |

| Surface roughness Ra (μm) | ≤0.5 | Metallization adhesion |

| Chemical resistance | High | Environmental durability |

| Fire behavior | Non-flammable | Safety compliance |

How Alumina Substrate Properties Translate into PCB-Level Benefits

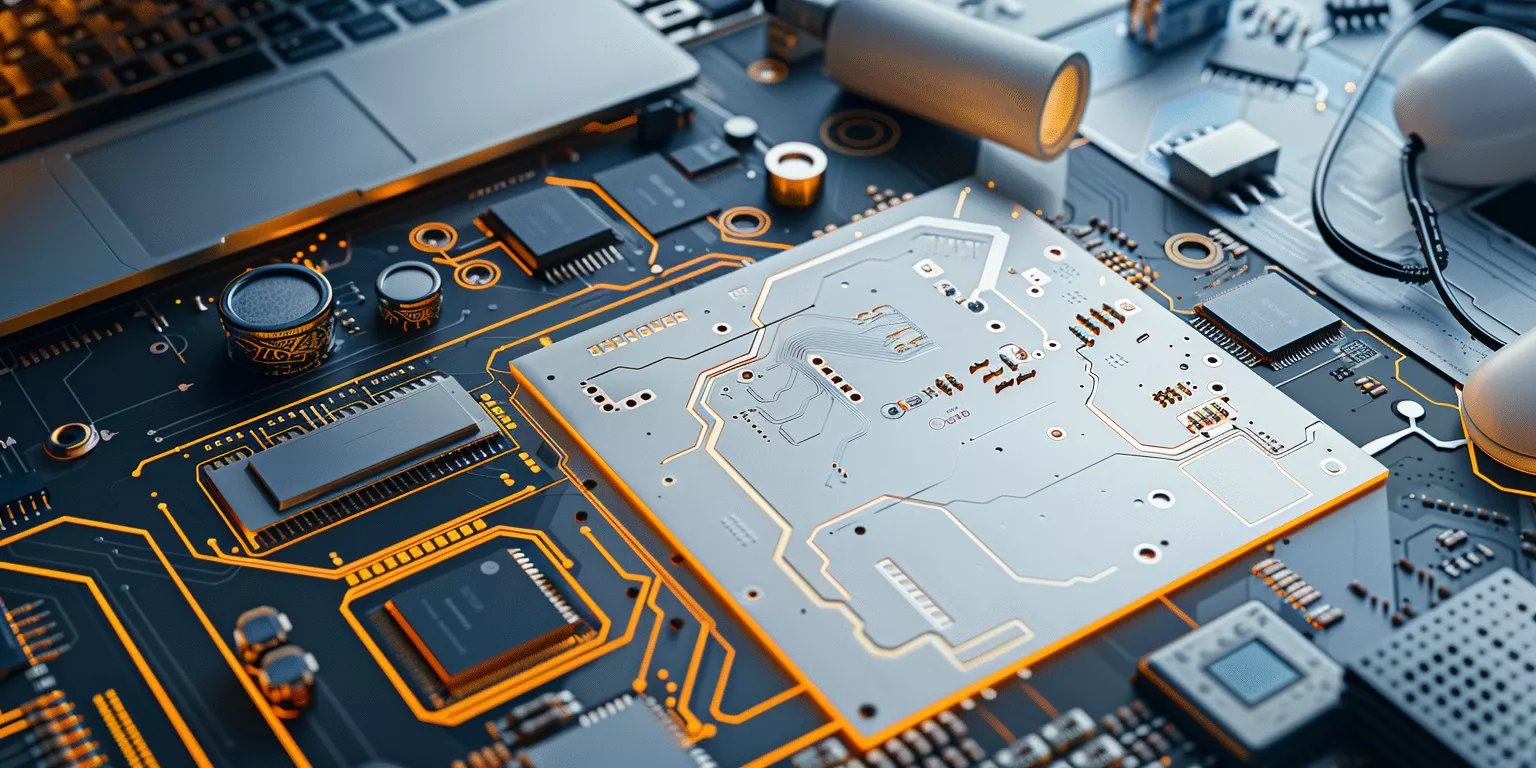

Alumina substrate performance becomes most visible at the PCB level, where thermal, electrical, and mechanical behaviors interact simultaneously. Moreover, these interactions determine long-term reliability rather than short-term functionality.

In practical engineering reviews, PCB failures rarely stem from a single property. Therefore, understanding how alumina substrate characteristics combine at board level is essential for robust design.

Thermal Management at the PCB Assembly Level

Thermal dissipation is a defining benefit of alumina substrates. Typical alumina substrates provide thermal conductivity between 20 and 30 W/m·K, which is significantly higher than standard FR-4 materials.

In power PCB assemblies, hotspot temperature reductions of 15–25°C are commonly observed under identical load conditions. This reduction directly lowers thermal stress on solder joints and semiconductor junctions.

As a result, improved thermal pathways extend component lifespan and stabilize electrical performance.

Electrical Isolation and Signal Integrity

Electrical insulation remains critical when high voltage and dense routing coexist. Alumina substrates offer dielectric constants around 9.5–10, combined with extremely low dielectric loss.

During mixed-signal PCB testing, leakage currents remain minimized even above 1 kV operating voltage. Additionally, consistent dielectric behavior supports predictable impedance control.

Therefore, alumina substrates enhance both safety and signal reliability at the PCB level.

Mechanical Reliability During Assembly and Operation

Mechanical robustness influences assembly yield and operational durability. Alumina substrates resist flexing, vibration, and localized stress far better than polymer alternatives.

In automated assembly environments, fewer pad cracks and trace delamination events are observed with alumina-based PCBs. This stability remains consistent even after multiple thermal reflow cycles.

Thus, mechanical rigidity directly contributes to higher manufacturing yields and reduced field failures.

Fire Safety and Failure Containment

Fire resistance becomes critical in high-power or safety-sensitive electronics. Alumina substrates are non-combustible and remain structurally stable beyond 1,000°C.

In failure simulations involving component short circuits, flame propagation and structural collapse are prevented. This containment reduces secondary damage and improves overall system safety.

Consequently, alumina substrates support compliance with strict fire and safety standards.

Summary Table: PCB-Level Benefits Enabled by Alumina Substrates

| PCB-Level Benefit | Supporting Property | Typical Value | Practical Outcome |

|---|---|---|---|

| Heat dissipation | Thermal conductivity (W/m·K) | 20–30 | Lower junction temperature |

| Electrical safety | Dielectric strength (kV/mm) | ≥10 | High-voltage isolation |

| Assembly robustness | Flexural strength (MPa) | ≥300 | Reduced assembly damage |

| Signal stability | Dielectric loss | <0.001 | Predictable impedance |

| Fire containment | Combustibility | Non-flammable | Enhanced safety |

Once performance characteristics are understood, selecting the correct material variant becomes essential. Therefore, this section explains how different alumina substrate types are engineered and where each is most effectively applied.

Types of Alumina Substrates Used in Industry

Industrial alumina substrates are primarily differentiated by density, porosity, and alumina purity. Consequently, these variations directly influence thermal behavior, mechanical strength, and functional suitability.

From practical sourcing analysis, mismatching substrate type to application is a common root cause of premature failure. Thus, understanding these distinctions is critical for engineering-grade selection.

High-Density Sintered Alumina Substrates

High-density alumina substrates typically contain 96% to 99.6% Al₂O₃, resulting in low porosity and high mechanical integrity. Bulk density commonly exceeds 3.7 g/cm³, which supports both strength and thermal conduction.

In PCB manufacturing lines, high-density alumina is frequently specified for power modules operating above 150 W/cm² heat flux. Structural integrity is consistently maintained during metallization firing and reflow soldering.

As a result, high-density alumina remains the default choice for reliability-critical electronic assemblies.

Porous Sintered Alumina Substrates

Porous alumina substrates intentionally incorporate controlled porosity, often ranging from 15% to 35% by volume. This structure reduces weight while enabling fluid or gas permeability.

In filtration-oriented electronics and sensor housings, porous alumina enables uniform diffusion without sacrificing chemical stability. However, mechanical strength typically decreases by 20–40% compared to dense alumina.

Therefore, porous alumina is selected when permeability outweighs load-bearing requirements.

Alumina Purity Grades and Their Implications

Alumina purity influences dielectric stability, thermal conductivity, and long-term aging. For example, 96% alumina offers balanced cost and performance, while 99%+ alumina provides superior insulation and thermal consistency.

During qualification testing, higher-purity substrates consistently show lower dielectric loss, often <0.001 at 1 MHz. This advantage becomes important in high-frequency or precision circuits.

Thus, purity selection should align with electrical performance targets rather than cost alone.

Thickness and Dimensional Options

Alumina substrates are commonly produced in thicknesses from 0.15 mm to 2.0 mm, with standard panel sizes such as 50.8 × 50.8 mm and 168 × 168 mm.

In thin-substrate applications, thickness below 0.25 mm requires careful handling to avoid microcracking. Conversely, thicker substrates improve rigidity but increase thermal mass.

Hence, thickness optimization balances mechanical robustness and thermal response.

Summary Table: Industrial Alumina Substrate Types

| Type | Key Parameter | Typical Range | Primary Use Case |

|---|---|---|---|

| High-density alumina | Al₂O₃ content (%) | 96–99.6 | Power electronics |

| Porous alumina | Porosity (%) | 15–35 | Filtration, sensing |

| High-purity alumina | Dielectric loss | <0.001 | High-frequency PCBs |

| Thin substrates | Thickness (mm) | 0.15–0.25 | Compact layouts |

| Thick substrates | Thickness (mm) | 1.0–2.0 | Structural stability |

With PCB-level benefits established, application context becomes the final validation step. Accordingly, this section outlines where alumina substrates are most commonly deployed and why their material characteristics align with those environments.

Where Alumina Substrates Are Commonly Applied

Alumina substrates are selected when thermal stability, electrical insulation, and mechanical reliability must coexist. Moreover, predictable behavior under stress makes them suitable for applications where failure tolerance is low.

Across multiple industries, alumina substrates consistently appear in systems requiring long service life under elevated thermal or electrical loads. Therefore, their application footprint continues to expand.

LED Modules and High-Brightness Lighting

LED assemblies generate concentrated heat at the junction level. Alumina substrates, with thermal conductivity up to 30 W/m·K, efficiently spread this heat across the board.

In high-brightness LED systems, junction temperature reductions of 18–22°C are typically achieved compared with polymer substrates under identical drive currents. This reduction directly improves luminous efficiency and color stability.

As a result, alumina substrates are widely adopted in industrial and automotive LED modules.

Power Electronics and Power Modules

Power electronics demand both insulation and thermal control. Alumina substrates support operating voltages above 1 kV while maintaining structural integrity under continuous thermal load.

In inverter and converter platforms, compact layouts are enabled without compromising isolation distances. Additionally, rigidity supports heavy components such as IGBTs and power MOSFETs.

Thus, alumina substrates remain a standard material for power modules and motor drives.

Hybrid Integrated Circuits and Thick-Film PCBs

Hybrid circuits rely on stable substrates for precise conductor patterning. Alumina’s smooth surface and low porosity support reliable thick-film and thin-film metallization.

During hybrid PCB qualification, line width stability within ±10 μm is maintained after firing cycles exceeding 850°C. This consistency ensures repeatable electrical characteristics.

Consequently, alumina substrates are integral to hybrid IC production.

High-Temperature and Harsh-Environment Electronics

Electronics used in high-temperature or chemically aggressive environments benefit from alumina’s inert nature. Dimensional and electrical stability is maintained beyond 500°C continuous operation.

In industrial sensing equipment, resistance to oil exposure, vibration, and thermal cycling reduces maintenance frequency and downtime.

Therefore, alumina substrates are favored in harsh-environment electronics.

Summary Table: Common Application Areas for Alumina Substrates

| Application Area | Key Requirement | Alumina Advantage | Typical Operating Range |

|---|---|---|---|

| LED modules | Heat dissipation | High thermal conductivity | Up to 200°C |

| Power electronics | Insulation + strength | Dielectric stability | >1 kV |

| Hybrid circuits | Pattern accuracy | Surface smoothness | 850°C firing |

| Industrial sensors | Chemical resistance | Material inertness | −40 to 500°C |

| Automotive systems | Reliability | Thermal stability | Wide temperature range |

Beyond electronic systems, alumina substrates also serve functional roles in several non-electronic and cross-industry environments. Accordingly, this section highlights where the same material properties enable performance outside traditional PCB applications.

Non-Electronic and Cross-Industry Applications of Alumina Substrates

Alumina substrates are not limited to electronic assemblies. Moreover, chemical stability, thermal endurance, and structural integrity make them suitable for mechanical, chemical, and process-oriented uses.

Across industries, alumina substrates often replace metals or polymers where long-term stability is critical. Therefore, adoption extends well beyond circuit-related functions.

-

Filtration and Fluid Handling Components

Porous alumina substrates are used for liquid and gas filtration because controlled pore sizes enable uniform flow. In pilot filtration systems, substrates with 20–30% porosity maintain stable permeability over 1,000+ operating hours. Consequently, use is common in chemical processing and environmental equipment. -

Catalyst Supports and Reaction Media

Alumina substrates provide a chemically inert and thermally stable base for catalyst coatings. In high-temperature reactors, dimensional stability above 800°C prevents catalyst delamination. As a result, reaction efficiency remains consistent. -

Thermal and Kiln Equipment Components

Alumina substrates are employed as spacers, supports, and insulation elements in furnaces and sintering equipment. Resistance to repeated exposure above 1,000°C minimizes deformation. Therefore, process repeatability is improved in thermal systems. -

Medical and Analytical Devices

In medical and laboratory equipment, alumina substrates offer biocompatibility and chemical resistance. During cleaning validation, no surface degradation is observed after repeated exposure to sterilization chemicals. Hence, hygienic and stable operation is supported.

Overall, these applications demonstrate how alumina substrate performance translates effectively across industries, reducing material changeover and maintenance complexity.

After application scope is clarified, understanding how material performance is achieved becomes essential. Therefore, this section outlines the manufacturing stages that define alumina substrate quality and consistency.

How Alumina Substrates Are Manufactured

Alumina substrate manufacturing is a controlled ceramic process designed to achieve uniform density, purity, and microstructural stability. Moreover, each stage directly influences thermal, electrical, and mechanical performance in the final product.

From manufacturing audits and process reviews, variability in early-stage processing is identified as a common source of downstream performance deviation. Consequently, disciplined manufacturing control is critical.

-

Raw Material Selection and Purity Control

Alumina substrates are produced primarily from aluminum oxide powders with purities ranging from 96% to above 99.6% Al₂O₃. Particle size distribution is typically controlled below 5 μm to ensure uniform sintering behavior. Therefore, raw material quality establishes the baseline for all subsequent properties. -

Powder Preparation and Conditioning

Selected powders undergo washing, milling, and blending to remove impurities and achieve consistent granulation. In controlled production lines, moisture content is maintained within ±0.2% to prevent forming defects. As a result, powder preparation directly affects green body integrity. -

Forming and Shaping Processes

Alumina substrates are shaped using tape casting, dry pressing, or extrusion, depending on thickness and geometry requirements. Tape-cast green sheets commonly range from 0.15 to 1.5 mm before sintering. Subsequently, precision cutting defines final substrate dimensions. -

Pre-Sintering Drying and Binder Removal

Organic binders introduced during forming are removed through staged heating below 600°C. Controlled debinding prevents internal cracking and warpage. Hence, dimensional accuracy is protected.

Overall, these manufacturing stages establish the structural foundation required for high-performance alumina substrates.

Once forming and pre-processing are complete, material performance is finalized during high-temperature firing. Accordingly, this section explains how sintering conditions determine the structural, electrical, and thermal behavior of alumina substrates.

The Role of High-Temperature Sintering in Alumina Substrate Performance

High-temperature sintering is the decisive step that transforms a fragile green body into a fully functional alumina substrate. Moreover, sintering parameters directly control density, grain structure, and long-term stability.

In manufacturing evaluations, inconsistent sintering profiles are often responsible for performance spread. Therefore, this stage requires focused engineering attention.

-

Densification and Grain Growth Control

Alumina substrates are typically sintered at temperatures between 1,500°C and 1,650°C, depending on purity and formulation. At these temperatures, particle diffusion eliminates pores and increases bulk density above 3.7 g/cm³. Consequently, mechanical strength and dielectric reliability are improved. -

Mechanical Strength Development

Properly sintered alumina achieves a modulus of rupture exceeding 300 MPa. In comparative trials, substrates fired with insufficient soak time exhibit up to 25% lower strength, even when chemical composition is identical. Thus, sintering duration is as critical as peak temperature. -

Electrical and Thermal Property Stabilization

Grain boundary formation during sintering influences dielectric loss and thermal conductivity. Well-controlled sintering consistently yields dielectric loss values below 0.001 and thermal conductivity up to 30 W/m·K. As a result, electrical insulation and heat dissipation remain stable over time. -

Dimensional Accuracy and Warpage Reduction

Controlled heating and cooling rates limit residual stress. In optimized processes, post-sintering warpage remains below 0.3 mm per 100 mm length. Therefore, dimensional predictability is preserved for downstream PCB fabrication.

Overall, high-temperature sintering defines whether an alumina substrate performs as a commodity ceramic or as an engineering-grade PCB material.

With material properties, applications, and processing clarified, final selection decisions can be made. Accordingly, this section summarizes the engineering-level considerations that determine whether an alumina substrate is appropriate for a specific design.

Final Engineering Considerations When Choosing an Alumina Substrate

Selecting an alumina substrate requires balancing thermal, electrical, mechanical, and manufacturing constraints rather than optimizing a single parameter. Moreover, overlooking application boundaries often leads to over-specification or unexpected reliability issues.

-

Operating Temperature and Thermal Load

Alumina substrates perform reliably when continuous operating temperatures remain below 500°C, with short-term exposure tolerating significantly higher peaks. In such cases, confirmation is required that thermal gradients do not exceed 30–40°C/mm, which could introduce localized stress. Therefore, thermal modeling is recommended early in the design phase. -

Electrical Requirements and Insulation Margins

For high-voltage designs, dielectric strength above 10 kV/mm provides sufficient safety margin. However, trace spacing and metallization quality still govern real insulation performance. Consequently, substrate selection must align with layout rules rather than being treated as a standalone solution. -

Mechanical Handling and Assembly Constraints

Alumina substrates offer high rigidity but limited flexibility. During assembly, thickness below 0.25 mm increases sensitivity to edge chipping, whereas thicker substrates add thermal mass. Thus, mechanical handling methods should influence thickness choice. -

Cost-to-Performance Alignment

Higher alumina purity improves stability and dielectric behavior but increases material and processing cost. In practice, 96% alumina satisfies most power and LED applications, while 99%+ grades are reserved for high-frequency or precision circuits. Therefore, purity should match functional need rather than assumed superiority.

Ultimately, an alumina substrate should be selected as part of an integrated electrical, thermal, and mechanical design strategy rather than as a material upgrade alone.

Conclusion

Overall, Alumina Substrate combines thermal stability, electrical insulation, and mechanical reliability in a single ceramic platform. Consequently, it remains a proven engineering solution for demanding electronic and industrial applications.

When stable thermal performance and long-term reliability are required, early evaluation of Alumina Substrate options can significantly reduce downstream risk. Technical consultation during material selection is strongly recommended.

FAQ

What purity level of alumina substrate is suitable for most PCB applications?

In most power electronics and LED applications, 96% alumina substrates provide an effective balance between cost, thermal conductivity, and mechanical strength. Higher purities are typically reserved for high-frequency or precision circuits.

Can alumina substrates be used in high-voltage environments?

Yes, alumina substrates commonly support operating voltages above 1 kV, thanks to dielectric strength exceeding 10 kV/mm. However, PCB layout and metallization quality remain critical factors.

Are alumina substrates suitable for multilayer PCB designs?

Alumina substrates are primarily used in single-layer and hybrid configurations. Multilayer designs are possible but require specialized processing and precise alignment control.

How does alumina substrate compare to FR-4 in thermal performance?

Alumina substrates offer thermal conductivity up to 30 W/m·K, significantly higher than FR-4. As a result, superior heat dissipation is achieved in power-dense designs.

References:

-

Learn how MOSFETs work and why their thermal management is crucial for efficient power PCB design and prototyping. ↩

-

Learn how screen printing impacts conductor quality and yield in electronics, helping you optimize your manufacturing processes. ↩

-

Learn how sputtering processes work and why they're crucial for creating high-quality electronic components with precise surface properties. ↩