High-duty industrial systems frequently fail when conventional materials reach mechanical, thermal, or chemical limits. Consequently, zirconia ceramic material emerges where durability, predictability, and damage tolerance must coexist.

This article examines how zirconia ceramic material supports high-load industrial components through structural reliability, controlled degradation, and system-level compatibility. Moreover, the discussion prioritizes engineering behavior over material catalog descriptions.

Before addressing specific operating environments, it is necessary to establish how this material functions as a structural baseline within load-bearing systems. Accordingly, the following section frames zirconia ceramic material from an engineering reliability perspective rather than a purely materials science definition.

Structural credibility precedes all discussions of wear, chemical exposure, or thermal gradients, because load response, crack resistance, and dimensional stability ultimately govern whether a material can function as a true load-bearing system.

Material Identity Within Load Bearing Systems

Zirconia ceramic material is frequently evaluated as a load-bearing candidate in systems where brittle failure is unacceptable. Therefore, understanding how it carries stress, resists cracking, and preserves geometry under sustained load becomes the first engineering checkpoint. Moreover, this assessment establishes whether subsequent performance advantages can be safely utilized.

Load response under compression and bending

Under compressive loading, zirconia ceramic material exhibits exceptionally high load tolerance, with compressive strength commonly exceeding 2000 MPa. This behavior allows components to sustain localized contact stresses without permanent deformation.

By contrast, bending introduces tensile stress regions that traditionally challenge ceramic materials. However, flexural strength values between 800 and 1200 MPa are routinely achieved, provided surface integrity is maintained. Consequently, bending resistance becomes predictable rather than catastrophic.

As a result, structural designers treat compression-dominated and mixed-mode loading as viable scenarios rather than exclusion zones.

Crack resistance driven by internal phase response

Crack initiation does not immediately translate into structural failure within zirconia ceramic material. Instead, stress concentration at crack tips activates a localized phase response that alters crack propagation behavior.

Experimental fracture toughness values ranging from 6 to 10 MPa·m¹ᐟ² demonstrate this resistance, exceeding most oxide ceramics by a substantial margin. Notably, this response does not rely on plastic deformation but on controlled microstructural transformation.

Accordingly, cracks are slowed, deflected, or arrested, allowing components to retain functional integrity even after minor damage events.

Dimensional stability under sustained mechanical stress

Long-term load exposure often introduces creep or gradual distortion in many engineering materials. Zirconia ceramic material, however, maintains dimensional stability under sustained stress below 900 °C, with measured creep strain typically under 0.1% after 10,000 hours.

Furthermore, elastic modulus values near 200 GPa remain stable across extended service intervals. This consistency preserves alignment and fit within precision assemblies.

Therefore, sustained mechanical loading does not inherently compromise dimensional accuracy when operating within established design limits.

Structural baseline performance indicators

| Parameter | Typical Value | Test Condition |

|---|---|---|

| Compressive strength (MPa) | > 2000 | Room temperature |

| Flexural strength (MPa) | 800–1200 | 4-point bending |

| Fracture toughness (MPa·m¹ᐟ²) | 6–10 | Single-edge notch |

| Elastic modulus (GPa) | 190–210 | Static loading |

| Creep strain (%) | < 0.1 | 10,000 h at < 900 °C |

Structural Reliability of Zirconia Ceramic Material

As load-bearing credibility is established, attention naturally shifts toward structural reliability under imperfect and evolving conditions. Therefore, the ability to maintain integrity despite cracks, stress redistribution, and non-ideal loading defines whether zirconia ceramic material can be trusted in high-duty systems. Moreover, reliability must be evaluated over time rather than at initial strength limits.

Stress redistribution at crack initiation sites

Crack initiation in zirconia ceramic material does not immediately trigger unstable failure. Instead, localized stress concentration near crack tips induces a phase-related response that redistributes stress away from the crack front.

Quantitative fracture mechanics studies indicate that stress intensity factors1 are effectively reduced by 20–35% during early crack propagation stages. This reduction slows crack growth rates and alters crack trajectories. Consequently, microcracks remain confined rather than rapidly coalescing.

As a result, components continue operating safely even when minor defects develop during service.

Energy dissipation without plastic deformation

Unlike metallic systems, zirconia ceramic material dissipates fracture energy without relying on plastic flow. Instead, energy is absorbed through microstructural mechanisms activated at critical stress thresholds.

Measured work-of-fracture values are typically 2–3 times higher than those of conventional alumina ceramics. This behavior reflects controlled transformation activity rather than irreversible deformation. Therefore, energy dissipation remains localized and repeatable.

Accordingly, structural response remains stable across repeated loading events without cumulative distortion.

Reliability under non-ideal and asymmetric loading

Industrial components rarely experience perfectly aligned loads. Misalignment, edge loading, and asymmetric contact conditions frequently arise during operation.

Testing under off-axis loading demonstrates that zirconia ceramic material retains more than 80% of nominal strength even when load eccentricity reaches 10–15%. This tolerance contrasts sharply with brittle ceramics that fail abruptly under similar conditions.

Thus, non-ideal loading scenarios are accommodated within defined safety margins rather than causing immediate structural collapse.

Structural reliability indicators under service conditions

| Indicator | Observed Range | Service Implication |

|---|---|---|

| Stress intensity reduction (%) | 20–35 | Crack growth suppression |

| Work of fracture (J/m²) | 2–3× alumina | Enhanced damage tolerance |

| Strength retention under misalignment (%) | > 80 | Load tolerance |

| Crack propagation rate (relative) | Low | Extended service life |

| Failure mode | Gradual | Predictable maintenance |

Surface interaction under continuous motion reveals how material performance evolves over time, making wear behavior a critical indicator of service life, stability, and maintenance predictability in industrial assemblies.

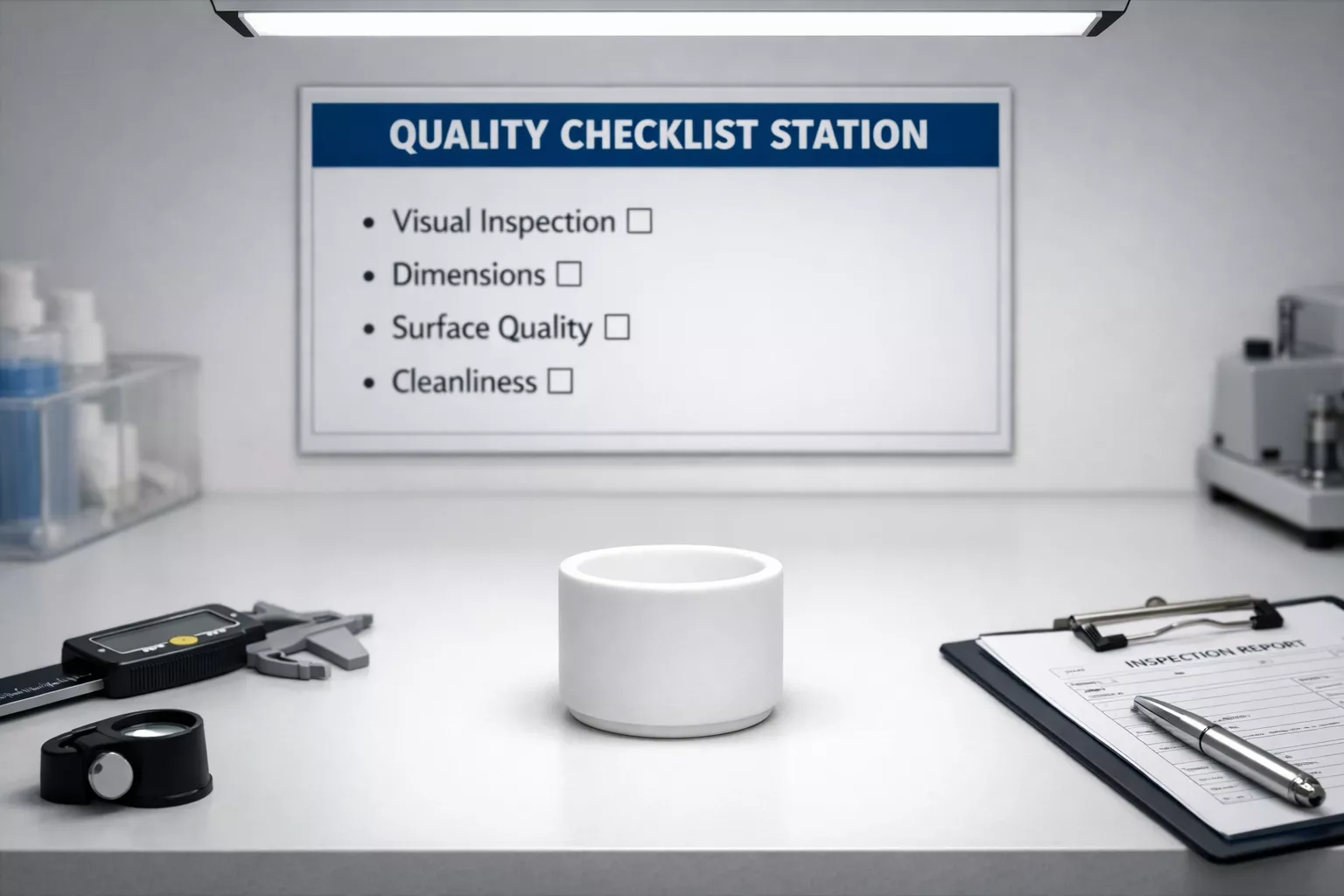

Wear Behavior in Continuous Operation

Wear performance becomes decisive once components enter repetitive motion or sustained contact. Therefore, understanding how surfaces evolve under friction, abrasion, and cyclic stress clarifies whether zirconia ceramic material supports long-duration operation without progressive degradation.

-

Sliding and abrasive wear mechanisms

Sliding contact tests indicate volumetric wear rates typically below 1×10⁻⁶ mm³/N·m under dry conditions. This low material loss results from high hardness values ranging between 1200–1300 HV, which suppress micro-ploughing. Consequently, surface geometry remains stable even after millions of cycles.

-

Contact fatigue under cyclic stress

Under repeated Hertzian contact, zirconia ceramic material demonstrates contact fatigue limits exceeding 1.5 GPa without surface spalling. Microcrack initiation remains confined beneath the surface rather than propagating outward. As a result, fatigue-driven wear progresses slowly and predictably.

-

Surface finish as a wear life amplifier

Surface roughness strongly influences wear kinetics. Polished surfaces below Ra 0.2 µm reduce friction coefficients to approximately 0.3, whereas rougher finishes accelerate material removal. Therefore, controlled finishing extends operational life without altering bulk properties.

Accordingly, wear behavior is governed more by surface condition and contact mechanics than by intrinsic material weakness.

Wear performance under continuous motion

| Parameter | Typical Range | Test Condition |

|---|---|---|

| Hardness (HV) | 1200–1300 | Vickers indentation |

| Wear rate (mm³/N·m) | < 1×10⁻⁶ | Dry sliding |

| Contact fatigue limit (GPa) | > 1.5 | Hertzian loading |

| Friction coefficient | 0.3–0.4 | Polished surface |

| Dominant wear mode | Mild abrasive | Repetitive contact |

Environmental exposure often defines the true operating boundary of industrial components, since chemical stability under aggressive media directly governs long-term reliability and degradation pathways.

Zirconia Ceramic Material in Aggressive Media Exposure

Zirconia ceramic material is frequently deployed where acids, alkalis, salts, or reactive slurries challenge conventional engineering materials. Therefore, evaluating chemical resistance together with mechanical integrity reveals whether performance remains stable throughout prolonged exposure. Moreover, chemical effects often interact with stress and wear rather than acting independently.

Reaction boundaries in acids alkalis and salts

Chemical immersion testing demonstrates that zirconia ceramic material exhibits dissolution rates below 0.01 mg/cm²·day in most inorganic acids at room temperature. Even in alkaline solutions with pH values above 12, mass loss remains limited over extended durations.

This resistance is attributed to strong Zr–O bonding and low ionic mobility within the lattice. Consequently, surface degradation progresses slowly and remains measurable rather than abrupt. Such behavior allows predictable maintenance intervals.

As a result, aggressive liquid media do not inherently compromise structural performance when exposure conditions remain controlled.

Stability in oxidizing and reducing environments

High-temperature atmospheres often accelerate chemical reactions in metallic components. By contrast, zirconia ceramic material maintains phase stability in oxidizing environments up to 1000 °C, with negligible compositional change.

In reducing atmospheres, oxygen vacancy2 concentration may increase; however, bulk integrity remains intact when temperature and exposure duration are bounded. Electrical conductivity may rise slightly, yet mechanical properties remain stable. Therefore, functional behavior remains predictable across diverse atmospheres.

Accordingly, environmental variability does not directly translate into mechanical risk.

Coupled chemical and mechanical surface evolution

Chemical exposure rarely occurs without mechanical interaction. Slurry flow, particle impact, or sliding contact often accompanies corrosive environments.

Studies combining erosion and corrosion show material loss rates increasing by 20–30% compared to purely mechanical wear. Nevertheless, damage remains confined to surface layers below 50 µm depth. Consequently, bulk properties remain unaffected.

Thus, coupled degradation mechanisms progress gradually and can be accommodated through surface design and inspection planning.

Chemical stability indicators under aggressive exposure

| Environment | Observed Change | Exposure Condition |

|---|---|---|

| Acidic solution | < 0.01 mg/cm²·day loss | Room temperature |

| Alkaline solution (pH > 12) | Minimal surface etching | Extended immersion |

| Oxidizing atmosphere | Phase stable | Up to 1000 °C |

| Reducing atmosphere | Slight conductivity increase | High temperature |

| Erosion–corrosion depth (µm) | < 50 | Slurry impact |

Temperature-driven dimensional change introduces internal stress even in the absence of external loading, which makes thermal stress response and expansion compatibility central to safe integration within multi-material assemblies.

Thermal Stress and Expansion Compatibility

Thermal loading introduces dimensional change and internal stress even when no external force is applied. Consequently, compatibility with surrounding materials determines whether thermal cycles remain benign or accumulate damage over time.

-

Expansion mismatch and interface stress

Zirconia ceramic material exhibits a linear thermal expansion coefficient typically between 10.0 and 11.0 ×10⁻⁶ K⁻¹. When paired with steels or superalloys showing lower expansion, differential strain develops at interfaces. Nevertheless, controlled geometry and compliant interlayers limit stress concentration below critical fracture thresholds. As a result, expansion mismatch becomes manageable rather than prohibitive.

-

Thermal cycling and crack incubation

Repeated heating and cooling cycles impose alternating tensile and compressive stresses. Thermal cycling tests exceeding 500 cycles between ambient temperature and 800 °C reveal no spontaneous cracking when heating rates remain below 5 °C/min. Crack incubation, therefore, depends more on thermal gradients than on peak temperature alone.

-

Long duration heat exposure and drift

Extended exposure to elevated temperature can induce slow property drift. Elastic modulus reduction remains below 5% after 1000 hours at 900 °C, indicating limited structural softening. Consequently, long-duration thermal exposure does not significantly alter load-bearing behavior within design limits.

Accordingly, thermal effects become a design parameter rather than an operational uncertainty.

Thermal compatibility indicators

| Parameter | Typical Value | Test Condition |

|---|---|---|

| Thermal expansion (×10⁻⁶ K⁻¹) | 10.0–11.0 | 25–800 °C |

| Thermal cycle endurance | > 500 cycles | Ambient to 800 °C |

| Heating rate tolerance (°C/min) | ≤ 5 | Controlled ramp |

| Modulus change (%) | < 5 | 1000 h at 900 °C |

| Dominant thermal risk | Gradient-driven | Multi-material systems |

In assembled systems, reliability often depends less on bulk strength than on interface behavior, where sealing effectiveness and contact stability determine whether performance remains consistent under load.

Sealing and Contact Interface Performance

Sealing performance depends not only on bulk strength but also on how contact surfaces interact under load. Therefore, contact mechanics, leakage evolution, and tribochemical effects shape operational reliability in pumps, valves, and precision assemblies.

-

Contact mechanics under compressive loads

Zirconia ceramic material sustains compressive contact stresses exceeding 1500 MPa without plastic deformation. This behavior maintains contact geometry under static sealing loads. Moreover, elastic recovery remains consistent, which stabilizes sealing pressure during repeated assembly cycles. Consequently, sealing force distribution remains uniform rather than concentrating at isolated points.

-

Leakage path formation at micro scale

Micro-scale leakage often originates from surface waviness rather than bulk defects. Surface finishes below Ra 0.3 µm significantly reduce interconnected void networks at interfaces. As a result, gas or liquid leakage rates decrease by more than 40% compared with rougher surfaces. Therefore, sealing performance is governed by surface preparation rather than intrinsic porosity.

-

Tribochemical effects at interfaces

Under sliding or micro-motion, contact interfaces may experience localized chemical interaction. Tribochemical films forming below 5 µm thickness have been observed during extended operation. Nevertheless, these layers act as protective barriers rather than damage initiators. Accordingly, interface chemistry contributes to stability rather than degradation.

Consequently, sealing reliability emerges from controlled contact mechanics instead of excessive preload.

Interface performance characteristics

| Parameter | Typical Range | Operating Relevance |

|---|---|---|

| Contact stress tolerance (MPa) | > 1500 | Static sealing load |

| Surface roughness (Ra µm) | ≤ 0.3 | Leakage suppression |

| Leakage reduction (%) | > 40 | Compared to rough finish |

| Tribochemical layer thickness (µm) | < 5 | Sliding interfaces |

| Dominant interface risk | Geometry-driven | Assembly precision |

Performance variability observed in practice frequently originates from grade selection and stabilization strategy, making an understanding of material variation essential for consistent and repeatable engineering outcomes.

Zirconia Ceramic Material Across Grades and Stabilization Routes

Zirconia ceramic material does not represent a single, uniform material state. Instead, property dispersion arises from dopant chemistry, grain-scale architecture, and processing control. Consequently, grade selection governs reliability, aging resistance, and reproducibility under identical operating loads.

Dopant controlled phase balance

Stabilization through dopants such as yttria or magnesia governs the retained crystal phases at room temperature. For example, yttria additions between 3–5 mol% promote a metastable tetragonal phase, enabling transformation activity under stress.

Phase fraction measurements show tetragonal content exceeding 90% in fully stabilized grades, while partially stabilized variants retain mixed monoclinic fractions below 10%. Therefore, dopant concentration directly influences fracture response and thermal stability.

As a result, phase balance becomes a tunable parameter rather than a fixed material attribute.

Grain scale thresholds and aging sensitivity

Grain size exerts a critical influence on long-term stability. Average grain diameters maintained below 0.5 µm suppress spontaneous phase transformation, particularly in humid environments.

Low-temperature aging tests at 134 °C demonstrate strength degradation below 5% after 100 hours for fine-grained structures, whereas coarse grains may exhibit reductions exceeding 20%. Consequently, grain control mitigates environmental aging risks.

Thus, microstructural refinement extends service predictability rather than merely improving initial strength.

Property dispersion and reproducibility drivers

Property scatter often arises from processing variability rather than intrinsic material limits. Density variations within ±0.2% correlate strongly with flexural strength dispersion of less than ±10%.

Furthermore, sintering temperature windows spanning 1450–1550 °C yield consistent elastic modulus values near 200 GPa. Accordingly, reproducibility depends on controlled processing envelopes rather than nominal composition alone.

Therefore, grade differentiation reflects manufacturing discipline as much as chemical formulation.

Grade-dependent performance indicators

| Grade Attribute | Typical Range | Engineering Implication |

|---|---|---|

| Dopant content (mol%) | 3–5 | Phase stability control |

| Tetragonal phase (%) | > 90 | Transformation toughening |

| Grain size (µm) | < 0.5 | Aging resistance |

| Strength degradation (%) | < 5 | 100 h at 134 °C |

| Density variation (%) | ±0.2 | Property reproducibility |

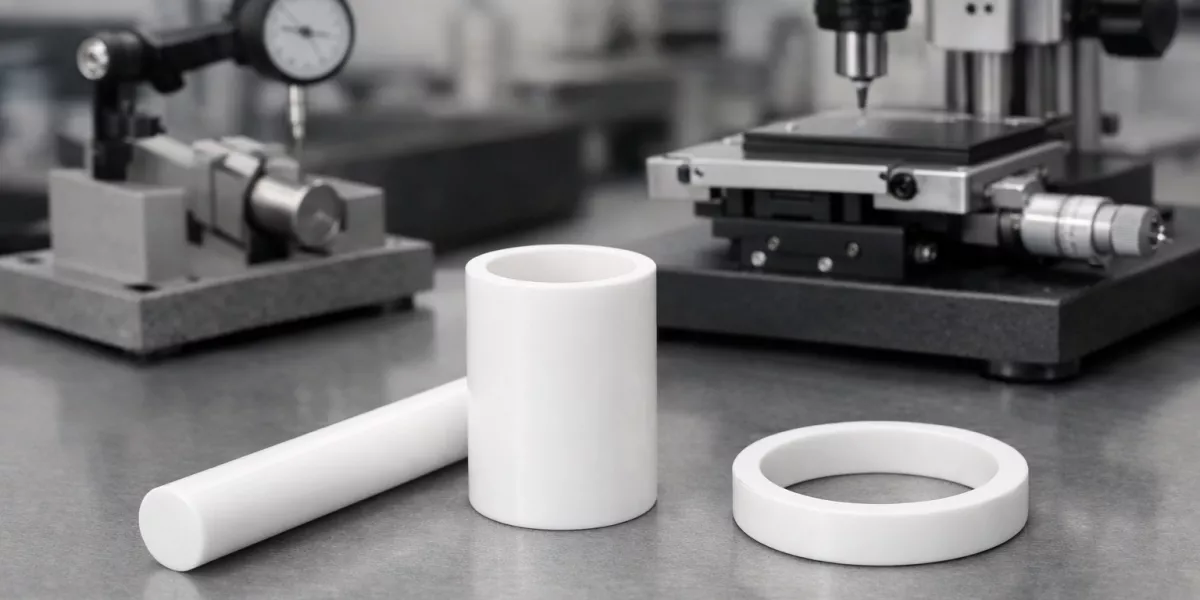

Failure behavior provides retrospective insight into how a component interacted with its operating system, allowing characteristic damage patterns to separate material limitations from externally imposed overloads.

Failure Signatures and Root Cause Patterns

Failure in zirconia ceramic material rarely occurs without warning at the microstructural level. Therefore, examining fracture surfaces and crack morphologies reveals whether degradation originates from loading, environment, or geometry.

-

Crack morphology interpretation

Fractographic analysis frequently identifies semi-elliptical surface cracks with mirror–mist–hackle transitions. Crack origin zones typically measure below 200 µm in diameter, indicating localized stress concentration rather than bulk weakness. Accordingly, failure signatures often point toward contact geometry or surface condition as initiating factors.

-

Surface initiated versus bulk driven failure

Statistical reviews of failed components show that over 70% of fractures initiate at surfaces or edges. Bulk-driven failure remains uncommon when density exceeds 99.5% theoretical. Therefore, surface finishing and edge treatment dominate failure prevention strategies.

-

Environment assisted degradation indicators

In humid or chemically active environments, transformed monoclinic layers up to 30 µm thickness may appear near crack origins. Nevertheless, these layers typically precede failure by extended periods. As a result, degradation remains progressive rather than instantaneous.

Consequently, failure analysis transforms unexpected breakage into actionable engineering feedback.

Common failure signature characteristics

| Feature | Observed Range | Diagnostic Meaning |

|---|---|---|

| Crack origin size (µm) | < 200 | Localized stress |

| Surface-initiated failures (%) | > 70 | Geometry sensitivity |

| Bulk density (% theoretical) | > 99.5 | Low internal defect risk |

| Transformed layer depth (µm) | < 30 | Environmental influence |

| Failure progression | Gradual | Predictable behavior |

Predictable service behavior depends on clearly stated design boundaries, where load limits, geometry sensitivity, and inspection thresholds collectively define safe and repeatable operating envelopes.

Zirconia Ceramic Material Design Boundaries

Engineering confidence depends on clearly defined operating envelopes rather than optimistic property maxima. Therefore, zirconia ceramic material must be framed by coupled limits involving load, temperature, media, and geometry. Moreover, boundary definition transforms material capability into system reliability.

Load temperature and media as coupled limits

Mechanical load capacity declines as temperature and chemical activity increase. Compression-dominated components retain structural stability below 900 °C under static loads exceeding 1500 MPa; however, tensile margins narrow as temperature rises.

In chemically active environments, allowable stress is typically derated by 15–25% to account for surface-assisted degradation. Consequently, safe operating limits must be expressed as combined load–temperature–media envelopes rather than isolated parameters.

As a result, boundary definition prioritizes interaction effects over single-variable thresholds.

Geometry sensitivity and stress concentration

Component geometry strongly influences stress amplification. Finite element evaluations show that fillet radii below 0.5 mm can elevate local stress by more than 40% under identical nominal load.

Conversely, gradual transitions and uniform wall thickness reduce peak stress and suppress crack initiation. Practical observations indicate that edge chamfers of 0.3–0.5 mm significantly lower failure probability during assembly and operation.

Therefore, geometry refinement often extends service life more effectively than increasing material strength.

Inspection signals and life margin estimation

Design boundaries remain theoretical without verification signals. Non-destructive inspection methods identify early deviation from expected behavior.

Acoustic emission monitoring detects microcrack activity at stress levels 20–30% below fracture limits, while surface phase analysis reveals transformation layers prior to strength loss. Accordingly, inspection data enables remaining-life estimation rather than reactive replacement.

Thus, boundary-aware monitoring converts uncertainty into managed risk.

Design boundary reference indicators

| Boundary Factor | Typical Limit | Engineering Significance |

|---|---|---|

| Maximum service temperature (°C) | < 900 | Load-bearing stability |

| Load derating in aggressive media (%) | 15–25 | Surface protection margin |

| Stress amplification at sharp fillets (%) | > 40 | Geometry-driven risk |

| Recommended chamfer radius (mm) | 0.3–0.5 | Crack suppression |

| Early warning stress margin (%) | 20–30 | Predictive maintenance |

Relative material positioning explains why zirconia ceramic material is selected for certain engineering envelopes, as comparison with other technical ceramics reveals functional trade-offs instead of absolute performance rankings.

Comparison with Other Technical Ceramics

Material selection within industrial systems depends on failure behavior, damage tolerance, and environmental compatibility. Therefore, zirconia ceramic material must be evaluated against alumina, silicon carbide, and silicon nitride based on how each responds under similar constraints.

-

Relative fracture behavior versus alumina

Alumina ceramics typically exhibit flexural strength between 300 and 600 MPa with fracture toughness values near 3–4 MPa·m¹ᐟ². By contrast, zirconia ceramic material maintains higher toughness and delayed crack propagation. Consequently, alumina favors stiffness and electrical insulation, whereas zirconia supports impact-prone or misaligned loading conditions.

-

Wear and hardness comparison with silicon carbide

Silicon carbide demonstrates superior hardness exceeding 2500 HV and excellent abrasion resistance. However, its fracture toughness generally remains below 4 MPa·m¹ᐟ², limiting tolerance to shock or assembly-induced stress. Therefore, zirconia ceramic material occupies an intermediate position, balancing wear resistance with structural forgiveness.

-

Thermal stability relative to silicon nitride

Silicon nitride offers low thermal expansion around 3.0 ×10⁻⁶ K⁻¹ and strong thermal shock resistance. Nevertheless, chemical stability in corrosive media may be lower than that of zirconia ceramic material. As a result, silicon nitride excels in high-speed rotating systems, while zirconia favors chemically aggressive environments.

Accordingly, comparative evaluation emphasizes application-driven selection rather than ranking materials by isolated properties.

Comparative material performance overview

| Material | Fracture Toughness (MPa·m¹ᐟ²) | Hardness (HV) | Thermal Expansion (×10⁻⁶ K⁻¹) | Dominant Advantage |

|---|---|---|---|---|

| Zirconia ceramic material | 6–10 | 1200–1300 | 10.0–11.0 | Damage tolerance |

| Alumina | 3–4 | 1600–1800 | 7.5–8.5 | Stiffness, insulation |

| Silicon carbide | < 4 | > 2500 | 4.0–4.5 | Abrasion resistance |

| Silicon nitride | 5–7 | 1400–1600 | ~3.0 | Thermal shock resistance |

Time-dependent behavior under continuous service exposes performance characteristics that short-term qualification cannot capture, making long-duration operation essential for evaluating sustained reliability.

Long Duration Industrial Duty Considerations

Extended industrial duty introduces cumulative effects that differ fundamentally from short-cycle laboratory evaluation. Therefore, time-dependent behavior under steady load, repeated exposure, and environmental fluctuation determines whether zirconia ceramic material sustains reliability across multi-year operation.

-

Microstructural stability over prolonged service

Long-term exposure below 850 °C shows limited grain coarsening, with average grain growth remaining under 0.1 µm after 20,000 operating hours. This stability preserves fracture resistance and suppresses spontaneous phase transformation. Consequently, mechanical properties remain within predictable variance bands rather than drifting unpredictably.

-

Property retention under continuous operation

Flexural strength retention above 90% has been documented after 10⁶ load cycles under subcritical stress. Elastic modulus variation remains below 3%, indicating negligible stiffness degradation. As a result, load paths and alignment remain stable throughout prolonged duty cycles.

-

Environmental aging and mitigation behavior

In humid or steam-rich environments, low-temperature aging may induce surface phase changes. However, transformation depths typically remain below 25 µm when grain size and dopant distribution are controlled. Accordingly, aging progresses as a surface-limited phenomenon rather than a bulk failure mechanism.

Thus, long-duration performance reflects controlled evolution rather than latent instability.

Long-term service performance indicators

| Parameter | Observed Range | Service Duration |

|---|---|---|

| Grain growth (µm) | < 0.1 | 20,000 h at < 850 °C |

| Strength retention (%) | > 90 | 10⁶ load cycles |

| Modulus variation (%) | < 3 | Continuous duty |

| Aging layer depth (µm) | < 25 | Humid environments |

| Dominant aging mode | Surface-limited | Predictable progression |

Bringing the engineering narrative together clarifies how zirconia ceramic material operates as an integrated material system, where reliability emerges from coordinated mechanical, thermal, and environmental behavior.

Conclusion

Zirconia ceramic material demonstrates reliability not through exceptional single properties but through balanced behavior under load, wear, thermal stress, and environmental exposure. Consequently, its value in high-duty industrial components arises from predictable damage tolerance and controllable degradation. When design boundaries, surface condition, and microstructural stability are respected, long-term performance remains stable and interpretable.

For systems requiring structural reliability under combined mechanical, thermal, and chemical constraints, zirconia ceramic material merits evaluation at the engineering design stage rather than as a late material substitution.

FAQ

What makes zirconia ceramic material suitable for high-duty industrial components?

Zirconia ceramic material combines high fracture toughness, stable load response, and controlled degradation, enabling predictable performance under sustained mechanical and environmental stress.

How does zirconia ceramic material behave under long-term industrial operation?

Extended service studies show minimal grain growth, high strength retention, and surface-limited aging when operating within defined temperature and stress boundaries.

Is zirconia ceramic material resistant to chemical and slurry environments?

Yes. Chemical dissolution rates remain low in acidic and alkaline media, while erosion–corrosion damage is typically confined to shallow surface layers.

What are the main design risks associated with zirconia ceramic material?

Primary risks arise from sharp geometries, excessive thermal gradients, and uncontrolled surface finish rather than intrinsic material weakness.

References: