ZrO₂ Ceramics Solutions for High Temperature & Wear Control by ADCERAX®

Zirconia Ceramics are engineered for equipment operating under intense friction loads and thermal cycles, providing reliable performance in abrasive and corrosive environments.

These materials maintain mechanical integrity up to 2200 °C.

ADCERAX® guarantees stable performance through controlled sintering and dimensional inspection.

continuous to 2200 °C.

< 0.1 %.

impact wear control.

> 2000 MPa.

Advanced Zirconia Ceramics Built for Industrial Resilience

Zirconia Ceramics are engineered ceramic materials designed to withstand extreme wear, corrosion, and thermal shocks in high-value industrial systems. These components are preferred where metallic parts fail under aggressive media or magnetic sensitivity.

Built from ZrO₂ Ceramic stabilized with yttria or magnesia, they offer unmatched dimensional precision and mechanical reliability.

Each Zirconium oxide ceramic part supports both standard and complex geometries with stable microstructure and low porosity.

≤ 2000 MPa compressive load

supports 2200 °C in open flame

resistivity exceeds 10¹² Ω·cm

stable in acid/alkali conditions

Technical Foundation Behind ADCERAX® Zirconia Ceramics Performance

Zirconia Ceramics offer a balanced combination of thermal endurance, electrical insulation, chemical stability, and mechanical toughness for mission-critical use.

Thermal Properties of Zirconia Ceramics

| Test Parameter | Y‑TZP | PSZ | MSZ |

|---|---|---|---|

| Maximum Service Temperature | 2200 °C | 2100 °C | 1900 °C |

| Thermal Expansion Coefficient (20–1000 °C) | 10.3×10⁻⁶/K | 10.5×10⁻⁶/K | 9.6×10⁻⁶/K |

| Thermal Conductivity (W/m·K) | 2.5 | 2.2 | 2.0 |

| Specific Heat Capacity (J/g·K) | 0.46 | 0.42 | 0.38 |

| Thermal Shock Resistance (ΔT failure threshold) | >300 °C | ~250 °C | ~220 °C |

Electrical Properties of Zirconia Ceramics

| Test Parameter | Y‑TZP | PSZ | MSZ |

|---|---|---|---|

| Volume Resistivity (Ω·cm at 20 °C) | >1×10¹² | >1×10¹¹ | >1×10¹¹ |

| Surface Resistivity (Ω) | >1×10¹³ | >1×10¹² | >1×10¹² |

| Dielectric Constant (1 MHz) | ~25 | ~23 | ~21 |

| Dielectric Strength (kV/mm) | >18 | >16 | >15 |

| Electrical Breakdown Voltage (kV) | ~30 | ~28 | ~25 |

Chemical Properties of Zirconia Ceramics

| Test Parameter | Y‑TZP | PSZ | MSZ |

|---|---|---|---|

| Apparent Porosity (%) | <0.1 | <0.2 | <0.3 |

| Acid Resistance (HCl, 24h) | No visible attack | No visible change | Slight haze |

| Alkali Resistance (NaOH, 24h) | No visible change | Minor surface dullness | Surface layer affected |

| Density (g/cm³) | 6.05 | 5.85 | 5.70 |

| Water Absorption (%) | <0.01 | <0.02 | <0.03 |

Mechanical Properties of Zirconia Ceramics

| Test Parameter | Y‑TZP | PSZ | MSZ |

|---|---|---|---|

| Flexural Strength (MPa) | ≥1000 | ~850 | ~650 |

| Compressive Strength (MPa) | ≥2000 | ~1800 | ~1500 |

| Vickers Hardness (HV0.5) | >1200 | ~1150 | ~1000 |

| Fracture Toughness (MPa·m½) | 7–11 | 6–8 | 5–6 |

| Young’s Modulus (GPa) | ~210 | ~200 | ~180 |

Custom Types of ADCERAX® Zirconia Ceramic Products & Parts

ADCERAX® provides precision-engineered Zirconia Ceramics across 9 product categories, each designed for distinct high-performance industrial uses.

Zirconia Tubes

Used for gas flow control, insulation and thermal processing applications.

- Supports 2200 °C operation

- Excellent acid/base resistance

- Precise outer/inner dimensions

Zirconia Rods

Ideal for drive shafts, guide pins, alignment parts and non-metallic bearings.

- High flexural strength > 1000 MPa

- Non-magnetic, corrosion-proof

- Surface Ra < 0.2 μm finish

ZrO2 Crucibles

Engineered for oxide melting, high-temp reaction containment, and vacuum sintering.

- Stable at 2200 °C in air

- Thermal shock resistance > 300 °C

- Inert to molten metals and slags

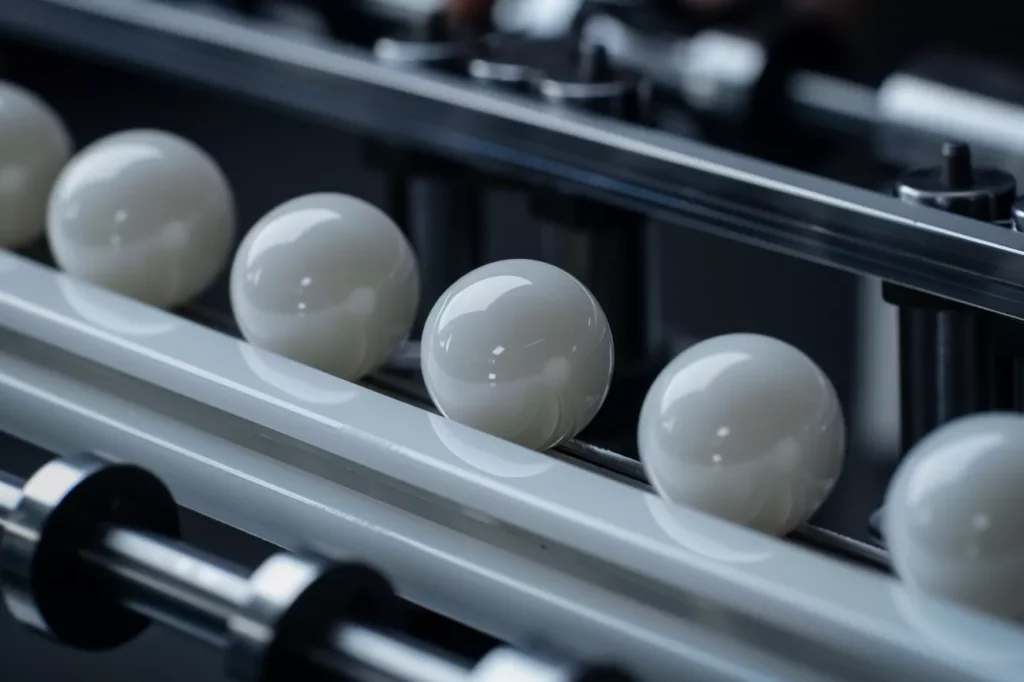

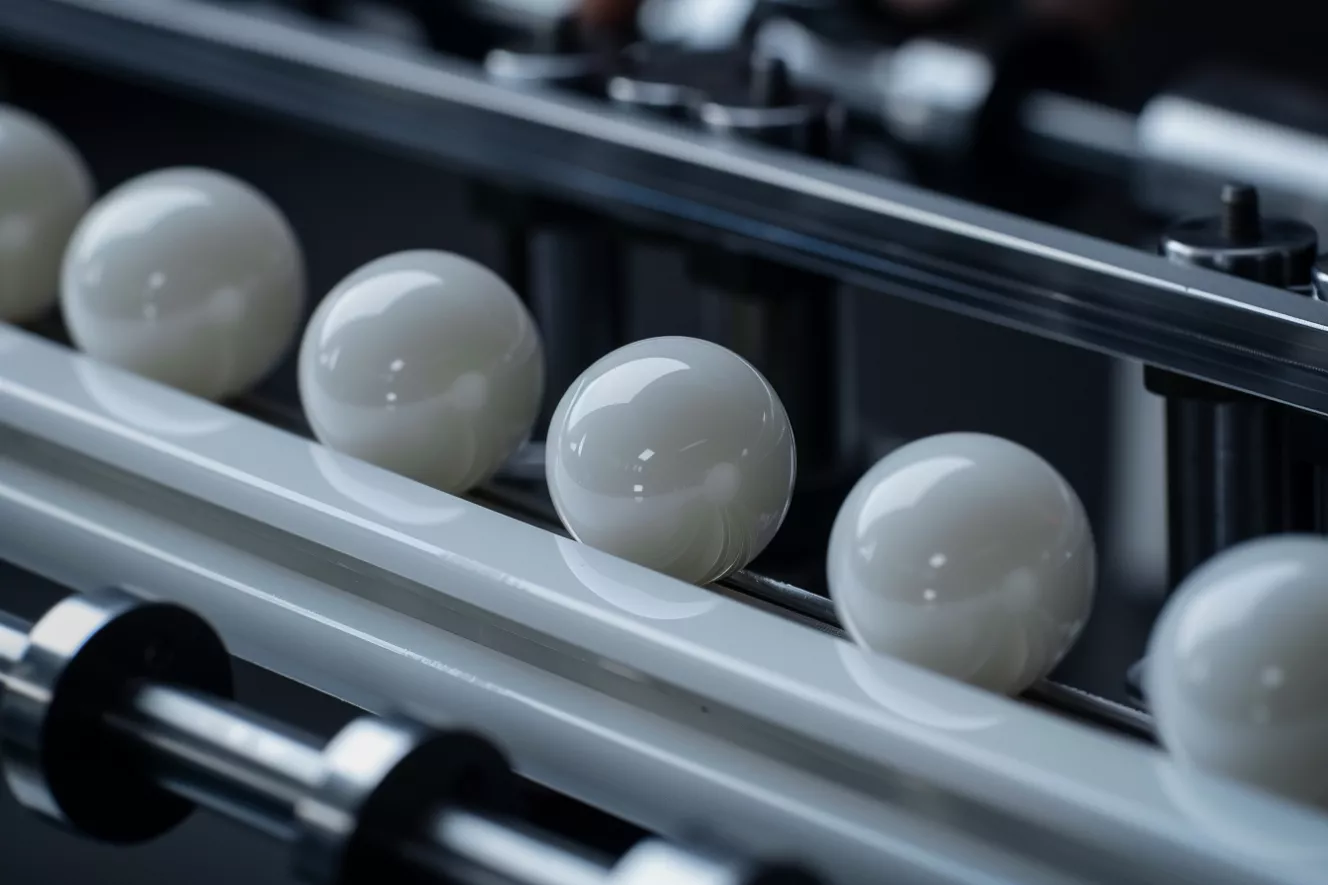

ZrO2 Balls

Applied in mechanical bearings, dispersing media, and rotational alignment.

- Hardness > 1200 HV, non-magnetic

- High density: 6.05 g/cm³

- Low wear rate < 0.1×10⁻⁶ cm³/N·m

Zirconia Valve

Designed for fluid control in abrasive, acidic, or high-pressure systems.

- Leak-proof sealing under pressure

- Corrosion-resistant in slurry lines

- Certified ISO/REACH/RoHS materials

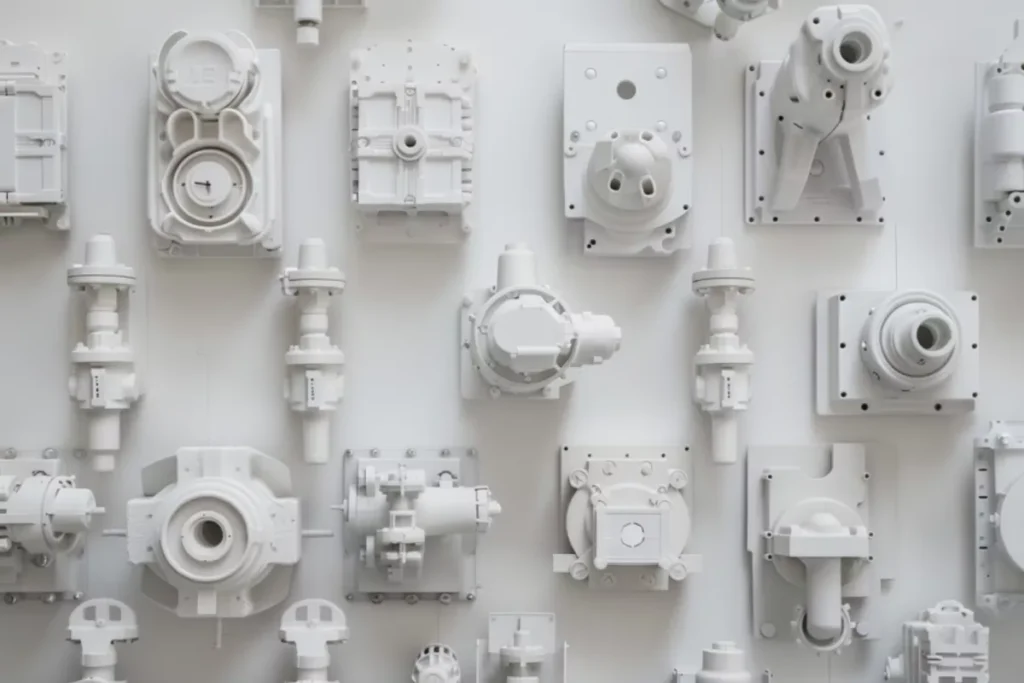

Zirconia Pump

Critical in metering, filling, and dosing tasks for chemical and medical systems.

- Precision plunger and pump bodies

- CHigh cycle life > 10× metal

- Dimensional stability under heat

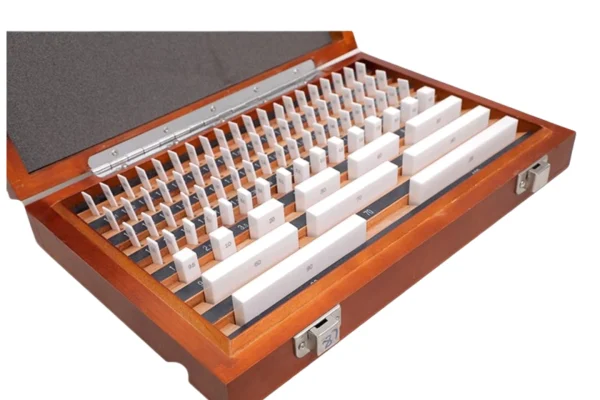

ZrO2 Gauges

Used in tool calibration, tolerance setting and automated detection lines.

- ±0.001 mm dimensional tolerance

- No oxidation or deformation

- Wear resistance > 10⁶ cycles

ZrO2 Plates

Used as thermal supports, fixture bases, or insulation interfaces.

- Dielectric strength > 18 kV/mm

- Thermal shock ΔT > 300 °C

- Available in polished or porous

Zirconia Parts

Custom-shaped parts for mechanical systems, sensors, and material handling tools.

- Precision-fit in high-wear systems

- Stable up to 2200 °C

- Corrosion-proof under load

We maintain a ready stock of standard zirconia ceramic products, ensuring 24-hour dispatch for urgent requirements, enabling you to minimize downtime and maintain operational continuity.

Where ADCERAX® Zirconia Ceramics Deliver Industrial Impact

High-Temperature Structural Systems

Zirconia Ceramics are ideal for resisting deformation and thermal shock in demanding heating environments.

- Zirconia Tube for furnace insulation conduits

- Zirconia Plate as kiln setters and support bases

- Zirconia Crucible for high-purity oxide melting

Designed to maintain structural integrity in kilns, reactors, and sintering furnaces operating beyond 2000 °C. Zirconia ceramics minimize heat distortion and ensure stable process control.

Corrosive Fluid Control Equipment

In acid/alkaline slurries or solvent systems, Zirconium oxide ceramics maintain sealing and dimensional integrity.

- Zirconia Valve for abrasive media isolation

- Zirconia Pump in chemical and pharmaceutical dosing

- Zirconia Ceramic Components for wear-resistant seats and guides

Built for aggressive chemical and slurry systems where metal valves or pumps fail. The dense ZrO₂ ceramics structure prevents corrosion and leakage under continuous operation.

Precision Motion & Bearing Systems

These non-magnetic and wear-resistant parts ensure stability under dry run and high-speed rotation.

- Zirconia Rods for shafts and alignment pins

- Zirconia Balls & Beads in dry or lubricated bearings

- Zirconia Ceramic Gauge in micron-level measurement jigs

Used in robotic axes, miniature drives, and precision bearings where non-magnetic, friction-stable materials ensure accurate mechanical response.

Grinding, Dispersion & Slurry Systems

ZrO₂ Ceramics offer dense, inert grinding interfaces for particle-size-critical processes.

- Zirconia Balls & Beads for wet milling of battery slurry

- Zirconia Ceramic Components for rotor and disc elements

- Zirconia Crucible in pigment formulation and calcination

Optimized for particle uniformity and minimal contamination. Zirconia grinding media and components enable reliable dispersion for pigments and battery materials.

Electronic, Sensor & Isolation Devices

Zirconia ceramic insulators protect signal integrity in electrically sensitive systems and harsh environments.

- Zirconia Plate for insulating interface assemblies

- Zirconia Ceramic Components in injector pins and flanges

- Zirconia Tube for thermocouple sheath protection

Applied in oxygen sensors, injector modules, and electronic housings. Zirconia ceramics ensure insulation stability and high dielectric strength in fluctuating conditions.

Empowering Precision: ADCERAX® Services & Capabilities for Zirconia Ceramic Machining

Integrated Processing Services from Raw to Ready

ADCERAX® offers full-spectrum zirconia ceramic machining services—from blank preparation to final precision finishing. Each production step is quality-tracked to ensure repeatable performance in demanding industrial applications.

Zirconia blanks procured to specification standards

Precision shaping using advanced CNC equipment

Sub-micron dimensional control across part geometries

Each piece verified under strict tolerance criteria

Complex shapes bonded or inserted with metal/glass

Removal of micro-particle residues post-processing

Advanced Facilities and Process Expertise Behind Every Zirconia Part

The machining of ZrO₂ ceramics at ADCERAX® is enabled by a fusion of high-performance equipment and skilled ceramic engineers. This integration ensures that zirconia components achieve their designed function, even in high-load, high-wear environments.

| Category | Specification | Detail | Application Focus |

|---|---|---|---|

| Machining Center | 5-axis CNC Milling Systems | ±0.01 mm repeat accuracy | High-precision bearing and valve parts |

| Laser Equipment | Industrial Laser Marking and Engraving | 0.02 mm linewidth resolution | Code traceability, ID marking |

| Inspection Tools | Digital Micrometers & CMMs | Tolerance verification to ±0.002 mm | Quality assurance for custom fittings |

| Forming Tools | Hydraulic Isostatic Presses (CIP) | Uniform density up to 3.5 g/cm³ | Critical shaping for rod and sleeve blanks |

| Thermal Processing | High-Temp Sintering Furnaces (up to 1700°C) | Controlled shrinkage and grain growth | Densification of zirconia structures |

| Polishing Lines | Precision Lapping & Polishing Machines | Surface roughness Ra < 0.2 µm | Optical-grade and fluid-contact surfaces |

| Threading Units | Ultrasonic and Diamond Tooling Systems | Non-metallic thread forming | M6/M8 ports and custom fluidic joints |

| Batch Traceability | ERP-Integrated Manufacturing Record System | Full-process material batch logging | Critical for regulated industry supply |

Precision in ADCERAX® Zirconia Ceramic Machining

CNC Ultra-Fine Turning for

Cylindrical Components

The cylindrical turning process is performed with micron-level control on high-rigidity CNC lathes.

Equipped with ±2 µm precision spindle

Mirror-grade on outer diameter

Applied on zirconia shaft rods

Ensures both throughput and accuracy

Fit for rotating or sliding functions

Multi-Axis Grinding for Flat and Step Features

Step faces and precision flats are ground using 5-axis grinders with dynamic toolpath compensation.

Enables sub-±0.005 mm correction

Achieved on jigs, plates, rings

For safe assembly and stress relief

Maintains profile through tool life

Suitable for tooling and alignment

Laser-Assisted Drilling for Micro Pores and Slots

Advanced laser CNC platforms allow non-contact, thermally-stable drilling of dense zirconia ceramics.

High-frequency pulsed UV laser

Uniformity across dense batches

No chipping at exit points

Maintains zirconia grain structure

Ideal for critical fluidic precision

Let our advanced capabilities bring your ceramic component vision to life.

Customized Zirconia Ceramics

ADCERAX® offers full-spectrum customization of zirconia ceramic components tailored to demanding industrial applications. From prototype engineering to batch-scale manufacturing, every detail is optimized for performance, durability, and fit.

2200 °C

Thermal Stability Design

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX for Your Zirconia Ceramic Needs?

Choosing the right advanced ceramic supplier is crucial for the success of your industrial projects. ADCERAX stands out as a reliable and competitive partner.

Direct manufacturer eliminating intermediaries for cost-effective solutions without compromising quality.

20+ years of B2B experience providing unparalleled technical support and collaborative design.

Agile manufacturing for small-batch customization and rapid prototyping capabilities.

Stringent quality measures from raw material inspection to final product testing.

24-hour response guarantee with dedicated support for global clientele.

Trusted by global customers for advanced ceramic materials and precision components.

Technical Questions Answered About ADCERAX® Zirconia Ceramics Custom Machining

ADCERAX® Zirconia Ceramics can withstand continuous use up to 2200 °C, far exceeding the limits of metals and alumina. This makes them ideal for high-temperature reactors, furnaces, and thermal barrier systems. The material maintains mechanical integrity even under prolonged thermal cycling.

Zirconia’s low thermal conductivity and high fracture toughness enable excellent thermal shock resistance. Rapid temperature fluctuations are tolerated better than with most ceramics, minimizing crack propagation risks. This property is essential in dynamic thermal environments like kilns or crucibles.

- ADCERAX® Zirconia offers a Vickers hardness of over 1200 HV, enabling extreme wear resistance under friction, sliding, or abrasive contact. This ensures long service life in applications like plungers, shafts, and valve components under repetitive motion.

Yes. Zirconia Ceramics exhibit outstanding chemical inertness against acids, alkalis, and most solvents. This stability ensures corrosion-free performance in chemical reactors, semiconductor cleaning tools, and pharmaceutical systems.

ADCERAX® precision machining delivers tight tolerances down to ±0.01 mm. Post-sintering grinding allows accurate dimensions for integration into mechanical systems requiring interference or transition fits.

Zirconia Ceramics are excellent electrical insulators with volume resistivity >10¹² Ω·cm. They are used in high-voltage, high-frequency, and sensitive electronic environments where dielectric isolation is critical.

Partially stabilized Zirconia exhibits transformation toughening, making it up to 3–5× tougher than alumina. This mechanism allows it to absorb more energy before cracking, ideal for structural and load-bearing components.

High-gloss polishing or fine-ground matte finishes can be achieved, with surface roughness (Ra) below 0.2 µm. This is essential for medical tools, precision metrology, or fluid handling systems requiring ultra-smooth surfaces.

Zirconia possesses a compressive strength exceeding 2000 MPa, enabling its use in high-load environments such as hydraulic valves, piston rings, and punch tools. Unlike metals, it resists plastic deformation even under extreme forces.

Yes. Owing to transformation toughening and high fracture energy, ADCERAX® Zirconia Ceramics outperform traditional ceramics in resisting mechanical impact. This is valuable for mobile tools and high-speed moving parts.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact ADCERAX for Your Zirconia Ceramic Solutions

Ready to elevate your industrial applications with high-performance zirconia ceramics? Whether you need standard products or custom-engineered solutions, ADCERAX is your trusted partner.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours