High-Density Zirconia Balls for Industrial Applications by ADCERAX®

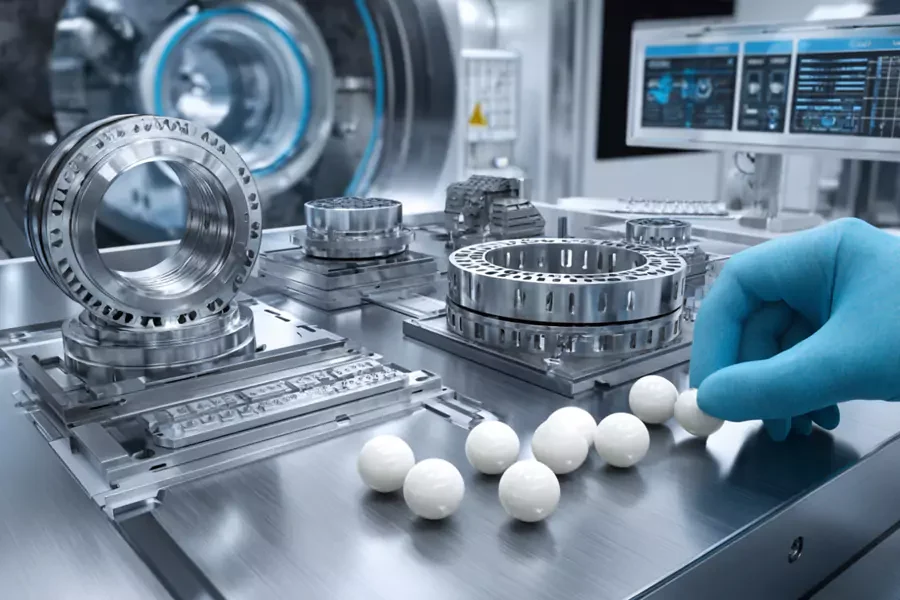

Zirconia Balls with high density are engineered to deliver durability, precision, and chemical stability across multiple industries. They function as efficient grinding media in milling processes and as reliable rolling elements in bearings and valves. Their low wear rate, smooth surfaces, and strong resistance to corrosion help extend equipment service life and reduce contamination risks.

ADCERAX® provides factory-direct supply of Zirconia Balls, including grinding balls, zirconia beads, and zirconia bearing balls. With support for technical drawings, strict ISO and REACH compliance, and flexible customization. ADCERAX® offers high-density ceramic ball solutions tailored to demanding environments.

Contact ADCERAX® today for your Zirconia Balls requirements.

±0.01 mm

Diameter precision control

What is a Zirconia Ball?

Zirconia Balls are dense ceramic spheres made from stabilized ZrO₂, valued for their strength, hardness, and stability. These zirconia ceramic balls are widely used in both grinding systems and precision bearings.

Their smooth surfaces and low wear rate reduce contamination, while their resistance to heat and chemicals supports reliable use across industries.

Performance Values of ADCERAX® Zirconia Balls

The material properties of Zirconia Balls define their reliability in industrial use. At ADCERAX®, these values are consistently achieved through careful process control and attention to detail.

| Technical Specification Table | ||

|---|---|---|

| Parameter | Typical Value Range | |

| Density | ~6.0 g/cm³ (Y-TZP grade) | |

| Hardness (Vickers) | 1200 – 1300 HV | |

| Fracture Toughness | 7 – 10 MPa·m½ | |

| Compressive Strength | > 2000 MPa | |

| Thermal Expansion (CTE) | 10 × 10⁻⁶/K (25–500°C) | |

| Electrical Properties | Insulating, non-conductive | |

| Chemical Resistance | Stable in acids and alkalis | |

Characteristics of ADCERAX® Zirconia Balls

The unique performance of Zirconia Balls comes from a balance of chemical stability, physical density, and mechanical strength. These qualities make them a trusted choice for engineers worldwide.

Chemical Properties

ADCERAX® Zirconia ceramic Balls remain stable even in aggressive environments.

- Resist acids and alkalis, withstand pH 2–12 reliably

- Non-magnetic, insulating above 10¹² Ω·cm

- Inert surface reduces contamination risk by >95%

Physical Properties

ZrO2 Balls provide consistent performance under thermal and structural stress.

- Density ~6.0 g/cm³ ensures efficient grinding processes

- Thermal expansion 10 × 10⁻⁶/K maintains dimensional accuracy

- Porosity <0.1% prevents absorption and leakage

Mechanical Properties

Zirconia grinding balls and zirconia bearing balls deliver strength where it matters most.

- Hardness 1200–1300 HV increases wear resistance

- Fracture toughness 7–10 MPa·m½ resists heavy load

- Polished surface Ra <0.05 μm lowers friction effectively

Surface and Purity Features

Zirconia beads and zirconia ceramic balls maintain purity and smooth finishes for sensitive applications.

- >99.9% ZrO₂ purity protects powders and slurries

- Polished surface reduces adhesion by over 90%

- Easy-clean finish ensures repeatable reliable performance

ADCERAX® High-Quality Zirconia Balls Series for Demanding Industries

ADCERAX® zirconia balls are designed in different sizes to meet varied industrial applications. Each type offers reliable performance with properties suited to grinding, dispersion, or precision bearing use.

Pure zirconia mill ball is ideal for ultra-fine particle reduction.

- >99.9% purity prevents contamination

- Polished surface reduces friction losses

- High hardness resists wear damage

Zirconia bearing balls provide stability in precision bearing systems.

- Low friction extends bearing service

- Lightweight design reduces centrifugal force

- Strong corrosion resistance supports chemicals

Shaping Industrial Success with ADCERAX® Zirconia Balls

At ADCERAX®, we are committed to supporting your engineering projects with tailored zirconia balls solutions.

Whether you need grinding media, precision bearing balls, or custom designs, our team offers direct factory supply, technical drawing assistance, and dependable delivery.

Reach out today and let us provide the right ceramic ball solution for your application.

Application Scenarios of ADCERAX® Zirconia Balls

ADCERAX®Zirconia ballsare trusted across many industries for their strength, purity, and durability. Their versatility allows them to serve as grinding media, bearing components, and corrosion-resistant parts in demanding environments.

Grinding and Milling Systems

Zirconia grinding balls and zirconia mill ball support efficient particle size reduction.

- High density increases energy transfer efficiency

- Low wear rate minimizes contamination during milling

- Consistent roundness ensures stable dispersion performance

Precision Bearings

Zirconia bearing balls provide reliable rotation in advanced bearing designs.

- Lightweight structure reduces centrifugal forces at high speeds

- Low friction coefficient extends bearing operating lifetime

- Excellent toughness prevents cracking under heavy load

Automotive and Aerospace

Zirconia balls are applied in engines, turbines, and critical moving parts.

- High strength resists extreme mechanical operating stresses

- Corrosion resistance supports long-term reliability outdoors

- Lightweight design enhances efficiency in rotating systems

Medical and Biotechnology

Zirconia ceramic balls and zirconia beads ensure safe use in healthcare.

- Biocompatible structure suitable for medical environments

- Non-toxic composition supports pharmaceutical processing needs

- Easy cleaning meets sterile production requirements

ADCERAX® One-Stop Service and Strong Manufacturing Capabilities

ADCERAX® One-Stop Services for Reliable Supply

ADCERAX® one-stop approach allows clients to reduce risks and save time. By integrating engineering, production, and distribution, ADCERAX® delivers real value in every project.

- Design Support: We start with drawing assistance to clarify requirements. This reduces miscommunication and speeds up the approval stage.

- Quotation and Pricing: Clients receive transparent and competitive wholesale zirconia ball price. Clear cost structures help them plan budgets with confidence.

- Flexible Ordering: We accept orders without strict minimum quantities. This allows both trial runs and large projects to proceed smoothly.

- Quality Assurance: Every batch is verified by ISO-certified testing. This ensures compliance and reliability as a high pure zirconia ball supplier.

Manufacturing Strength and Processing Capabilities

ADCERAX® demonstrates strong manufacturing capacity for zirconia balls, supported by advanced machinery and strict process control. Our facility integrates precision equipment and skilled engineering teams to ensure both consistency and scalability.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Aspect | Manufacturing Strengths | ||

| Production Equipment | Over 50 CNC machines and automated polishing lines | ||

| Precision Level | Achieves ±0.01 mm tolerance for diameter accuracy | ||

| Annual Capacity | More than 100 million zirconia balls produced yearly | ||

| Testing Systems | Equipped with CMM, hardness testers, SEM analysis | ||

| Quality Standards | ISO 9001 certified, REACH & RoHS compliant processes | ||

| R&D Support | Dedicated engineers for drawings and custom prototyping | ||

customized zirconia balls supplier

We specialize in custom zirconia ceramic balls with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Frequently Asked Questions About Zirconia Balls

Zirconia Balls offer high density and hardness, which improve grinding efficiency and consistency. Their smooth surfaces reduce friction and minimize contamination during milling. This makes them reliable media for ultra-fine dispersion of battery materials, pigments, and ceramics.

Zirconia Balls resist strong acids and alkalis, maintaining stability even in harsh chemical processes. Their inert structure prevents contamination of sensitive slurries and fluids. This reliability extends their service life in pumps, valves, and reactors.

Zirconia Balls are lighter than steel yet highly durable. They reduce centrifugal force at high speeds and minimize wear in bearing tracks. Their resistance to corrosion also supports use in aerospace, medical, and cleanroom applications.

The high fracture toughness of Zirconia Balls minimizes breakage during operation. Their durability extends replacement cycles, reducing maintenance intervals. This lowers operational costs and improves overall productivity.

Zirconia Balls are lighter than steel and have lower friction. They resist corrosion and require less or no lubrication. These advantages extend service life and reduce maintenance compared to conventional steel balls.

Yes, Zirconia Balls maintain strength and dimensional stability under elevated temperatures. They are often used in environments exceeding 1400°C. This makes them ideal for aerospace, automotive, and high-temperature process equipment.

Zirconia Balls can be manufactured with diameter tolerances as tight as ±0.01 mm. This precision ensures reliable performance in critical bearing and valve systems. ADCERAX® maintains strict control to meet engineering specifications.

ADCERAX® supports custom dimensions, surface finishes, and stabilizer grades. Customers can provide drawings or samples for tailored solutions. This flexibility allows integration into specialized equipment and projects.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision Zirconia Ceramic Balls

Looking for a reliable zirconia balls supplier? Let us help you with your next project.

info@adcerax.com

Tel.:

+(86) 0731-74427743

WhatsApp:

+(86)19311583352

Within 24 hours