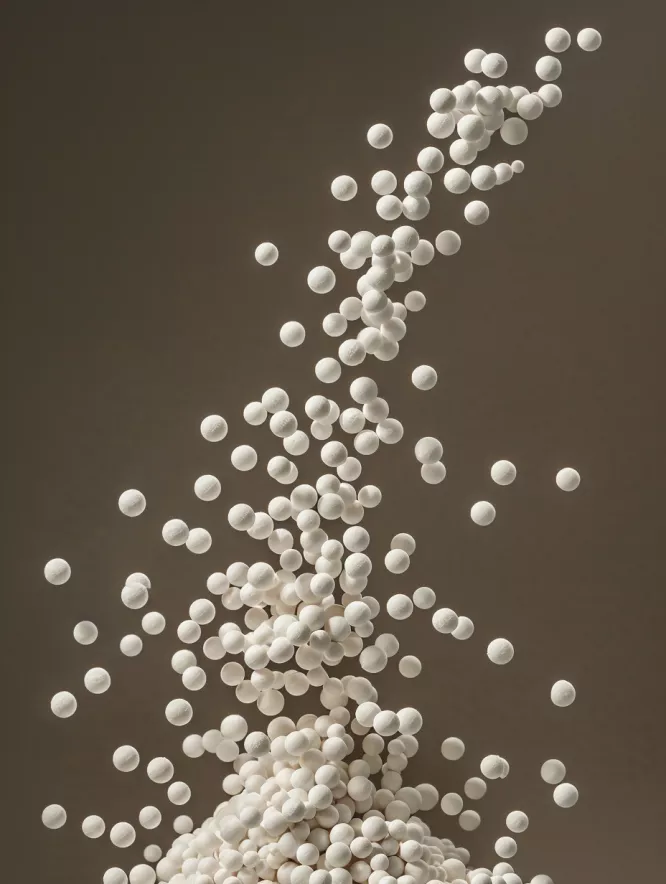

Industrial Zirconia Beads with Consistent Particle Control by ADCERAX®

Zirconia Beads deliver controlled particle behavior and density stability required in demanding milling environments across battery materials, ceramic powders, and coating systems. Their uniform structure supports consistent PSD outcomes even under high-energy or long-duration grinding cycles.

Enhanced resistance to wear allows these beads to maintain efficiency in industrial lines operating under continuous load. Stable morphology across all batches helps reduce quality variation and strengthens reproducibility in large-scale processing.

Contact ADCERAX® for engineering-grade support.

420 MPa

Flexural Strength

What is a Zirconia Bead?

Zirconia Beads are precision-formed ceramic media designed to optimize grinding behavior across nano-dispersion, slurry conditioning, and high-shear milling environments. Their controlled density profile supports stable particle interaction under both high-viscosity and high-energy operating conditions. The uniform microstructure minimizes contamination risk during extended processing, providing a consistent foundation for powder transformation and slurry preparation.

These characteristics allow zirconia ceramic beads to deliver dependable performance in industrial systems where repeatability and quality control are essential.

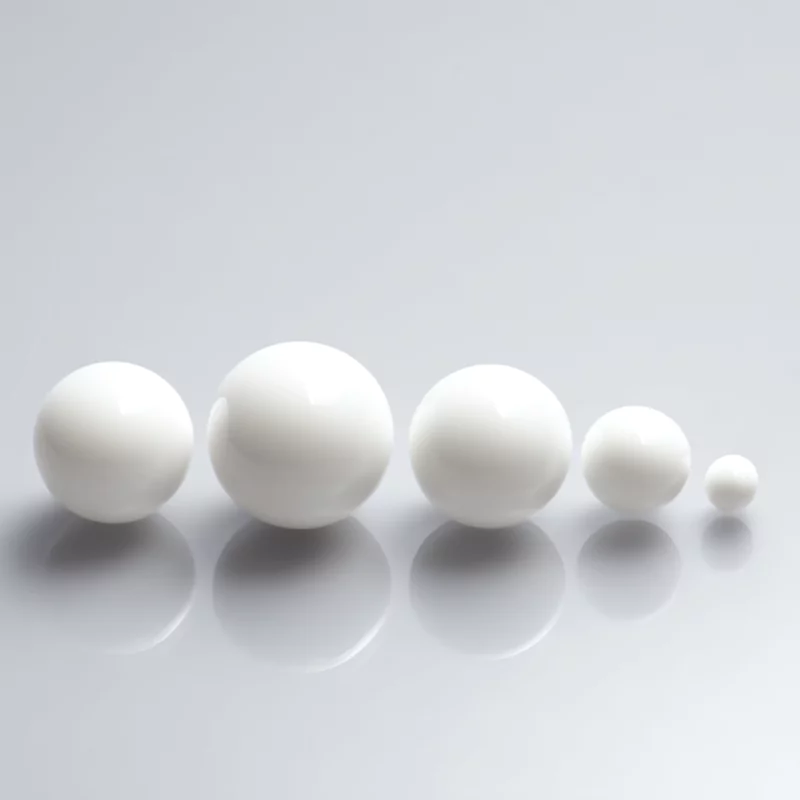

Technical Specifications of ADCERAX® Zirconia Beads

Zirconia Beads require well-defined technical parameters to ensure reliable evaluation under laboratory and industrial quality frameworks.

| Technical Specification Table | ||

|---|---|---|

| Parameter | Typical Value Range | |

| Diameter Tolerance | ±0.02–0.03 mm, tolerance range, depending on bead size | |

| Sphericity / Roundness | ≥ 0.98, roundness ratio, for controlled flow dynamics | |

| True Density | 5.8–6.1 g/cm³, measured by Archimedes method | |

| Bulk Density | 3.5–3.9 g/cm³, influenced by bead size and packing structure | |

|

Wear Rate (Loss on Attrition) |

≤ 0.01% per hour, under standard wet-milling test conditions | |

| Metal Contamination Index | Fe Cu Ni migration, typically ≤ 0.1–0.3 ppm, depending on test medium | |

Key Material Characteristics of Zirconia Beads

Zirconia Beads support demanding industrial workflows. Each property contributes to stable milling output and predictable process performance.

Chemical Purity And Stability

Zirconia ceramic beads maintain chemical integrity across varied pH conditions.

- High inert purity: prevents metal migration.

- Cross-media tolerance: fits composite bead systems.

- Contamination reduction: supports clean formulation processes.

Density Uniformity Structural Balance

Zirconia oxide beads provide predictable density behavior during industrial milling.

- Consistent true density: stabilizes particle movement.

- Uniform bead morphology: narrows PSD variation.

- Balanced flow dynamics: assists precision dispersion.

Mechanical Strength Wear Resistance

High purity zirconia beads deliver stable strength under repeated mechanical loading.

- High impact endurance: maintains shape under stress.

- Low wear generation: keeps slurry contamination minimal.

- Crack resistance behavior: protects long milling cycles.

Thermal Stability Operation Reliability

Zirconia fine beads retain structural stability under thermal fluctuation.

- Low thermal deviation: limits expansion drift.

- Heat load tolerance: maintains operational continuity.

- Process stability support: protects precision systems.

ADCERAX® Zirconia Beads Product Showcase

ADCERAX® Zirconia Beads are available in multiple stabilized compositions to support distinct industrial grinding conditions and viscosity ranges. Each category is optimized for density behavior, wear consistency, and compatibility with high-energy milling environments.

- Balanced density profile: supports mid-viscosity dispersion

- 0.02 mm tolerance: maintains uniform bead motion

- Moderate wear stability: extends milling duration

- 4.0 gcm3 density: suitable for low-viscosity media

- Cost-efficient grinding: supports high-volume systems

- Wider size availability: covers multiple milling needs

- 6.0 gcm3 density: drives high-energy impact

- Low attrition rate: improves slurry cleanlines

- High toughness grade: withstands repeated stress

- 0.98 roundness ratio: stabilizes PSD output

- Minimal metal leaching: protects sensitive formulas

- Nano-scale grinding: supports fine ceramic powders

Your Next Zirconia Beads Solution Starts Here with ADCERAX®

Industrial milling performance often improves when zirconia ceramic beads are matched accurately to viscosity, energy load, and PSD requirements.

Precise selection across stabilized bead types helps maintain cleaner slurry behavior and more stable long-run milling output.

Contact ADCERAX® for a tailored engineering review.

Industrial Zirconia Beads Applications Across Multiple Processing Fields

ADCERAX® ZrO2 Beads support high-energy milling, viscosity-controlled dispersion, and nano-scale material refinement across advanced industrial sectors.

Medium-Viscosity Material Systems

Composite Zirconia Beads enable controlled grinding behavior where both particle uniformity and moderate density are required.

- Mid-shear dispersion: stabilizes 10k cps slurry

- Size consistency control: maintains 0.02 mm tolerance

- Thermal loading balance: supports multi-hour cycles

Coatings and Pigment Grinding

Zirconium Silicate Beads offer cost-efficient grinding performance suited for large-volume coating and pigment systems.

- High-flow efficiency: supports 300 L circulation

- Density matched media: optimized for 4.0 gcm3

- Broad process coverage: fits general dispersion lines

High-Energy Slurry Processing

Ceria Stabilized Zirconia Beads deliver strong impact transfer for demanding high-energy and high-viscosity milling operations.

- High-impact output: reaches 6.0 gcm3 density

- Abrasion control stability: below 0.01 percent wear

- Cycle durability strength: supports heavy-load milling

Nano-Scale Functional Material Production

Yttrium Stabilized Zirconia Beads provide precision grinding behavior required for nano-scale ceramic, electronic, and battery-grade materials.

- Nano-PSD refinement: enables sub-200 nm output

- High roundness control: ensures 0.98 ratio stability

- Low contamination grade: protects sensitive compounds

One-Stop Customized Zirconia Beads Supplier ADCERAX®

ADCERAX® Engineering Support and Customization

ADCERAX® full-process guidance helps align custom bead parameters with operational demands and custom specifications improve consistency across varied industrial grinding environments.

- Viscosity matching advice: ensures slurry movement remains stable under processing.

- Milling parameter guidance: improves energy transfer efficiency throughout milling cycles.

- Material system evaluation: ensures stable performance across multiple milling conditions.

- Size tolerance control: maintains predictable PSD behavior during continuous operation.

- Density composition tuning: aligns bead impact response with processing viscosity targets.

- Roundness stability setup: improves uniform grinding performance during extended operation.

ADCERAX® Manufacturing Strength for Consistent Zirconia Beads Production

High-performance Zirconia Beads require precise forming, calibrated firing profiles, and stable mass-production capability to maintain mechanical uniformity. These manufacturing strengths demonstrate process repeatability essential for demanding industrial milling environments.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Category | Capability Description | ||

| High-Density Forming Control | Achieves ≥6.0 g/cm³ uniform density across large production batches. | ||

| Advanced Sintering Stability | Operates controlled firing curves to secure consistent microstructure. | ||

| Low-Wear Manufacturing Line | Delivers wear rates below 0.01% under standardized abrasion testing. | ||

| Contamination-Free Finishing | Ensures metal impurity levels remain under 30 ppm per batch. | ||

| Automated Classification Workflow | Sorts bead grades with >99.5% accuracy for industrial-scale applications. | ||

customized zirconia beads supplier

ADCERAX® specializes in custom zirconia ceramic beads with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Engineering FAQs About Zirconia Beads from ADCERAX®

Wear resistance depends on grain uniformity, microstructural density, and stabilized zirconia phase content. Higher density reduces microcrack propagation during repeated impacts. This keeps the mill charge stable over thousands of cycles. Using ADCERAX® Zirconia Beads minimizes unexpected contamination caused by bead attrition.

Rounder beads deliver smoother impact distribution inside the milling chamber. This reduces dead zones and decreases PSD deviation during long-run batches. When using ADCERAX® beads with controlled 0.02 mm tolerance, users observe a tighter PSD curve and higher formulation consistency.

Higher-density Zirconia Beads increase kinetic impact force at the same rotor speed. This shortens milling time and improves nano-scale dispersion efficiency. Many battery-electrode manufacturers prefer ADCERAX® high-density beads because they maintain throughput even in 10,000 cps slurries.

Metal contamination mainly results from bead–liner abrasion or poorly stabilized ceramic phases. High-purity zirconia reduces ionic leaching and surface pitting. ADCERAX® Zirconia Beads routinely keep Fe/Cu/Ni contamination below 30 ppm, suitable for electronic ceramics and sensitive slurries.

Phase stability prevents structural collapse under repeated compressive loading. Stabilized zirconia forms a toughened matrix that resists crack growth. This behavior enables ADCERAX® beads to perform reliably in high-impact mills without fracture or density drift.

Diameter deviations create inconsistent shear layers inside the mill. This leads to uneven stress distribution and fluctuating milling efficiency. ADCERAX® Zirconia Beads maintain tight diameter tolerance to ensure predictable energy transfer and controlled slurry behavior.

Nano-scale milling requires high fracture toughness, ultra-low contamination, and uniform surface finish. Zirconia Beads provide the necessary mechanical and chemical stability to handle long-run dispersion cycles. ADCERAX® beads maintain consistent roundness, enabling repeatable sub-200 nm particle outputs.

Thick slurries increase drag and reduce bead mobility, lowering grinding efficiency. High-density zirconia compensates by delivering stronger impacts at lower movement speeds. ADCERAX® high-viscosity-grade beads maintain dispersion uniformity even in multi-hour high-load conditions.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision Zirconia Beads

Looking for a reliable zirconia beads supplier? Let us help you with your next project.

info@adcerax.com

Tel.:

+(86) 0731-74427743

WhatsApp:

+(86)19311583352

Within 24 hours