Anti-Abrasion Yttria Stabilized Zirconia Rod Solutions by ADCERAX®

Anti-abrasion yttria stabilized zirconia rod solutions from ADCERAX® are engineered to withstand wear and friction in demanding environments. Their dense microstructure provides hardness and stability, reducing downtime and replacement costs. Reliable thermal shock resistance ensures consistent performance across chemical and mechanical applications.

ADCERAX® delivers customized zirconia ceramic rod options, including round rods, square bars, shafts, and strips. Each product is made with isostatic pressing and high-temperature sintering to ensure precision and durability. With no MOQ and fast prototyping, we support projects from small testing to bulk production.

Contact ADCERAX® today for durable anti-abrasion yttria stabilized zirconia rod solutions.

±0.1 mm

Dimensional Precision

What is a Zirconia Rod?

A Zirconia Rod is a ceramic component made from stabilized zirconia powders, processed by isostatic pressing and high-temperature sintering. The dense structure provides high hardness, excellent wear resistance, and long service life. These rods remain stable under high temperature and chemical exposure.

With precise tolerance control, zirconia ceramic rods support critical applications in mechanical, chemical, and energy systems.

Technical Specification of Zirconia Rods

Technical parameters of zirconia ceramic rods confirm their ability to meet demanding industrial requirements. These specifications are produced under controlled processes to guarantee stable and repeatable quality.

| Technical Specification Table | ||

|---|---|---|

| Specification Item | Typical Value / Capability | |

| Material Composition | Yttria-Stabilized Zirconia (3Y-TZP, 8YSZ) | |

| Purity Level | ≥ 99.9% ZrO₂ content | |

| Density | 5.9 – 6.1 g/cm³ | |

| Flexural Strength | > 900 MPa | |

| Hardness (Vickers) | ~12 GPa | |

| Fracture Toughness | 7–10 MPa·m¹/² | |

| Thermal Expansion Coefficient | ~10.5 × 10⁻⁶/K (20–400°C) | |

| Thermal Conductivity | 2–3 W/m·K | |

| Electrical Insulation | Volume resistivity >10¹² Ω·cm | |

Advanced Material Properties of ADCERAX® Zirconia Rods

Zirconia Rods deliver outstanding performance through their unique combination of chemical, physical, and mechanical properties. They are widely used in industries that demand anti-abrasion, corrosion resistance, and high-temperature stability.

Chemical Properties

Zirconia ceramic rods provide stable resistance against acids, alkalis, and salts.

- Stable in acids and alkalis up to pH 1–14.

- No measurable reaction with salts or solvents at 25–200°C.

- Tested stability beyond 1,000 hours in corrosive exposure.

Physical Properties

The physical performance of yttria stabilized zirconia rod ensures suitability in extreme conditions.

- Withstands ΔT > 200°C without cracking.

- 5.9–6.1 g/cm³ for structural integrity.

- Volume resistivity > 10¹² Ω·cm at room temperature.

Mechanical Properties

Industrial zirconia ceramic rods deliver strength and toughness unmatched by many ceramics.

- Vickers hardness ~12 GPa.

- > 900 MPa for demanding load conditions.

- Machined to ±0.1–0.2 mm tolerance.

Thermal and Structural Stability

YSZ zirconia rods retain structural integrity under severe thermal cycles.

- Stable up to 1,400°C in continuous service.

- Coefficient ~10.5 × 10⁻⁶/K (20–400°C).

- Uniform fine grains limit crack propagation.

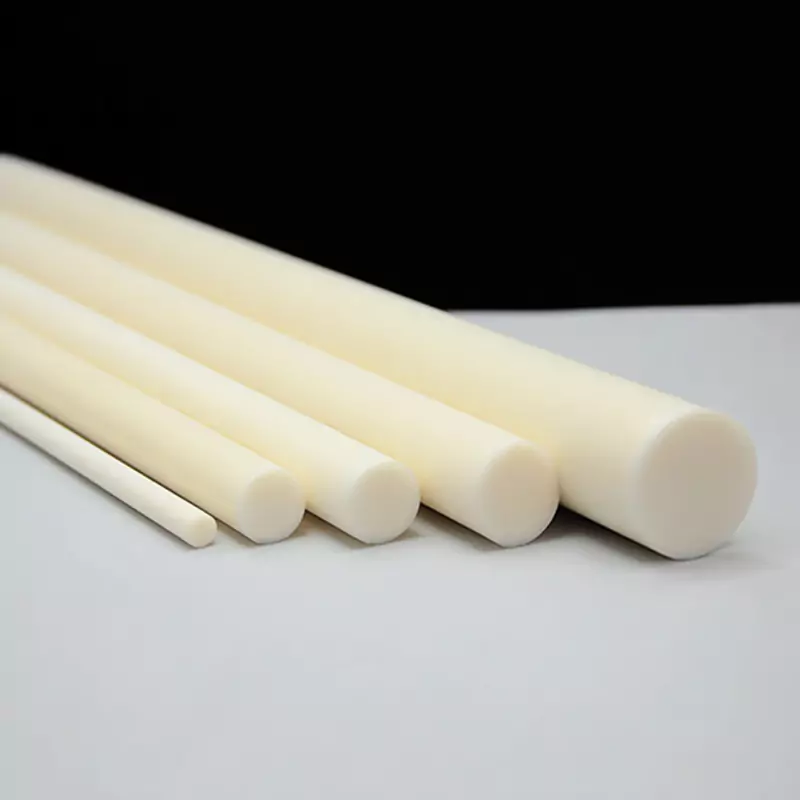

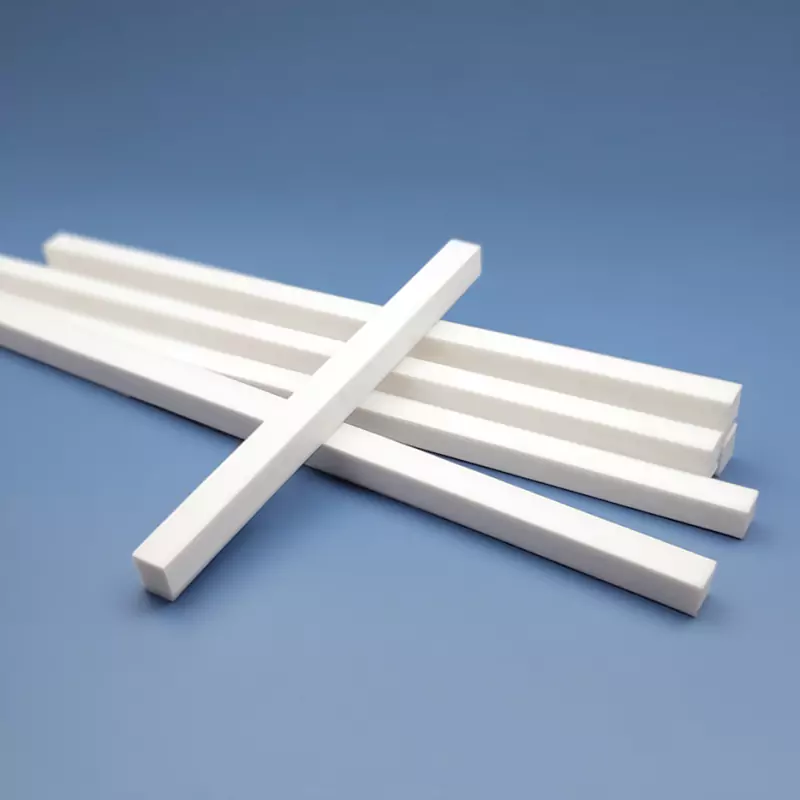

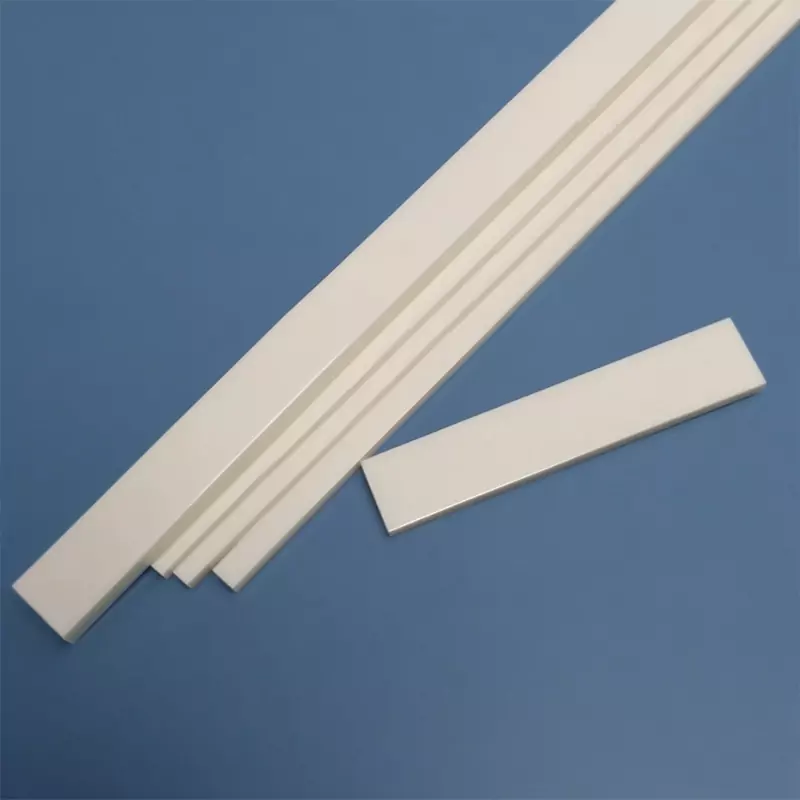

ADCERAX® Zirconia Rod Products Showcase

Zirconia Rod solutions from ADCERAX® include round rods, square bars, shafts, and strips. These zirconia ceramic rods are available in standard sizes and custom options to support different engineering needs.

Zirconia Rods in round form are widely used for grinding pins, plungers, and structural components.

- High density and smooth surface finish for reliable wear resistance.

- Precision diameters available for mechanical and energy applications.

Zirconia ceramic bars offer strength and versatility for industrial assemblies.

- Excellent flexural strength supports heavy load environments.

- Custom lengths and widths to meet design specifications.

Industrial zirconia ceramic rods in shaft form provide stability for rotating and sliding parts.

- High fracture toughness reduces breakage during operation.

- Self-lubricating properties lower friction in moving systems.

Anti-abrasion zirconia rods shaped as strips are ideal for equipment requiring flat contact surfaces.

- Stable microstructure prevents wear and chipping over time.

- Used in chemical, electronic, and mechanical device assemblies.

Looking for a Reliable Zirconia Rod Supplier?

At ADCERAX®, we are committed to providing complete solutions for your engineering projects.

Whether you need round rods, square bars, shafts, or strips, our team delivers technical guidance, fast customization, and international logistics support.

Partner with us to secure consistent quality, flexible order quantities, and expert engineering assistance.

Engineering Use Cases for ADCERAX® Zirconia Ceramic Rod Solutions

ADCERAX® Zirconia Ceramic Rod Solutions are engineered to address critical performance needs across diverse industrial sectors. They combine wear resistance, thermal stability, and dimensional accuracy to ensure reliable operation in demanding engineering environments.

Precision Mechanical Components

Industrial zirconia ceramic rods provide exceptional strength and wear resistance in high-load systems. They are widely applied in equipment where long-term stability and accuracy are critical.

-

Plungers and hydraulic rods:

Zirconia rods withstand contact pressures above 900 MPa, reducing deformation under repeated cycles. Service life is extended by 30–40% compared with conventional steel. -

Grinding pins and shafts:

With Vickers hardness ~12 GPa, anti-abrasion zirconia rods maintain precision and reduce downtime. Maintenance intervals are shortened from monthly replacement to quarterly replacement.

Chemical and Petrochemical Equipment

Zirconia ceramic rods demonstrate high chemical inertness across aggressive processing environments. They retain stability when exposed to strong acids, alkalis, and salts in continuous operations.

-

Mixing shafts and supports:

Stable in solutions from pH 1 to 14, zirconia rods operate for over 1,000 hours without structural degradation. This lowers unplanned maintenance costs by up to 20%. -

Flow and guiding components:

Yttria stabilized zirconia rods resist corrosion at 200 °C in hydrochloric and sulfuric acid systems. Their replacement rate is reduced by nearly half compared with alumina ceramics.

Energy and Thermal Systems

Zirconia rods manufacturer solutions meet demanding needs in energy and high-temperature applications. Their low thermal conductivity and stable microstructure improve thermal efficiency.

-

SOFC components:

YSZ rods exhibit thermal expansion ~10.5 × 10⁻⁶/K, ensuring compatibility with metallic housings. This prevents cracking after 500+ thermal cycles between 200–1000 °C. -

Thermal barrier uses:

With service stability up to 1400 °C, zirconia rods maintain structural integrity. Power plants report >95% operational reliability over three-year inspection cycles.

Metallurgy and Mining Equipment

Zirconia ceramic rods deliver consistent durability under extreme abrasion and impact conditions. They are widely adopted for processing, grinding, and support functions.

-

Crushing and grinding elements:

Zirconia rods show wear loss rates 40% lower than tungsten carbide in slurry systems. This translates into extended equipment life by an additional 8–12 months. -

Structural supports:

With flexural strength above 900 MPa, rods resist heavy impact in smelting furnaces. Downtime due to component fracture is reduced by more than 25%.

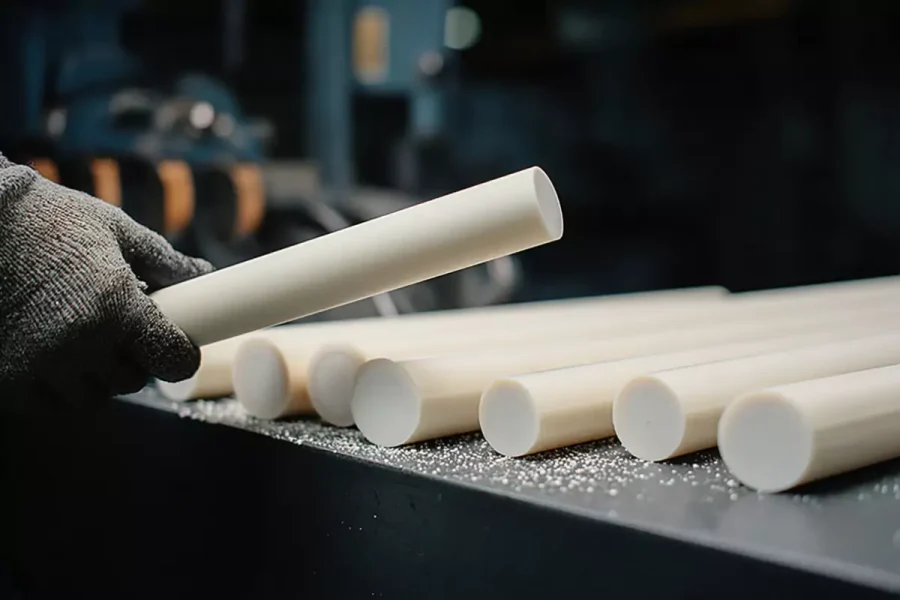

ADCERAX® Zirconia Rod Manufacturer for Industrial Needs

ADCERAX® as Your One-Stop Zirconia Rod Supplier for Custom Solutions

Zirconia Rod supply from ADCERAX® integrates custom engineering support with direct factory manufacturing. As a zirconia ceramic rod factory, zirconia rods manufacturer, and zirconia rods supplier, we provide global customers with tailored solutions that meet strict industrial requirements.

-

Dimensional Stability:

We resolve tolerance complaints (±0.5 mm error, 10–15% rejection rate) by providing machining control to ±0.1 mm. -

Flexible Order Management:

We support both single-sample validation and $100,000+ bulk projects with no MOQ restrictions, solving the challenge of trial-to-mass production transition. -

End-to-End Technical Support:

Our engineers provide drawing reviews and application advice, reducing design iteration costs by up to 20%.

ADCERAX® Advanced Manufacturing Strengths for Zirconia Rods

ADCERAX® operates with advanced production lines that integrate isostatic pressing, high-temperature sintering, and CNC precision machining. These capabilities ensure consistent rod quality, tighter tolerances, and faster delivery compared with conventional suppliers.

| Manufacturing Capabilities and Data | |||

|---|---|---|---|

| Capability Item | Factory Strength & Data | ||

| Isostatic Pressing | Up to 200 MPa forming pressure, ensuring uniform density across large diameters | ||

| High-Temperature Sintering | Furnaces operating at 1600–1700 °C for stable microstructure and long-term thermal resistance | ||

| CNC Machining Precision | Tolerances controlled to ±0.1 mm on diameter and ±0.2 mm on length for repeatable accuracy | ||

| Surface Polishing | Polished finish down to Ra < 0.8 µm, suitable for low-friction and high-fit applications | ||

| Production Capacity | Over 5,000 zirconia rods produced monthly, covering round, square, shaft, and strip types | ||

| Quality Testing | Three-stage QC: dimensional inspection, density check (>5.9 g/cm³), and thermal cycling tests (>500 cycles, 200–1000 °C) | ||

customized zirconia rod supplier

We specialize in custom zirconia ceramic rods with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Frequently Asked Questions about Zirconia Ceramic Rod

Yttria-stabilized zirconia maintains a tetragonal crystal phase, which enhances fracture toughness. This improves flexural strength to levels above 900 MPa. As a result, Zirconia Rods can withstand higher stresses without premature failure.

Zirconia Rod manufacturer processes allow tolerances controlled to ±0.1 mm on diameter and ±0.2 mm on length. This reduces assembly rejection rates reported as high as 15% in Europe. Precision machining ensures stable fitting with other industrial components.

Yes, Zirconia Rods remain stable in acids and alkalis ranging from pH 1 to 14. They have shown resistance in hydrochloric and sulfuric acid at 200 °C. This makes them reliable for chemical processing and petrochemical applications.

The Zirconia Rod is engineered using isostatic pressing and high-temperature sintering to achieve density above 5.9 g/cm³. This dense structure resists cracking and minimizes internal defects. It provides long-term durability even under continuous mechanical stress.

Zirconia ceramic rods maintain structural integrity after more than 500 heating and cooling cycles between 200 °C and 1000 °C. The yttria stabilization controls thermal expansion at ~10.5 × 10⁻⁶/K. This ensures compatibility with metal housings and reduces fatigue cracking.

Yttria stabilized zirconia rods remain stable in continuous use up to 2200 °C. Short-term peaks of 1600 °C can be tolerated depending on the environment. This ensures reliable performance in energy and high-temperature devices.

Yes, zirconia ceramic rods are excellent electrical insulators with resistivity >10¹² Ω·cm. They can be safely applied in sensor housings and electrical isolation systems. The closed-end design adds protection in sensitive circuits.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision Zirconia Ceramic Rods

Looking for a reliable zirconia rod supplier? Let us help you with your next project.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours