ADCERAX® Yttria Stabilized Zirconia Ceramic Tube with One End Closed is engineered for high-temperature furnaces, chemical reactors, and laboratory heating systems. Its dense structure, formed by isostatic pressing and sintering, delivers exceptional strength, thermal shock resistance, and chemical stability. By combining yttria stabilization with a closed-end design, the tube ensures reliable performance in demanding industrial environments. Industries that require durability and consistent operation value this product for reducing downtime and extending service life.

Features of Yttria Stabilized Zirconia Ceramic Tube with One End Closed

The Yttria Stabilized Zirconia Ceramic Tube with One End Closed combines advanced mechanical strength, chemical stability, and thermal reliability, making it suitable for furnaces, chemical reactors, and laboratory applications that demand consistent performance.

- Thermal conductivity measured at ≈3 W/m·K, providing effective insulation in furnace systems.

- Maintains stability at operating temperatures of ≥1000 °C, suitable for continuous industrial use.

- Thermal expansion coefficient at 10 × 10⁻⁶/K, ensuring compatibility with metal assemblies.

- Bending strength between 480–1000 MPa, supporting heavy-duty industrial loads.

- Compressive strength rated at 1600–2300 MPa, preventing deformation under pressure.

- Fracture toughness of 6–8 MPa·m½, reducing risk of catastrophic failure during rapid cycling.

Technical Properties for Yttria Stabilized Zirconia Ceramic Tube with One End Closed

The Yttria Stabilized Zirconia Ceramic Tube with One End Closed delivers proven reliability for industrial buyers by combining advanced material properties with consistent performance. This section outlines the key technical parameters and specification tables covering its physical, chemical, optical, and mechanical features, along with its standard size options.

| Property |

Specification |

| Density |

5.65–6.05 g/cm³ |

| Thermal Conductivity |

≈3 W/m·K |

| Maximum Service Temp. |

≥1000 °C |

| Thermal Expansion |

10 × 10⁻⁶ /K |

| Hardness (Vickers HV1) |

1200–1450 HV |

| Bending Strength |

480–1000 MPa |

| Compressive Strength |

1600–2300 MPa |

| Fracture Toughness |

6–8 MPa·m½ |

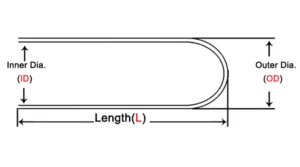

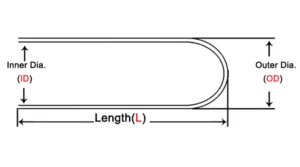

Dimensions of Yttria Stabilized ZrO2 Ceramic Tube with One End Closed

Packaging of Yttria Stabilized Zirconia Ceramic Tube with One End Closed

Each Yttria Stabilized Zirconia Ceramic Tube with One End Closed is securely packed in foam-lined wooden boxes to prevent breakage during transit. Multiple units are further reinforced with inner cartons and sealed crates for safe international shipping. This packaging ensures the YSZ Tube with One End Closed arrives in perfect condition, ready for immediate industrial use.

Solving Application Challenges with ADCERAX® Yttria Stabilized Zirconia Ceramic Tube with One End Closed

The Yttria Stabilized Zirconia Ceramic Tube with One End Closed addresses specific operational difficulties across industries where extreme heat, corrosive chemicals, and precision testing demand advanced ceramic solutions.

-

Thermocouple Protection in High-Temperature Furnaces

✅Key Advantages

1. Low Thermal Conductivity (≈3 W/m·K) — limits thermal shunting at ≥1000 °C to stabilize junction readings.

2. High Fracture Toughness (6–8 MPa·m½) — resists crack growth during rapid heat-up and cool-down cycles.

3. Closed-End Integrity (5.65–6.05 g/cm³ density) — forms a gas-tight barrier that shields the junction from combustion by-products.

✅ ️Problem Solved

A continuous heat-treat line at 1050 °C reported monthly probe failures from cracked alumina guards and drift from gas ingress. After switching to the Yttria Stabilized Zirconia Ceramic Tube with One End Closed, mean time between replacements increased threefold. Unplanned stoppages fell by ~12 hours per quarter due to stable thermocouple output and fewer tube swaps. Measurement scatter tightened, improving furnace control limits and scrap rates.

-

High-Temperature Gas Flow Monitoring Systems

✅Key Advantages

1. Chemical Inertness (>95% acid/alkali media) — withstands SOx/NOx and reactive species without material degradation.

2. Dimensional Stability (CTE 10 × 10⁻⁶/K) — maintains probe alignment and seal integrity above 1000 °C.

3. Erosion Resistance (1200–1450 HV) — hard surface endures high-velocity, particulate-laden streams.

✅ ️Problem Solved

A combustion line’s flow probe housings deformed or cracked after 3–4 weeks, causing sensor dropouts and recalibration events. With the Yttria Stabilized Zirconia Ceramic Tube with One End Closed, service life extended to 12+ weeks in the same duty. Maintenance callouts dropped by ~50%, and continuous data capture restored compliance reporting. Process control stabilized as sensor drift events declined.

-

Precision Control in Metallurgical Laboratory Testing

✅Key Advantages

1. Dense Microstructure (5.65–6.05 g/cm³) — blocks molten alloy penetration during dwell tests up to 1100 °C.

2. Thermal-Shock Capacity (6–8 MPa·m½) — survives repeated quench/heat cycles without fracture.

3. Thermal Insulation (≈3 W/m·K) — supports stable gradients for reproducible thermal measurements.

✅ ️Problem Solved

A metallurgy lab saw tube fractures in 1 of 10 high-temperature alloy runs and occasional sample contamination. Replacing guards with the Yttria Stabilized Zirconia Ceramic Tube with One End Closed eliminated breakage across 30 consecutive runs. Repeatability improved, with variance in measured transition points narrowing by double-digit percentages. Turnaround time shortened as re-tests and post-run cleaning decreased.

User Guide for Yttria Stabilized Zirconia Ceramic Tube with One End Closed

The Yttria Stabilized Zirconia Ceramic Tube with One End Closed is designed for industrial users who demand reliability in high-temperature and corrosive environments. This guide provides practical instructions to ensure safe handling, proper installation, and extended service life, helping buyers maximize performance and reduce operational risks.

-

Handling and Storage Guidelines

1. Always handle tubes with clean gloves to avoid surface contamination.

2. Store in a dry, dust-free area to prevent moisture absorption and surface damage.

3. Keep away from sudden mechanical impacts that may cause microcracks.

-

Installation Recommendations

1. Gradually preheat tubes before reaching working temperatures above 1000 °C.

2. Ensure proper alignment when integrating with thermocouples or reactor systems.

3. Avoid overtightening clamps that may induce stress fractures.

-

Operational Best Practices

1. Maintain steady temperature ramps to reduce thermal shock during cycling.

2. Use the closed-end design for applications requiring containment of gases or liquids.

3. Avoid contact with hydrofluoric acid to preserve chemical stability.

-

Maintenance and Service Life Extension

1. Clean gently with non-abrasive tools to preserve surface finish.

2. Record operational hours and conditions to track performance history.

3. Conduct periodic inspections under magnification to detect early-stage cracking.