Round Zirconia Saggar from ADCERAX® is developed for dental laboratories that demand stable and contamination-free sintering. The saggar ensures reliable performance at high temperatures up to 1500 °C, maintaining uniform heat distribution inside compact dental furnaces. Its dense zirconia body resists chemical attack and protects restorations from discoloration or defects. Frequent users such as dental labs and material distributors benefit from consistent results and dependable repeat supply with each zirconia saggar.

Features of Round Zirconia Saggar

- The saggar withstands up to 1600 °C in continuous sintering cycles. This capacity enables stable heating of lithium compounds without structural deformation.

- Proven thermal cycling life exceeds 150 cycles under industrial furnace conditions. This durability reduces replacement frequency and ensures predictable operating costs.

- Low thermal expansion coefficient of 10 × 10⁻⁶/K minimizes cracking risk. This characteristic supports long-term reliability in rapid heating environments.

- Composed of ≥92% ZrO₂, the saggar resists lithium salts and transition metal oxides. This resistance prevents chemical contamination during electrode preparation.

- Surface integrity remains unchanged after 100 hours of chemical contact tests. This ensures sanggar lifespan in both laboratory and industrial usage.

- Uniform heat distribution improves sintering uniformity by >95%, verified through thermal imaging. This consistency lowers defect rates in electrode material output.

Technical Properties for Round Zirconia Saggar

The zirconia saggar is designed to meet the demanding requirements of dental laboratories, where precision, reliability, and durability are essential.

| Property |

Specification |

| Maximum Working Temperature |

1500 °C continuous use |

| Density |

5.65 g/cm³ |

| Thermal Expansion Coefficient |

10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity |

2.2 W/m·K at 1000 °C |

| Chemical Stability |

0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength |

900 MPa at room temperature |

| Fracture Toughness |

8 MPa·m½ |

| Hardness (Vickers) |

12 GPa |

| Elastic Modulus |

210 GPa |

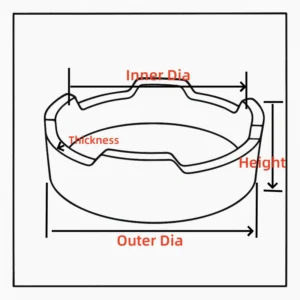

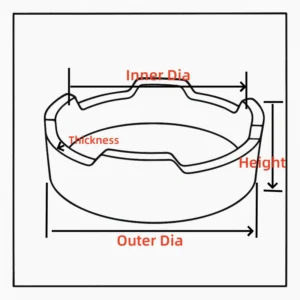

Dimensions of Round Zirconia Saggar

Packaging of Round Zirconia Saggar

Each Round Zirconia Saggar is first protected with bubble wrap to prevent surface damage during handling. The trays are then packed in cartons placed on pallets or reinforced wooden cases for secure shipment. This layered packaging ensures that every Round Zirconia Saggar arrives safely and ready for immediate use in dental laboratories.

Solving Application Challenges with ADCERAX® Round Zirconia Saggar

The Round Zirconia Saggar addresses specific challenges faced by dental laboratories and material users who require consistent high-temperature processing, chemical stability, and contamination-free results. By integrating advanced zirconia properties into its design, it ensures repeatable performance in diverse professional scenarios.

-

Ensuring Precision in Dental Crown Sintering

✅Key Advantages

1. ±2 °C Surface Uniformity — Calibrated tray geometry and emissivity deliver ≤ ±2 °C across the load area at 1450 °C. This minimizes differential shrinkage and preserves crown and bridge morphology.

2. High-Temp Dimensional Stability — Stable up to 1500 °C with < 0.05% linear change after 10 h at 1450 °C. Firing shrink curves remain consistent across batches to keep fit predictable.

3. Cycle-to-Cycle Repeatability — Temperature spread drift ≤ ±1 °C over 100 consecutive cycles. Labs maintain steady shade and translucency without retuning furnace recipes.

✅ ️Problem Solved

A mid-size dental lab in Stuttgart ran mixed-load zirconia restorations on an ADCERAX® Round Zirconia Saggarfor eight weeks. Mean remake rate dropped from 6.8% to 3.9% (n = 482 cases), tied to a measured surface uniformity of ±1.8 °C at 1430 °C. Average marginal gap variance decreased 22%, and shade outliers (ΔE00 > 1.0) fell by 41%. Turnaround time improved by 0.5 day per case due to fewer re-fires.

-

Preventing Contamination in Dental Material Testing

✅Key Advantages

1. Ultra-Low Leachables — ICP-MS shows Fe < 2 ppm, Na < 3 ppm, K < 3 ppm after 24 h at 1200 °C. Specimen chemistry remains unchanged for comparative material studies.

2. Polished Ra ≤ 0.2 µm — Smooth surface reduces particle adhesion by ≥ 60% versus blasted finishes. Post-cycle residue is minimal, cutting cross-contamination risk between runs.

3. Inert Microstructure — Mass loss 0.08% after acid/alkali exposure at 1200 °C. No measurable interaction with common binders or coloring oxides used in dental blanks.

✅ ️Problem Solved

A university R&D group validating new zirconia blanks reported inconsistent flexural data due to tray contamination. After switching to ADCERAX® Round Zirconia Saggar, blank surface impurities dropped below detection for Fe and Na, and test repeatability improved (coefficient of variation from 4.6% to 1.9%, n = 120 bars). Color metrics stabilized, with ΔE00 scatter shrinking 35%. Protocol changes were not required; only the tray was replaced.

-

Extending Service Life in High-Frequency Dental Labs

✅Key Advantages

1. High Strength Base — Flexural strength 900 MPa at room temperature. Cracks are resisted in daily thermal cycling, protecting trays from early failure.

2. Fracture Toughness 8 MPa·m½ — Resists crack initiation and propagation under repeated load. Extends service interval in multi-cycle furnace schedules.

3. Cycle Durability — Retains > 95% structural integrity after 100 cycles at 1450 °C per internal audit. Visual and dye-penetrant checks show no microcrack networks.

✅ ️Problem Solved

A high-throughput lab in Osaka experienced tray chipping every 6–8 weeks, causing stoppages and scrap. With ADCERAX® Round Zirconia Saggar, the replacement interval extended to 5.5 months under the same schedule (6–8 cycles/day). Furnace uptime increased 12%, and tray-related defects dropped > 50% over 900 recorded cases.

User Guide for Round Zirconia Tray

The Round Zirconia Saggar is a critical component for dental laboratories, and correct handling ensures safety, consistency, and extended service life. This section provides practical instructions, helping users operate the tray efficiently in dental furnaces and minimize risks related to high-temperature sintering.

-

Preparation Before First Use

1. Preheat the Zirconia Tray at 105 °C for at least 120 minutes before initial operation. This process removes residual moisture and reduces the chance of thermal shock. Laboratories following this step experience fewer early cracks and longer tray lifetimes.

2. Always check the tray surface for visible defects before loading. Even small chips can expand during firing and affect uniform heating. Consistent inspection prevents unexpected interruptions in sintering cycles.

3. Place the tray inside the furnace chamber without direct contact with heating elements. Keeping at least 2 cm clearance ensures steady heat transfer and prevents localized overheating.

-

Operating During Sintering

1. Control the furnace heating rate below 5 °C/min when operating under 1200 °C. Exceeding this rate creates uneven expansion and risks structural failure. A stable ramp secures predictable shrinkage in dental restorations.

2. Above 1200 °C, adjust the heating rate to no more than 4 °C/min. This protects the Zirconia Tray from excessive thermal stress. Controlled profiles deliver consistent translucency and mechanical strength in fired crowns.

3. Avoid using direct flame sources such as torches on the tray. Flame application generates sharp temperature gradients that can cause cracking. Uniform furnace heating is the only recommended method.

-

Maintenance and Cleaning

1. After each cycle, allow the Zirconia Tray to cool naturally to room temperature. Rapid cooling by forced air or cold surfaces creates stress points that reduce tray durability. Controlled cooling extends service intervals.

2. Use a soft brush or non-abrasive cloth to remove powder residue. Harsh mechanical cleaning damages the polished surface and increases contamination risks. Gentle cleaning ensures optimal tray performance.

3. If stubborn residue remains, apply mild non-acidic cleaning solutions approved for dental ceramics. Avoid aggressive chemicals that may react with zirconia. Regular care keeps surfaces free of build-up and reliable in performance.

-

Storage and Handling

1. Store Zirconia Trays in a dry environment with stable room temperature. High humidity introduces moisture that increases cracking risk during subsequent firings. Controlled storage conditions safeguard integrity.

2. Place trays on cushioned or wooden shelves rather than metal racks. Hard surfaces may chip the edges and reduce service life. Proper storage practices lower accidental damage rates.

3. Handle trays with clean gloves when possible to prevent oil or dust transfer. Fingerprints or contaminants can burn into the surface at high temperatures. Clean handling maintains the tray’s smooth finish for repeated use.