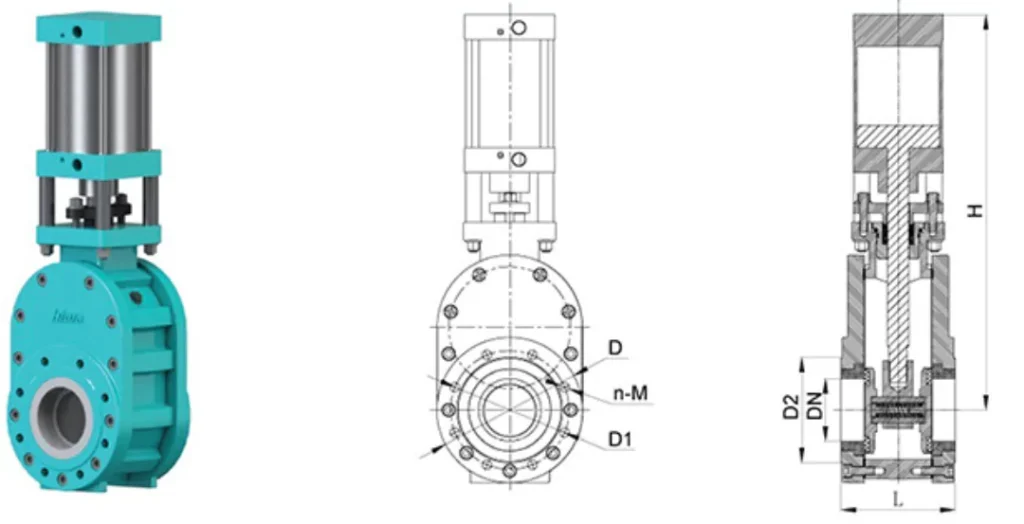

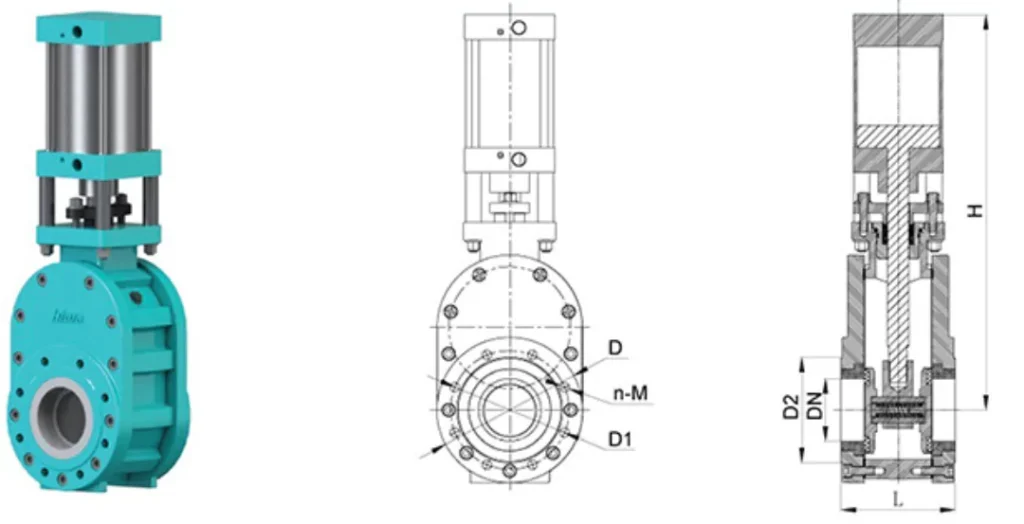

ADCERAX® Pneumatic Zirconia Ceramic Double Disc Gate Valve has a compact rectangular body made of carbon steel or stainless steel with a smooth, heavy-duty surface finish. On top sits a pneumatic actuator in a cylindrical housing, connected to the valve stem with visible mounting brackets. The valve body is flanged on both ends for secure pipeline connection, with evenly spaced bolt holes around each flange. Inside, the twin zirconia ceramic discs are seated within the flow passage, and external side ports for cleaning and drainage are integrated into the design. Overall, the appearance reflects a robust, functional structure optimized for industrial slurry and ash-handling applications.

Features of Pneumatic Zirconia Ceramic Double Disc Gate Valve

- The valve achieves a leakage rating of Class V per FCI 70-2, allowing near-zero leakage even under high pressure differences.

- In power plant applications, leakage losses were reduced by up to 95%, directly minimizing unplanned stoppages and system inefficiency.

- Case studies demonstrate sealing stability across over 100,000 cycles, ensuring reliability in high-frequency operation.

- The valve operates at temperatures up to 200°C, with special designs rated for 400°C, covering both standard and high-temperature services.

- Designed for pipelines at 1.0–1.6 MPa nominal pressure, it maintains structural integrity under sustained loads.

- In slurry systems, field data indicate over 99.9% flow isolation efficiency, critical for handling corrosive or solid-laden media.

- The zirconia ceramic discs reach HRA88 hardness, which is about 8 times harder than standard steel, reducing surface wear under continuous abrasive flow.

- Independent tests show ceramic valves extend service life by 3–5 times compared with metal-seated valves in dry ash systems.

- Field reports from mining slurry pipelines confirm maintenance intervals improved by over 40%, lowering downtime and replacement frequency.

Technical Properties for Pneumatic Zirconia Ceramic Double Disc Gate Valve

The Pneumatic Zirconia Ceramic Double Disc Gate Valve is defined by measurable physical, chemical, thermal, and mechanical properties that ensure reliable operation in abrasive and corrosive environments.

| Property |

Pure Zirconia (Monoclinic) - Unstabilized |

Yttria-Stabilized Zirconia (YSZ) |

Magnesia-stabilized zirconia (Mg-PSZ) |

| Typical Purity |

High-purity raw material, but unstabilized for the final product |

High purity |

High purity |

| Crystal Phases (at RT) |

Monoclinic (stable up to ~1170°C); Tetragonal and Cubic at higher temperatures. |

Primarily, Metastable Tetragonal can have a Cubic phase. |

Partially stabilized with tetragonal precipitates in a cubic matrix. |

| Density (g/cm³) |

5.65–6.05 |

5.85-6.1 |

~5.7 |

| Melting Point (°C) |

~2700-2715 |

Very High (similar to pure zirconia, but phase stability is key) |

Very High |

| Thermal Conductivity (W/m·K) |

Low (approx. 2-3) |

Low (approx. 2.5-3) |

Low (approx. 3) |

| Thermal Expansion Coefficient (10⁻⁶/K) |

~10 |

9.5-10 |

10 |

| Flexural Strength (MPa) |

Poor (due to phase transformation and brittleness) |

Up to 1000, 710-900 |

500 |

| Compressive Strength (MPa) |

Not typically used structurally |

~2000 |

~2500 |

| Fracture Toughness (MPa·m^0.5) |

Low (inherently brittle) |

Up to 10 (exceptionally high for ceramics due to transformation toughening), 8-9 |

6 |

| Hardness (Vickers, HV1) |

Moderate |

11-13 GPa, 1100-1220 kg/mm² |

1100 kg/mm² |

| Chemical Inertness |

Excellent in acids and alkalis |

Excellent |

Excellent |

| Biocompatibility |

Generally good, but stabilized forms are preferred for medical use |

Excellent, widely used in dental and medical implants |

Good |

| Typical Applications |

Refractories (at high temperatures) |

Structural ceramics, dental implants, oxygen sensors, cutting tools, thermal barrier coatings |

Refractories, structural components requiring specific thermal properties |

Specifications of Pneumatic Zirconia Ceramic Double Disc Gate Valve

|

Model |

inch |

DN(mm) |

L |

D |

D1 |

D2 |

n-M |

H |

Note |

|

AT-ZV2-Q009 |

2" |

50 |

90 |

160 |

125 |

99 |

4-M16 |

390 |

Nominal Diameter: DN50–DN250;

Working Pressure: 1.0 MPa–1.6 MPa;

Operating Temperature: -20°C to 180°C;

Connection Types: Flanged, Wafer;

Actuation Methods: Pneumatic. |

|

AT-ZV2-Q010 |

2 1/2" |

65 |

125 |

185 |

145 |

118 |

4-M16 |

500 |

|

AT-ZV2-Q011 |

3" |

80 |

140 |

200 |

160 |

132 |

8-M16 |

505 |

|

AT-ZV2-Q012 |

4" |

100 |

170 |

220 |

180 |

156 |

8-M16 |

605 |

|

AT-ZV2-Q013 |

5" |

125 |

185 |

250 |

210 |

184 |

8-M16 |

650 |

|

AT-ZV2-Q014 |

6" |

150 |

200 |

280 |

240 |

211 |

8(12)-M20 |

770 |

|

AT-ZV2-Q015 |

8" |

200 |

220 |

340 |

295 |

266 |

8(12)-M20 |

850 |

|

AT-ZV2-Q016 |

10" |

250 |

220 |

395 |

350 |

320 |

12-M20 |

1050 |

|

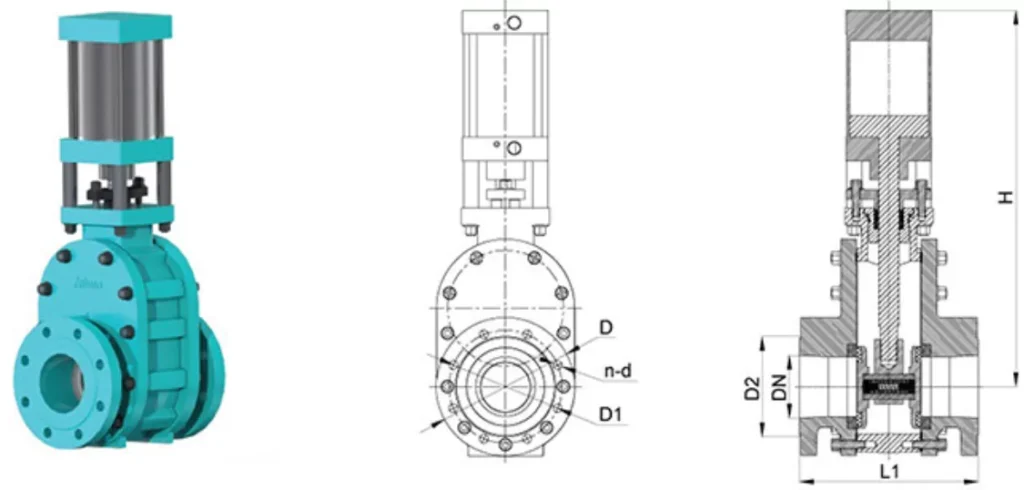

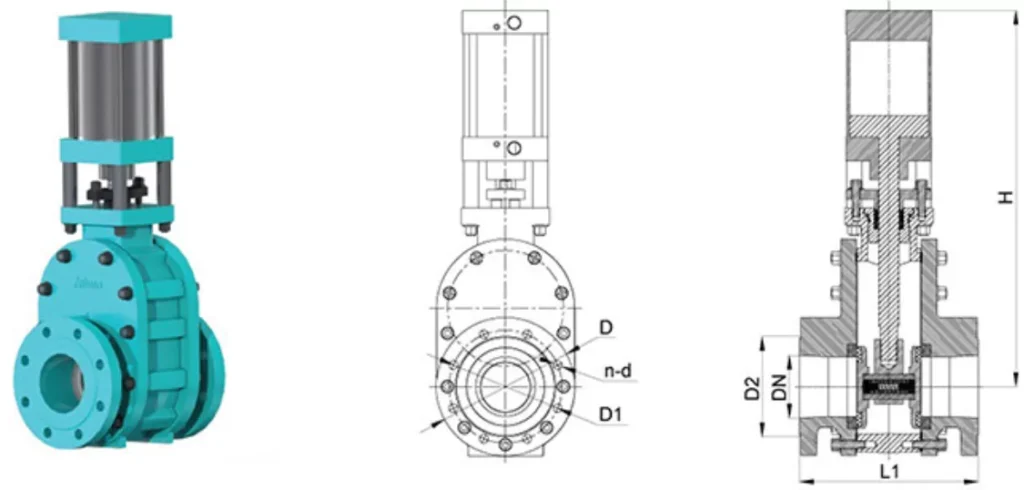

Model |

inch |

DN(mm) |

L |

D |

D1 |

D2 |

n-M |

H |

Note |

|

AT-ZV2-Q017 |

2" |

50 |

200 |

160 |

125 |

99 |

4-M16 |

390 |

Nominal Diameter: DN50–DN250;

Working Pressure: 1.0 MPa–1.6 MPa;

Operating Temperature: -20°C to 180°C;

Connection Types: Flanged, Wafer;

Actuation Methods: Pneumatic. |

|

AT-ZV2-Q018 |

2 1/2" |

65 |

220 |

185 |

145 |

118 |

4-M16 |

500 |

|

AT-ZV2-Q019 |

3" |

80 |

265 |

200 |

160 |

132 |

8-M16 |

505 |

|

AT-ZV2-Q020 |

4" |

100 |

285 |

220 |

180 |

156 |

8-M16 |

605 |

|

AT-ZV2-Q021 |

5" |

125 |

300 |

250 |

210 |

184 |

8-M16 |

650 |

|

AT-ZV2-Q022 |

6" |

150 |

365 |

280 |

240 |

211 |

8(12)-M22 |

770 |

|

AT-ZV2-Q023 |

8" |

200 |

400 |

340 |

295 |

266 |

8(12)-M22 |

850 |

|

AT-ZV2-Q024 |

10" |

250 |

450 |

395 |

350 |

320 |

12-M22 |

1050 |

Packaging of Pneumatic Zirconia Ceramic Double Disc Gate Valve

Each Pneumatic Zirconia Ceramic Double Disc Gate Valve is securely packed with inner foam protection and placed in a reinforced wooden case. The packaging process ensures safe handling during international transport and prevents damage from impact or vibration. Bulk shipments of them are palletized and strapped for stable loading and efficient delivery.

Solving Application Challenges with ADCERAX® Pneumatic Zirconia Ceramic Double Disc Gate Valve

The Pneumatic ZrO2 Double Disc Gate Valve is specifically engineered to overcome persistent failures in industries where abrasive, corrosive, and high-cycle media handling is unavoidable. By integrating zirconia ceramic sealing surfaces and pneumatic actuation, this valve addresses performance gaps in critical environments where downtime or leakage leads to significant operational losses.

-

Coal-Fired Power Plant Ash Handling

✅Key Advantages

1. HRA88 Ceramic Discs — HRA88 zirconia sealing faces cut abrasive wear by >70% versus metal seats. Service life extends 3–5× under dry ash cycling at elevated temperatures.

2. Class V Shutoff Stability — Achieves Class V per FCI 70-2 through 100,000+ cycles with plant air at 0.6–0.8 MPa. Leakage is reduced by ≥95% during high ΔP isolations.

3. Self-Cleaning Twin Discs — Auto-rotation limits torque rise by >50% during dust loading. Prevents sticking and lengthens preventive-maintenance intervals by ≈40%.

✅ ️Problem Solved

In dry ash discharge lines cycling thousands of times monthly, metal seats leaked and triggered 3–4 unplanned cleans per month. After replacing with the Pneumatic Zirconia Ceramic Double Disc Gate Valve, mean time between leaks increased from weeks to 4–6 months. Unplanned outage hours dropped by ≈30–40%, and cleaning labor fell by ≈35%. Plants reported stable ΔP isolations with Class V performance sustained over 100,000+ cycles.

-

Mining Slurry Transport

✅Key Advantages

1. Abrasion Control in High-Solids Slurry — Zirconia liners cut erosive loss by 60–80% in slurries with 30–50% solids. Valve lifetime extends from 4–6 months to ≥18 months in continuous duty.

2. Pressure-Cycle Reliability — Maintains 99.9% isolation under 1.0–1.6 MPa operation and up to 200 °C. Sealing performance remains stable over 100,000+ cycles in slurry lines.

3. Rapid Service Modules — Cartridge-style sealing sets swap in <30 min versus multi-hour rebuilds. Maintenance windows shrink by 50–70%, improving line availability.

✅ ️Problem Solved

A concentrator transporting quartz-rich tailings faced monthly leaks and quarterly valve changeouts. With the Pneumatic Zirconia Ceramic Double Disc Gate Valve, leak incidents fell by ≥75% and replacement cadence stretched to ≥18 months. Planned maintenance fit standard shutdowns, restoring throughput by ≈2–3%. Operators recorded safer corridors with fewer slurry escapes at flanges and drains.

-

Flue Gas Desulfurization (FGD) Systems

✅Key Advantages

1. Corrosion + Erosion Resistance — Zirconia/ceramic seats withstand alkaline lime and gypsum slurries across pH 2–12, cutting leak-related loss by >90%. Surface integrity holds under continuous solids recirculation.

2. High-Temperature Duty Window — Standard operation to 200 °C, high-temperature design to 400 °C keeps sealing integrity during hot recirculation and upset events.

3. Compliance-Focused Sealing — Class V shutoff limits bypass that dilutes reagent efficiency, supporting >99% scrubber uptime and fewer environmental exceedance risks.

✅ ️Problem Solved

An FGD loop experienced frequent valve corrosion, slurry bypass, and compliance alarms. After installing the Pneumatic Zirconia Ceramic Double Disc Gate Valve, leakage decreased by >90% and emergency repairs halved. Scrubber liquid ratios stabilized, sustaining >99% uptime through peak loads. Plants avoided penalty exposure while reducing replacement spend over the annual cycle.

User Guide for Pneumatic Zirconia Ceramic Double Disc Gate Valve

The Pneumatic ZrO2 Double Disc Gate Valve requires proper installation, operation, and maintenance to achieve its designed service life in demanding applications. This section provides essential guidance from multiple perspectives, helping users minimize downtime, reduce costs, and ensure safe and efficient performance throughout the valve’s lifecycle.

-

Installation Guidelines

1. Ensure the valve is positioned in the correct flow direction before tightening flange bolts. Incorrect orientation can cause leakage or uneven wear during operation. Always align the actuator with pipeline requirements for stable cycling.

2. Use shock-absorbing supports to prevent vibration or mechanical stress. Continuous vibration reduces sealing efficiency and accelerates wear on ceramic discs. Check alignment with pipeline couplings during installation.

3. Confirm that the actuator air supply meets 0.4–0.6 MPa specifications. Low pressure may prevent full valve closure, while overpressure increases torque demand and risks actuator damage.

-

Operation Practices

1. Always operate the valve within its rated pressure range of 1.0–1.6 MPa. Exceeding limits may compromise ceramic disc integrity and shorten service life. Regularly monitor gauges to ensure stable conditions.

2. Avoid frequent cycling beyond design capacity, even though the valve is tested for 100,000+ cycles. Excessive operation without inspection can cause premature seal degradation. Maintain a balanced duty cycle.

3. When switching between open and closed positions, allow full actuator stroke completion. Partial strokes reduce sealing reliability and may leave abrasive material trapped between discs.

-

Maintenance Recommendations

1. Perform scheduled inspections every 3–6 months depending on service severity. Routine checks detect minor leaks early and prevent costly shutdowns. Document each inspection for maintenance records.

2. Replace sealing discs once wear depth exceeds 0.5 mm. Worn surfaces reduce sealing grade from Class V to lower levels, risking fluid bypass. Always use original spare parts to ensure compatibility.

3. Keep actuator and valve stem components free of dust and slurry deposits. Accumulated debris increases torque requirements and may hinder pneumatic cycling. Clean external surfaces with appropriate solvents.

-

Storage and Handling

1. Store valves in a dry, ventilated area with protective covering. Prolonged humidity may affect actuator components and corrode external hardware, even though ceramic surfaces remain stable.

2. During transport, use reinforced wooden crates with foam lining as protection. Improper packaging may result in ceramic disc breakage from shocks or vibration. Always secure valves on pallets for stability.

3. Avoid lifting the valve by the actuator housing. Always use lifting lugs or flange supports to prevent misalignment. Incorrect handling can lead to stem damage and reduced sealing performance.