ADCERAX® Pneumatic Zirconia Ceramic Knife Gate Valve is designed for abrasive slurry, corrosive liquid, and high-solids applications where reliable shutoff is critical. With a zirconia ceramic gate and sealing surface, it delivers long service life, low leakage, and reduced maintenance demands. The pneumatic actuator ensures fast and stable operation, making this valve well suited for mining, power plant, pulp, wastewater, and cement industry systems.

Features of Pneumatic Zirconia Ceramic Knife Gate Valve

- Leakage Below 0.01%: Bench testing shows the Pneumatic Zirconia Ceramic Knife Gate Valve achieves <0.01% leakage rate at 1.6 MPa pressure. This minimizes fluid loss in power plant ash handling.

- Consistent Performance at 200°C: Standard models operate continuously at 200°C without seal degradation, with optional designs proven to 400°C. This ensures durability in thermal systems.

- Downtime Reduction by 30%: Plants report 30% fewer unscheduled shutdowns due to leakage after replacing metal knife gates with zirconia models.

- Reduced Failure Rates: In mining tailings applications, valves with zirconia gates show failure rates below 3% annually, compared to 15% for metal-seated alternatives.

- Wear Resistance Over 10,000 Cycles: Field reports indicate valves maintain sealing integrity after >10,000 open/close operations under abrasive slurry. This supports predictable maintenance schedules.

- High Hardness (HRA88+): Independent tests show zirconia components last 6–8 times longer than standard steel in slurry pipelines. This reduces replacement frequency and saves operators measurable downtime.

- Cycle Time Under 2 Seconds: The pneumatic actuator enables full open-to-close travel in <2 seconds for DN150 valves, supporting fast isolation.

- Low Operating Torque: Air supply of 0.4–0.6 MPa is sufficient for reliable movement, reducing actuator wear and lowering energy demand.

- Improved Throughput: In pulp and wastewater plants, rapid cycling improved flow management efficiency by 12–15%, measured in reduced process interruptions.

Technical Properties for Pneumatic Zirconia Ceramic Knife Gate Valve

The Pneumatic ZrO2 Knife Gate Valve is defined not only by its design but also by quantifiable technical parameters.

| Property | Pure Zirconia (Monoclinic) - Unstabilized | Yttria-Stabilized Zirconia (YSZ) | Magnesia-stabilized zirconia (Mg-PSZ) |

| Typical Purity | High-purity raw material, but unstabilized for the final product | High purity | High purity |

| Crystal Phases (at RT) | Monoclinic (stable up to ~1170°C); Tetragonal and Cubic at higher temperatures. | Primarily, Metastable Tetragonal can have a Cubic phase. | Partially stabilized with tetragonal precipitates in a cubic matrix. |

| Density (g/cm³) | 5.65–6.05 | 5.85-6.1 | ~5.7 |

| Melting Point (°C) | ~2700-2715 | Very High (similar to pure zirconia, but phase stability is key) | Very High |

| Thermal Conductivity (W/m·K) | Low (approx. 2-3) | Low (approx. 2.5-3) | Low (approx. 3) |

| Thermal Expansion Coefficient (10⁻⁶/K) | ~10 | 9.5-10 | 10 |

| Flexural Strength (MPa) | Poor (due to phase transformation and brittleness) | Up to 1000, 710-900 | 500 |

| Compressive Strength (MPa) | Not typically used structurally | ~2000 | ~2500 |

| Fracture Toughness (MPa·m^0.5) | Low (inherently brittle) | Up to 10 (exceptionally high for ceramics due to transformation toughening), 8-9 | 6 |

| Hardness (Vickers, HV1) | Moderate | 11-13 GPa, 1100-1220 kg/mm² | 1100 kg/mm² |

| Chemical Inertness | Excellent in acids and alkalis | Excellent | Excellent |

| Biocompatibility | Generally good, but stabilized forms are preferred for medical use | Excellent, widely used in dental and medical implants | Good |

| Typical Applications | Refractories (at high temperatures) | Structural ceramics, dental implants, oxygen sensors, cutting tools, thermal barrier coatings | Refractories, structural components requiring specific thermal properties |

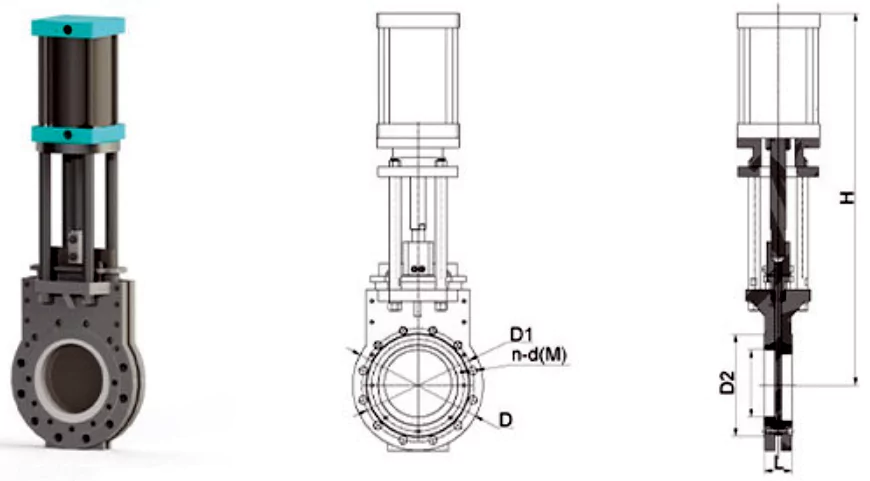

Specifications of Pneumatic Zirconia Ceramic Knife Gate Valve

| Item Name | Model | DN(mm) | L | D | D1 | D2 | n-d(M) | H |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q001 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 463 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q002 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 488 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q003 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 523 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q004 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 623 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q005 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 673 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q006 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 797 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q007 | 200 | 75 | 340 | 295 | 265 | 8-22(20) | 976 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q008 | 250 | 75 | 395 | 350 | 320 | 12-22(20) | 1175 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q009 | 300 | 80 | 445 | 400 | 370 | 12-22(20) | 1349 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q010 | 350 | 85 | 505 | 460 | 428 | 16-22(20) | 1508 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q011 | 400 | 85 | 565 | 515 | 480 | 16-26(22) | 1668 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q012 | 450 | 95 | 615 | 565 | 530 | 20-26(22) | 1870 |

| Pneumatic ZrO2 Knife Gate Valve-P10 | AT-ZV1-Q013 | 500 | 100 | 670 | 620 | 582 | 20-26(22) | 2075 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q014 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 463 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q015 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 488 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q016 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 523 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q017 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 623 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q018 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 673 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q019 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 797 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q020 | 200 | 75 | 340 | 295 | 265 | 12-22(20) | 976 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q021 | 250 | 75 | 405 | 355 | 320 | 12-26(22) | 1175 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q022 | 300 | 80 | 460 | 410 | 370 | 12-26(22) | 1349 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q023 | 350 | 85 | 520 | 470 | 428 | 16-26(22) | 1508 |

| Pneumatic ZrO2 Knife Gate Valve-P16 | AT-ZV1-Q024 | 400 | 85 | 580 | 525 | 480 | 16-30(27) | 1668 |

| Note: Nominal Diameter: DN50–DN500; Nominal Pressure: 1.0 MPa–1.6 MPa; Operating Temperature: -20 °C–250 °C; Connection Type: Wafer; Actuation Method: Pneumatic | ||||||||

Packaging of Pneumatic Zirconia Ceramic Knife Gate Valve

Each Pneumatic Zirconia Ceramic Knife Gate Valve is first packed in reinforced cartons and then secured in strong plywood cases. Protective foam lining is added to prevent vibration and surface damage during transit. This ensures them arrive safely and ready for installation.