Alumina Pump –Corrosion Resistant & Precision Fluid Solutions

ADCERAX supplies alumina pump solutions tailored for chemical processing, pharmaceutical dosing, water treatment, and electroplating applications. With ceramic wet-ends for chemical stability, our pumps ensure precise flow control, long-term durability, and contamination-free handling in both acidic and alkaline media.

Standard assemblies are available for immediate shipment, while custom builds are produced to your drawings with full engineering support. 🚀 Contact our team today to request a quote and secure reliable alumina pump solutions for your project.

≥1200 °C

High Temperature

Resistance Suitable for corrosive fluid transfer in heated processes

High-Purity Alumina

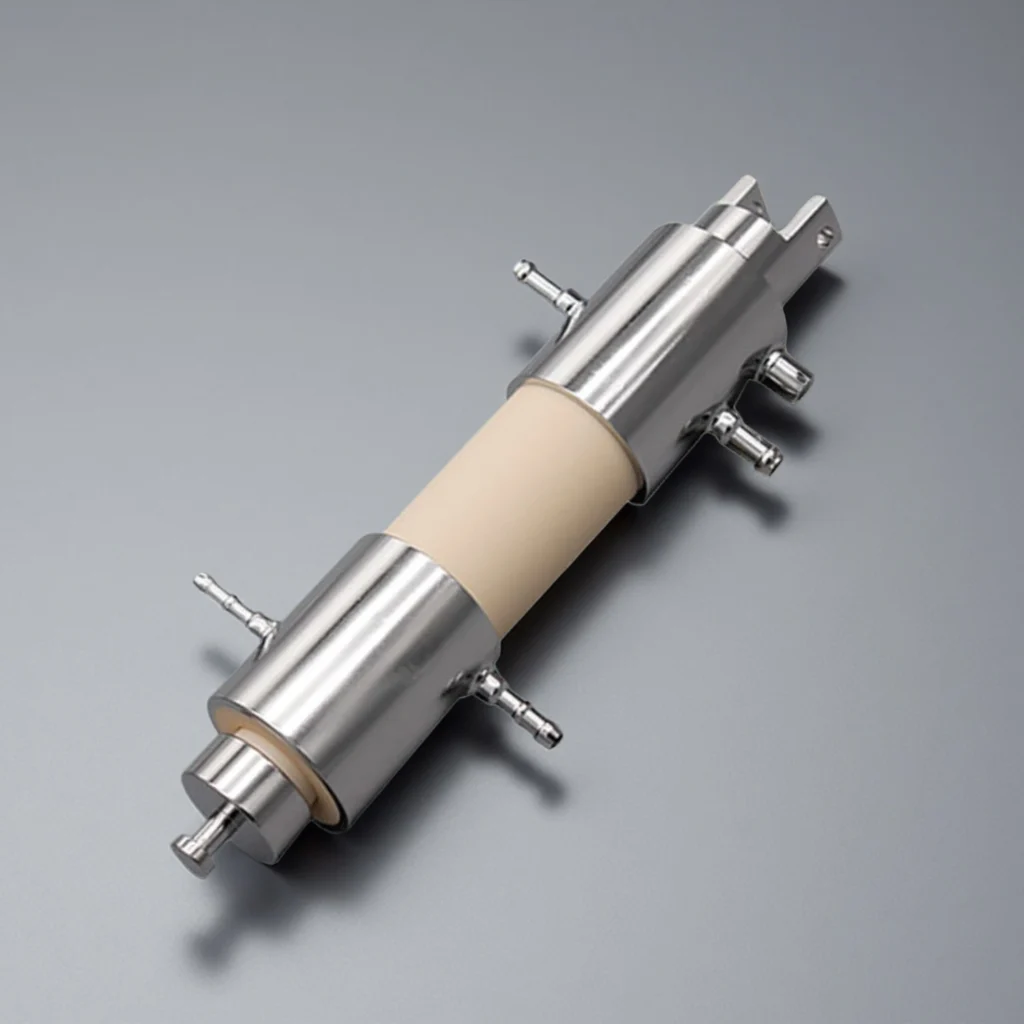

What is Alumina Pump?

Alumina pump is a precision fluid-handling device constructed with ceramic components such as plungers, sleeves, and pump heads. Made from high-purity Al₂O₃, these pumps deliver chemical stability, precise flow control, and long-term durability, making them ideal for critical applications requiring cleanliness and reliability.

Alumina Pump vs. Metal or Polymer Pumps

| Feature | Alumina Pump | Metal Pump (e.g. Stainless, Hastelloy) | Polymer Pump (e.g. PTFE, PEEK) |

| Corrosion Resistance | Excellent, withstands acids/alkalis pH 1–14 | Good but limited in strong acids | High chemical resistance, but degrades at high temp |

| Temperature Tolerance | Up to 1200 °C | Typically < 600 °C | < 250 °C |

| Purity / Contamination Risk | Inert, no metal ion leaching | Possible ion release into medium | Risk of polymer particles under wear |

| Durability / Service Life | > 3 years continuous use | Moderate, subject to corrosion & scaling | Lower in abrasive or heated processes |

| Cost of Ownership | Higher initial cost, but lowest long-term maintenance | Medium, frequent part replacement | Low entry cost, but high replacement frequency |

Alumina Ceramic Pump Benefits & Properties

Alumina ceramic pumps ensure reliable performance in both acidic and alkaline media, combining purity assurance with long-term operational strength. They are widely applied in chemical processing, pharmaceuticals, plating solutions, and water treatment systems, supporting consistent fluid control and reduced upkeep demands.

Alumina Pump Benefits

Tight tolerance control (±0.05–0.2 mm) delivers highly accurate, repeatable fluid metering.

96–99.7% Al₂O₃ prevents cross-contamination in pharmaceutical, biotech, and high-purity chemical processes.

Robust ceramic build minimizes wear, reduces maintenance downtime, and lowers lifecycle costs.

Withstands acids, alkalis, and corrosive fluids (pH 1–14) while maintaining stable long-term performance.

Alumina Ceramic Pumps Properties

| Property | 96% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.7% Al₂O₃ |

| Density (g/cm³) | 3.65–3.8 | 3.8–3.9 | 3.9 | ≥3.93 |

| Hardness (Mohs) | 8.8 | 9 | 9 | 9.1 |

| Max Operating Temp (°C) | 1600 | 1680 | 1700 | 1730 |

| Flexural Strength (MPa) | 260 | 300 | 320 | 330 |

| Thermal Conductivity (W/m·K) | 22 | 24 | 27 | 29 |

| Volume Resistivity (Ω·cm) | 10¹³–10¹⁵ | 10¹⁴–10¹⁵ | >10¹⁴ | >10¹⁵ |

| Dielectric Strength(kV/mm) | 15 | 19 | 21 | 22 |

Alumina Pump Products & Function

Alumina ceramic pumps include metering, plunger, filling, and piston designs, all built with high-purity Al₂O₃ components. They are perfect for critical fluid-handling systems.

Alumina ceramic filling pumps deliver precise micro-volume dosing with repeatable accuracy, ideal for high-purity chemical processes and laboratory fluid control applications.

- Accurate volume dispensing maintains uniform product consistency

- Smooth flow control reduces foaming and air entrapment in liquids

- Adjustable stroke capacity adapts to diverse filling line operations

Alumina ceramic cylinder liners provide outstanding wear and corrosion resistance, ensuring stable, reliable sealing and long service life in high-pressure, high-temperature applications.

- High-hardness material resists abrasion and scratching

- Excellent corrosion resistance, suitable for chemical handling

- Precision machining ensures a perfect fit in pumps and valves

Alumina ceramic metering pumps achieve micro-volume accuracy with stable repeatability, making them ideal for precision dosing in laboratory analysis and high-purity chemical processes.

- Consistent micro-volume delivery ensures repeatable dosing results

- High accuracy reduces deviation in laboratory and process systems

- Custom-fit designs integrate smoothly with precision dosing equipment

Alumina ceramic plunger pumps support consistent high-pressure delivery, maintain dimensional accuracy, and reduce maintenance downtime in critical fluid-handling systems.

- Strong mechanical sealing withstands continuous reciprocating motion

- Stable dosing control ensures reliability in high-pressure systems

- Precision-engineered plunger reduces leakage and extends service cycles

💡 Lower Maintenance Costs and Secure Stable Supply with ADCERAX Alumina Pumps

High-purity alumina pumps are engineered for buyers seeking reliable fluid handling with chemical stability, accurate dosing, and reduced maintenance costs.

Alumina Pump Applications Across Industries

Alumina pumps are widely applied in chemical dosing, pharmaceutical fluid handling, plating baths, and water treatment, offering accurate flow control.

Pharmaceutical & Biotech

📌 Application: Sterile filling systems, buffer solution transfer, precision dosing in R&D and production lines.

⚡Challenges: Risk of cross-contamination, strict GMP/FDA standards, and downtime leading to batch rejection.

⚙️ ADCERAX Solution:

High-purity Al₂O₃ construction prevents ion leaching and particle generation.

Smooth internal surfaces reduce cleaning validation time.

Custom plunger/filling pump heads support precise micro-dosing.

- 🎯With ADCERAX alumina pumps, you secure stable compliance, reduced product waste, and uninterrupted production performance.

Chemical Processing

📌 Application: Acid/alkali transfer, solvent dosing, pilot plants, and continuous process equipment.

⚡Challenges: Rapid wear of polymer pumps, high replacement frequency, and leaks causing safety hazards.

⚙️ ADCERAX Solution:

Alumina pumps withstand pH 1–14 corrosive media at elevated temperatures.

Dimensional precision (±0.05 mm) ensures consistent flow without leakage.

Engineering support enables custom pump integration for skid systems.

- 🎯Choosing ADCERAX alumina pumps means fewer interruptions, optimized uptime, and sustained operational reliability.

Energy & Thermal Systems

📌 Application: Serves in furnace systems, thermal processing equipment, and sealing interfaces exposed to high temperatures.

- ⚡Challenges: Chemical drift impacting coating quality, frequent pump wear, and high operating expenses.

⚙️ ADCERAX Solution:

Wear-resistant alumina plungers maintain stable flow for long periods.

Non-metallic fluid path eliminates contamination of plating baths.

Custom dimensions match OEM plating equipment.

- 🎯ADCERAX alumina ceramic pumps help you achieve improved output rates, extended bath durability, and high quality assurance.

Water Treatment & Environmental Engineering

📌 Application: Ultrapure water dosing, desalination systems, wastewater neutralization.

⚡Challenges: Chloride attack on steel pumps, high system maintenance costs, difficulty ensuring purity.

⚙️ ADCERAX Solution:

Corrosion resistance in both acidic and alkaline treatment steps.

Long service life (>3 years) reduces plant maintenance interventions.

Flexible pump head customization supports OEM water system integration.

- 🎯ADCERAX alumina ceramic pumps keep processes running smoothly, reduce manual intervention, and simplify long-term maintenance scheduling.

Semiconductor & Electronics

📌 Application: Wafer cleaning, etching, slurry polishing, and chemical vapour deposition support.

- ⚡Challenges: Nanometer-level contamination tolerance, risk of yield loss, expensive downtime.

⚙️ ADCERAX Solution:

High-purity alumina components prevent trace contamination.

Tight dimensional tolerances ensure stable micro-flow dosing.

Cleanroom packaging and inspection guarantee defect-free supply.

- 🎯ADCERAX offer ceramic pumps that help improve wafer production, reduce quality issues, and maintain stable performance over time.

Customize Alumina Pump manufacturer

ADCERAX specializes in customized alumina pumps, engineered to match your exact process requirements. From dimensions, tolerances, and Al₂O₃ purity grades to plunger designs and sealing interfaces, every pump can be tailored from drawings or samples. Standard stock ships within 24 hours, while customized assemblies are typically delivered in 3–7 weeks, ensuring both flexibility and reliability for your projects.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Your Trusted Alumina Pump Supplier

ADCERAX is a trusted China alumina pump manufacturer, delivering factory-direct supply, reliable quality, and engineering support. From standard models to custom assemblies, we provide fast lead times and dependable service worldwide.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

Alumina Ceramic Pump Factory-ADCERAX

ADCERAX is a professional China alumina pump manufacturer and supplier, providing a full range of metering pumps, plunger pumps, filling pumps, and piston pumps. With over 20 years of advanced ceramic pump production expertise, we serve global customers in the USA, Germany, Japan, and other high-end industrial markets,delivering pumps that meet stringent requirements for precision, chemical stability, and low maintenance frequency.

- 96%–99.7% Al₂O₃ ceramic ensures superior chemical stability and process cleanliness

- Pump heads, plungers, and sealing components customize from drawings or samples

- Fast prototyping (7–15 days) & flexible MOQ

- Rigorous QC on tolerance, dielectric strength, and surface finish

- Engineering support for OEM designs and application-specific solutions

Alumina Pump Processing

By combining advanced forming, sintering, and machining processes, our alumina pumps achieve tight dimensional tolerances, high-purity fluid transfer, and reliable performance under corrosive and high-temperature conditions. All products undergo rigorous QC inspection to ensure consistency in demanding applications such as chemical dosing, pharmaceutical filling, plating baths, and ultrapure water systems.

| Technical Capabilities Overview | |

|---|---|

| Material Grades | 96%, 99%, 99.5–99.7% Al₂O₃ |

| Pump Range | Dimensions customizable based on ID/OD, stroke length, and sealing requirements; tolerance typically ±0.05–0.2 mm |

| Forming Methods | Forming, isostatic pressing, and CNC machining for high-precision pump heads, plungers, and sealing components |

| Processing | High-temperature sintering, grinding, polishing, and sealing surface optimization to ensure smooth fluid transfer |

| Surface Finish | Smooth / Ground / Polished sealing interfaces to enhance wear resistance and prevent leakage |

| Customization | OEM solutions supported with drawings or samples for tailored designs |

Alumina Ceramic Pump Quality & Certifications

FAQ

Typical alumina pumps are manufactured with 96%-99.7% Al₂O₃, depending on the chemical compatibility, temperature, and contamination requirements of the application.

With proper operation, alumina pumps often exceed 3–5 years of continuous service, significantly reducing replacement frequency.

Yes, we offer full customization of ID, OD, length, sealing interfaces, and tolerances (down to ±0.05 mm) based on drawings or samples.

We ensure precision by combining isostatic pressing, CNC machining, and high-temperature sintering, allowing tolerances as tight as ±0.05 mm. Each component undergoes surface grinding, polishing, and dimensional inspection to guarantee consistent fit, smooth operation, and reliable sealing in demanding applications.

Yes, we provide design compatibility support and OEM adaptation to existing pump housings or assemblies.

For standard stock items, shipment is typically arranged within 7 days.

For custom alumina pumps, the lead time is usually 3–5 weeks, depending on the design requirements.

For projects with complex geometries, tighter tolerances, or multi-component assemblies, production may extend to 6–8 weeks to ensure precise quality control and reliable performance.

The price of alumina pumps is determined by several key factors:

| Factor | Impact on Price | Customer Note |

|---|---|---|

| Alumina Purity | Higher purity (99.5–99.7% Al₂O₃) costs more due to refined raw materials & processing | Improves durability & chemical resistance |

| Design Complexity | Tight tolerances (±0.05 mm), intricate structures, multi-part assemblies increase cost | Ensures precision & reliable performance |

| Size & Dimensions | Larger pump bodies use more material & longer sintering cycles → higher price | Needed for heavy-duty or large-volume transfer |

| Order Volume | Small lots & prototypes = higher unit cost; bulk orders lower cost | Consider MOQ & batch discounts |

| Customization | Special coatings, polishing, sealing interfaces, OEM solutions add cost | Enhances fit for unique applications |

In general, the higher the purity and the more complex the design, the higher the unit cost. However, these factors also improve pump durability and reduce long-term maintenance expenses, balancing overall value for critical applications.

Alumina Pump vs. Zirconia Pump Comparison:

| Property | Alumina Pump (Al₂O₃) | Zirconia Pump (ZrO₂) |

|---|---|---|

| Material Strength | High hardness, good wear resistance, lower fracture toughness | Very high strength, excellent wear resistance, high toughness |

| Corrosion Resistance | Excellent resistance to acids, alkalis, and most chemicals | Comparable corrosion resistance, but better under extreme stress |

| Operating Conditions | Suitable for chemical dosing, plating baths, water treatment | Ideal for high-pressure, high-impact, or abrasive applications |

| Purity & Cleanliness | >99% purity, stable for pharma and water treatment | High purity, used where contamination-free operation is critical |

| Cost Level | More economical, widely used as standard solution | Higher cost due to tougher processing and superior properties |

| Typical Applications | Chemical processing, pharmaceuticals, plating, water treatment | Semiconductor, advanced manufacturing, aerospace, precision dosing |

Alumina pumps (Al₂O₃): High purity, strong corrosion resistance, cost-effective, widely used in chemical dosing, plating baths, pharma, and water treatment.

Zirconia pumps (ZrO₂): Higher strength and fracture toughness, better for high-pressure or high-impact conditions, commonly used in semiconductor and advanced manufacturing.

👉 Conclusion: Alumina pumps are reliable and economical for most corrosive environments, while zirconia pumps are chosen for extreme strength and precision-demanding applications.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Get a Quote for Your Custom Alumina Pump

Looking for reliable alumina pumps tailored to your process? Share your specifications with the ADCERAX engineering team and receive a fast, competitive quotation. From standard designs to fully customized assemblies, we deliver solutions that balance performance, durability, and timely delivery.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours