Fused quartz ceramic crucible is a containment vessel made from fused quartz (also called fused silica), an amorphous form of silicon dioxide (SiO₂). It is produced by melting high-purity silica and then cooling to form a glassy, non-crystalline material. These crucibles are used where low contamination, high thermal stability and low thermal expansion are required for high-temperature processing.

Fused Quartz Ceramic Crucible Benefits

- Low contamination fused quartz — material formulations with measured low metallic and hydroxyl content for reduced melt contamination; available in 99.9%–99.99% SiO₂ grades.

- Thermal performance tuned for process — designed continuous use up to ~1200°C with engineering margins and recommended limits per grade.

- Dimensional accuracy for process repeatability — wall thickness and diameter tolerances suitable for crystal pulling and lab repeatability (custom tolerance options).

- Low thermal expansion — reduces thermal stress in rapid heating/cooling cycles, lowering breakage risk during process transitions.

- Custom geometry options — cylindrical, tapered, deep-well, large-mouth and closed-end forms produced per drawing.

Fused Quartz Ceramic Crucible Properties

| Item | Value | |

| Chemical Composition | SiO2(Wt) | ≥99.8% |

| Al2O3 | ≤0.12% | |

| Fe2O3 | ≤0.02% | |

| TiO2 | ≤0.018% | |

| MgO | ≤0.004% | |

| Na2O | ≤0.004% | |

| CaO | ≤0.007% | |

| K2O | ≤0.004% | |

| Physical Properties | Bulk Density | ≥1.90-1.95g/cm3 |

| Apparent Porosity | ≤15% | |

| Apparent Porosity | ≥50MPa | |

| Flexural Strength (Room Temperature) | ≥25MPa | |

| Flexural Strength (High Temperature) | ≥28MPa | |

| Crystal Phase Content | <1% | |

| Thermal Shock Resistance (1100°C → water quench) | ≥10 | |

| Thermal Properties | Thermal Conductivity @ 20°C | 20℃:0.64W/m°K |

| 500℃:0.81W/m°K | ||

| 1090℃:0.88W/m°K | ||

| Thermal Expansion Coefficient (20–1100°C) | ≤0.9×106 | |

| Thermal Expansion Coefficient (20–1100°C) | 1650 |

Fused Quartz Ceramic Crucible Specification

Type 1: Cylindrical Fused Quartz Ceramic Crucible

| Cylindrical Fused Quartz Ceramic Crucible | ||||

| Item | Outer Dia(mm) | Inner Dia(mm) | Height(mm) | Thickness(mm) |

| AT-TCY-G1001 | 60 | 40 | 90 | 5 |

| AT-TCY-G1002 | 82 | 70 | 130 | 6 |

| AT-TCY-G1003 | 100 | 80 | 60 | 10 |

| AT-TCY-G1004 | 100 | 74 | 300 | 13 |

| AT-TCY-G1005 | 100 | 88 | 120 | 6 |

| AT-TCY-G1006 | 117 | 106 | 205 | 5.5 |

| AT-TCY-G1007 | 120 | 110 | 125 | 5 |

| AT-TCY-G1008 | 128 | 102 | 300 | 13 |

| AT-TCY-G1009 | 140 | 120 | 130 | 10 |

| AT-TCY-G1010 | 160 | 140 | 170 | 10 |

| AT-TCY-G1011 | 190 | 164 | 300 | 13 |

| AT-TCY-G1012 | 200 | 175 | 164 | 12.5 |

| AT-TCY-G1013 | 305 | 265 | 300 | 20 |

| AT-TCY-G1014 | 305 | 265 | 400 | 20 |

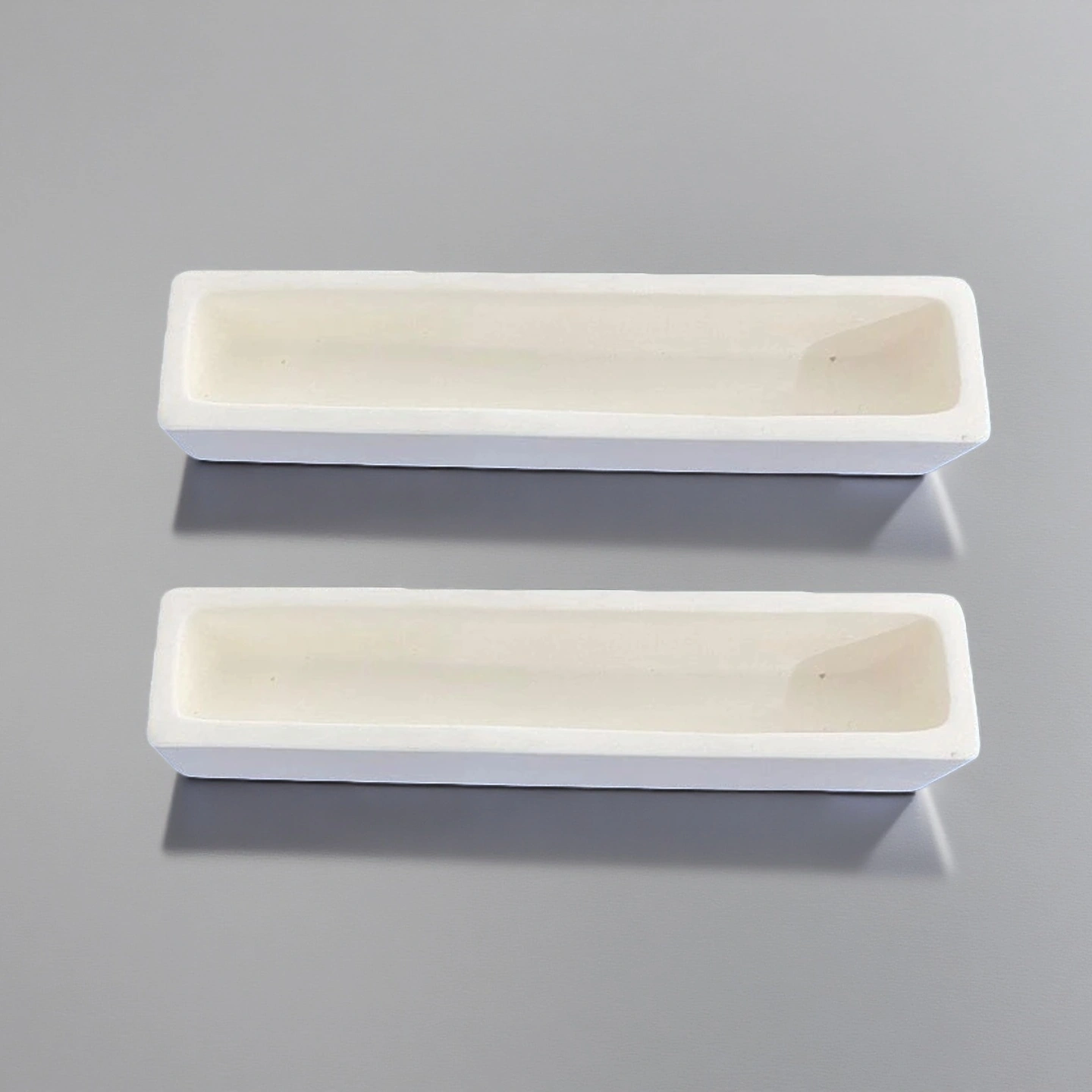

Type 2: Square Fused Quartz Ceramic Crucible

| Square Fused Quartz Ceramic Crucible | |||

| Item | Length(mm) | Width(mm) | Height(mm) |

| AT-TCY-G2001 | 250 | 250 | 100 |

| AT-TCY-G2002 | 300 | 300 | 110 |

| AT-TCY-G2003 | 300 | 300 | 150 |

| AT-TCY-G2004 | 300 | 300 | 200 |

| AT-TCY-G2005 | 320 | 320 | 48 |

| AT-TCY-G2006 | 320 | 320 | 55 |

| AT-TCY-G2007 | 320 | 320 | 60 |

| AT-TCY-G2008 | 320 | 320 | 75 |

| AT-TCY-G2009 | 320 | 320 | 80 |

| AT-TCY-G2010 | 320 | 320 | 85 |

| AT-TCY-G2011 | 320 | 320 | 120 |

| AT-TCY-G2012 | 320 | 320 | 130 |

| AT-TCY-G2013 | 320 | 320 | 150 |

| AT-TCY-G2014 | 320 | 320 | 190 |

| AT-TCY-G2015 | 370 | 370 | 185 |

| AT-TCY-G2016 | 420 | 420 | 150 |

| AT-TCY-G2017 | 520 | 520 | 120 |

| AT-TCY-G2018 | 530 | 530 | 120 |

| AT-TCY-G2019 | 530 | 530 | 135 |

| AT-TCY-G2020 | 520 | 520 | 150 |

Fused Quartz Ceramic Crucible Packaging:

- Individual padded wooden or molded foam boxes for each crucible; external wooden crate for pallet shipments.