Aluminum silicate fiber felt is a flexible, high-temperature insulation material made from fine alumina–silica fibers that are formed into a lightweight felt by needle-punching or similar processes. It belongs to the family of ceramic fiber products and is often described as a soft, compressible refractory lining material rather than a rigid refractory brick or board.

Aluminum Silicate Fiber Felt Benefits

-

Stable high-temperature insulation

Aluminum silicate fiber felt maintains insulating performance up to 1260–1430 °C, with controlled linear shrinkage after long-term exposure, which helps keep furnace shell temperatures within design limits for steel, aluminum and glass processes. -

Low thermal mass for fast heating cycles

The low heat storage of the alumino-silicate fiber matrix shortens heat-up and cool-down times compared with dense refractories, supporting frequent start–stop or batch furnace operation and reducing idle energy losses. -

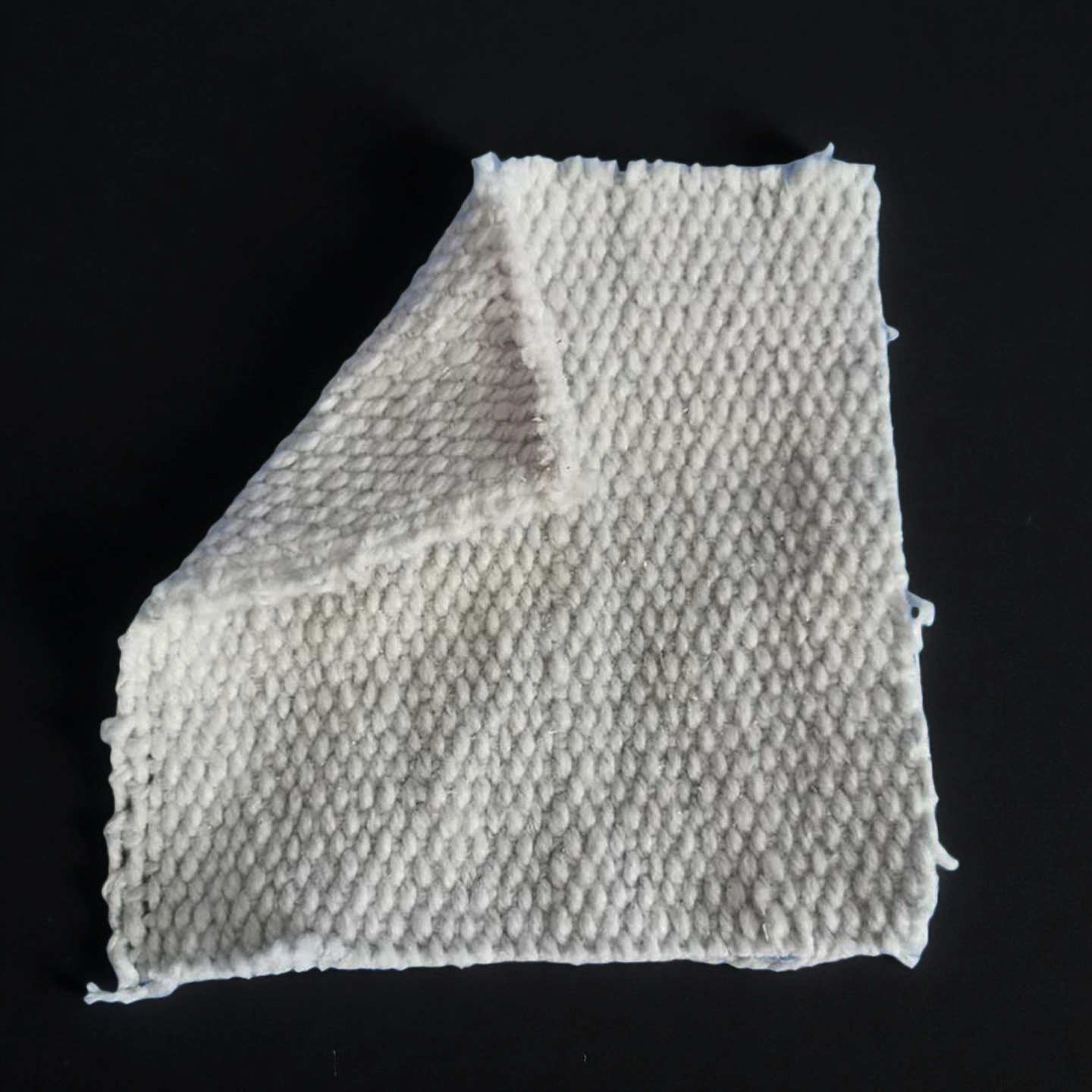

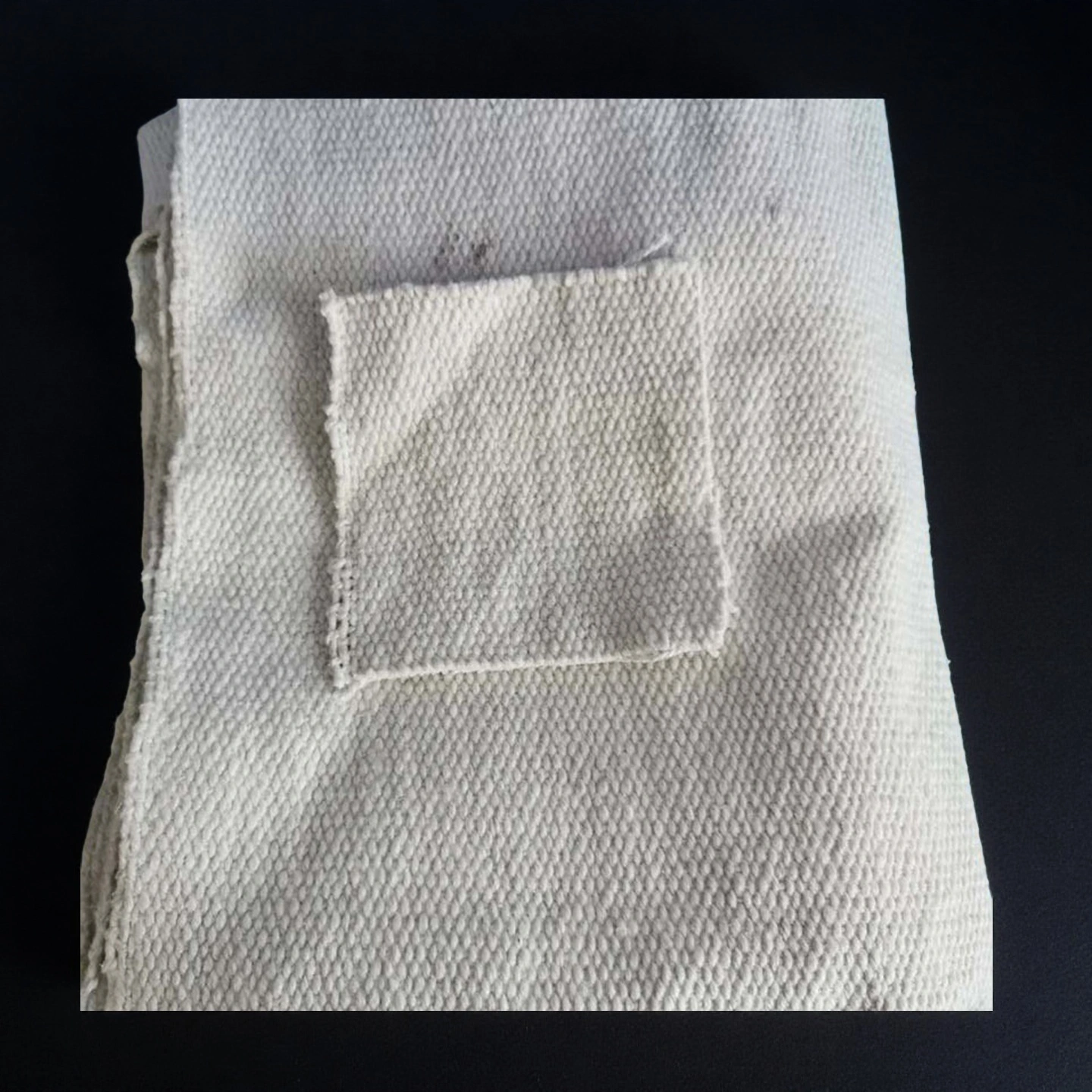

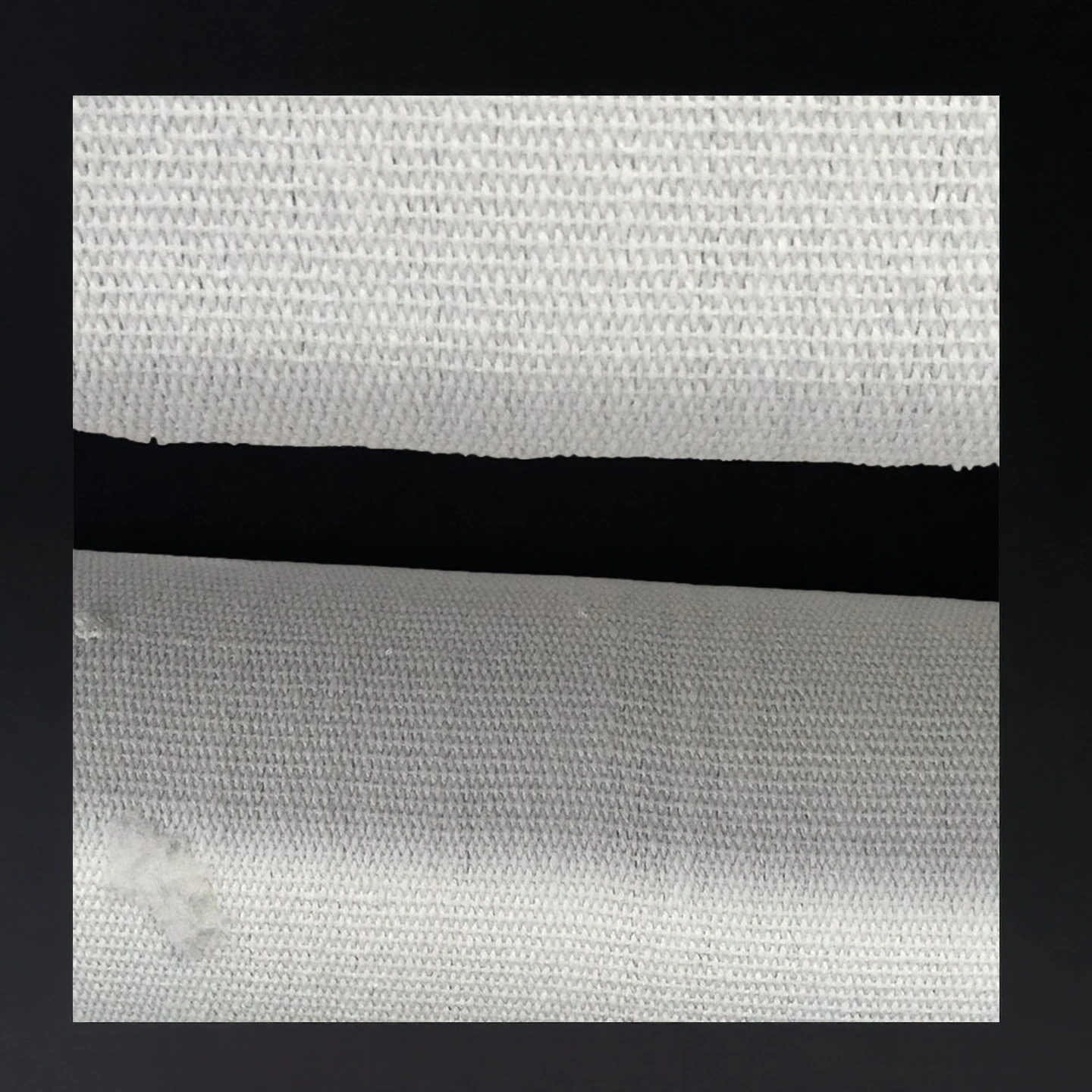

Soft, flexible and easy to install

Needle-punched construction yields a tough yet compressible felt that conforms to curved shells, expansion joints and complex shapes, simplifies on-site fitting and reduces the risk of cracking during thermal cycling. -

Consistent thermal conductivity across grades

Tested thermal conductivity values around 0.09 W/m·K at 400 °C and 0.16–0.20 W/m·K at 800–1000 °C help engineers calculate heat loss accurately and optimise layer thickness and density for each zone. -

Optional bio-soluble AES grades

For plants under stricter health and safety regulations, aluminum silicate fiber felt can be offered in AES bio-soluble compositions that dissolve in physiological fluids while retaining similar insulation performance.

Aluminum Silicate Ceramic Fiber Felt Properties

| Item | General Grade | Standard Grade | High Purity Grade | High Alumina Grade | Zirconia-Containing Grade |

| Classification Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 |

| Service Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1350 |

| Color | White | Off-white | Off-white | Off-white | Off-white |

| Bulk Density (kg/m³) | 260–320 | 260–320 | 260–320 | 260–320 | 260–320 |

| Permanent Linear Shrinkage (%) (24 h holding; based on 128 kg/m³) | <2.5 (1000°C) | <2.5 (1050°C) | <2.5 (1100°C) | <2.5 (1100°C) | <2.5 (1350°C) |

| Thermal Conductivity (W/m·K) (bulk density 128 kg/m³) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) |

| 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | |

| 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | ||

| Tensile Strength (MPa) (bulk density 128 kg/m³) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Chemical Composition (wt%) | |||||

| Al₂O₃ | 44 | 46 | 47–49 | 52–55 | 39–40 |

| Al₂O₃ + SiO₂ | 96 | 97 | 99 | 99 | – |

| Al₂O₃ + SiO₂ + ZrO₂ | – | – | – | – | 99 |

| ZrO₂ | – | – | – | – | 15–17 |

| Fe₂O₃ | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na₂O + K₂O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

Aluminum Silicate Fiber Felt Specifications

| Item | Thickness (mm) | Width (mm) | Weight (g/m²) | Weave Pattern | 增强形式 | Continuous Service Temp (°C) |

| AT-GSL-WB1001 | 2 | 1000 | 1000 | Plain Weave | Glass Fiber Reinforced | 650 |

| AT-GSL-WB1002 | 3 | 1000 | 1400 | Plain Weave | ||

| AT-GSL-WB1003 | 5 | 1000 | 2300 | Twill Weave | ||

| AT-GSL-WB1004 | 6 | 1000 | 2600 | Twill Weave | ||

| AT-GSL-WB1005 | 2 | 1000 | 1100 | Plain Weave | SUS304 Stainless Steel Wire Reinforced | 1050 |

| AT-GSL-WB1006 | 3 | 1000 | 1500 | Plain Weave | ||

| AT-GSL-WB1007 | 5 | 1000 | 2400 | Twill Weave |

Aluminum Silicate Fiber Felt Packaging

- Fiber felt rolls wrapped with plastic film to reduce dust release during transport.