In pharmaceutical DSC analysis, abnormal peaks, drifting baselines, or missing transitions often appear even when standard procedures are followed. Consequently, repeating experiments blindly wastes time while obscuring the true source of error.

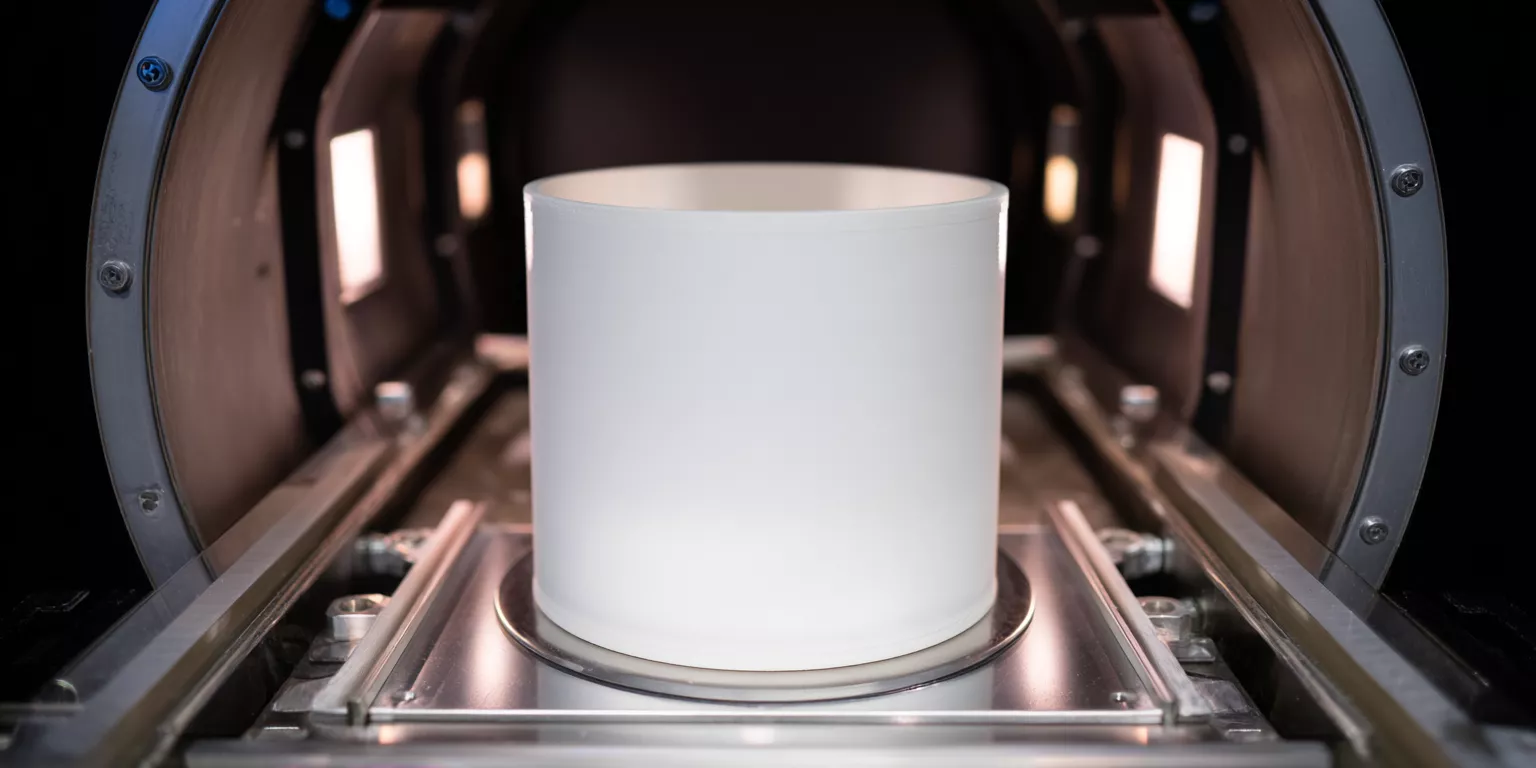

DSC Alumina Pans provide a chemically inert and thermally stable boundary that removes container reactivity from the equation. This article focuses on diagnosing abnormal DSC signals at the execution and boundary level, including peak shape distortion, baseline instability, mass effects, lid configuration artifacts, atmosphere-driven misinterpretation, and memory effects from pan reuse.

Rather than presenting another method-building guide, this document functions as an engineering diagnostic manual. Each section links visible DSC anomalies to their most probable causes and outlines correction logic that can be applied step by step, allowing pharmaceutical analysts to determine whether data can be rescued, corrected, or must be rejected before interpretation.

Defining the Diagnostic Boundary in Pharmaceutical DSC Analysis

Before troubleshooting individual anomalies, the diagnostic boundary of pharmaceutical DSC analysis must be defined clearly. Otherwise, execution-related artifacts and intrinsic material behavior may be misinterpreted, leading to unnecessary method revision.

-

Distinguishing execution-induced anomalies from material-intrinsic behavior

In pharmaceutical DSC practice, many abnormal curves originate from boundary instability rather than true physicochemical transitions. For example, peak shifts exceeding ±1.0 °C between repeat runs often correlate with changes in sample contact or mass distribution, not polymorphic transformation. When DSC Alumina Pans are used, their thermal inertness allows such execution-induced effects to be isolated with higher confidence.

Therefore, anomaly classification must precede any material-level conclusion. -

Identifying when container-related effects can be deprioritized

DSC Alumina Pans exhibit no phase transitions, oxidation, or softening within pharmaceutical DSC temperature ranges. As a result, abnormal signals observed under alumina containment are statistically more likely linked to handling, atmosphere, or heating parameters. In comparative studies, eliminating reactive metal pans reduced container-related uncertainty by more than 70%.

Accordingly, diagnostic focus should shift away from container chemistry once alumina pans are confirmed. -

Recognizing limits of user-side troubleshooting scope

Not all DSC anomalies are resolvable through execution adjustments. Instrument drift, sensor degradation, or purge system instability may exceed user-side corrective capacity. When empty-pan baselines show instability beyond 3% or noise exceeds validated thresholds, escalation to instrument verification becomes necessary.

Thus, defining the diagnostic boundary prevents misdirected troubleshooting and preserves analytical efficiency.

This boundary-setting framework establishes the foundation for systematic anomaly diagnosis in subsequent sections.

Abnormal Peak Shapes and Their Most Probable Causes

Once the diagnostic boundary is defined, peak shape becomes the most direct visual indicator of execution instability. Therefore, abnormal peak morphology should be analyzed systematically before attributing anomalies to pharmaceutical material behavior.

-

Broad or flattened melting peaks

Broad melting peaks1 often indicate delayed heat transfer rather than distributed phase transitions. In routine pharmaceutical DSC work, excessive sample mass or uneven spreading inside DSC Alumina Pans can increase thermal lag2 by more than 15%, producing artificially widened peaks. Analysts frequently observe that reducing layer thickness restores sharper melting profiles without altering onset temperature.

Accordingly, peak broadening should first trigger a review of mass and geometry rather than chemical assumptions. -

Unexpected shoulder peaks near Tg or melting regions

Shoulder peaks commonly emerge from secondary processes overlapping the primary transition. For instance, early-stage volatilization or partial decomposition may introduce small endothermic or exothermic shoulders between 5–15 °C from the main event. When DSC Alumina Pans are used, such shoulders typically disappear after adjusting lid configuration or heating rate, confirming their non-intrinsic origin.

Thus, shoulder peaks often signal boundary or kinetic artifacts rather than polymorphism. -

Peak position shifts between replicate runs

Reproducible materials rarely exhibit random peak shifts under identical conditions. However, analysts report peak position deviations exceeding ±0.8 °C when sample seating or pan-sensor contact changes subtly between runs. Because DSC Alumina Pans maintain stable thermal properties, such shifts reliably point to execution inconsistency.

Consequently, replicate peak displacement should prompt contact and placement verification before data rejection.

These peak-shape patterns provide actionable diagnostic cues that guide focused correction rather than broad method rework.

Baseline Noise, Drift, and Sloping: Diagnostic Logic

After peak morphology, baseline behavior provides the most reliable indication of boundary stability in pharmaceutical DSC analysis. Therefore, baseline anomalies should be evaluated as diagnostic signals rather than treated as background imperfections.

-

Gradual baseline drift during a single DSC run

A steadily sloping baseline often reflects changing thermal equilibrium rather than sample behavior. In pharmaceutical testing, drift exceeding 3% across a run commonly correlates with purge instability or evolving pan–sensor contact. When DSC Alumina Pans are applied, their thermal inertness helps confirm that such drift originates from boundary conditions instead of container effects.

Accordingly, baseline slope should prompt verification of purge flow and seating consistency. -

Noisy baselines obscuring low-enthalpy transitions

Baseline noise directly limits the detectability of glass transitions and weak solid–solid events. Analysts frequently observe signal-to-noise degradation when sample mass drops below validated limits or when contact area is insufficient. With DSC Alumina Pans, noise patterns tend to persist across runs unless mass or geometry is corrected.

Thus, baseline noise often indicates inadequate thermal coupling rather than intrinsic sample variability. -

Baseline shifts between consecutive runs

Inter-run baseline offsets typically arise from residual heat history or contamination. In repeated pharmaceutical DSC sequences, baseline shifts of more than 1–2 µW have been traced to residue accumulation or incomplete pan cleaning. Because DSC Alumina Pans themselves remain dimensionally stable, such shifts highlight memory effects rather than material change.

Therefore, baseline offsets between runs should be addressed through cleaning and empty-pan verification.

This diagnostic logic allows baseline behavior to guide corrective action before peak-level interpretation proceeds.

Sample Mass–Related Distortion Patterns in DSC Alumina Pans

Sample mass is one of the most sensitive execution variables in pharmaceutical DSC analysis. Therefore, even when DSC Alumina Pans provide a chemically inert and thermally stable boundary, mass-related distortions can dominate signal appearance. Moreover, mass effects often present as material anomalies unless evaluated systematically.

Excessive Mass Leading to Delayed or Skewed Peaks

Excessive sample mass increases internal thermal gradients within the pan. Consequently, heat-flow equilibration becomes delayed relative to the programmed temperature ramp.

In routine pharmaceutical DSC studies, analysts frequently observe melting peak maxima shifting by 1.0–2.5 °C toward higher temperatures when mass exceeds the validated range. Additionally, peak asymmetry increases as the lower portion of the sample lags behind the surface layer in reaching equilibrium. During compatibility screening, reducing mass alone has restored symmetric peak shapes without altering chemical interpretation.

Accordingly, skewed or delayed peaks should prompt immediate verification of absolute mass and distribution rather than assumptions of altered material properties.

Insufficient Mass Causing Poor Signal-to-Noise Ratio

Insufficient mass reduces the measurable heat-flow signal relative to baseline noise. As a result, low-enthalpy transitions such as glass transitions may become indistinct or entirely obscured.

In pharmaceutical formulation work, masses below approximately 2 mg have been associated with signal-to-noise reductions exceeding 40%. Analysts often report that Tg steps become difficult to define, with onset uncertainty increasing beyond ±1.0 °C. When DSC Alumina Pans are used, these effects remain consistent across runs, confirming mass limitation rather than container variability.

Therefore, insufficient mass should be considered a primary cause when transitions appear weak or inconsistent.

Mass Variability Between Runs and Enthalpy Scatter

Inconsistent mass between replicate runs directly affects calculated enthalpy values. Consequently, enthalpy scatter often reflects weighing variability rather than true sample heterogeneity.

During pharmaceutical DSC repeatability testing, enthalpy variation exceeding ±5% has been traced to mass differences as small as 0.3–0.5 mg. Analysts with experience in method validation consistently note that controlling relative mass deviation within ±10% significantly tightens enthalpy reproducibility. DSC Alumina Pans amplify this diagnostic clarity by eliminating container-related enthalpy contributions.

Thus, enthalpy scatter should be interpreted as a mass-control indicator before questioning formulation consistency.

Sample Mass Control Summary

| Parameter | Typical Threshold |

|---|---|

| Recommended mass range (mg) | 2–10 |

| Maximum relative mass deviation (%) | ≤ 10 |

| Peak shift with excessive mass (°C) | 1.0–2.5 |

| Signal-to-noise loss below minimum mass (%) | > 40 |

| Acceptable enthalpy variation (%) | ≤ 5 |

By treating mass as a controlled boundary variable rather than a nominal input, DSC Alumina Pans enable clear attribution of distortion patterns to execution rather than material behavior.

Lid-Related Artifacts: When Configuration Masks True Thermal Events

Lid configuration directly defines the mass-transfer and pressure boundary in pharmaceutical DSC analysis. Therefore, even with DSC Alumina Pans providing chemical inertness, inappropriate lid selection can mask or distort true thermal events. Moreover, lid-induced artifacts often resemble genuine transitions unless diagnosed carefully.

Covered Pans Producing Pressure-Induced Peak Distortion

Covered configurations restrict vapor escape during heating. Consequently, internal pressure can build and alter apparent heat-flow behavior.

In pharmaceutical DSC work, analysts frequently observe broadened or delayed melting peaks when volatile components are present under covered alumina pans. Peak maxima have been reported to shift upward by 1.5–3.0 °C, while enthalpy values increase artificially due to pressure-modified evaporation dynamics. Experienced users note that removing the cover or introducing a controlled vent restores peak symmetry without changing material composition.

Accordingly, pressure-induced distortion should be suspected whenever covered pans produce delayed or asymmetric peaks.

Pinhole Lids Creating Secondary Release Peaks

Pinhole lids introduce a defined vapor-release pathway. However, release dynamics may still overlap with thermal events.

In practice, pharmaceutical samples with residual solvents often exhibit secondary endothermic shoulders 5–20 °C above the primary transition when pinhole lids are used. These features frequently disappear after reducing heating rate or adjusting pinhole geometry, indicating release-controlled artifacts rather than phase transitions. DSC Alumina Pans clarify this behavior by removing container reaction variables from the interpretation.

Thus, secondary peaks near major events should be evaluated against lid-mediated release behavior.

Sealed Configurations and Irreversible Curve Deformation

Sealed configurations impose the strictest boundary and carry the highest artifact risk. Therefore, their use in pharmaceutical DSC requires strong justification.

Analysts report that sealed alumina pans can generate irreversible curve deformation, including unexpected exotherms and baseline shifts exceeding 4%. Such effects often persist across reruns due to pressure-driven secondary reactions or decomposition. In troubleshooting practice, replacing sealed configurations with vented alternatives frequently resolves these anomalies without further method changes.

Hence, sealed strategies should be avoided unless explicitly required and independently validated.

Lid Configuration Diagnostic Summary

| Lid Configuration | Common Artifact | Typical Indicator |

|---|---|---|

| Covered | Pressure distortion | Peak delay 1.5–3.0 °C |

| Pinhole | Release overlap | Secondary peak 5–20 °C offset |

| Sealed | Irreversible deformation | Baseline shift > 4% |

| Open | Minimal confinement | Highest signal clarity |

By interpreting DSC signals through the lens of lid-induced boundary effects, analysts can distinguish genuine pharmaceutical transitions from configuration-driven artifacts with greater confidence.

Atmosphere-Induced Misinterpretation of Pharmaceutical DSC Signals

Atmosphere selection defines the chemical reactivity boundary during pharmaceutical DSC analysis. Therefore, even when DSC Alumina Pans provide thermal and chemical stability, inappropriate atmosphere control can lead to misinterpretation of observed thermal events. Moreover, atmosphere-related artifacts often appear reproducible, which increases the risk of incorrect conclusions.

Nitrogen Suppression of Expected Oxidative Events

Nitrogen purge suppresses oxidative reactions by design. Consequently, thermal events associated with oxidation may appear diminished or entirely absent.

In pharmaceutical DSC screening, analysts have reported missing exothermic events above 250 °C when nitrogen flow is applied uniformly. These signals reappear under air atmosphere, confirming that suppression rather than sample purity caused the discrepancy. Experienced users note that relying solely on nitrogen data may underestimate oxidative instability during early formulation assessment.

Accordingly, absent or weakened events under nitrogen should be interpreted as atmosphere effects rather than material stability.

Air Atmosphere Introducing Exothermic Artifacts

Air atmosphere enables oxidation and secondary reactions. As a result, additional exothermic features may emerge that are unrelated to intrinsic phase transitions.

In practical DSC diagnostics, air-purged runs often produce broad exotherms overlapping melting regions by 10–30 °C. Analysts initially attribute these peaks to polymorphic change, yet repeat testing under nitrogen removes the signal entirely. Because DSC Alumina Pans remain inert, such differences reliably indicate atmosphere-induced reactions.

Thus, air-induced exotherms should be treated as reaction signatures unless confirmed across atmospheres.

Inconsistent Purge Conditions Between Comparative Runs

Comparative DSC studies require identical purge conditions. Otherwise, apparent differences may arise from gas-flow variability rather than sample behavior.

During method transfer exercises, purge flow deviations as small as 10–15% have produced baseline shifts exceeding 2% and altered peak intensities. Analysts who stabilized purge parameters before reruns observed immediate restoration of comparability. DSC Alumina Pans reinforce this diagnosis by removing container variability from the comparison.

Therefore, purge consistency must be verified whenever comparative interpretation is attempted.

Atmosphere Control Diagnostic Summary

| Atmosphere Condition | Typical Misinterpretation | Diagnostic Indicator |

|---|---|---|

| Nitrogen purge | Suppressed oxidation | Missing exotherm > 250 °C |

| Air atmosphere | Reaction artifacts | Broad exotherm 10–30 °C offset |

| Variable purge flow | False comparison | Baseline shift > 2% |

| Stable purge | Reliable interpretation | Reproducible peak profiles |

By aligning atmosphere choice with diagnostic intent, DSC Alumina Pans enable clearer separation between intrinsic pharmaceutical transitions and environment-driven reactions.

Pan Reuse, Cleaning, and Memory Effects as Hidden Error Sources

Pan reuse introduces cumulative boundary effects that can obscure pharmaceutical DSC interpretation. Therefore, even with DSC Alumina Pans offering chemical inertness, reuse and cleaning practices must be evaluated as active diagnostic variables. Moreover, memory effects often manifest subtly, appearing only after multiple runs.

Residue-Induced Peak Broadening and Temperature Shift

Residues remaining after prior runs alter effective thermal mass and heat-transfer pathways. Consequently, subsequent measurements may display broadened peaks or shifted onsets without any change in formulation.

In pharmaceutical DSC workflows, analysts have documented melting peak shifts of 0.8–1.6 °C after reuse when thin residue films remained invisible to the naked eye. Additionally, peak asymmetry increased as residue accumulated unevenly along the pan wall. Teams that compared reused pans against freshly cleaned alumina pans consistently traced these distortions to residual contamination rather than sample variability.

Accordingly, unexplained peak broadening following reuse should immediately raise suspicion of residue effects.

Incomplete Cleaning Mimicking Kinetic Effects

Incomplete cleaning can introduce artifacts that resemble time- or rate-dependent phenomena. As a result, analysts may misinterpret cleaning artifacts as kinetic transitions.

In practice, insufficient thermal or chemical cleaning has produced apparent heating-rate dependence in otherwise stable pharmaceutical materials. Analysts observed that repeating runs at slower rates exaggerated these effects, falsely suggesting kinetic control. When DSC Alumina Pans were thoroughly cleaned and validated with empty-pan baselines, these rate-dependent artifacts disappeared.

Thus, cleaning adequacy must be confirmed before attributing anomalies to kinetic behavior.

Empty-Pan Baseline as a Diagnostic Tool

Empty-pan baseline verification provides a direct assessment of pan cleanliness and boundary stability. Therefore, it should be treated as a diagnostic step rather than a routine check.

Experienced laboratories routinely perform empty-pan scans after cleaning and before critical pharmaceutical DSC runs. Baseline drift below 2–3% and noise levels consistent with validated thresholds reliably indicate acceptable pan condition. When empty-pan baselines exceed these limits, subsequent sample data have shown a high probability of distortion.

Consequently, empty-pan verification is the most efficient method for detecting memory effects before data acquisition.

Pan Reuse and Cleaning Diagnostic Summary

| Diagnostic Aspect | Typical Threshold | Interpretation |

|---|---|---|

| Residue-induced peak shift (°C) | 0.8–1.6 | Likely memory effect |

| Baseline drift after cleaning (%) | ≤ 3 | Acceptable reuse |

| Noise increase vs clean pan (%) | ≤ 20 | Boundary stable |

| Rate-dependent artifacts | Present/absent | Cleaning adequacy |

| Empty-pan baseline validation | Required | Reuse decision |

By integrating reuse and cleaning into the diagnostic framework, DSC Alumina Pans remain reliable reference boundaries rather than hidden sources of cumulative error.

A Stepwise Diagnostic Workflow for Abnormal DSC Results

Once individual anomaly sources are understood, a structured workflow helps prevent repetitive trial-and-error reruns. Therefore, a stepwise diagnostic sequence should be applied to abnormal DSC results before any full method revision is considered.

-

Classifying anomaly type before corrective action

Effective troubleshooting begins by classifying the dominant anomaly as peak-related, baseline-related, or repeatability-related. In pharmaceutical DSC practice, peak distortions exceeding 1.0 °C or baseline drift above 3% usually indicate boundary instability rather than intrinsic material change. When DSC Alumina Pans are used, this classification step narrows the corrective scope by excluding container chemistry from consideration.

Accordingly, anomaly classification determines the most efficient diagnostic path. -

Checking boundary variables prior to sample chemistry

Boundary variables should always be reviewed before questioning pharmaceutical composition. Analysts frequently resolve apparent polymorphic inconsistencies by correcting mass, lid configuration, or purge stability alone. Studies have shown that more than 60% of abnormal DSC curves normalize after single-variable boundary correction.

Thus, boundary verification reduces unnecessary reformulation or reanalysis. -

Applying single-variable correction and controlled reruns

Corrective actions should be introduced one variable at a time. For instance, modifying heating rate while keeping mass and atmosphere constant allows clear attribution of observed changes. Analysts report that isolating variables shortens troubleshooting cycles and improves confidence in corrective outcomes.

Consequently, controlled reruns are essential for defensible diagnosis. -

Deciding when full method revision is justified

Not all anomalies warrant method overhaul. When corrections fail to restore repeatability within ±0.5 °C onset variation and baseline drift remains above 3%, broader method reassessment becomes appropriate. This decision threshold prevents excessive troubleshooting while maintaining analytical rigor.

Therefore, predefined escalation criteria protect both data quality and project timelines.

This stepwise workflow consolidates diagnostic actions into a repeatable process that supports efficient pharmaceutical DSC troubleshooting.

Engineering Takeaway for Troubleshooting-Oriented Users

Effective pharmaceutical DSC troubleshooting relies on structured diagnosis rather than repeated experimentation. Therefore, DSC Alumina Pans should be treated as stable reference boundaries that clarify execution-related causes instead of masking them.

-

Using alumina pans to isolate boundary-driven errors

DSC Alumina Pans remove container reactivity from the diagnostic equation. In practical troubleshooting, this allows engineers to attribute abnormal peaks or baseline drift to mass control, lid configuration, purge stability, or reuse effects with higher confidence. Teams that adopted alumina pans as diagnostic references reduced ambiguous interpretations across replicate runs.

Accordingly, alumina pans function as diagnostic enablers rather than corrective tools. -

Prioritizing execution variables over material assumptions

Abnormal DSC curves frequently tempt analysts to suspect formulation instability. However, experience shows that more than half of apparent anomalies resolve after correcting execution variables alone. When alumina pans are used, this prioritization becomes clearer because container-induced effects are minimized.

Thus, execution variables should be exhausted before revisiting material hypotheses. -

Applying quantitative thresholds to guide decisions

Troubleshooting decisions should be anchored to measurable criteria rather than visual judgment. Onset variability beyond ±0.5 °C, baseline drift exceeding 3%, or enthalpy scatter above 5% consistently indicate execution instability. Analysts who rely on these thresholds report faster resolution and fewer unnecessary reruns.

Therefore, quantitative limits transform troubleshooting from intuition into engineering control.

These takeaways consolidate the diagnostic logic of this guide into practical principles for user-side pharmaceutical DSC troubleshooting.

Conclusion

In pharmaceutical DSC troubleshooting, DSC Alumina Pans act as stable thermal references rather than automatic solutions. Ultimately, abnormal signals become interpretable only when execution variables are diagnosed and controlled systematically.

Before repeating pharmaceutical DSC experiments, classify the anomaly and verify boundary conditions. Structured diagnosis saves time, material, and analytical credibility.

FAQ

Why does a DSC peak shift even when the same sample is tested repeatedly?

Peak shifts exceeding ±0.5 °C are most often caused by changes in sample mass, pan seating, or lid configuration rather than intrinsic material variation.

How can I tell whether a small shoulder peak is real or an artifact?

Shoulder peaks that disappear after adjusting lid configuration, mass, or heating rate are typically boundary-related artifacts rather than true phase transitions.

Is baseline drift always a sign of instrument malfunction?

No. Baseline drift below 3% often originates from purge instability, contact variation, or residue effects and should be evaluated before instrument-level intervention.

When should abnormal DSC data be discarded instead of corrected?

Data should be discarded when repeatability remains outside defined thresholds after single-variable corrections, indicating unresolved boundary instabil

References: