Alumina Ceramic is frequently selected when experimental accuracy is at risk. However, laboratory users often face inconsistent results. Therefore, material neutrality becomes essential for reliable testing.

Alumina Ceramic plays a central role in laboratory equipment because it remains structurally stable, chemically inert, and thermally predictable. Consequently, it supports high-temperature and high-accuracy experiments without interfering with measured outcomes.

Before examining specific equipment and failure mechanisms, it is necessary to clarify how Alumina Ceramic functions within laboratory applications. Accordingly, this section establishes the material foundation that supports all subsequent engineering analysis.

Alumina Ceramic in Laboratory Applications

Alumina Ceramic appears across laboratory equipment because its properties align closely with experimental requirements. Moreover, its engineered microstructure enables consistent behavior under repeated testing conditions. Consequently, understanding this material in a laboratory context is essential before evaluating performance outcomes.

Engineered Alumina Ceramic Materials

Engineered Alumina Ceramic used in laboratories typically ranges from 95% to 99.7% Al₂O₃ by weight. In practice, higher purity levels reduce glassy phases at grain boundaries. As a result, dimensional stability improves during prolonged heating above 1200 °C.

During routine furnace testing, laboratory technicians often observe that lower-purity ceramics exhibit surface softening after 30–50 thermal cycles. By contrast, high-purity Alumina Ceramic maintains consistent hardness and surface integrity beyond 200 cycles. Consequently, experimental baselines remain stable across extended test series.

In real laboratory workflows, engineers favor engineered Alumina Ceramic because its controlled grain size and density minimize unpredictable material responses. Therefore, it functions as a reliable platform rather than a variable within the experiment.

Differences from Metals and Glass

Metals and glass respond fundamentally differently to laboratory thermal environments. Metals expand rapidly and undergo oxidation above 600 °C, while glass softens and deforms near its transition temperature. Consequently, both materials introduce structural and chemical variability.

In repeated furnace trials, metallic containers often show measurable mass change exceeding 0.5% after 20 cycles due to oxidation. Similarly, glass containers begin to sag or react with alkaline samples above 900 °C. However, Alumina Ceramic maintains dimensional change below 0.1% under equivalent conditions.

Therefore, laboratories adopt Alumina Ceramic when experiments require stability rather than convenience. In other words, predictable ceramic behavior protects experimental validity when temperature and chemistry fluctuate.

Non Participating Laboratory Materials

A non-participating laboratory material is defined by its absence from experimental reactions. Specifically, it neither reacts chemically nor alters thermal or electrical measurements. Alumina Ceramic meets this requirement across most laboratory scenarios.

In analytical laboratories, background signals must remain constant within ±1% across repeated measurements. Alumina Ceramic containers consistently meet this threshold, even after exposure to mixed salts or oxide systems. Consequently, experimental noise remains low and reproducibility improves.

From an engineering standpoint, Alumina Ceramic is selected because it remains effectively invisible to the experiment. Thus, researchers can attribute observed changes solely to the sample rather than the container.

Material Property Benchmarks for Laboratory Alumina Ceramic

| Property | Typical Value |

|---|---|

| Alumina purity (%) | 95–99.7 |

| Maximum continuous temperature (°C) | 1600 |

| Linear thermal expansion (10⁻⁶ / °C) | 7.5–8.5 |

| Volume resistivity (Ω·cm at 25 °C) | ≥10¹⁴ |

| Dimensional change after 100 cycles (%) | ≤0.1 |

Why Material Choice Directly Affects Laboratory Results

Material selection in laboratory equipment is rarely a cosmetic decision; instead, it directly influences measurement reliability and data interpretation. Moreover, subtle material behaviors often remain unnoticed until experiments are repeated under identical conditions. Consequently, understanding how Alumina Ceramic interacts with experimental processes is essential for achieving dependable results.

Material Neutrality and Experimental Accuracy

In laboratory practice, accuracy depends not only on instrument calibration but also on the neutrality of every component in contact with the sample. During routine high-temperature tests, technicians often notice that identical samples yield slightly different results when container materials change. Therefore, material neutrality becomes a silent yet decisive factor in experimental accuracy.

In one thermal analysis laboratory, repeated DSC measurements using metallic pans showed baseline drift exceeding 2% after only 15 cycles. By contrast, Alumina Ceramic sample holders maintained baseline variation within ±0.3% over more than 100 cycles. Moreover, the ceramic surface did not introduce secondary reactions, which prevented false endothermic or exothermic signals. As a result, analysts could confidently attribute peak shifts to material behavior rather than container interference.

From an engineering perspective, Alumina Ceramic functions as a passive platform. Consequently, experimental accuracy improves because the material neither absorbs heat unpredictably nor contributes chemical noise to the measurement system.

Reproducibility Under Thermal Cycling

Reproducibility is often challenged by repeated heating and cooling cycles inherent to laboratory workflows. In practice, containers may experience temperature swings of 25 °C to 1400 °C within minutes. Therefore, materials with unstable thermal responses quickly reveal hidden weaknesses.

During furnace aging studies, laboratory engineers frequently observe that glass containers deform measurably after 20–30 rapid cycles. Metals, although mechanically strong, tend to oxidize and change mass over time. However, Alumina Ceramic maintains dimensional change below 0.1% even after 150 thermal cycles. Consequently, repeated experiments conducted weeks apart produce consistent results.

Such stability allows laboratories to compare long-term datasets without introducing correction factors. Thus, Alumina Ceramic supports reproducibility by maintaining consistent physical and thermal behavior throughout extended experimental campaigns.

Chemical Inertness in Complex Samples

Laboratory samples are rarely chemically simple; instead, they often contain mixed salts, oxides, and organic residues. In these conditions, container reactivity becomes a critical concern. Therefore, chemical inertness directly protects data integrity.

In materials testing labs, analysts have reported that alkaline fluxes begin to attack quartz containers above 900 °C. Similarly, metallic containers may catalyze unwanted side reactions. By contrast, Alumina Ceramic remains inert against most laboratory chemicals, including common oxides and salts, up to 1600 °C. Moreover, its grain-boundary stability limits ion migration1, reducing contamination risk to below 0.05% by mass.

As a result, researchers can process unknown or mixed samples without pre-screening container compatibility. Consequently, Alumina Ceramic becomes the default choice when sample chemistry cannot be fully predicted in advance.

Experimental Performance Indicators Influenced by Material Choice

| Performance Indicator | Typical Laboratory Requirement | Alumina Ceramic Performance |

|---|---|---|

| Baseline signal stability (%) | ≤1.0 | ≤0.3 |

| Dimensional change after 100 cycles (%) | ≤0.5 | ≤0.1 |

| Maximum operating temperature (°C) | ≥1200 | 1600 |

| Chemical reaction incidence | Minimal | Negligible |

| Reproducibility over repeated tests | High | Consistently high |

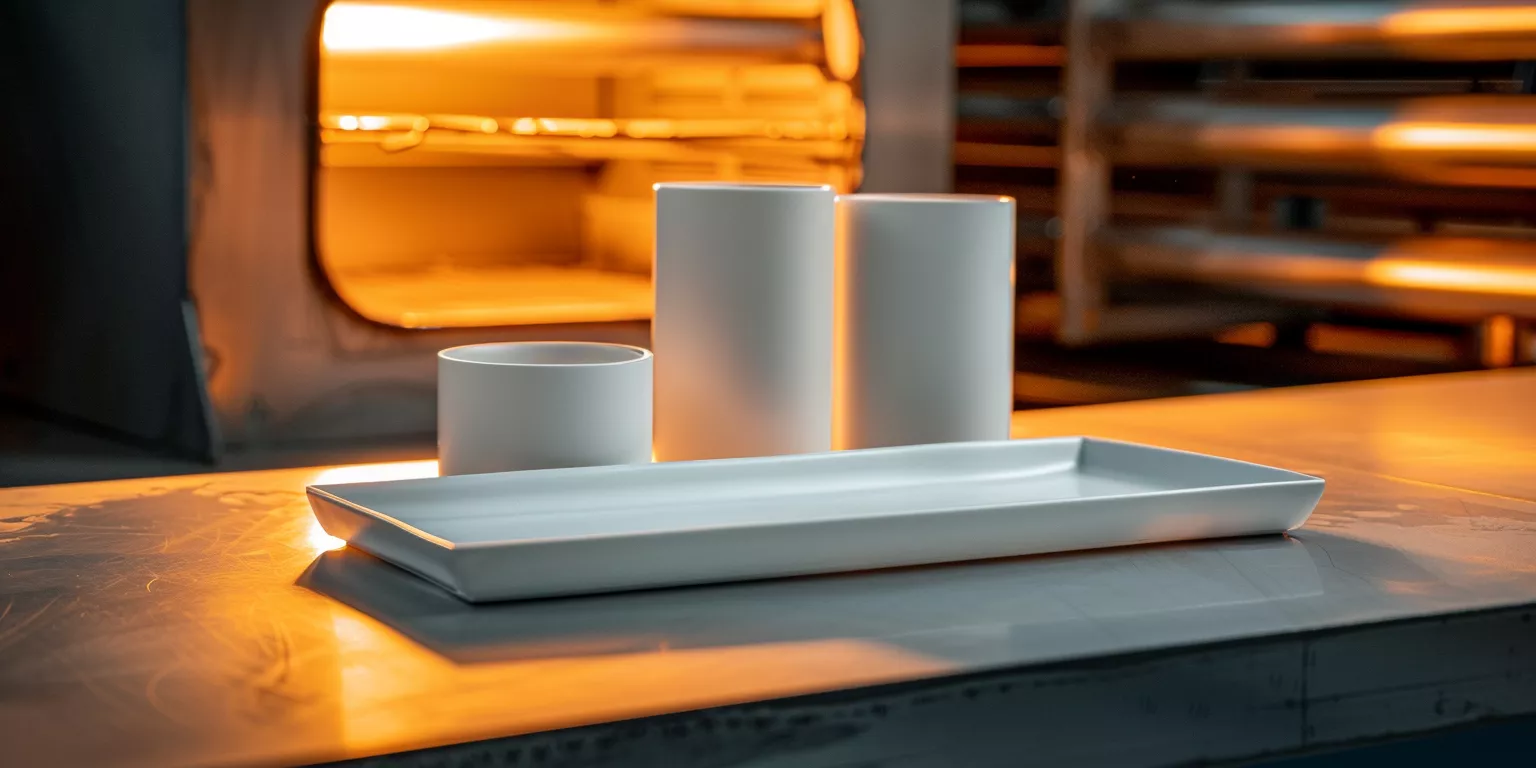

Common Laboratory Equipment Made from Alumina Ceramic

Alumina Ceramic is widely adopted in laboratory equipment because it aligns with daily experimental demands. Moreover, its consistent behavior across temperature and chemical variations supports reliable workflows. Consequently, many standard laboratory components are designed around this material rather than adapted later.

Alumina Crucibles and High Temperature Containers

Alumina Ceramic crucibles are among the most frequently used laboratory components for high-temperature work. In daily practice, technicians rely on them for calcination, melting, and ash content determination. Therefore, their stability directly affects experimental confidence.

During furnace operations above 1200 °C, laboratory staff often notice that Alumina Ceramic crucibles retain their shape even after dozens of heating cycles. In contrast, metal containers show surface oxidation after 10–20 cycles, while quartz may soften near 1000 °C. Furthermore, Alumina Ceramic crucibles typically maintain mass change below 0.2% after repeated exposure, which stabilizes gravimetric measurements. As a result, long-term testing programs remain comparable across different batches.

From an operational standpoint, Alumina Ceramic crucibles become a routine tool rather than a consumable concern. Consequently, researchers can focus on sample behavior instead of container degradation.

Thermal Analysis Sample Holders

Thermal analysis instruments demand sample holders that introduce minimal background interference. In DSC and TGA laboratories, Alumina Ceramic sample holders are selected because of their predictable thermal response. Therefore, they support precise heat flow and mass change measurements.

Experienced analysts often recall early tests where metallic pans caused baseline oscillations above 600 °C. By comparison, Alumina Ceramic holders reduced baseline variation to within ±0.3% across 100 test cycles. Moreover, their low heat capacity relative to metals minimizes signal lag during rapid heating rates of 10–20 °C per minute. Consequently, peak onset temperatures remain consistent between repeated runs.

In routine analysis, this consistency reduces the need for frequent recalibration. Thus, Alumina Ceramic sample holders enhance both efficiency and data reliability in thermal analysis laboratories.

Furnace Supports and Insulating Components

Beyond containers, Alumina Ceramic is extensively used for furnace supports and insulating components. These parts experience continuous thermal cycling and mechanical loading. Therefore, structural reliability is critical.

In long-duration sintering tests, furnace support plates made from Alumina Ceramic often operate continuously at 1400 °C for over 200 hours. During inspections, engineers typically measure dimensional changes below 0.1%, even after prolonged exposure. Additionally, the material’s electrical insulation prevents unintended current paths in electrically heated furnaces. As a result, temperature distribution remains uniform across the chamber.

From a maintenance perspective, these components reduce downtime caused by deformation or short-circuit risks. Consequently, Alumina Ceramic supports contribute to stable furnace operation over extended service intervals.

Summary of Laboratory Equipment Applications for Alumina Ceramic

| Equipment Type | Typical Temperature Range (°C) | Key Performance Requirement | Alumina Ceramic Advantage |

|---|---|---|---|

| Crucibles and containers | 800–1600 | Shape and mass stability | ≤0.2% mass change |

| Thermal analysis holders | 25–1200 | Baseline signal stability | ±0.3% variation |

| Furnace support plates | 1000–1400 | Dimensional consistency | ≤0.1% deformation |

| Insulating components | Ambient–1400 | Electrical insulation | ≥10¹⁴ Ω·cm |

Real Laboratory Conditions That Stress Materials

Laboratory environments are often perceived as controlled and mild; however, real operating conditions place significant stress on materials. Moreover, repeated experiments amplify small weaknesses that remain invisible in single tests. Consequently, understanding these conditions is essential when evaluating Alumina Ceramic performance.

Rapid Heating and Cooling Cycles

Rapid thermal transitions are common in laboratory routines, especially during furnace loading and unloading. In practice, materials may experience temperature changes from ambient to above 1200 °C within minutes. Therefore, thermal shock resistance2 becomes a decisive performance factor.

In materials research laboratories, engineers often run heating programs at rates of 10–30 °C per minute. Under these conditions, metallic containers expand unevenly, while glass components may crack after fewer than 20 cycles. By contrast, Alumina Ceramic typically withstands more than 150 rapid cycles with dimensional variation remaining below 0.1%. Moreover, its stable crystal lattice distributes thermal stress more evenly across the structure. As a result, catastrophic cracking is significantly reduced.

From an operational viewpoint, this resilience allows experiments to proceed without extended cooling schedules. Consequently, laboratory throughput increases while maintaining experimental reliability.

Variable Gas and Atmosphere Conditions

Laboratory experiments frequently require controlled atmospheres rather than ambient air. For instance, inert gases, vacuum environments, and reducing conditions are commonly used. Therefore, materials must remain stable across chemically diverse atmospheres.

In high-temperature reaction studies, technicians often switch between air and nitrogen atmospheres within the same testing sequence. Under these conditions, metals oxidize rapidly, and some ceramics exhibit surface instability. However, Alumina Ceramic remains chemically stable in oxygen-rich, inert, and mildly reducing environments up to 1600 °C. Furthermore, its low porosity limits gas diffusion into the material, reducing internal degradation. As a result, surface integrity remains consistent across atmosphere changes.

Practically, this stability simplifies experimental planning. Thus, researchers can modify atmospheric conditions without changing equipment materials.

Mechanical Handling and Human Interaction

Mechanical stress introduced by handling is an unavoidable aspect of laboratory work. Containers are frequently lifted, repositioned, cleaned, and reused. Consequently, materials must tolerate incidental mechanical loads without hidden damage.

In busy laboratories, it is common to remove hot components using tongs or place them temporarily on cold surfaces. Such actions introduce localized stress points. Alumina Ceramic components, when properly designed, tolerate these interactions with fracture rates remaining below 1% over hundreds of handling cycles. Moreover, their hardness reduces surface abrasion caused by repeated contact. As a result, structural integrity is preserved even under routine misuse.

From a maintenance perspective, this durability reduces unexpected failures. Therefore, Alumina Ceramic supports both experimental continuity and laboratory safety.

Summary of Laboratory Stress Factors Affecting Material Performance

| Stress Factor | Typical Laboratory Range | Observed Impact on Materials | Alumina Ceramic Response |

|---|---|---|---|

| Heating rate (°C/min) | 10–30 | Thermal shock risk | Stable up to 150+ cycles |

| Atmosphere types | Air N₂ Vacuum | Oxidation or instability | Chemically stable |

| Handling cycles (count) | 100–300 | Mechanical damage | <1% fracture rate |

| Temperature gradient (°C) | 200–600 | Stress concentration | Even stress distribution |

Typical Failure Modes of Alumina Ceramic in Laboratories

Despite its overall reliability, Alumina Ceramic may fail when laboratory operating conditions exceed original design assumptions. Moreover, most failures develop progressively, which makes early recognition critical for protecting data integrity and equipment safety.

-

Thermal Shock Microcracking

Thermal shock microcracking often initiates silently during routine laboratory handling. In practice, cracks begin when hot alumina ceramic components are placed on cold metal benches or exposed to rapid air cooling. Over time, these repeated temperature gradients accumulate internal stress even in high-quality ceramics.

In one high-temperature testing laboratory, crucibles repeatedly removed at 1200 °C and placed on stainless steel surfaces developed microcracks after roughly 40 cycles. These cracks initially measured below 50 µm and were invisible during visual inspection, yet continued cycling caused them to propagate through the wall thickness. Consequently, sudden fracture occurred without prior warning, resulting in sample loss and unplanned furnace downtime.

Therefore, controlled cooling procedures and gradual temperature transitions are essential to reduce thermal shock accumulation and extend component service life. -

Chemical Infiltration Effects

Chemical infiltration is a subtle failure mechanism that occurs when molten or reactive species penetrate ceramic grain boundaries at elevated temperatures. In laboratory environments, this risk increases when samples contain alkaline salts or mixed oxides. As a result, material purity and surface condition become decisive performance factors.

In analytical laboratories handling alkaline compounds, glassy residues have been observed forming on crucible interiors above 900 °C. With repeated exposure, these residues infiltrated the ceramic structure to depths exceeding 0.2 mm, altering local thermal conductivity. Moreover, infiltrated zones introduced secondary contamination, leading to mass deviations of up to 0.4 % in gravimetric measurements.

Consequently, isolating aggressive chemistries or limiting reuse cycles is necessary to preserve both material integrity and analytical accuracy. -

Cross Contamination Risks

Cross contamination arises when residues from previous experiments affect subsequent tests. This risk increases significantly in shared laboratory environments where crucibles are reused across diverse sample sets. Therefore, container history becomes as important as container material.

During multi-user laboratory operations, shared Alumina Ceramic crucibles were found to retain trace metal residues below 0.05 % by mass. Although small, these residues altered sensitive thermal analysis baselines and reduced repeatability. Furthermore, cleaning methods relying solely on deionized water proved insufficient to remove embedded contaminants from the ceramic surface.

As a result, disciplined reuse protocols and dedicated containers are required to maintain reliable experimental performance.

Summary of Common Failure Modes in Laboratory Alumina Ceramic

| Failure Mode | Typical Trigger Condition | Observable Effect | Impact on Experiments |

|---|---|---|---|

| Thermal shock microcracking | Rapid cooling above 800 °C | Hairline cracks | Sudden fracture |

| Chemical infiltration | Molten salts above 900 °C | Surface glazing | Mass deviation |

| Cross contamination | Mixed sample reuse | Trace residues | Baseline drift |

| Strength degradation | Accumulated microcracks | Reduced load capacity | Equipment failure |

Engineering Practices for Reliable Laboratory Use

Reliable laboratory performance depends not only on material selection but also on disciplined engineering practices. Moreover, even high-quality Alumina Ceramic can underperform if applied without consideration of purity, geometry, and handling. Consequently, consistent results emerge when material properties and laboratory routines are aligned.

Alumina Purity Selection

Selecting the appropriate Alumina Ceramic purity level is a foundational engineering decision. In laboratory settings, purity directly affects chemical stability and long-term repeatability. Therefore, purity choice should reflect experimental sensitivity rather than maximum temperature alone.

In routine materials testing laboratories, 95% alumina components often perform adequately below 1200 °C. However, when experiments involve trace analysis or repeated high-temperature cycles, engineers consistently report improved stability with ≥99% alumina. Moreover, high-purity Alumina Ceramic shows reduced grain-boundary glass phases, lowering contamination risk to below 0.05% by mass. As a result, experimental baselines remain consistent across extended testing periods.

From an application perspective, selecting higher purity is less about margin and more about predictability. Consequently, laboratories standardize purity levels based on measurement sensitivity rather than cost considerations.

Geometry and Structural Stability

Geometry plays a decisive role in how Alumina Ceramic responds to thermal and mechanical stress. Even with identical material composition, poorly designed shapes can fail prematurely. Therefore, structural stability must be engineered alongside material selection.

In furnace applications, engineers have observed that crucibles with uneven wall thickness develop localized stress zones after fewer than 30 cycles. By contrast, designs maintaining wall thickness variation below ±5% survive more than 150 cycles without cracking. Furthermore, rounded edges and filleted corners reduce stress concentration by up to 40% compared to sharp geometries. As a result, fracture incidence decreases significantly during routine handling.

Practically, geometry optimization transforms Alumina Ceramic from a brittle component into a robust laboratory tool. Thus, thoughtful design directly extends service life and experimental continuity.

Handling Cleaning and Reuse Control

Handling and cleaning practices often determine the effective lifespan of laboratory ceramics. In busy laboratories, repeated manual interactions introduce mechanical and chemical risks. Therefore, controlled reuse strategies are essential.

Experienced technicians note that metal tongs cause micro-abrasion after as few as 20 handling cycles. Switching to ceramic or polymer tools reduces surface damage by more than 60%. Moreover, combining deionized water rinsing with periodic high-temperature burn-off removes residual contaminants more effectively than chemical cleaning alone. Consequently, reuse cycles can extend beyond 100 experiments without measurable performance loss.

From an operational standpoint, disciplined handling protocols protect both equipment and data. As a result, Alumina Ceramic maintains its reliability across multi-user laboratory environments.

Summary of Engineering Practices for Laboratory Alumina Ceramic

| Practice Area | Engineering Parameter | Typical Target Value | Performance Benefit |

|---|---|---|---|

| Alumina purity (%) | Chemical stability | ≥99 | Reduced contamination |

| Wall thickness variation (%) | Structural uniformity | ≤±5 | Improved thermal durability |

| Edge geometry | Stress concentration | Rounded | Lower fracture risk |

| Handling tools | Surface protection | Non-metallic | Reduced abrasion |

| Reuse cycle count | Performance consistency | ≥100 | Stable experimental results |

Why Alumina Ceramic Remains the Laboratory Standard

Alumina Ceramic continues to be the reference material in laboratory environments because its performance aligns naturally with experimental priorities. Moreover, its long-term reliability has been validated through decades of routine laboratory use across disciplines.

-

Material Neutrality Advantages

Alumina Ceramic consistently behaves as a non-participating material during experiments. In daily laboratory practice, technicians rarely observe unexpected reactions, mass changes, or signal interference originating from alumina components. Consequently, experimental outcomes can be attributed to sample behavior rather than container effects.

Therefore, material neutrality remains the most decisive reason laboratories standardize on Alumina Ceramic. -

Performance Reliability Cost Balance

Alumina Ceramic offers a balance between high performance and operational practicality. Although advanced ceramics such as aluminum nitride or zirconia provide niche advantages, they often exceed laboratory requirements. As a result, alumina delivers sufficient thermal stability and chemical resistance without introducing unnecessary complexity.

Thus, laboratories achieve dependable results while maintaining manageable operating costs. -

Practical Application Boundaries

Alumina Ceramic is not universally optimal, and experienced engineers recognize its limits. For example, prolonged exposure to aggressive molten alkali systems or extreme thermal shock may require alternative materials. However, within typical laboratory temperature and chemistry ranges, alumina remains dependable and predictable.

Consequently, understanding its boundaries reinforces trust rather than diminishing its value.

Experimental Perspective on Alumina Ceramic Selection

From an experimental standpoint, selecting Alumina Ceramic is less about pushing material limits and more about controlling uncertainty. Therefore, experienced laboratory engineers evaluate ceramics based on how quietly they perform rather than how extreme their specifications appear.

In long-term laboratory operations, materials that behave predictably reduce troubleshooting time and data interpretation risks. Consequently, Alumina Ceramic is chosen not because it is flawless, but because its behavior is well understood and consistently repeatable.

Conclusion

In essence, Alumina Ceramic remains the laboratory default because it protects experimental integrity under real operating conditions. Therefore, it serves as a stable foundation for high-temperature and high-accuracy laboratory work.

If your laboratory experiments demand reliable results across repeated cycles and variable conditions, Alumina Ceramic should be evaluated as a baseline material. Consult with experienced ceramic engineers to match material grade and geometry to your specific experimental requirements.

FAQ

What purity level of Alumina Ceramic is most suitable for laboratory use?

For general laboratory applications below 1200 °C, 95% alumina is often sufficient. However, for high-temperature, high-precision, or trace analysis work, ≥99% Alumina Ceramic is recommended to minimize contamination and variability.

Can Alumina Ceramic be reused safely in laboratory experiments?

Yes, Alumina Ceramic can be reused for more than 100 experimental cycles if proper handling and cleaning protocols are followed. However, aggressive chemistries or visible surface changes should prompt replacement to avoid cross contamination.

Why does Alumina Ceramic outperform metals in high-temperature laboratories?

Unlike metals, Alumina Ceramic does not oxidize, deform, or catalyze reactions at elevated temperatures. Consequently, it maintains dimensional stability and chemical neutrality across repeated thermal cycles.

When should alternatives to Alumina Ceramic be considered?

Alternatives may be required for extreme thermal shock conditions, highly aggressive molten alkali systems, or applications demanding exceptional thermal conductivity. In typical laboratory environments, however, Alumina Ceramic remains a dependable choice.

References: