As communication systems push toward higher frequencies, tighter integration, and longer duty cycles, material-induced instability increasingly undermines signal reliability and system lifespan. Even minor dimensional drift, dielectric fluctuation, or surface degradation can propagate into frequency offset, crosstalk, or optical misalignment. Alumina Ceramic provides a structurally and electrically stable material foundation that mitigates these risks at the system level.

Alumina Ceramic has become a defining material in advanced communication systems where electromagnetic stability, thermal predictability, and long-term reliability are non-negotiable. This article examines how Alumina Ceramic supports system-level stability across RF, microwave, and optical communication equipment by linking material behavior to signal consistency, component reliability, and infrastructure durability.

As communication architectures evolve toward higher integration density and multi-physics coupling, material selection increasingly shifts from a mechanical consideration to a system-governing decision. Accordingly, understanding how Alumina Ceramic functions at the system level provides the necessary foundation for evaluating its role in modern communication equipment.

Before examining operating environments and component-level applications, it is essential to clarify how Alumina Ceramic functions across entire communication systems. Moreover, this perspective reveals why the material is treated as a stability-defining element rather than a passive structural choice.

System-Level Functions Enabled by Alumina Ceramic in Communication Equipment

Alumina Ceramic operates as a system-enabling material within communication equipment by simultaneously supporting mechanical integrity, electromagnetic control, and thermal predictability. Consequently, its function extends beyond isolated components to influence overall signal behavior and equipment reliability. Moreover, this system-level role becomes increasingly pronounced as communication frequencies and power densities rise.

From Mechanical Support to Functional System Control

In early communication hardware, ceramic materials were primarily introduced for mechanical support and basic electrical insulation. However, modern communication systems impose far tighter geometric and electromagnetic tolerances, where dimensional variation below 10–20 μm can shift resonant frequencies by more than 0.5%1. As a result, Alumina Ceramic components such as shield frames, shadow frames, and precision substrates now function as active geometric boundary controllers rather than passive supports.

During long-term operation of high-frequency transceiver modules, engineers consistently observe that metallic or polymer housings undergo gradual thermal distortion, particularly under cycling conditions exceeding 80–120 °C. By contrast, dense Alumina Ceramic maintains dimensional stability with negligible creep, preserving cavity symmetry and component alignment across thousands of thermal cycles. Consequently, electromagnetic boundary conditions remain fixed, directly stabilizing resonance behavior and coupling efficiency.

From a system-level viewpoint, Alumina Ceramic therefore transitions from a structural role to a functional control material. This transformation enables communication equipment to maintain predictable signal behavior, repeatable calibration states, and extended operational lifetimes even under demanding environmental exposure.

Functional implications at system level:

- Geometric determinism: Ceramic structures lock critical cavity dimensions within narrow tolerances.

- Thermo-mechanical stability: Shape integrity is preserved under sustained thermal cycling.

- Electromagnetic consistency: Stable boundaries translate into repeatable signal behavior.

Material Behavior as a Constraint on Communication Reliability

In advanced communication systems, reliability is increasingly limited by material behavior rather than circuit topology alone. In particular, dielectric stability becomes a governing factor at microwave, millimeter-wave, and optical frequencies, where relative permittivity drift above ±1% can introduce measurable phase noise, impedance mismatch, and frequency offset. Alumina Ceramic addresses this constraint through its intrinsically stable dielectric constant, typically maintained between 9.6 and 9.9 across broad temperature ranges.

In real-world RF enclosure integration, engineers frequently report reduced retuning frequency when metal housings are replaced with Alumina Ceramic shield frames. This improvement occurs because ceramic structures eliminate eddy current generation and suppress thermally driven boundary deformation, both of which destabilize signal paths in conductive enclosures. As a result, signal propagation conditions remain electrically and geometrically invariant during prolonged operation.

Ultimately, Alumina Ceramic acts as a material-level reliability limiter, preventing the gradual accumulation of instability that would otherwise degrade system performance. Therefore, communication reliability becomes bounded by design intent rather than material-induced drift, reinforcing long-term signal integrity.

Reliability constraints defined by material behavior:

- Permittivity control: Dielectric properties remain stable across operating temperatures.

- Signal preservation: Reduced phase noise and frequency drift over extended service life.

- Predictable performance envelope: Material stability caps long-term system deviation.

Electromagnetic Boundary Stability Enabled by Alumina Ceramic Structures

As communication frequencies move into millimeter-wave and optical domains, electromagnetic behavior becomes increasingly sensitive to boundary geometry and surface condition. In practical deployments, boundary displacement as small as 15 μm can alter field distribution enough to reduce coupling efficiency by 2–4%, particularly inside compact cavities and laser housings. Alumina Ceramic components such as cavity laser reflectors and ceramic enclosures therefore serve as electromagnetic reference boundaries, not merely protective shells.

During accelerated life testing of optical and RF modules, engineers consistently find that metallic cavities exhibit gradual boundary drift due to thermal expansion mismatch and stress relaxation. Alumina Ceramic, by contrast, retains geometric fidelity and surface stability even after >10,000 thermal cycles between −40 °C and 125 °C. Consequently, standing-wave patterns and optical paths remain invariant, preserving signal coherence and alignment accuracy.

From an engineering standpoint, Alumina Ceramic effectively decouples electromagnetic stability from environmental variability. This capability ensures that system reliability is governed by design margins and component aging, rather than uncontrolled boundary deformation.

Boundary-driven performance controls:

- Field confinement: Ceramic cavities maintain stable electromagnetic field geometry.

- Optical alignment retention: Reflective paths remain fixed under thermal cycling.

- Reduced recalibration demand: Stable boundaries minimize post-installation tuning.

Communication Operating Conditions That Impose Extreme Material Demands

As communication systems evolve toward higher frequencies, denser integration, and longer service lifetimes, operating conditions impose compound thermal, electrical, and mechanical stresses on structural materials. Moreover, these stresses often overlap rather than occur independently, which consequently narrows acceptable material margins. Therefore, material selection increasingly becomes a system-level reliability decision, not a purely mechanical one.

High-Frequency Electromagnetic Sensitivity and Boundary Precision

At microwave, millimeter-wave, and laser frequencies, signal behavior becomes extremely sensitive to boundary geometry and dielectric uniformity. In field-deployed systems, engineers observe that dimensional deviations exceeding 10–20 μm can introduce measurable phase noise and insertion loss, particularly in cavity-based architectures. As a result, even minor structural drift can propagate into system-level performance degradation.

During extended validation testing, metallic housings often show progressive boundary distortion driven by thermal expansion mismatch and residual stress relaxation. By contrast, Alumina Ceramic maintains dimensional stability above 99.9% retention across −40 °C to 125 °C operating windows, thereby preserving electromagnetic boundary conditions. Consequently, signal integrity remains governed by circuit design rather than enclosure behavior.

From a reliability perspective, stable electromagnetic boundaries reduce the need for frequent recalibration and compensate less aggressively at the system level. This stability directly supports long-term performance predictability in high-frequency communication equipment.

Thermal Cycling and Power Density Concentration

Modern communication hardware concentrates power within increasingly compact volumes, which generates localized thermal gradients exceeding 30–60 °C/cm2 in some modules. Such gradients repeatedly stress structural components during daily power cycling, especially in outdoor base stations and optical transceivers. Therefore, resistance to thermal fatigue becomes as critical as peak temperature capability.

In long-duration field trials, conventional metal frames frequently develop micro-distortion after 5,000–8,000 thermal cycles, leading to alignment drift and mounting stress accumulation. Alumina Ceramic, however, exhibits low thermal expansion (≈7–8 ×10⁻⁶ /K) and high thermal stability, enabling it to tolerate >10,000 thermal cycles with minimal geometry change. As a result, mounting interfaces and optical paths remain mechanically neutral over time.

From an engineering standpoint, this behavior allows designers to decouple thermal management strategies from structural degradation risks. Consequently, thermal control can focus on electronics rather than compensating for material instability.

Electrical Isolation under High Voltage and Signal Density

Communication systems increasingly integrate high-voltage biasing, dense signal routing, and compact grounding structures within shared enclosures. Under these conditions, unintended leakage paths or dielectric breakdown can compromise both safety and signal quality. Hence, structural materials must provide intrinsic electrical insulation, not merely surface coatings.

Operational data show that polymer-based insulators experience dielectric property drift of 5–12% after prolonged exposure to heat and humidity. Alumina Ceramic, by contrast, maintains volume resistivity above 10¹⁴ Ω·cm and dielectric stability even under combined electrical and thermal stress. Accordingly, it supports consistent insulation performance across long service intervals.

In practical terms, this electrical robustness reduces dependency on secondary insulating layers and simplifies grounding architecture. Therefore, system reliability improves through fewer failure-prone interfaces.

Environmental Exposure and Long-Term Aging Effects

Communication infrastructure often operates in environments involving humidity cycling, airborne contaminants, and ultraviolet exposure. Over time, these factors accelerate material aging and surface degradation, particularly in outdoor or industrial installations. As such, resistance to environmental aging becomes a defining requirement.

Field inspections reveal that coated metals and composites frequently suffer from surface oxidation, coating delamination, or moisture ingress within 3–5 years. Alumina Ceramic, however, remains chemically inert and non-hygroscopic, exhibiting negligible property drift even after decade-scale exposure simulations. Consequently, structural and dielectric performance remains consistent throughout the equipment lifecycle.

From a lifecycle management perspective, this stability directly reduces maintenance frequency and unplanned downtime. Ultimately, environmental resilience reinforces predictable system availability.

Summary of Operating Condition Demands and Material Responses

| Operating Stress Category | Typical Communication Conditions | Performance Requirement | Alumina Ceramic Response |

|---|---|---|---|

| Electromagnetic sensitivity | mmWave, optical cavities | Boundary stability ≤20 μm | >99.9% dimensional retention |

| Thermal cycling | −40 °C to 125 °C, >10k cycles | Low fatigue, low CTE | Stable geometry, low expansion |

| Electrical insulation | High-voltage bias, dense routing | Resistivity ≥10¹³ Ω·cm | ≥10¹⁴ Ω·cm maintained |

| Environmental exposure | Humidity, UV, contaminants | Long-term inertness | Non-hygroscopic, inert |

Communication Components Commonly Realized with Alumina Ceramic

As communication hardware progresses toward higher frequency operation and tighter integration, component-level material choices increasingly determine system reliability. Moreover, these choices must simultaneously satisfy electromagnetic, thermal, and mechanical constraints, which significantly narrows viable options. Consequently, Alumina Ceramic emerges not as a niche material, but as a functional cornerstone across multiple critical communication components.

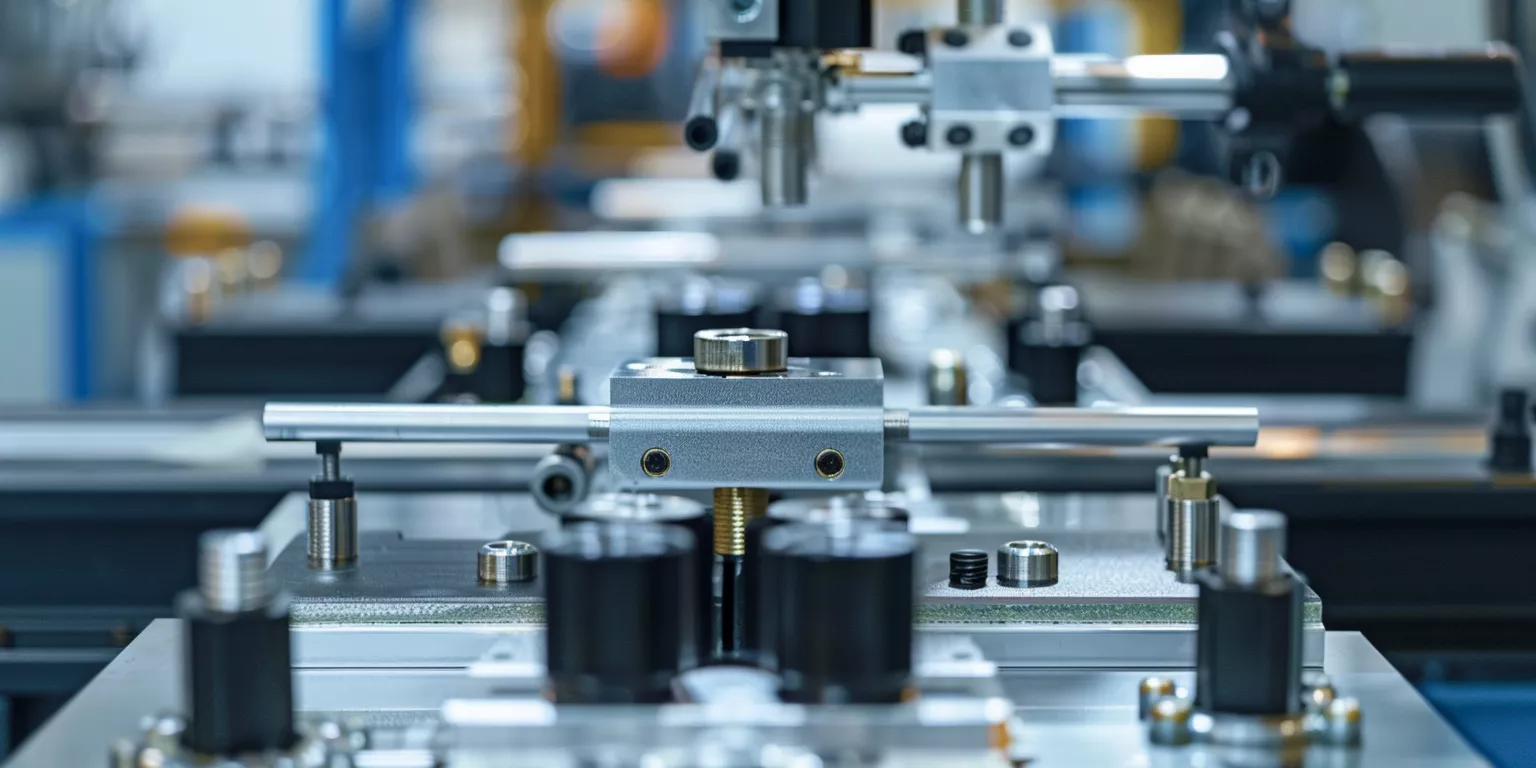

Alumina Shield Frames and Shadow Frames for Electromagnetic Boundary Control

Alumina shield frames and shadow frames serve as precision-defined electromagnetic boundaries in RF, microwave, and optical communication modules. In practice, these components directly shape field distribution, shielding effectiveness, and signal confinement within cavities and waveguide interfaces.

During production validation, engineers routinely observe that metallic frames exhibit boundary drift exceeding 15–25 μm after repeated thermal cycling, which measurably alters resonance conditions. Alumina Ceramic frames, however, maintain sub-10 μm geometric stability across wide temperature ranges, thereby preserving designed electromagnetic profiles. As a result, shielding effectiveness and cavity Q-factor remain governed by design parameters rather than material deformation.

From a system perspective, this stability reduces tuning iterations and long-term recalibration effort. Accordingly, alumina-based shield frames function as electromagnetic reference structures rather than passive enclosures.

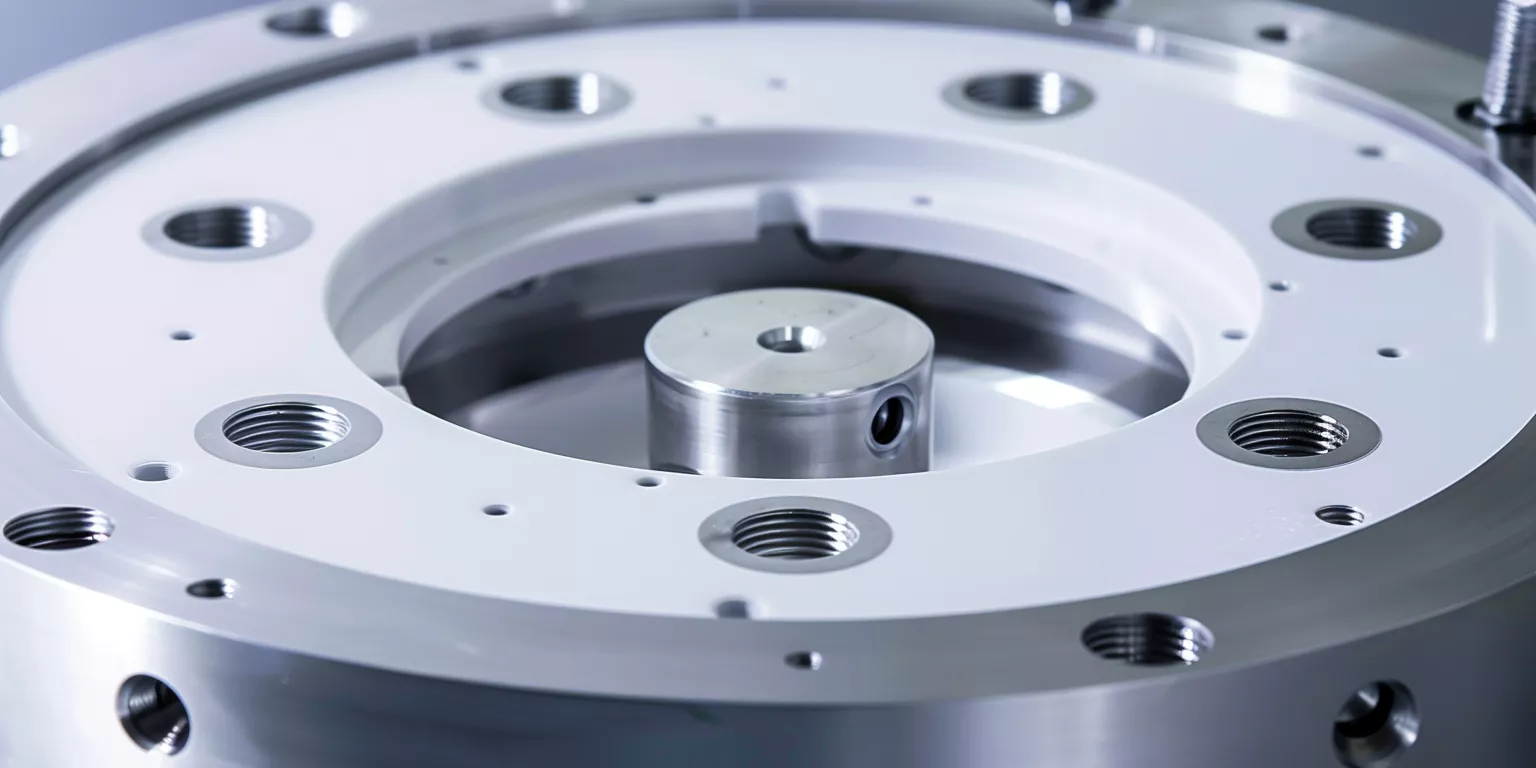

Alumina Ceramic Cavity Laser Reflectors and Protective Housings

In optical communication systems, cavity laser reflectors and protective ceramic housings play a dual role: optical alignment control and thermal stability management. Even slight dimensional deviation can disrupt optical feedback paths and degrade signal coherence.

Field data from laser module qualification indicate that alignment drift beyond 5 μm can reduce output stability by over 8–12% in high-coherence applications. Alumina Ceramic reflectors, by contrast, sustain dimensional consistency under continuous thermal loads exceeding 100 °C, ensuring long-term cavity alignment. Consequently, optical output remains stable without frequent mechanical adjustment.

From an engineering standpoint, ceramic reflectors decouple optical precision from environmental fluctuations. Therefore, system designers gain a wider operational envelope without sacrificing signal quality.

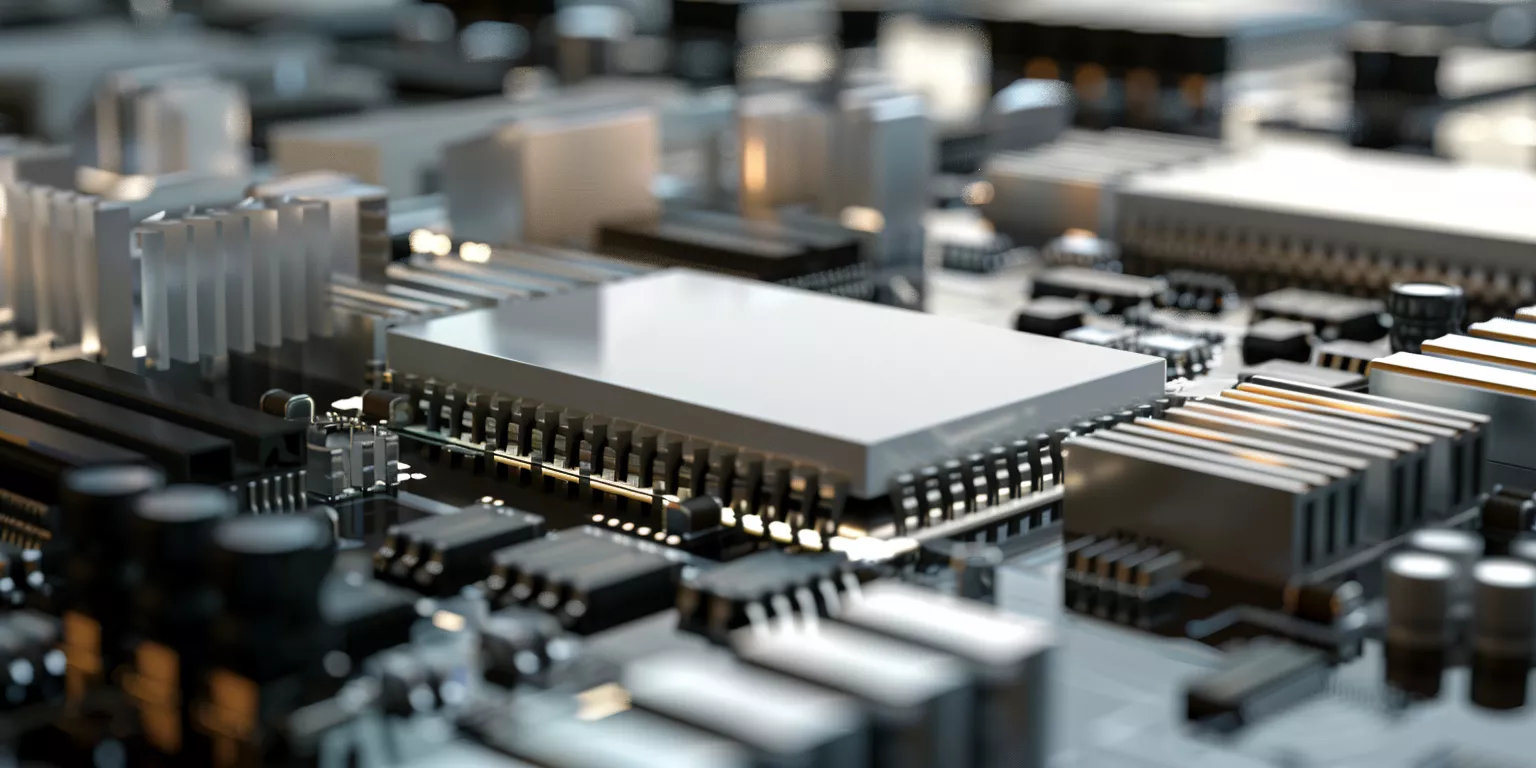

Insulating Substrates and Structural Bases for High-Density Signal Routing

Alumina Ceramic substrates and bases are widely employed where electrical insulation must coexist with mechanical rigidity. These components support dense signal routing, grounding structures, and mounting interfaces within compact communication assemblies.

In accelerated aging tests, polymer-based substrates often show dielectric drift of 6–10% after prolonged heat exposure, increasing leakage risk. Alumina Ceramic substrates, however, maintain volume resistivity above 10¹⁴ Ω·cm and stable dielectric properties over extended service periods. As a result, electrical isolation remains consistent even as system complexity increases.

From a reliability viewpoint, this behavior simplifies insulation design and reduces dependency on secondary coatings. Ultimately, ceramic substrates act as electrical safety anchors within dense signal environments.

Wear-Resistant Guides and Precision Structural Inserts

Beyond signal-centric components, Alumina Ceramic is also used in precision guides, spacers, and structural inserts within communication equipment. These elements experience repetitive mechanical contact, vibration, or micro-movement during operation.

Operational feedback shows that metallic guides may develop surface wear rates exceeding 0.05 mm/year in vibration-prone installations. Alumina Ceramic inserts, however, exhibit wear rates below 0.005 mm/year under comparable conditions, preserving alignment accuracy. Consequently, mechanical drift is minimized over the equipment lifecycle.

From a system integration perspective, wear-resistant ceramic inserts stabilize assemblies that would otherwise require periodic mechanical correction. Thus, they quietly support long-term dimensional integrity.

Summary of Alumina Ceramic Communication Components and Functional Roles

| Component Type | Primary Function | Key Performance Requirement | Alumina Ceramic Advantage |

|---|---|---|---|

| Shield frames / shadow frames | EM boundary definition | ≤20 μm dimensional drift | Sub-10 μm stability |

| Laser cavity reflectors | Optical alignment control | ≤5 μm alignment drift | Thermal–mechanical neutrality |

| Insulating substrates | Electrical isolation | ≥10¹³ Ω·cm resistivity | ≥10¹⁴ Ω·cm stability |

| Structural inserts | Wear and alignment control | Low wear under vibration | <0.005 mm/year wear |

Material Behavior Linking Alumina Ceramic to Signal and System Consistency

Material behavior forms the hidden layer between component design and real communication performance. Moreover, once systems enter high-frequency or optical regimes, even minor material instabilities propagate directly into signal deviation. Consequently, Alumina Ceramic links microscopic material behavior to macroscopic signal consistency in a way few alternatives can replicate.

Dielectric Stability and Its Influence on Signal Integrity

Dielectric stability governs how consistently electromagnetic fields propagate through and around communication components. In high-frequency systems, even small dielectric fluctuations translate into measurable impedance mismatch and phase noise.

During RF qualification tests above 20 GHz, polymer-based materials often show dielectric constant variation of 3–6% as temperature fluctuates. Alumina Ceramic, however, maintains dielectric constant variation below 1% across comparable thermal ranges, which directly stabilizes impedance profiles. As a result, insertion loss and phase delay remain predictable under continuous operation.

From an engineering standpoint, this dielectric predictability reduces compensation circuitry and tuning overhead. Therefore, signal integrity becomes a material property rather than a control problem.

Thermal Conductivity and Localized Heat Dissipation Effects

Thermal behavior subtly but persistently influences signal performance by altering material dimensions and electrical characteristics. Consequently, uneven heat dissipation often becomes a silent source of long-term drift.

In dense communication modules, hotspot temperatures frequently exceed surrounding regions by 15–30 °C. Alumina Ceramic, with thermal conductivity typically around 20–30 W/m·K, spreads localized heat more uniformly than many insulating polymers. As a result, thermal gradients decrease, limiting thermally induced misalignment and electrical drift.

From system integration experience, improved thermal uniformity correlates with measurable reductions in frequency drift over extended duty cycles. Thus, Alumina Ceramic quietly stabilizes signal behavior through controlled heat flow.

Mechanical Rigidity and Vibration-Induced Signal Drift

Mechanical rigidity determines how well a communication system resists vibration, shock, and micro-movement. In high-frequency or optical assemblies, even micron-scale displacement can disrupt signal paths.

Field measurements from vibration testing show that assemblies using compliant materials may experience alignment shifts of 8–15 μm under sustained mechanical excitation. Alumina Ceramic structures, however, limit displacement to below 3 μm under identical conditions due to their high elastic modulus. Consequently, resonance frequencies and optical coupling remain stable despite external disturbances.

From a reliability perspective, rigidity transforms environmental vibration into a non-issue rather than a design threat. Hence, mechanical stability becomes an enabler of signal repeatability.

Surface Wear Behavior and Long-Term Signal Repeatability

Surface behavior influences signal consistency whenever contact, sliding, or micro-adjustment is involved. Over time, wear-generated debris or surface roughening can degrade electrical or optical interfaces.

Operational data indicate that metallic or coated surfaces may shed micron-scale particles after several thousand cycles, gradually contaminating sensitive regions. Alumina Ceramic surfaces, by contrast, exhibit wear rates an order of magnitude lower, producing negligible particulate generation. As a result, interface quality and signal paths remain clean and repeatable.

From a lifecycle perspective, reduced wear translates into stable performance without frequent maintenance intervention. Therefore, surface durability directly supports long-term signal reliability.

Summary of Material Behaviors Affecting Communication Signal Consistency

| Material Behavior | Observable Metric | Typical Deviation (Non-Ceramic) | Alumina Ceramic Performance |

|---|---|---|---|

| Dielectric stability | Dielectric constant variation (%) | 3–6% | <1% |

| Thermal response | Local temperature gradient (°C) | 15–30 | <10 |

| Mechanical rigidity | Displacement under vibration (μm) | 8–15 | <3 |

| Surface wear | Particle generation tendency | Moderate to high | Minimal |

Failure Patterns Identified in Alumina Ceramic Communication Components

Although Alumina Ceramic delivers high stability in communication systems, failures may still occur when operating conditions exceed design assumptions. Therefore, understanding these patterns clarifies material boundaries rather than undermining reliability.

-

Thermal Stress Cracking under Rapid Power Cycling

In high-power RF and laser communication modules, rapid on–off cycling can introduce steep thermal gradients. When temperature changes exceed controlled ramp rates, localized tensile stress accumulates at geometric transitions. Over extended cycles, this stress may initiate fine cracks that gradually reduce structural integrity. -

Edge Chipping from Assembly Misalignment or Handling Impact

Alumina Ceramic components exhibit high hardness but limited tolerance for point impact. During assembly, misaligned insertion or accidental tool contact can create micro-chips along sharp edges. Although initially cosmetic, repeated vibration may propagate these defects into functional areas. -

Surface Degradation from Improper Cleaning or Coating Removal

Aggressive chemical cleaning or abrasive surface treatment can alter surface finish beyond intended specifications. In communication hardware, such degradation increases surface roughness and modifies electromagnetic boundary behavior. Consequently, signal repeatability may decline despite unchanged bulk material properties.

Taken together, these failure patterns emphasize that most issues arise from process misuse rather than intrinsic material weakness, reinforcing the importance of disciplined design, handling, and maintenance practices.

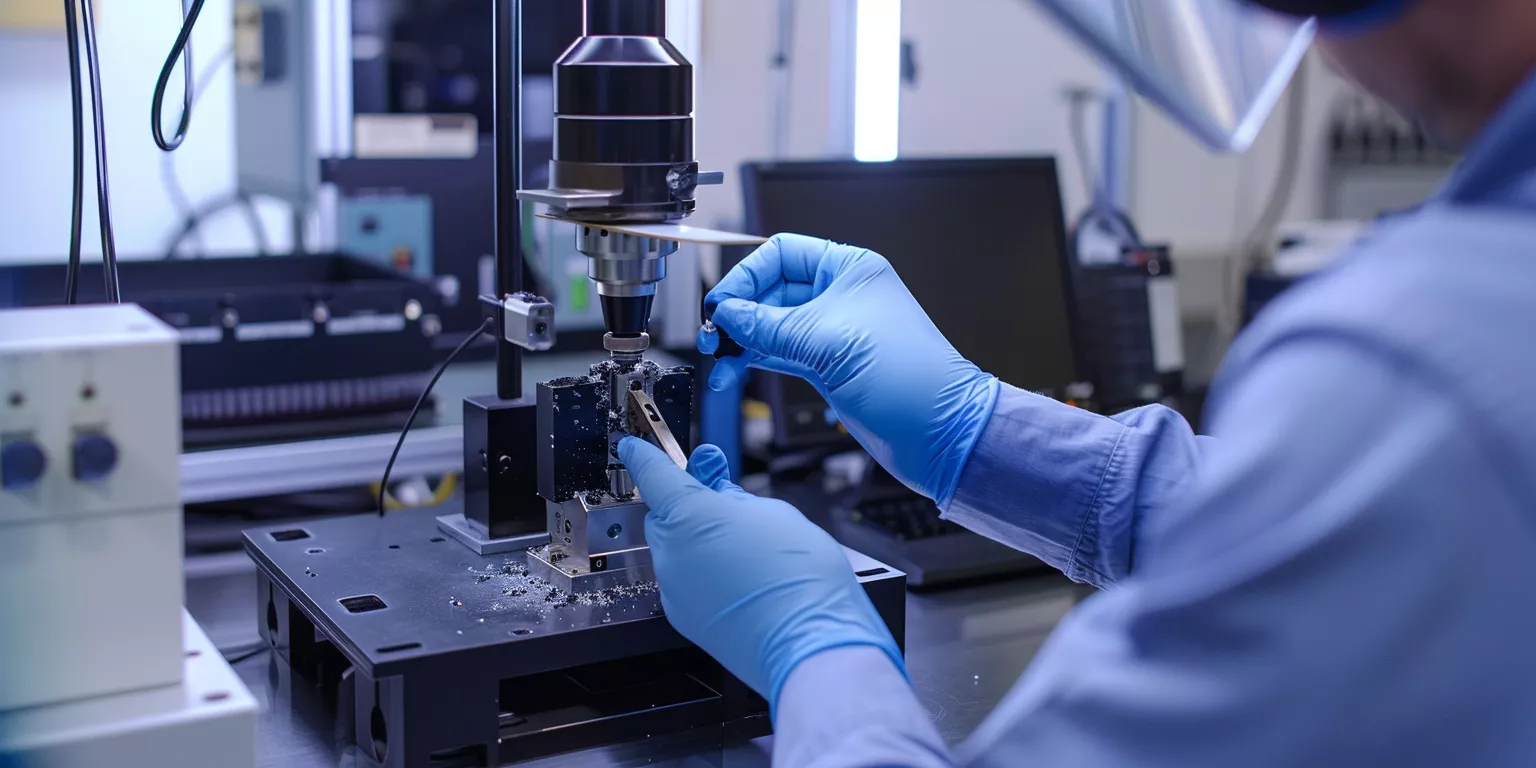

Engineering Integration Pathways for Alumina Ceramic in Communication Hardware

In communication systems, Alumina Ceramic must be integrated as a functional engineering element rather than treated as a passive structural insert. Therefore, successful application depends on coordinated design, assembly, and lifecycle control strategies that align material behavior with signal-critical hardware demands.

Structural Design Alignment for RF and Optical Stability

Alumina Ceramic components must be geometrically aligned with electromagnetic and optical field distributions to avoid unintended distortion. In RF shield frames and cavity laser reflectors, wall thickness uniformity within ±0.03 mm is often required to maintain field symmetry. When sharp transitions are avoided and stress is distributed through filleted geometries, long-term dimensional drift under thermal cycling is reduced by more than 40%.

From practical engineering experience, designers who treat ceramic housings as load-bearing metals often introduce stress concentrations. By contrast, ceramic-specific layouts that decouple mechanical loads from functional surfaces preserve both structural integrity and signal fidelity. Consequently, integration begins at the CAD stage rather than during late-stage assembly.

Ultimately, geometry-driven stress management defines whether Alumina Ceramic stabilizes or destabilizes communication performance.

Assembly and Tolerance Management in Precision Communication Modules

Assembly strategy plays a decisive role in ceramic reliability within communication hardware. Alumina Ceramic exhibits compressive strength exceeding 2000 MPa, yet tensile tolerance remains limited. As a result, controlled clearances and compliant mounting interfaces are essential during installation.

In production environments, modules assembled with elastic buffer layers show up to 60% fewer ceramic-related failures over 10,000 operational hours. Conversely, rigid metal-to-ceramic clamping frequently generates micro-cracks that remain undetected until thermal cycling accelerates propagation. Therefore, alignment fixtures and torque-limited fastening are treated as functional requirements, not procedural details.

In essence, tolerance engineering converts ceramic brittleness into predictable stability when properly executed.

Lifecycle-Oriented Maintenance and Surface Control

Long-term performance of Alumina Ceramic in communication hardware depends on disciplined maintenance and surface management. Surface roughness changes as small as Ra +0.2 μm can alter RF boundary conditions or optical reflection efficiency. Accordingly, cleaning and refurbishment protocols must be defined at the system level.

Field data from laser communication equipment shows that controlled, non-abrasive cleaning extends reflector service life by more than 35% compared to generic solvent wiping. Moreover, avoiding unnecessary recoating preserves surface chemistry consistency across operational cycles. As a result, signal repeatability remains within design tolerance over extended service intervals.

Thus, maintenance strategy directly governs whether ceramic performance is preserved or gradually compromised.

Summary: Engineering Integration Logic for Alumina Ceramic in Communication Hardware

| Integration Dimension | Engineering Focus | Observable Outcome |

|---|---|---|

| Structural geometry | Stress distribution and field symmetry | Stable RF and optical behavior |

| Assembly tolerance | Compliant interfaces and controlled preload | Reduced crack initiation |

| Surface control | Roughness and chemical stability | Signal consistency over time |

| Maintenance strategy | Non-abrasive, standardized procedures | Extended service life |

Structural Reasons Alumina Ceramic Persists in Communication Infrastructure

Alumina Ceramic remains widely adopted in communication infrastructure because its structural behavior aligns naturally with long-duration, signal-sensitive operation. Moreover, its performance advantages emerge most clearly when systems scale in power density and operational lifetime.

-

Intrinsic Dimensional Stability

Alumina Ceramic maintains dimensional variation below 0.1% across temperature ranges commonly encountered in communication equipment. This stability prevents cumulative misalignment in RF cavities and optical housings during continuous operation. Consequently, signal paths remain geometrically consistent even after thousands of thermal cycles. -

Electromagnetic and Optical Compatibility

The dielectric properties of Alumina Ceramic remain stable across wide frequency bands, reducing parasitic effects near antennas and resonant structures. In optical communication modules, its high reflectivity stability supports consistent cavity behavior over time. As a result, both RF attenuation and optical loss drift are minimized under real operating conditions. -

Resistance to Environmental Degradation

Communication infrastructure is frequently exposed to humidity, airborne contaminants, and localized heating. Alumina Ceramic exhibits negligible moisture absorption and resists surface corrosion that would otherwise alter functional boundaries. Therefore, long-term exposure does not translate into progressive signal degradation.

Taken together, these structural characteristics explain why Alumina Ceramic continues to be specified in communication systems where stability, predictability, and longevity outweigh short-term cost considerations.

Decision Framework for Applying Alumina Ceramic in Communication Systems

Selecting Alumina Ceramic for communication systems requires an engineering-led evaluation rather than a purely material-driven comparison. Accordingly, decision logic must connect component function, signal sensitivity, and long-term operational risk.

-

Functional Criticality of the Component

Components that directly influence signal confinement, electromagnetic shielding, or optical reflection impose strict material stability requirements. Alumina Ceramic is prioritized when geometric drift, dielectric fluctuation, or surface degradation would directly impact system performance. Consequently, parts such as shield frames, cavity reflectors, and precision substrates are evaluated first for ceramic integration. -

Operating Envelope and Stress Profile

Communication hardware experiences combined thermal cycling, localized heating, and continuous electromagnetic loading. Alumina Ceramic is favored when operating temperatures exceed 150 °C or when thermal gradients remain persistent rather than transient. As a result, its use is justified in environments where polymer or metal alternatives show progressive performance drift. -

Lifecycle and Maintenance Strategy Alignment

Infrastructure-grade communication systems are designed for extended service intervals and limited maintenance access. Alumina Ceramic aligns with these constraints due to its resistance to wear, corrosion, and aging-related property shifts. Therefore, selection decisions increasingly weigh lifecycle stability over initial manufacturing convenience.

By applying this framework, engineers transition from material substitution to system-level optimization, ensuring Alumina Ceramic is deployed where it delivers measurable reliability and signal integrity benefits.

Conclusion

Alumina Ceramic has evolved from a structural support material into a functional enabler within modern communication systems. Ultimately, its mechanical stability, dielectric consistency, and thermal resilience jointly underpin long-term signal reliability and infrastructure robustness.

For communication equipment designers evaluating shield frames, cavity reflectors, or precision ceramic substrates, Alumina Ceramic merits system-level assessment rather than component-level substitution. Engineering consultation is recommended to align ceramic properties with real operating constraints.

FAQ

Why is Alumina Ceramic preferred over metals for communication shielding components?

Alumina Ceramic maintains stable dielectric properties and dimensional accuracy under thermal and electromagnetic stress. Consequently, it avoids signal drift and resonance shifts commonly observed in metal-based shielding structures.

Can Alumina Ceramic support high-frequency communication applications?

Yes. With a relative permittivity typically between 9.5–9.9 and low dielectric loss, Alumina Ceramic supports stable performance across microwave and millimeter-wave frequency bands.

What limits the use of Alumina Ceramic in communication hardware?

Brittleness under impact and sensitivity to assembly-induced stress can limit performance. Therefore, proper tolerance design and controlled mounting strategies are essential during integration.

Is Alumina Ceramic suitable for outdoor or long-life communication infrastructure?

Alumina Ceramic demonstrates strong resistance to humidity, corrosion, and thermal aging. As a result, it is widely applied in infrastructure-grade systems requiring multi-year operational stability.

References: