Ceramic Heating Elements for OEM Equipment | Custom, Insulated, Export-Ready

Ceramic heating elements for conduction heating (non-PTC) provide stable heat transfer with electrical insulation, making them ideal for OEM equipment, repeatable production, and critical temperature control.

ADCERAX supplies factory-direct standard and custom ceramic heater elements (plates, tubes, rods, small heaters), backed by fast spec review, sampling, and batch inspection.

What is Ceramic Heating Element?

A ceramic heating element is an electrically insulated heater that uses a ceramic body to support and protect a resistive heating circuit, so it can deliver controlled, repeatable heat by conduction while keeping the surface and structure electrically safe.

Ceramic vs Metal Heating Elements: What’s the Difference?

🔒Insulation: Ceramic is inherently insulated; metal depends on added insulation that can degrade with heat cycling.

🌡️Thermal stability: Ceramic delivers more repeatable conduction heating; metal output drifts as oxidation or contact changes.

📐Contact heating: Ceramic maintains defined, flat heating surfaces; metal is more sensitive to assembly and pressure variation.

📏Dimensional accuracy: Ceramic holds geometry under heat; metal can creep or deform, affecting fit and uniformity.

🔁Long-term reliability: Ceramic reduces unplanned changeouts in continuous duty; metal often needs earlier replacement.

✅Decision rule: Choose ceramic when insulation integrity and process stability matter; choose metal only for low-cost or abuse-tolerant duty.

Ceramic Heating Element Properties

Built for conduction heating, ceramic heating elements deliver fast, even surface heating with stable resistance and a high insulation margin.

| Property | 95% Alumina | 99% Alumina | Silicon Carbide | Silicon Nitride | Aluminum Nitride |

|---|---|---|---|---|---|

| Density (g/cm³) | 3.25 | 3.95 | 3.21 | 3.2 | 3.2 |

| Porosity (%) | 15.0 | 1.0 | 0.5 | 0.5 | 0.2 |

| Hardness (HV) | 1200 | 1800 | 2500 | 1400 | 1800 |

| Compressive Strength (MPa) | 300 | 450 | 2200 | 300 | 300 |

| Flexural Strength (MPa) | 150 | 350 | 450 | 450 | 400 |

| Thermal Conductivity (W/m·K) | 20 | 25 | 150 | 20 | 200 |

| Electrical Resistivity (Ω·cm) | >10^14 | >10^14 | 10^6 | 10^14 | 10^14 |

| Breakdown Voltage (kV/mm) | 20 | 25 | 25 | 25 | 30 |

| Thermal Expansion Coefficient (×10⁻⁶/K) | 8.0 | 7.5 | 4.5 | 3.6 | 5.5 |

| Young’s Modulus (GPa) | 250 | 340 | 350 | 300 | 220 |

Stable, Insulated Ceramic Heating Elements for Industrial Duty

Ceramic heating elements provide insulated, repeatable conduction heating with reduced drift and more consistent fit. ADCERAX supports plates, tubes, rods, and compact heater formats with batch-controlled production for OEM use.

silicon carbide heating elements

High-temperature durability with strong oxidation and wear resistance.

Boron nitride heating element

Non-wetting surface to reduce sticking, buildup, and contamination.

alumina ceramic heating element

High insulation strength and stable output for repeatable conduction heating.

Silicon nitride heating element

High strength and thermal-shock resistance for cycling and vibration duty.

Aluminum Nitride Heating element

Higher thermal conductivity for faster, more uniform heat spreading.

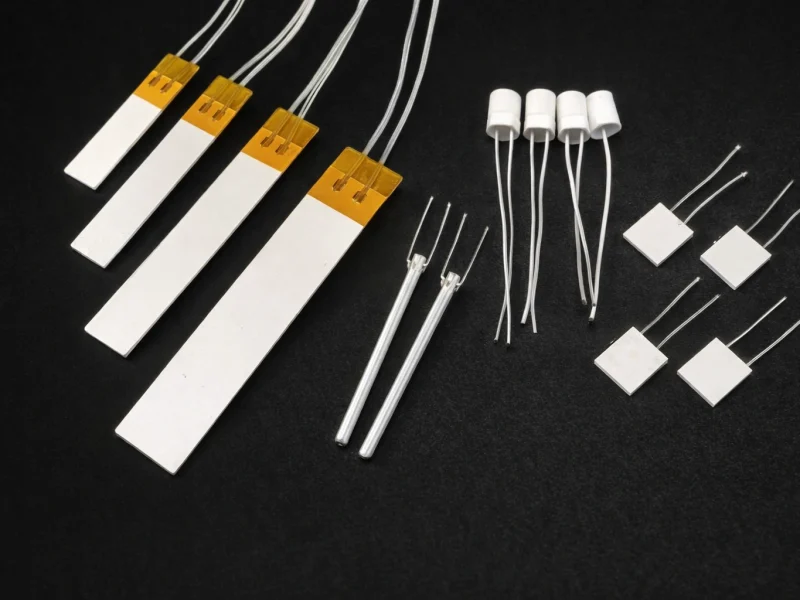

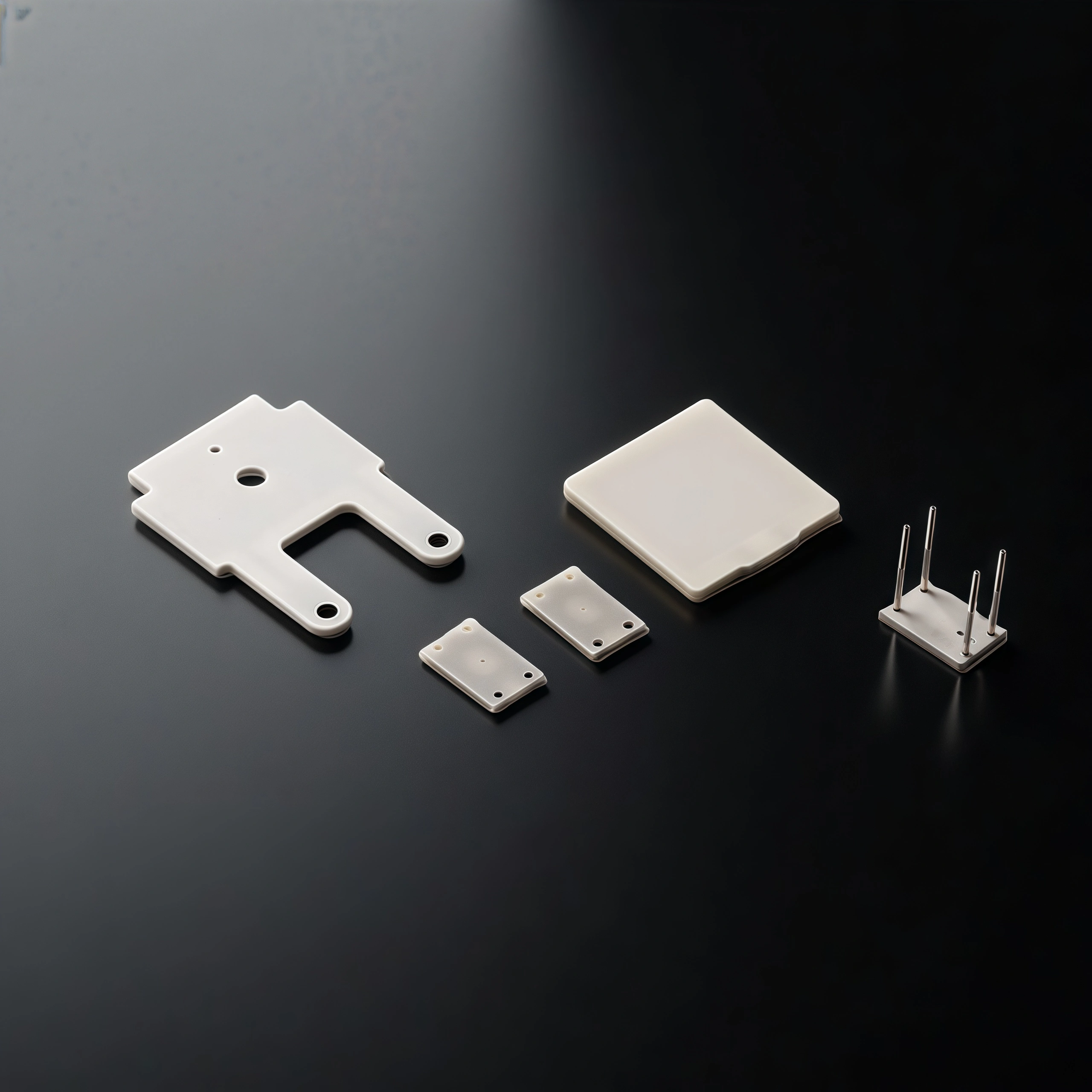

flat ceramic heating element

Even, stable contact heating for plates and tooling where uniformity matters.

ceramic tube heating element

Tube heating for sleeves and channels—guided, protected heat.

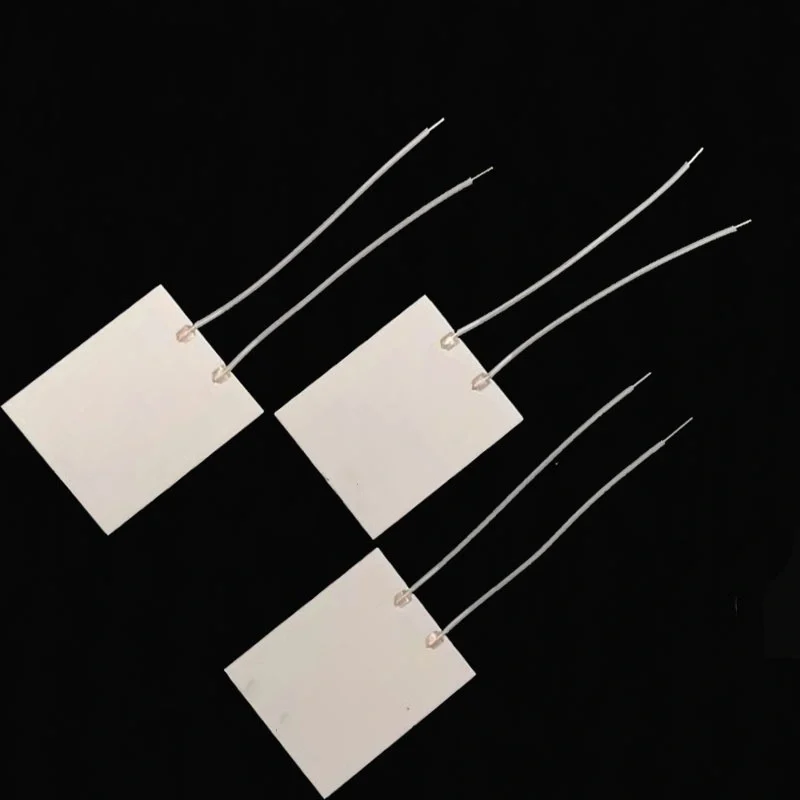

ceramic plate heating element

Stable surface heating for platens and fixtures—better uniformity

small ceramic heating element

Compact heater for tight spaces—fast response and easy integration.

Ceramic Igniter

Quick, concentrated heat for reliable ignition in demanding duty cycles.

Ceramic Heating Core

Insulated core format for consistent heating and repeatable OEM assembly.

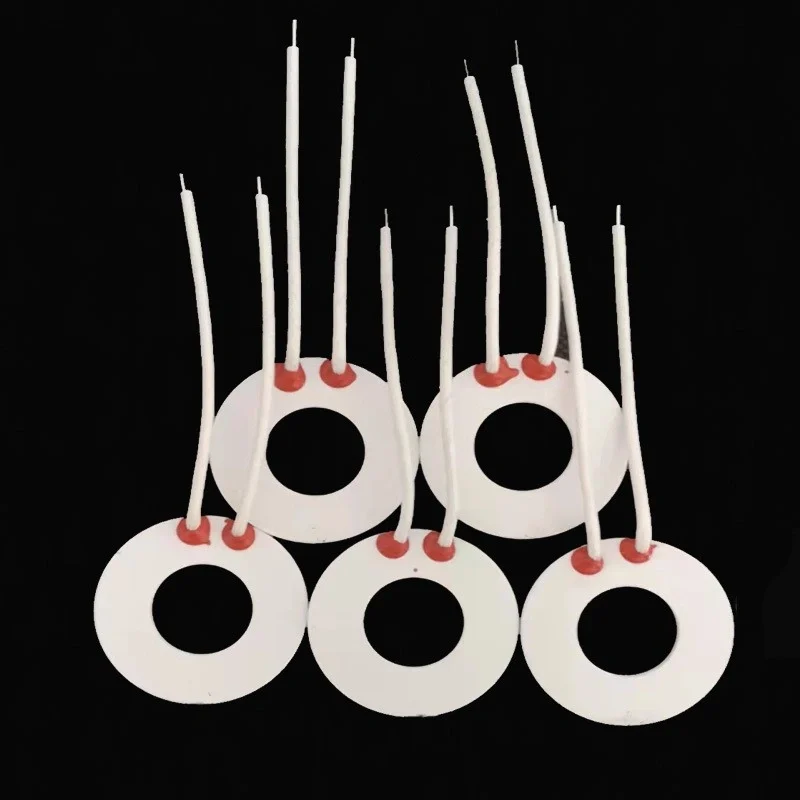

round ceramic heating element

360° heating around round mounts for balanced output and easier integration.

ceramic heating element rod

Compact rod format for localized heating in narrow spaces and inserts.

Ceramic Heating Elements — Stable Conduction Heating with Safer Insulation and Lower Drift.

ADCERAX supplies factory-direct ceramic heating elements for OEM builds and spare-part programs—custom-to-drawing options, consistent batches, and fast engineering response.

Ceramic Heating Element Applications

Ceramic heating elements are commonly integrated into molds and hot runners, packaging heat-sealing tools, heated fixtures, and automated stations where stable conduction heating and safe insulation near metal frames matter. Match the heater style to the shape, power target, and run time for consistent results.

Injection Molding & Hot Runner Systems

💠Where ceramic heating elements are used:

Ceramic heating elements are commonly integrated into hot runner manifolds and nozzles, installed on mold plates and gate-area heating zones, and used as temperature-controlled inserts near melt channels to keep the melt path thermally stable in compact, fit-critical assemblies.

💠Why ceramic heaters are preferred:

- Built-in electrical insulation protects mold steel and manifolds

- Lower thermal drift over long cycles improves shot-to-shot repeatability

- Rigid geometry supports precise fit in tight mold cavities

Packaging & Heat-Sealing Equipment

💠Where ceramic heating elements are used:

In packaging lines, ceramic heating elements are typically built into sealing jaws and heat bars, used as flat sealing plates for pouch and tray packaging, and integrated into labeling and bonding stations to deliver repeatable contact heating where seal strength and cycle stability matter.

💠Why ceramic heaters are preferred:

- Even surface temperature improves seal strength and appearance

- Insulated ceramic body reduces heat loss into machine frames

- Longer service life helps reduce changeout frequency on production lines

Industrial Tooling & Heated Fixtures

💠Where ceramic heating element are used:

Ceramic heating elements are commonly used in heated platens and press tools, built into pre-heating fixtures for bonding/forming, and applied in process-stabilization tooling to keep surface temperatures consistent.

💠Why ceramic heaters are preferred:

- High surface stability supports tight process tolerances

- Ceramic substrates maintain geometry under repeated thermal cycling

- Clean, insulated surfaces simplify integration into tooling assemblies

Automation & Mechanical Equipment

💠Where Ceramic heating element are used:

Ceramic heating elements fit compact machines with localized heating zones, run safely near metal frames or housings thanks to strong electrical insulation, and integrate into modular heating units inside automated stations for repeatable, service-friendly builds.

💠Why ceramic heaters are preferred:

- Electrical insulation margin improves safety near structural metal parts

- Rigid forms enable tight-fit integration in compact designs

- Stable resistance supports predictable output across batches

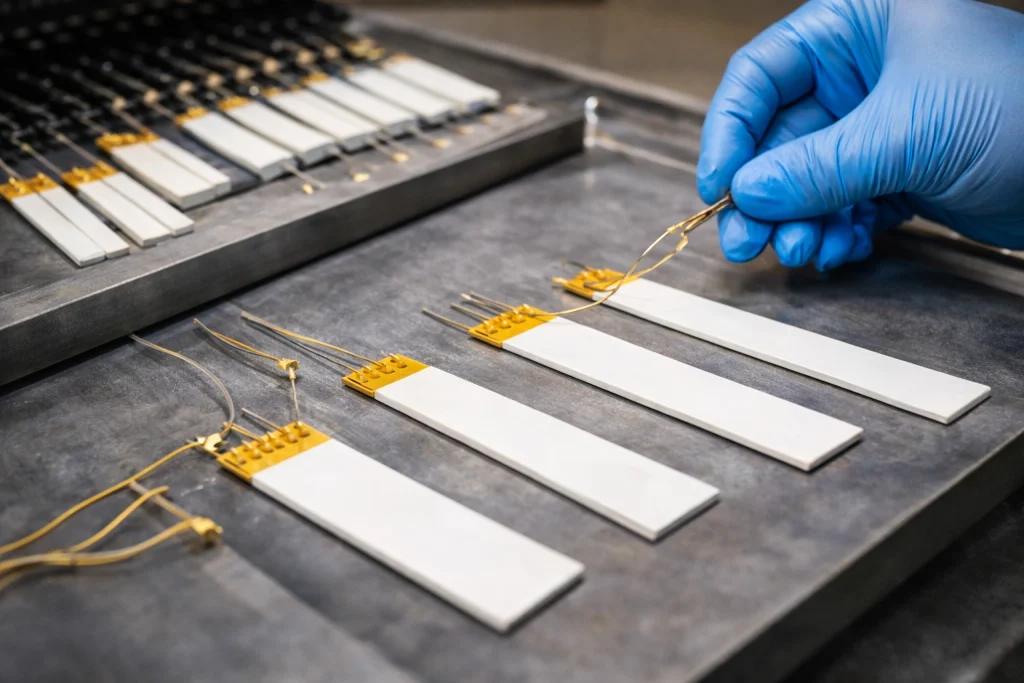

Custom Ceramic Heating Elements, Built to Your Drawing

ADCERAX delivers custom ceramic heating elements for conduction heating, optimized for fit, insulation, and repeatable production. Send your drawing or sample to receive a clear, manufacturable proposal.

Customization Options

outline, holes, slots, chamfers, locating features

rated voltage, wattage, resistance target & tolerance

single-zone or multi-zone heat patterns for uniformity control

lead direction, length, connector/terminal style

alumina, AlN, Si₃N₄, SiC, BN (matched to duty)

critical dimensions, dielectric checks, resistance test, marking/traceability

Customization Process

Confirm critical fit + heating targets + duty cycle

sample validation on your equipment

Lock drawing + test plan + marking + revision control

consistent builds with inspection records

ADCERAX: Ceramic Heating Element Manufacturer in China

ADCERAX supplies ceramic heating elements for conduction heating with factory-direct engineering support and controlled production for stable resistance, insulation margin, and repeatable fit. Fast spec review, flexible sampling, and batch inspection reduce failures and keep repeat orders consistent.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Ceramic Heating Element Factory ——ADCERAX

ADCERAX is a ceramic heating element supplier in China, delivering export-ready builds backed by 20+ years of advanced ceramics experience and proven process control. We supply ceramic heating elements for conduction heating with repeatable fit, stable insulation margin, and batch consistency.

Standard and custom builds are supported, with batch inspection, traceability, and export-ready packing to reduce failures and simplify repeat purchasing.

How Ceramic Heating Elements Are Made ?

Select the ceramic body and insulation system, then mix and condition powders for repeatable density.

High-temperature firing densifies the ceramic, stabilizing strength and dimensional behavior.

Apply or assemble the resistance heating path and electrical interfaces (leads/terminals), tuned to target resistance and power.

Shape the core geometry (flat, round, rod, tube) to lock the baseline dimensions and internal structure.

Grind/lap critical faces, thickness, holes, and edges to meet fit and mounting requirements.

Add insulation layers or protective treatments where needed to improve dielectric margin and durability in real assemblies.

FAQ About Ceramic Heating Element

Material choice is usually driven by temperature, dielectric requirement, mechanical constraints, and manufacturing route:

Alumina (Al₂O₃): strong electrical insulation, stable, cost-effective for many builds

Aluminum nitride (AlN): selected when heat spreading / thermal conductivity matters

Silicon nitride (Si₃N₄): strong mechanical robustness and thermal shock resistance in demanding duty

Boron nitride (BN): chosen for special thermal/electrical behaviors and machinability in certain designs

Silicon carbide (SiC): used in high-temperature harsh environments, depending on design and insulation strategy

Voltage selection should follow the system constraints, then confirm heater feasibility:

12V / 24V: higher current for the same power → thicker conductors, more terminal design attention, heavier wiring/driver requirements

110–120V / 230–240V: lower current for the same power → easier wiring, but requires stricter insulation design and safety considerations

Key rule: decide voltage from your platform first, then design resistance + terminal + insulation margin around it.

Uniformity comes from balancing heater circuit layout and thermal spreading:

circuit zoning (multi-zone patterns where needed)

controlled heat spreading layer/material

consistent contact pressure and flatness

correct sensor placement (thermocouple/RTD location)

If the sensor is placed wrong, you can read “stable temperature” while the work surface has hot spots.

Place sensors where they represent the controlled surface, not just the heater body:

near the working interface when possible

protected from airflow or external cooling effects

consistent from unit to unit (repeatable mounting geometry)

For multi-zone builds, each zone needs a control strategy; otherwise one sensor can hide local overheating.

Drift usually comes from system-level changes:

contact pressure changes (fasteners relax, interface materials age)

contamination layers at the interface

resistance shift from repeated thermal cycling

sensor attachment aging or location error

A robust design controls drift by locking down mounting repeatability, specifying interface materials, and validating under duty cycle.

Common failure modes are:

terminal degradation (heat + oxidation + mechanical strain)

localized hot spot damage (uneven contact or over-power density)

insulation breakdown (contamination, moisture, design margin too tight)

cracks from mechanical shock (handling/assembly impact)

Most failures are preventable by specifying mount design, strain relief, derating, and inspection checkpoints.

Cleaning must protect insulation and terminals:

avoid abrasive grinding on functional surfaces

use non-residue cleaning methods appropriate to contamination type

ensure fully dry before powering

If contamination is at the contact interface, clean both the heater and the mating surface; otherwise you “fix nothing” and drift returns.

Yes. ADCERAX offers ceramic heating element 12v for sale for conduction heating —standard replacements or custom-to-drawing builds.

To quote fast, share: size/drawing, target W @ 12V, duty cycle, and lead/connector needs.

If you want a factory-direct option with engineering support, ADCERAX is a practical choice. ADCERAX is a China-based ceramic heating element manufacturer and wholesaler for conduction heating , supporting standard replacements and custom-to-drawing builds with fast spec review and batch inspection to help reduce drift and early failures.

Ceramic heating element lifespan varies by temperature, power density, and thermal cycling. In well-designed conduction heating (non-PTC), many OEM builds achieve thousands of operating hours; harsh cycling or overloaded duty typically shortens life.

Most common life limiters: hot spots from poor contact/overpower, frequent heat-up/cool-down cycles, contamination causing insulation tracking, and lead/terminal fatigue.

How to extend lifespan (fast rules): de-rate power for continuous duty, keep uniform mounting/contact, control ramp rate, and keep surfaces clean/dry.

What we need to estimate life: target temperature, duty cycle/ramp, voltage/wattage, mounting method, and environment (dust/oil/moisture).

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.