Ceramic Insulating Tube for Electrical Isolation in High-Temperature Furnaces and Heaters

Ceramic insulating tubes maintain electrical isolation in high-temperature systems where conventional materials fail. Alumina and zirconia ceramics deliver stable insulation resistance above 10¹⁰ Ω·cm at temperatures exceeding 1200 °C, resist chemical attack in oxidizing or reducing atmospheres, and withstand continuous thermal cycling.

ADCERAX supports custom bore configurations, hole spacing, dimensional tolerances, and end finishes with engineering review. Engineers who specify ADCERAX ceramic insulating tubes gain:

✅Reduced drift and downtime

✅Extended service life

✅Dimensional consistency

✅Engineering support

Problems with conventional insulating tubes

In high-temperature measurement and heating systems, electrical leakage and signal drift degrade thermocouple accuracy and compromise equipment reliability.

Metal sheaths, polymer insulators, and fibrous materials fail when exposed to temperatures above 800 °C or chemically reactive atmospheres. This leads to:

- Short circuits between conductors

- Erratic readings and measurement errors

- Unplanned shutdowns and production loss

Insulation breakdown leads to measurement errors, process deviations, increased scrap, and costly downtime. In continuous operations, even brief interruptions can cost tens of thousands of dollars per hour.

Why do conventional insulating tubes fail in service?

Conventional insulation materials fail in high-temperature electrical applications due to fundamental material limitations.

Understanding these failure mechanisms helps engineers select appropriate ceramic solutions and avoid recurring problems.

Thermal Degradation of Polymers and Organic Insulators

- Standard insulation materials lose dielectric strength and mechanical integrity above 300–500 °C

Oxidation and Chemical Attack

- Metal oxides form on unprotected conductors in oxidizing atmospheres, creating conductive paths and drift

Creep and Deformation Under Load

- Soft insulation materials sag or collapse at elevated temperatures, allowing conductor contact

Moisture Absorption in Porous Materials

- Fibrous insulators degrade rapidly when exposed to humidity or process gases

Thermal Expansion Mismatch

- Dissimilar materials expand at different rates, causing mechanical stress and insulation failure during thermal cycling

Why Ceramic Are Used as Insulator Tubes?

Ceramic insulator tubes are selected in this application for their ability to maintain electrical isolation under sustained high temperature while remaining dimensionally stable. Unlike organic or laminated insulation, dense technical ceramics retain high resistivity and structural integrity well above 1000 °C, depending on composition and atmosphere.

What role does ceramic play in high-temperature electrical insulation?

Ceramics keep high resistivity at temperature, so insulation stays predictable.

Ceramics resist softening and creep, maintaining gaps and alignment.

Dense ceramic barriers reduce leakage current and surface tracking.

Ceramics resist hot-zone vapors and dust that degrade insulation.

Different Ceramic Insulation Tube Material Options

Provides stable dielectric performance and mechanical rigidity over a wide temperature range.

Offers very high electrical resistivity at elevated temperature

Offers lower thermal conductivity and better thermal shock resistance for rapid temperature swings

How to Choose a Ceramic Insulating Tube?

Selecting the right ceramic insulating tube requires matching material properties and geometric specifications to your operating conditions. The following outlines the critical parameters engineers need to consider and provides a material comparison framework to guide selection decisions.

Key Selection Parameters

Consider the following parameters when specifying ceramic insulating tubes:

Define maximum continuous and peak excursion temperatures; select alumina purity or alternative ceramic accordingly

Identify oxidizing, reducing, neutral, or vacuum conditions; some ceramics are atmosphere-sensitive

Specify required dielectric strength and leakage current limits at operating temperature

Determine number of holes, hole diameter, hole spacing, and positional tolerance for wire clearance

Confirm outer diameter, wall thickness, length, straightness, and end-finish requirements to ensure proper fit and alignment

Ceramic Insulating Tube Material Comparison

| Material | Strengths | Limitations | Best-fit Conditions | Notes |

|---|---|---|---|---|

| Alumina (Al₂O₃) | Stable dielectric behavior, good stiffness, broad availability | Brittleness under impact | Continuous electrical insulation above ~1000 °C | Widely specified for multi-bore insulators |

| Magnesia (MgO) | Very high resistivity at elevated temperature | Higher cost, handling sensitivity | Extreme-temperature electrical isolation | Often selected when insulation margin is critical |

| Zirconia (ZrO₂) | High fracture toughness, handling robustness | Lower max temperature than alumina | Mechanically demanding installations | Used where vibration or assembly stress exists |

Ceramic Insulating Tube Products

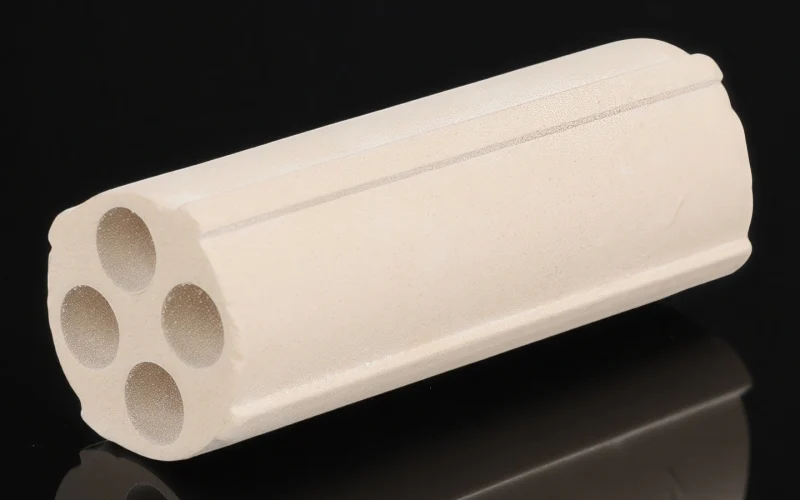

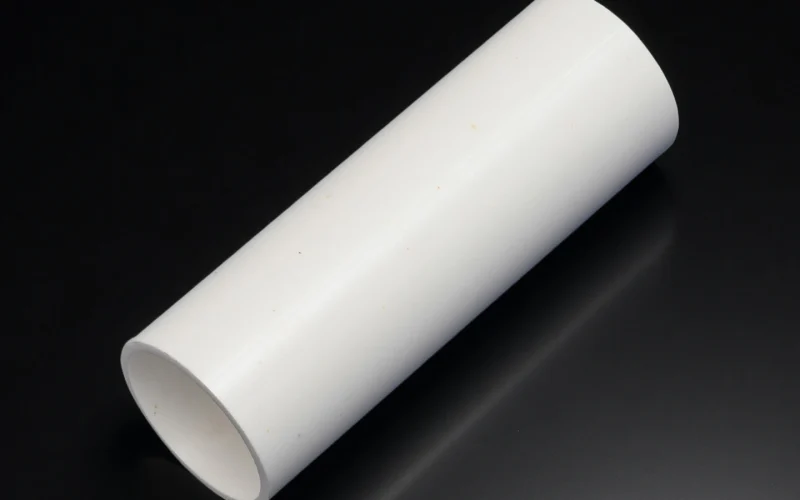

Ceramic insulating tubes provide electrical isolation and stable conductor spacing at high temperature. Common forms include single-bore, two-bore, and multi-bore tubes, plus cut-to-length or ground-finish parts. Material and geometry are set by temperature, voltage, and clearance needs.

alumina ceramic insulator tube

High electrical insulation and chemical stability for low drift protection.

Magnesia ceramic insulator tube

High toughness and thermal-shock resistance for cycling stability.

Zirconia ceramic insulator tube

High thermal conductivity and strength for fast, reliable response.

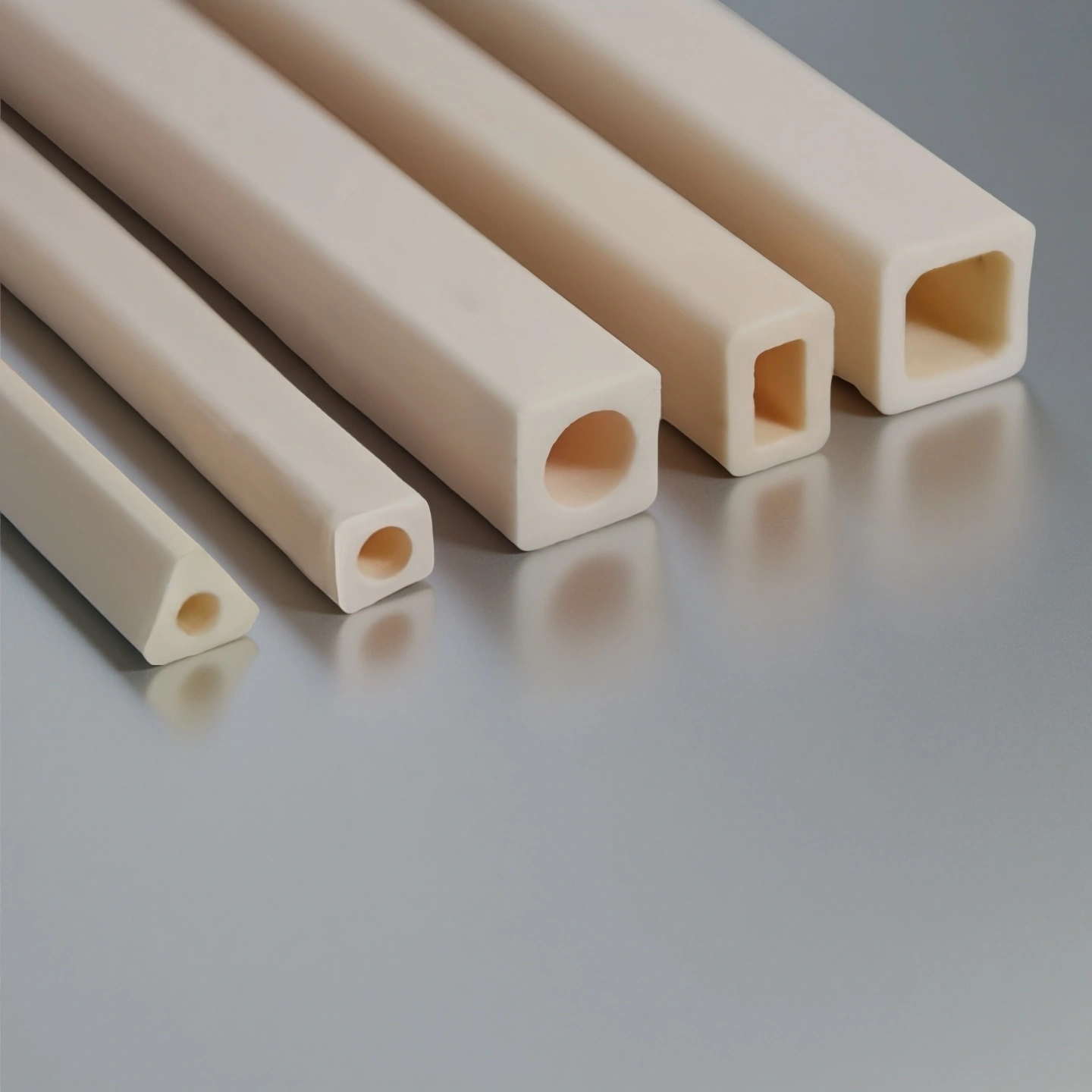

Square ceramic insulating tube

For constrained mounts and fixed-orientation requirements. Square profile prevents rotation and improves alignment.

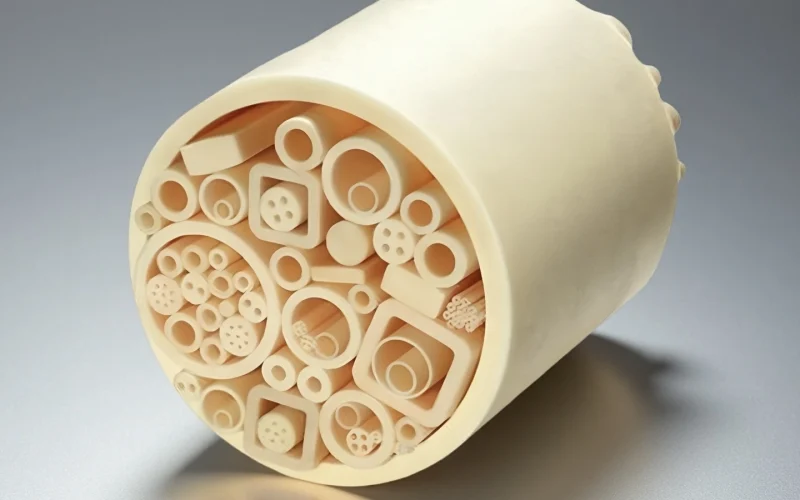

Multi-Bore ceramic insulating tube

For multi-element probes and drift-sensitive control loops. Separated bores improve insulation and reduce cross-talk.

ceramic insulator tube,Open Both Ends

For guided furnace installs and frequent probe replacement. Open-through design enables fast insertion and easy maintenance.

ceramic insulation tube,One End Closed

For corrosive atmospheres and drift-sensitive temperature control. Closed tip isolates the hot junction to reduce contamination exposure.

Black ceramic insulating tube

For threaded ports requiring adjustable insertion depth. Threaded mounting locks position with repeatable adjustment.

ceramic Shaped Bore Insulating Tube

For wall penetrations needing fixed depth and sealing. Flange mounting stabilizes position and supports sealing.

Ceramic Insulating Tube Applications

Ceramic insulating tubes serve multiple high-temperature electrical insulation roles across industrial heating, measurement, and processing equipment. Common applications where ceramic insulators maintain electrical isolation, prevent signal drift, and extend service life:

Thermocouple Assemblies for Industrial Furnaces

Multi-bore tubes isolate Type K, Type N, Type R, or Type S thermocouple wires in heat treatment, annealing, and sintering furnaces operating continuously above 1000 °C

Temperature Measurement in Kilns and Dryers

Single-bore or twin-bore insulators protect sensor wires in ceramic firing kilns, rotary calciners, and high-temperature dryers where chemical vapors or particulates are present

High-Temperature Test and Calibration Equipment

Precision-grade alumina tubes provide stable electrical isolation in temperature calibration furnaces and materials testing rigs where measurement accuracy and repeatability are critical

Metal Processing and Heat Treatment Lines

Twin-bore and multi-bore tubes enable multi-zone temperature profiling in continuous annealing lines, wire drawing furnaces, and aluminum or steel heat treatment systems

Electric Heater Assemblies

Insulating tubes separate power leads or control wiring from grounded metallic heater housings in cartridge heaters, band heaters, and immersion heaters

Laboratory Tube Furnaces

Standard-length insulating tubes support thermocouples in horizontal and vertical tube furnaces used for materials research, catalyst testing, and CVD processes

Common Failure Modes and Mitigation

Ceramic insulation tubes fail when operating conditions exceed material limits or design parameters are mismatched. Identifying failure mechanisms helps engineers select appropriate materials, tolerances, and installation methods to prevent premature failure.

| Symptom | Likely Cause | Design / Material Adjustment | Notes |

|---|---|---|---|

| Electrical leakage | Insulation resistivity drops at temperature | Switch to higher-purity alumina or magnesia | Verify resistivity at operating temperature |

| Cracking during operation | Thermal shock or uneven heating | Increase wall thickness or adjust heating rate | Avoid tight mechanical constraints |

| Chipping at ends | Handling or installation stress | Add chamfer or use tougher material | Zirconia may reduce handling damage |

| Short circuits | Insufficient clearance or creepage | Increase bore spacing or tube length | Review voltage and layout assumptions |

| Misalignment | Creep or fixture movement | Improve mechanical support strategy | Avoid over-constraining ceramic parts |

Custom Ceramic Insulating Tube Options

Engineers often require dimensional or geometric modifications beyond standard catalog offerings to match specific conductor layouts, installation constraints, or thermal environments. The following customization options address the most common application-driven requirements:

Custom Options Matrix

| Custom Parameter | Typical Specification | Why It Matters |

|---|---|---|

| Bore configuration | Single-bore, twin-bore (2-hole), multi-bore (4-hole, 6-hole, 8-hole) | Matches conductor count and separation requirements; prevents short circuits and signal interference |

| Outer diameter and wall thickness | OD 3–25 mm, wall 0.5–5 mm typical | Ensures mechanical strength and proper fit in mounting hardware or protection tubes |

| Length and straightness tolerance | 50–2000 mm length; straightness ±0.5–2 mm per meter | Long tubes require tighter straightness control to avoid bending stress and installation difficulty |

| Hole diameter and positional tolerance | ID 0.5–10 mm; hole spacing ±0.1–0.3 mm | Tight tolerances prevent wire contact and maintain consistent electrical isolation |

| End finish | As-fired, chamfered, one-end closed, ground flat | Affects ease of installation, sealing performance, and breakage risk during handling |

| Surface finish | As-fired, ground OD/ID, polished | Ground or polished surfaces improve dimensional consistency and fitting tolerance |

Quick Acceptance Checklist

| Thermal & Environment | Geometry & Installation |

|---|---|

| ☐ Maximum continuous temperature (and short-term overshoot) confirmed | ☐ Tube form specified (single-bore / two-bore / multi-bore; cut-to-length) |

| ☐ Atmosphere identified (oxidizing / reducing / moisture / conductive dust) | ☐ Mounting method confirmed (fixed seat vs floating support for expansion) |

| ☐ Thermal cycling severity defined (start–stop frequency, gradients) | ☐ Alignment and mechanical loading reviewed (vibration, assembly force) |

| Electrical Insulation | Dimensions & Quality |

| ☐ Working voltage and insulation margin defined (clearance / creepage target) | ☐ OD / ID / overall length and key tolerances confirmed |

| ☐ Leakage / tracking risk assessed for the hot-zone environment | ☐ Straightness / bore spacing / end features defined (chamfer, radii) |

| ☐ Conductors to be isolated confirmed (single lead vs multi-lead separation) | ☐ Inspection requirements set (critical dimensions, sampling, traceability level) |

Get in touch with us

Share your operating conditions, bore configuration, and dimensional requirements with our engineering team.

Visit the Ceramic Tubes page for standard specifications, or submit drawings for custom configurations and manufacturability review.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.