Ceramic Burner Tubes for Industrial Burners, Radiant Tubes, and Furnaces

Metal burner tubes fail at high temperature through creep, oxidation, and thermal shock—forcing unplanned shutdowns and frequent replacement.

ADCERAX engineers custom ceramic burner tubes in alumina, silicon carbide, and zirconia to eliminate these failure modes: zero oxidation degradation, dimensional stability at 1400-1700°C, and thermal shock resistance for extended service life.

Failures in Oxidizing Burner Environments

Industrial burner tube failures are rarely random. They typically originate at flame impingement zones, cold-end mounting interfaces, and hot-to-cold transition regions where thermal gradients are highest.

Early indicators usually include localized cracking, surface spallation, or dimensional drift, which disrupt flame stability and heat uniformity. As surface roughening and connected microcracks develop, hot gases penetrate the material and accelerate internal damage, leading to uneven heating, increased maintenance frequency, and unplanned burner shutdowns.

Why Burner Tube Fail Under Flame Cycling?

Burner tube failures in industrial furnaces follow predictable patterns driven by extreme operating conditions. Metal alloy tubes commonly fail due to high-temperature exposure, thermal cycling stress, and corrosive combustion atmospheres.

Understanding these failure mechanisms helps engineers select ceramic materials that address specific weaknesses in conventional burner components

High-temperature creep in metal alloys

- Sustained exposure above 1200°C enables grain boundary sliding, causing progressive sagging that disrupts flame positioning.

Cyclic oxidation and scale spalling

- Repeated thermal cycling creates tensile stress at the oxide-metal interface, leading to scale detachment that thins walls.

Thermal shock from rapid temperature transients

- Emergency shutdowns impose thermal gradients exceeding 100°C across tube walls, generating differential expansion stress that exceeds fracture strength.

Corrosive attack from combustion byproducts

- Sulfur compounds form sulfuric acid condensates; halogenated contaminants create volatile metal chlorides that accelerate material loss.

Flame impingement erosion

- Direct flame contact creates localized temperature spikes 200-400°C above bulk gas temperature, accelerating oxidation and potentially inducing phase transformation.

Mechanical stress from mounting constraints

- Thermal expansion mismatch combined with rigid mounting hardware generates bending stress that initiates fatigue cracks over time.

Why Are Ceramic Materials Used for Burner Tubes?

Ceramic burner tubes outperform metal alloys through superior oxidation resistance, creep resistance, and thermal shock tolerance. Material selection matches ceramic properties to operating temperature, thermal cycling severity, and combustion atmosphere composition.

What Role Does Ceramic Play in Burner tube?

Ceramic tubes create a stable combustion chamber that maintains controlled flame geometry and prevents flame blow-off while isolating combustion from furnace atmospheres.

Ceramic materials transfer radiant heat at 1400-1700°C while maintaining dimensional stability. Alumina and SiSiC enable continuous operation without thermal degradation.

Chemically inert ceramic surfaces resist sulfur compounds, chlorides, and corrosive byproducts that rapidly degrade metal components, shielding sensors and mounting hardware.

Different Ceramic Burner Tube Material Options

High-temperature shape retention, strong oxidation/chemical stability, and stable geometry for consistent burner alignment.

High thermal conductivity to reduce thermal gradients, strong thermal shock resistance, and robust performance under flame impingement.

Higher fracture toughness for resisting crack initiation under cycling, with good stability in localized hot-spot regions.

How to Choose a Ceramic Burner Tube?

Material and design selection for ceramic burner tubes requires balancing interdependent thermal, mechanical, chemical, and geometric parameters. The following framework guides engineers through the decision process, highlighting critical trade-offs and application-specific priorities.

Key Selection Parameters

Engineers must evaluate these interdependent factors:

Temperature profile: Average setpoint plus local flame-impingement peaks.

Atmosphere: Excess air level, moisture, and contaminants (S/alkali/chlorides).

Thermal cycling: Start/stop frequency, ramp rate, and expected ΔT.

Geometry: OD/ID, wall thickness, straightness/ovality for high-aspect tubes.

Installation: Allow axial expansion; avoid misalignment and point clamping.

Ceramic Burner Tubes Material Comparison

The following materials are commonly specified, each with distinct performance profiles:

| Material | Strengths in This Application | Limitations to Consider | Best-Fit Operating Conditions | Engineering Notes |

|---|---|---|---|---|

| High-alumina (≥99.5% Al₂O₃) | Oxidizing stability; strong shape retention | Lower thermal shock vs SiC; restraint-sensitive | High temp, controlled cycling | Uniform wall; allow axial growth; avoid hot spots |

| Zirconia (ZrO₂) | High toughness for cycling cracks; hot-spot tolerant | Low conductivity raises gradients | Severe cycling / hot spots | Add radii; avoid tight clamps; control ramps |

| Silicon Carbide (SiC) | High conductivity; strong shock resistance; impingement-ready | Oxidation window dependent | High heat flux / flame impingement | Control jetting; allow expansion; limit contaminants |

Typical Ceramic Burner Tube Configurations

Based on the engineering requirements outlined above, engineers typically select ceramic components in the following configurations. Each form factor addresses specific installation and performance needs.

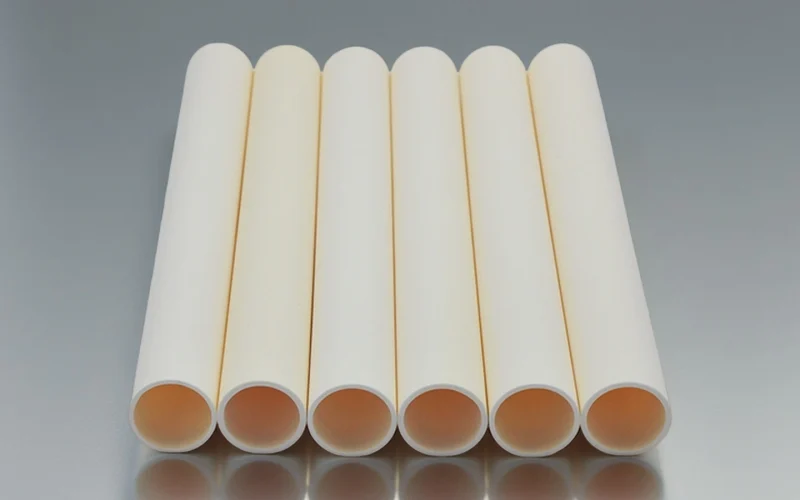

alumina ceramic burner tube

Stable geometry in oxidizing flames, with strong chemical resistance for long-term hot-zone service.

Silicon Carbide ceramic burner tube

Handles flame impingement and high heat flux, with fast heat spreading to reduce hot-spot cracking.

Zirconia ceramic burner tube

Higher fracture toughness for start-stop cycling, resisting crack initiation at hot-to-cold transition zones.

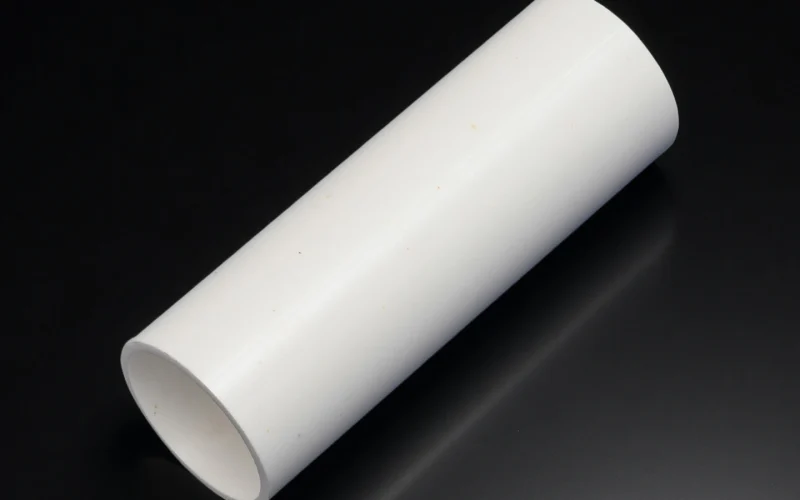

ceramic burner tube,Open-end

For through-flow mixing and flame guidance. Open-end design simplifies alignment in radiant-tube and direct-fired burner installs.

ceramic burner tube,Closed-end

For hot-gas isolation and controlled heat release. Closed-end tips reduce direct flame penetration in oxidizing cycling service.

Custom Ceramic Burner Tube Shapes

For fixed-depth mounting and sealing. Custom shoulders/tapers/flanges improve repeatable positioning and reduce clamp-stress cracking.

Ceramic Burner Tube Operating Scenarios

These ceramic burner components are deployed across multiple industries where high-temperature combustion stability, material longevity, and process reliability are critical to product quality and operational efficiency.

Steel and Metal Processing

Continuous annealing lines for steel strip: Operating at 800-1100°C in protective atmospheres (N₂-H₂ blends), ceramic radiant tubes contain combustion while radiating heat to the strip. Alumina or SiSiC tubes configured as U-tubes or W-tubes handle 50-100 thermal cycles annually.

Glass Manufacturing

Glass melting and forming furnaces: Combustion at 1400-1600°C with corrosive volatiles from batch materials. Mullite or high-purity alumina tubes resist alkali vapor attack and maintain dimensional stability, preventing ceramic particle contamination in glass products.

Industrial Boilers

Natural gas or oil combustion systems: Burner tubes resistant to thermal cycling from load following and startup/shutdown events. SiSiC handles thermal shock while alumina provides cost-effective solutions for base-load continuous operation.

Laboratory Research

Combustion research and materials testing: Custom ceramic burner tubes enable experimental control of combustion parameters and flame positioning. Precision-machined alumina tubes with specific internal geometries create repeatable flow conditions.

Cement and Lime Production

Rotary kiln burners: Extended length tubes (1000-2000mm) project into kiln hot zones above 1400°C surrounded by abrasive particulate and corrosive atmospheres. Mullite’s chemical inertness and crack tolerance address both chemical attack and mechanical impact.

Aerospace Heat Treatment

High-temperature furnaces for aerospace alloys: Precise temperature uniformity (±5-10°C) at 1200-1400°C in air or reducing atmospheres. Ceramic tubes prevent metallic contamination and maintain flame geometry over extended campaigns.

Failure Mode Analysis for Ceramic Burner Tubes

Understanding ceramic burner tube failure mechanisms improves material selection, mounting, and cycling reliability. The table links common ceramic burner tube symptoms to root causes and practical fixes.

| Observable Symptom | Root Cause Mechanism | Design/Material Adjustment | Prevention Strategy | Notes |

|---|---|---|---|---|

| Cracks near clamp/collar | Restrained expansion; stress at mount | Reinforce mount; add load sleeves | Add axial clearance; compliant gasket; avoid point clamping | Mounting often drives failure |

| Spalling in hot zone | Reaction layer + cycling; microcrack lift | SiC for high flux; tune wall thickness | Reduce impingement; tune for uniform heat; avoid quench | Verify atmosphere effects |

| Long cracks after fast start | Thermal shock from steep ΔT | Thicken hot-zone wall; consider SiC | Control ramp; preheat; avoid cold-air blast | “Fast start” is common trigger |

| Ovality/dimensional drift (metal) | Creep + oxidation scaling | Switch to ceramic direction | Maintain tuning; limit overtemp peaks | Early warning before failure |

| Gas-side wear/roughening | Erosion + turbulence hot spots | Improve finish; use tougher grade | Better filtration; reduce dust; avoid jetting | Roughness increases hot spots |

| Cracks at steps/transitions | Stress at geometry discontinuity | Add radii; gradual transitions | Specify min radii; align; avoid hard constraints | Detailing matters |

Custom Ceramic Burner Tube Options

Ceramic burner tube customization usually centers on hot-zone geometry and the cold-end mounting/sealing features that manage thermal expansion. Sharing these parameters—along with your temperature profile and cycling conditions—allows a faster design review and reduces revision loops during sampling.

Custom Options Matrix

| Custom Parameter | Typical Specification | Why It Matters |

|---|---|---|

| Hot-zone geometry (OD/ID, wall thickness) | OD 15–120 mm; wall 2–10 mm typical | Controls heat flux, hot-spot risk, and thermal shock margin under flame impingement |

| Length and straightness | 100–1500 mm length; straightness ±0.5–2 mm per meter | Prevents misalignment, clamp stress, and uneven heating across the burner path |

| End configuration | Open-end, closed-end, stepped end, tapered end | Sets flame/gas path behavior; closed-end limits direct flame entry; steps/tapers improve mounting stability |

| Mounting interface features | Shoulder, groove, flange, collar land | Improves repeatable positioning and sealing; reduces restraint-driven cracking at the cold end |

| Surface condition (ID/OD) | As-fired, ground, polished (selected zones) | Affects flow stability, sealing fit, and crack initiation at contact points |

| Special ports / holes (if needed) | Vent/relief holes or sensor ports (case-dependent) | Supports pressure equalization, purge control, or integration with burner assemblies when required |

Quick Acceptance Checklist for Ceramic Burner Tube

Thermal & Environment

| Thermal & Environment |

|---|

| ☐ Max temperature + flame-impingement peak confirmed |

| ☐ Atmosphere defined (oxidizing / reducing / mixed; moisture) |

| ☐ Thermal cycling defined (ramp rate, ΔT, start–stop) |

Geometry & Installation

| Geometry & Installation |

|---|

| ☐ Tube form defined (open/closed/step/taper) |

| ☐ Mounting method set (floating vs fixed clamp) |

| ☐ Expansion clearance + alignment confirmed |

Performance & Reliability

| Performance & Reliability |

|---|

| ☐ Hot-spot risk assessed (location/intensity) |

| ☐ Thermal shock risk evaluated (start/stop severity) |

| ☐ Erosion/particulate exposure reviewed |

Dimensions & Quality

| Dimensions & Quality |

|---|

| ☐ OD / ID / length + key tolerances confirmed |

| ☐ Wall thickness strategy defined |

| ☐ Straightness / ovality limits specified |

Get in touch with us

Share your operating conditions, bore configuration, and dimensional requirements with our engineering team.

Visit the Ceramic Tubes page for standard specifications, or submit drawings for custom configurations and manufacturability review.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.