High Quality Ceramic Bearings for High-Speed, Corrosion-Resistant Rotation

ADCERAX is a ceramic bearing supplier built for stable export delivery and fit-critical quality.We provide zirconia (ZrO₂), silicon nitride (Si₃N₄), silicon carbide (SiC), and aluminum oxide (Al₂O₃) components, including hybrid and full ceramic bearings—from miniature to large sizes.

These bearings support high-speed spindles, pumps, chemical-duty equipment, industrial automation, and high-temperature or corrosive service. By reducing wear, corrosion, heat build-up, and lubrication sensitivity, they help maintain smoother rotation, longer life, and more stable performance.

What is a Ceramic Bearing?

A ceramic bearing is a bearing that uses ceramic rolling elements and/or ceramic raceways to support rotation with lower friction and stronger resistance to harsh operating conditions.

In most designs, the ceramic material is used where contact stress is highest—such as the balls, rollers, or rings—so the bearing can maintain smoother motion as speed, temperature, corrosion exposure, or contamination risk increases.

Ceramic Bearings Pros and Cons

🌟 Advantages of ceramic bearings

Lower friction, less heat build-up at speed – Ceramic rolling elements typically run with lower friction and reduced sliding losses, so bearings can stay cooler at high RPM and keep rotational feel more consistent over time.

Strong corrosion and rust resistance – In wet, chemical, or washdown environments, ceramic options reduce corrosion attack and help maintain surface integrity where steel bearings may pit or seize.

More stable performance with limited lubrication – Many ceramic-bearing configurations are less sensitive to marginal lubrication than all-steel designs, helping reduce failure risk when oil or grease supply is inconsistent.

Electrical insulation and non-magnetic options – Full-ceramic designs can provide electrical isolation, and several ceramic materials are naturally non-magnetic, supporting equipment where stray currents or magnetic interference matters.

⚠️ Disadvantages and of ceramic bearings

More brittle under shock or impact– Ceramic components are less forgiving when you have sudden load spikes, impact events, or vibration-induced shock, which can raise the risk of cracking compared with steel.

Higher cost and higher consequence of wrong selection – Ceramic bearings usually cost more, and a mismatched material, clearance, or preload can make that investment fail to deliver the expected service life.

Fit-critical assembly requirements – Ceramic rings and rolling elements demand tighter control of shaft/housing tolerances, press fits, and cleanliness. Poor fits or contamination can reduce smoothness and shorten lifespan.

Not automatically “faster” in every system – Speed and efficiency gains depend on the full bearing system—lubrication method, cage design, preload, heat dissipation, and alignment. A ceramic upgrade alone does not guarantee higher RPM capability.

Ceramic Bearings Properties

Ceramic bearings have material-driven properties distinct from metal bearings. High hardness, chemical stability, and thermal resistance support more predictable performance. These core properties help engineers compare materials and select the right bearing for load, speed, temperature, and environment.

Aluminum Oxide Ceramic Bearing

Aluminum oxide ceramic bearings (Al₂O₃) offer high hardness and strong wear resistance, with stable chemical performance and dependable electrical insulation. They also maintain dimensional stability at elevated temperatures, helping reduce surface scoring and performance drift over time.

| Property | Unit | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Flexural strength | MPa | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | 200 | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.2 | 8.4 | – | – | – | – | – |

| Melting point | °C | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 |

Zirconia Ceramic Bearings

Zirconia ceramic bearings (ZrO₂) are valued for higher toughness and impact tolerance, helping resist chipping and crack growth in fit-critical parts. Their smooth finishing potential supports low noise and steady rotation, while corrosion resistance helps keep surfaces cleaner and more consistent.

| Property | Specification |

| Maximum Working Temperature | 1500 °C continuous use |

| Density | 5.65 g/cm³ |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity | 2.2 W/m·K at 1000 °C |

| Chemical Stability | 0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength | 900 MPa at room temperature |

| Fracture Toughness | 8 MPa·m½ |

| Hardness (Vickers) | 12 GPa |

| Elastic Modulus | 210 GPa |

Silicon Carbide Ceramic Bearings

Silicon carbide ceramic bearings (SiC) deliver very high hardness and outstanding abrasion resistance, staying chemically stable in aggressive media. With high stiffness and strong thermal stability, they help limit deformation and heat-related drift, supporting long-term dimensional consistency.

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

| Chemical Stability Range | pH 2–12 |

| Oxidation Stability | <1% microstructural oxidation after 50 cycles (1000°C → RT) |

Silicon Nitride Ceramic Bearing

Silicon nitride ceramic bearings (Si₃N₄) balance high strength with low density, supporting fast response and stable running at high speed. They offer good fracture resistance and excellent wear performance, while thermal shock resistance helps maintain geometry through rapid temperature changes.

| Property | Description | Notes |

|---|---|---|

| Density | ≈ 3.2 g/cm³ | About 60% lighter than bearing steel, reducing centrifugal force at high speed |

| Hardness | ≈ 1,500 – 1,700 HV | High surface hardness limits indentation and slows wear under rolling contact. |

| Elastic Modulus | ≈ 300 – 320 GPa | Maintains stiffness under load, supporting stable geometry at high RPM. |

| Thermal Expansion Coefficient | ≈ 3.0 × 10⁻⁶ /K | Much lower than steel, helping control preload and internal clearance as temperature changes. |

| Thermal Shock Resistance | High | Handles rapid temperature changes with lower cracking risk. |

| Electrical Insulation | Excellent (non-conductive) | Effectively blocks electrical discharge damage (EDM) in VFD-driven motors. |

| Corrosion Resistance | Excellent in most acids, alkalis, and humid environments | Resists rust, pitting, and chemical attack that degrade steel. |

High Quality Ceramic Bearing Products & Types

Ceramic bearings here include hybrid and full ceramic designs in miniature-to-large sizes. With ZrO₂ / Si₃N₄ / SiC / Al₂O₃ options and tight control on fit and finish, they minimize wear and heat rise while staying less oil-dependent.

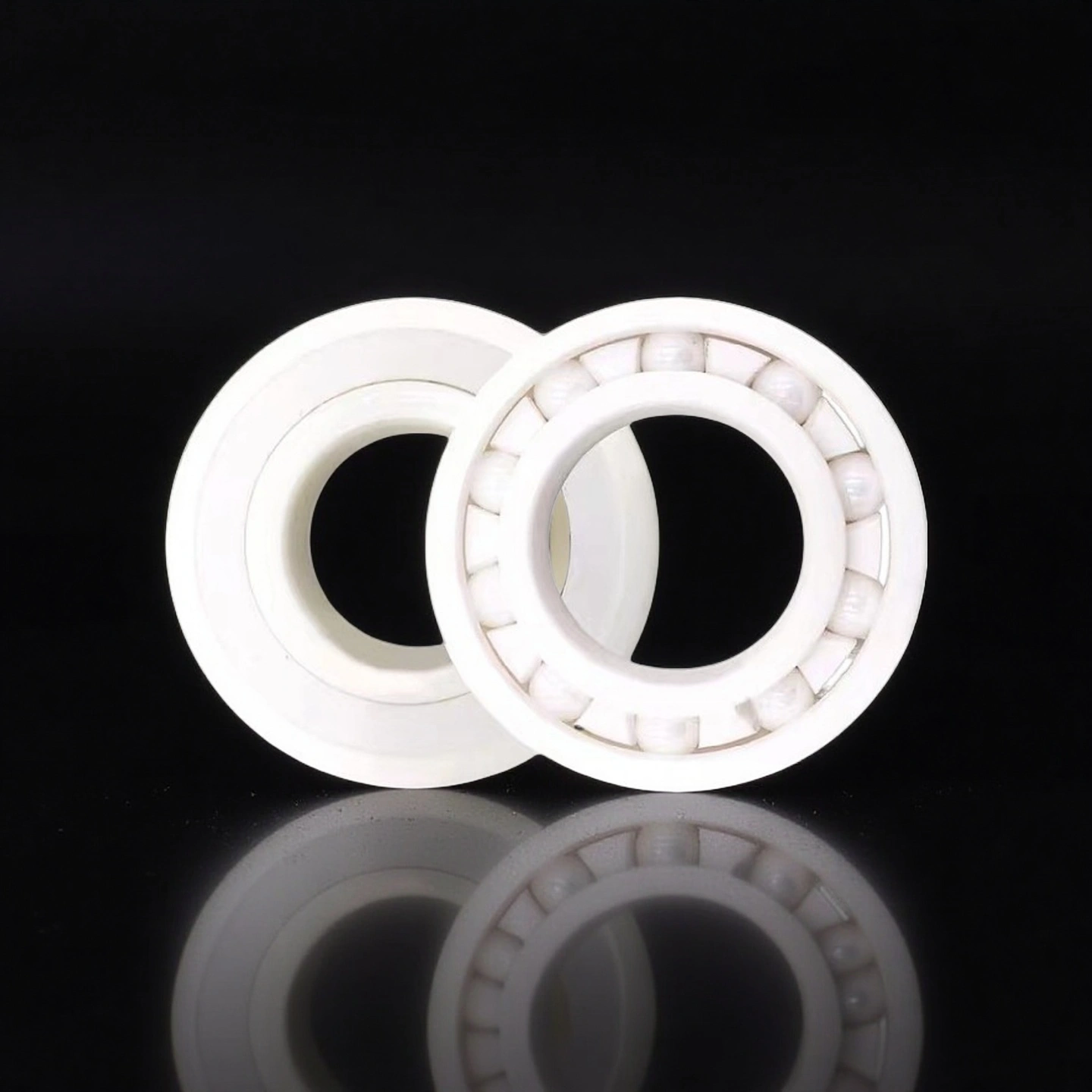

alumina ceramic bearing

Alumina bearing for stable insulation and low drift—helps prevent stray-current damage and contamination.

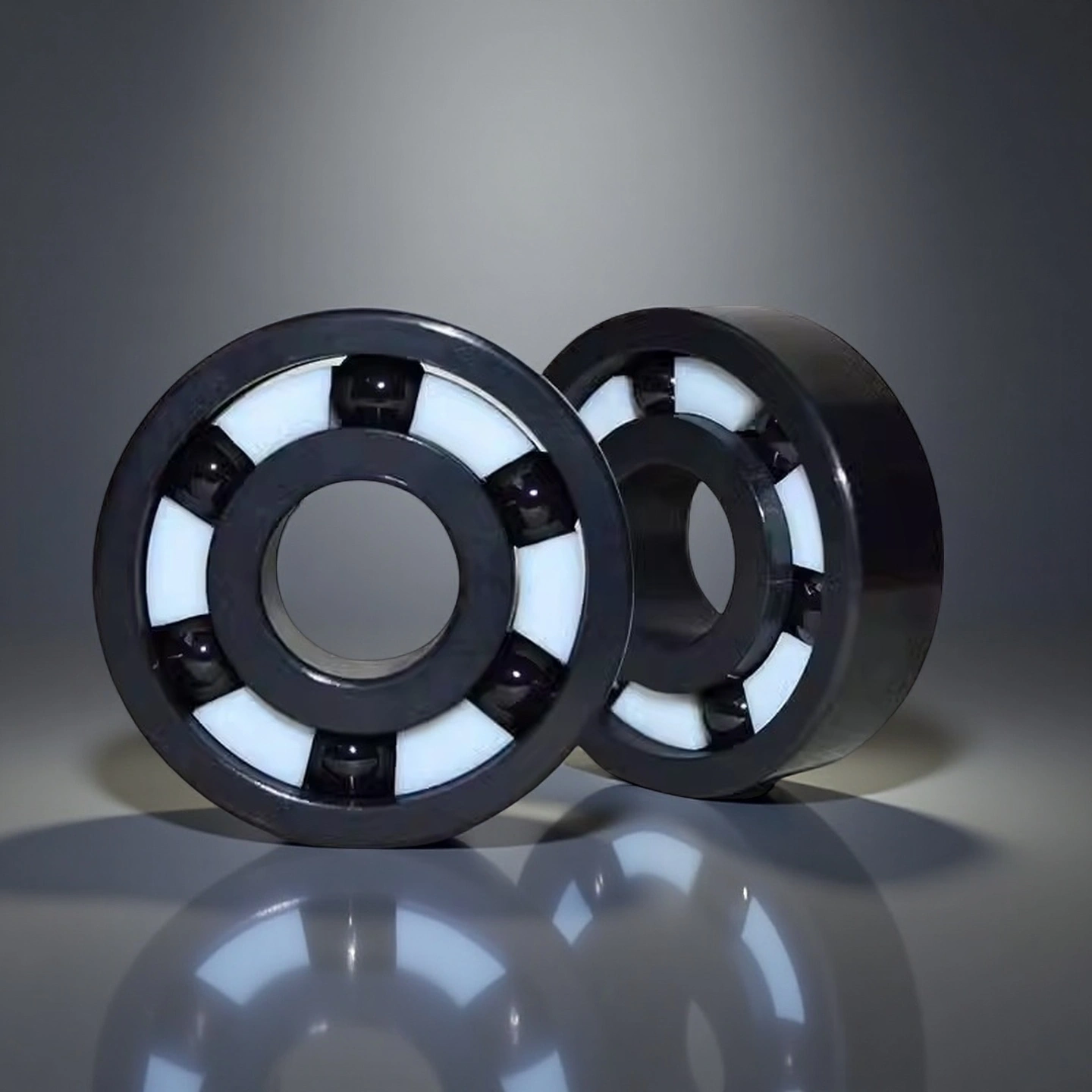

zirconia ceramic bearings

Zirconia (Zro2) ceramic bearings with higher toughness—reduce chipping and keep rotation stable under shock.

silicon carbide ceramic bearings

SiC ceramic bearings resist abrasion and corrosion—hold geometry in aggressive pump media.

silicon nitride ceramic bearing

Si3N4 Ceramic bearing built for high RPM—runs cooler and supports longer precision life.

Ceramic Self-Aligning Ball Bearing

Ceramic self-aligning ball bearings tolerate misalignment, reduce edge loading, heat build-up, and early wear.

ceramic deep groove ball bearings

Ceramic deep groove ball bearings run with low friction and low noise, delivering rotation and long service life.

Angular Contact Ceramic Bearing

Angular contact ceramic bearings hold stiffness at high speed, supporting higher axial load and more stable runout.

ceramic thrust ball bearings

Ceramic thrust ball bearings carry axial load with low heat rise, helping prevent face scoring and premature seizure.

Ceramic Insert Bearing

Ceramic insert bearings resist corrosion and washdown attack, helping extend uptime in wet or chemical-duty service.

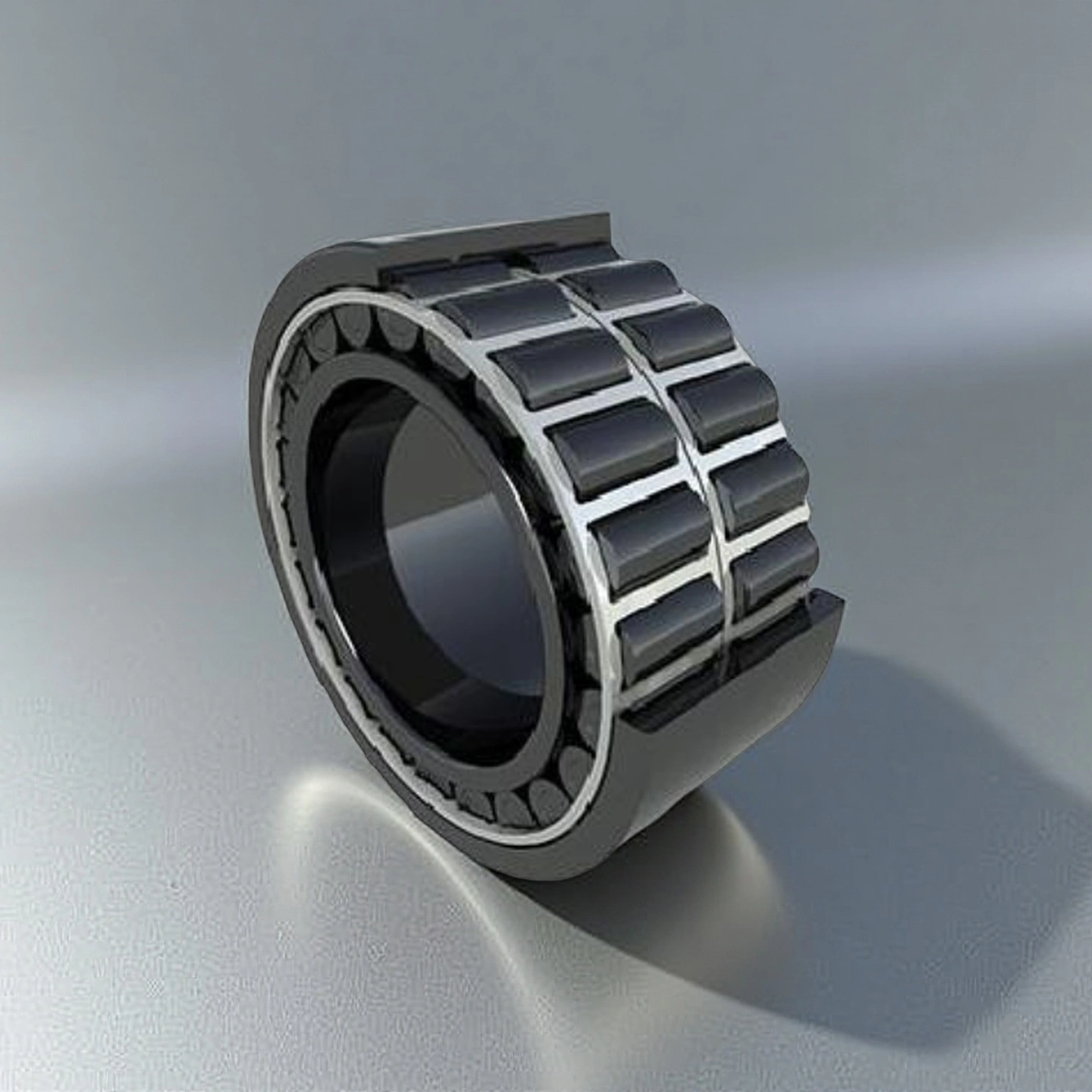

ceramic roller bearings

Ceramic roller bearings handle higher radial load with lower wear, extending life in abrasive or poor-lube duty.

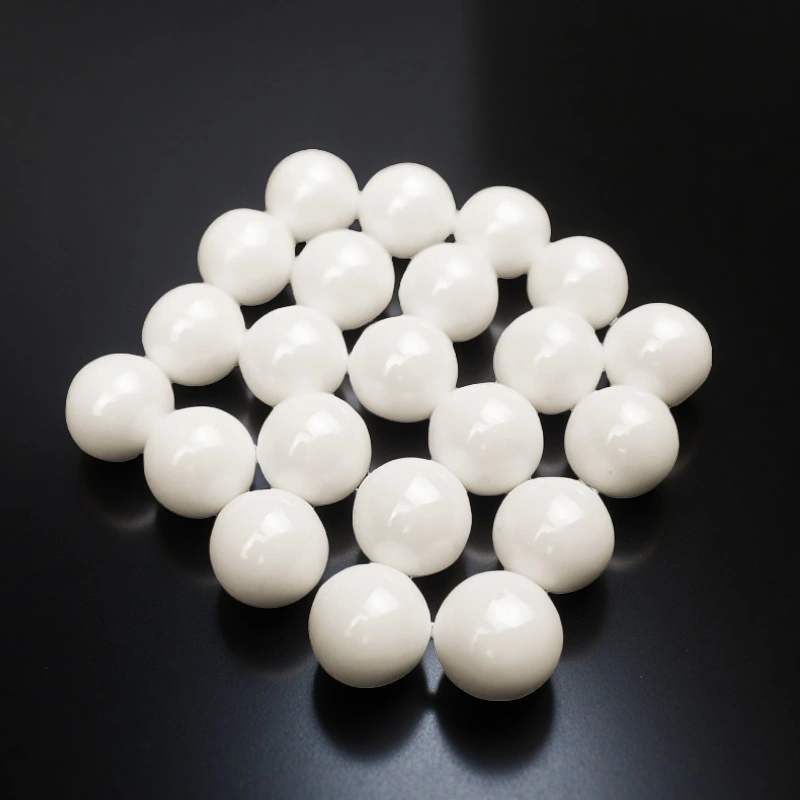

ceramic bearing rollers

Ceramic bearing rollers resist indentation and corrosion, keeping smoother rolling contact and steadier.

bearing ceramic ball

Bearing ceramic balls run hard and low-drag, reducing skid, vibration, and contamination versus steel balls.

Ceramic Bearings — Built to Run Longer, Fail Less.

Talk to an engineer about fit-critical ceramic bearing solutions.

High Performance Ceramic Bearing Applications

Ceramic bearings are used in corrosive media, electrical-motor environments, clean/vacuum systems, and hot-running machinery to prevent the common steel-bearing failures—rust, electrical pitting, lubricant breakdown, and particle-related jamming—so uptime stays predictable.

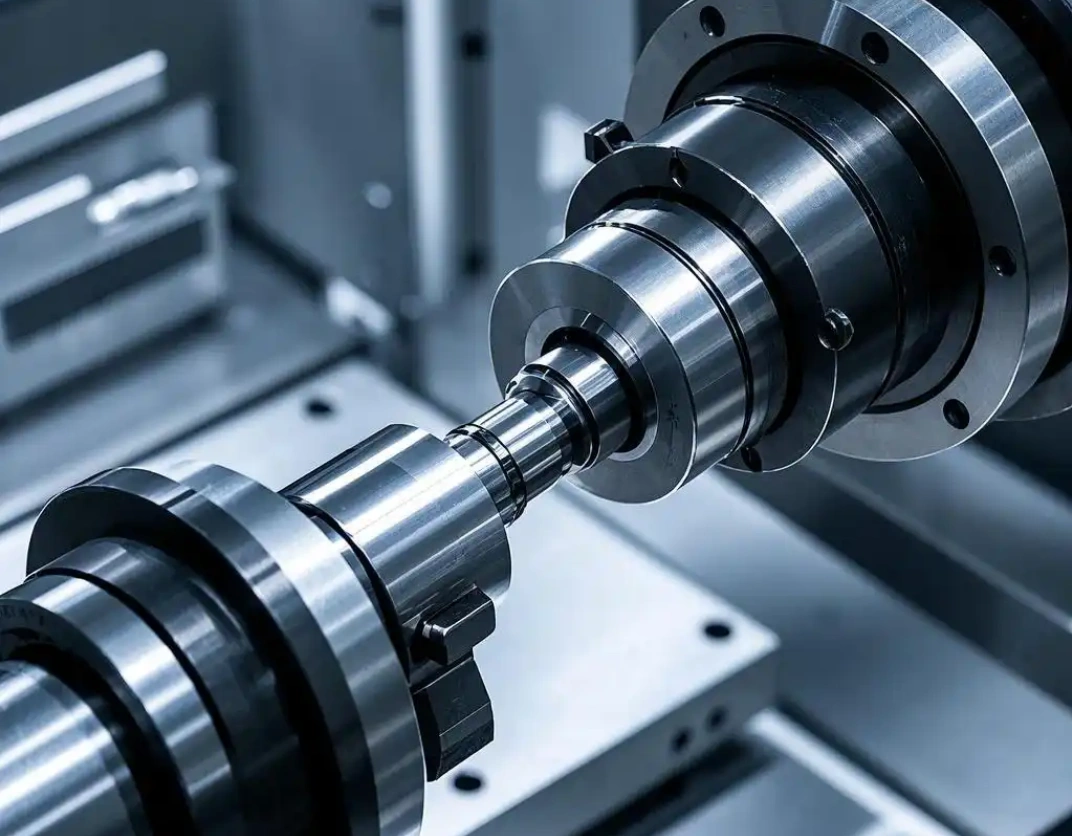

High-Speed Spindles & Machine Tools

Pain: heat build-up, grease breakdown, vibration drift

Result:steadier RPM, lower friction rise, more stable runout

🧩Ceramic bearing case: Excessive heat rise and accuracy drift at high RPM

A CNC spindle running at 18,000 RPM experienced a temperature rise of ≈20 °C within one hour when using steel bearings, leading to repeat positioning errors beyond tolerance. After switching to hybrid ceramic spindle bearings (Si₃N₄ balls), measured temperature rise dropped to ≈9 °C, and continuous stable operation time increased by over 30%, reducing recalibration frequency.

Measured improvement:

Heat rise ↓ ~55% | Stability window ↑ ~30%

Semiconductor & Clean Equipment Motion

Pain: particle contamination, outgassing sensitivity

Result: cleaner rolling contact, reduced contamination risk, stable motion

🧩Case of ceramic bearing: particle generation affecting yield consistency

In a clean motion stage, steel bearings contributed measurable particle counts during start–stop cycles. After adopting full ceramic bearings, airborne particle levels near the motion assembly dropped by over 40%, improving process repeatability and reducing cleaning intervals.

Measured improvement:

Particle generation ↓ ~40% | Cleaning frequency ↓

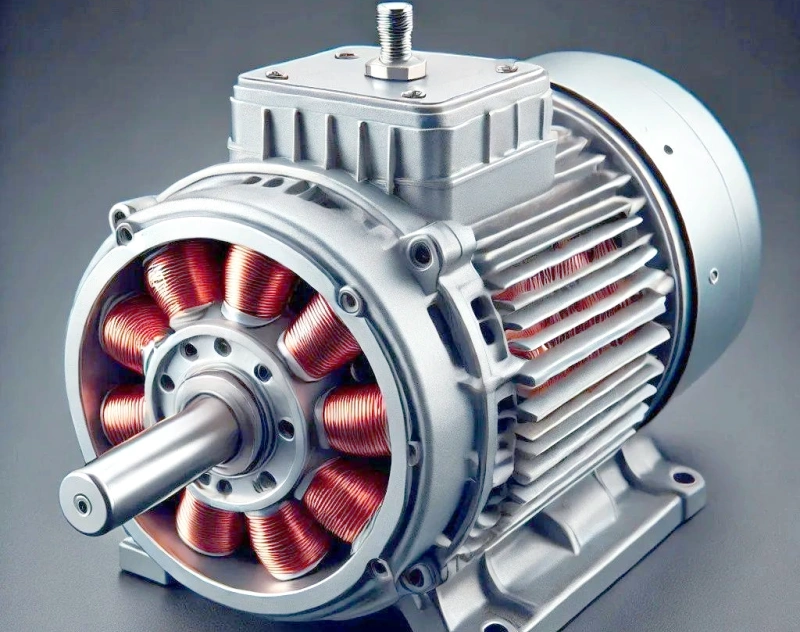

Motors / EV Auxiliary Systems

Pain: stop-start wear, micro-vibration, accuracy loss

Result: lower wear drift, smoother repeatability, longer maintenance intervals

🧩Ceramic bearing example: Electrical discharge damage (fluting) in motor bearings

An inverter-driven motor operating continuously showed bearing fluting and vibration increase after 10–12 months. Switching to hybrid ceramic bearings reduced electrical discharge damage, extending bearing life beyond 30 months and lowering vibration amplitude by ≈35%.

Measured improvement:

Bearing life ↑ ~2.5× | Vibration ↓ ~35%

Robotics & Industrial Automation

Pain: stop-start wear, micro-vibration, accuracy loss

Result: lower wear drift, smoother repeatability, longer maintenance intervals

🧩Case of ceramic bearing: Accuracy loss from stop-start wear

A robotic axis performing rapid stop-start cycles (> 2 million cycles/year) experienced increasing backlash due to steel bearing wear. Ceramic bearings reduced wear rate, allowing positioning accuracy to remain within specification for over 2× the original service interval.

Measured improvement:

Accuracy retention ↑ ~2× | Wear rate ↓

Custom High Precision Ceramic Bearings

ADCERAX supplies custom high precision ceramic bearings built to your specifications—covering dimensions, clearance, grade, raceway finish, and bearing configuration (hybrid or full ceramic). Typical lead time is 2–9 weeks, driven by material selection, tolerances, and finishing requirements.

Customization Options

Define the dominant failure mode first—wear, spalling, corrosion, thermal damage, or cage/retainer fatigue. Match bearing type (hybrid vs. full ceramic) and material (ZrO₂ / Si₃N₄ / SiC / Al₂O₃) to reduce raceway scoring, ball damage, and early noise rise. This improves service life stability under harsh duty.

Share your drawing and fit points for reliable installation—OD/ID, width, chamfers, and seat tolerances. Specify internal clearance and preload targets to prevent overheating, vibration loosening, and premature surface distress. Controlled fit helps maintain repeatable rotation and consistent runout.

Confirm shaft speed, load, and temperature range to manage heat build-up and thermal expansion mismatch. Proper material choice and lubrication strategy reduce friction rise, thermal cracking risk, and torque drift. This keeps rotation smooth across repeated start-stop and thermal cycles.

Specify contact requirements—raceway finish, ball/roller grade, roundness, and cleanliness level. A tighter surface and geometry window helps reduce particle shedding, micro-slip, and uneven wear growth. This supports lower noise, steadier torque, and more stable accuracy over time.

Customization Process

Send your application, speed/load, temperature, media exposure, and target service life. Include bearing type (hybrid/full ceramic), size (ID/OD/width), tolerance/clearance, quantity, and destination.

We confirm key specs: material grade, dimensions, clearance/preload, runout, and surface finish. If needed, we recommend a design to cut heat, noise, or early wear.

We manufacture to spec and inspect critical dimensions and geometry. Inspection records, part ID/marking, and QC traceability are available for repeatable replacements.

Bearings are protected, labeled, and packed to prevent chipping and surface damage, then shipped with export-ready documentation.

ADCERAX: A Trusted China Ceramic Bearing Supplier

ADCERAX is a wholesale high quality ceramic bearing exporter in China, supplying export-ready ceramic bearings with controlled manufacturing and batch inspection for consistent runout, clearance, and rotation stability. Fast engineering support helps confirm geometry, tolerances, surface finish, and lead time for reliable fit and repeatable replacements.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Premium Ceramic Bearing Manufacturers-ADCERAX

ADCERAX is a factory-direct ceramic bearing supplier with 20+ years of advanced ceramics experience, delivering corrosion-resistant, electrically insulating, and wear-stable bearings for harsh-duty service where runout control and rotation stability matter.

Standard ceramic bearings are available for faster replacement, and custom-to-drawing builds cover bearing size/series, fit class, clearance or preload, runout targets, cage/ball options, and surface finish. With batch inspection, traceable records, and protective packing, ADCERAX helps buyers keep fit consistency, reduce early wear or noise, and maintain predictable maintenance cycles.

Ceramic Bearings Processing

Ceramic bearings are produced through controlled powder preparation, precision forming, high-temperature sintering, and fine grinding/lapping to lock in stable runout, correct clearance, and repeatable surface finish. Below is a practical view of how bearings are made and what each step controls.

🧱 1)Material Preparation & Recipe Control

🔹Select bearing-grade powders (ZrO₂ / Si₃N₄ / SiC / Al₂O₃) to meet target purity and particle-size distribution

🔹 Add binder and disperse/mix to keep green strength stable and avoid agglomeration-driven defects

🔹Lot control and traceability to reduce batch-to-batch variation in density and shrinkage behavior

What it impacts: density consistency, defect risk, shrinkage stability

🧩 2)Forming & Green Machining

Choose forming route for ring/ball geometry and size: pressing / injection molding / CIP (as applicable):

🔹Control green density uniformity to prevent ovality, distortion, and uneven sintering shrinkagethickness

🔹Green machining for ID/OD features, raceway preforms, pockets/cage interfaces when required

What it impacts: geometry repeatability, roundness/runout baseline, machining allowance control

🔥3) Sintering / Firing & Dimensional Stabilization

🔹High-temperature sintering matched to each bearing ceramic (ZrO₂ / Si₃N₄ / SiC / Al₂O₃) for target density

🔹Controlled heating/cooling to reduce thermal stress, distortion, and microcrack risk

🔹Process tuning to lock in stable microstructure and predictable shrinkage for rings and balls

What it impacts: density & strength, roundness/runout stability, service life

🛠 4) Precision Finishing (Grinding / Lapping / Surface Control)

🔹ID/OD grinding to hit bore/OD size, roundness, and runout targets

🔹Raceway grinding/lapping to achieve contact geometry and tighter surface-finish requirements

🔹Edge/radius finishing to reduce chipping and improve handling and assembly robustness

What it impacts: rotational smoothness, noise/vibration level, contact fatigue resistance

FAQs About Ceramic Bearings

- Hybrid ceramic bearings (ceramic balls + steel rings) are the default choice for high-speed upgrades because they keep strong ring toughness while reducing friction, heat, and electrical damage.

- Full ceramic bearings (ceramic balls + ceramic rings) are preferred when corrosion resistance, electrical insulation, or non-magnetic performance must be maximized. If shock load and mounting errors are likely, hybrid is often safer.

Si₃N₄ is the best all-around for high-speed, low heat, and long rolling fatigue life.

ZrO₂ is strong in corrosion resistance and toughness, often favored for wet or chemical duty.

SiC excels in corrosion + high-temperature stability but is more brittle and typically used for special conditions.

Al₂O₃ is cost-effective and chemically stable, commonly used for moderate loads/speeds or where insulation matters.

They make sense when the cost of failure is high: unplanned stoppage, frequent changeouts, corrosion-related seizure, electrical pitting, or heat-driven instability. A simple way to estimate ROI is: compare total cost per operating hour (bearing cost + downtime + labor + collateral damage). Ceramic bearings often win by extending service intervals and reducing failure events.

In many setups, yes—mainly because ceramic balls reduce friction and heat generation, allowing higher speed or more stable temperature rise. But speed is limited by the whole system: cage design, lubrication method, preload, balance, and shaft/housing accuracy. “Faster” is real only when the bearing is correctly specified.

They can, but only with proper geometry control. Low runout, correct preload/clearance, and good raceway finish are the true drivers of low noise. Ceramic balls can improve smoothness because they resist surface damage and reduce micro-sliding, but poor fits or incorrect preload will still create vibration.

Some full ceramic bearing designs can operate dry or with minimal lubrication under light-to-moderate loads, especially in clean environments. However, dry running increases frictional heating and wear risk if load/speed is high or contamination exists. For most industrial duty, a controlled lubrication strategy remains the safest route.

Send: bearing type/size or drawing, material preference (ZrO₂/Si₃N₄/SiC/Al₂O₃), hybrid or full ceramic, target runout, clearance/preload, speed, load direction (radial/axial), temperature range, media exposure, lubrication method, and required quantity. If the bearing is for a precision spindle, also include balance grade and noise limits.

Ceramics are more brittle than steel, so impact damage and sharp stress risers are key risks. Good designs mitigate this with edge radii, correct fits, clean assembly tools, and controlled preload. ZrO₂ is typically more tolerant to handling shock than SiC; hybrid designs also reduce ring-brittleness risk.

Keep ceramic bearings clean, correctly lubricated (if used), and properly sealed. Most issues come from contamination, wrong grease amount/type, poor sealing, or misalignment—not the ceramic itself. Inspect noise/vibration/temperature trends, avoid over-greasing, and replace the bearing if roughness or heat rise persists after correction.

Ceramic bearing grades usually refer to the precision class of the rolling elements (ceramic balls)—most commonly Grade 3, Grade 5, Grade 10—which describe how tightly the balls are controlled for roundness, diameter variation, and surface quality. In general, lower grade numbers mean higher precision, which helps achieve lower vibration, lower noise, and more stable runout in high-speed or fit-critical builds.

Grade 3 ⭐ Ultra-precision / high-speed / low-vibration

Best for spindles, high RPM, tight runout targets, and applications where smoothness and stability matter most.Grade 5 ✅ Precision / most common “high-performance” choice

A strong balance of cost and performance for many hybrid ceramic bearings and general high-speed industrial use.Grade 10 💡 Standard precision / cost-sensitive builds

Suitable when the system tolerances are looser and ultra-low vibration is not critical.

Ceramic bearings are made by forming ceramic powder into rings/balls/rollers, high-temperature sintering to densify, then precision grinding/lapping to hit tight geometry and surface finish. Finally, they’re assembled as full ceramic or hybrid designs and verified by runout, clearance/preload, and rotation smoothness inspection.

Typical steps: powder prep → forming → debinding → sintering/HIP → precision grinding/lapping → cleaning → assembly → final inspection.

You can buy high quality ceramic bearings from specialized ceramic bearing suppliers like ADCERAX, a Chinese ceramic bearings wholesaler focused on controlled manufacturing and export-ready supply. They provides hybrid ceramic bearings and full ceramic bearings with batch inspection for stable runout, clearance consistency, and smoother rotation across repeat orders.

Specify the exact bearing you need

Providing clear specifications upfront makes quotes much faster and more accurate to info@adcerax.com. Typically include:

Bearing type: 608 ceramic bearing (hybrid or full ceramic)

Material: e.g., Si₃N₄ (silicon nitride), ZrO₂ (zirconia), etc.

Seals/shields: open / 2RS (double sealed) / ZZ (double shielded)

Grade/precision: e.g., Grade 3, Grade 5 (if precision matters)

Quantity needed: single samples vs bulk orders

Example specification: 608 ceramic bearing, Si₃N₄ balls, hybrid with steel races, 2RS seals, Grade 5, qty 100.

Ceramic bearings and steel bearings differ mainly in corrosion resistance, friction/heat behavior, electrical insulation, and speed stability.

✅ Choose ceramic bearings when steel bearings fail due to rust/corrosion, electrical arcing (EDM), contamination sensitivity, or heat-driven instability. Ceramic rolling elements can reduce friction and heat build-up, helping maintain smoother rotation and longer service life.

✅ Choose steel bearings when you need lower upfront cost, high shock tolerance, and your environment is clean, well-lubricated, and non-corrosive—especially where maintenance is easy and frequent relubrication is acceptable.

| Feature | Ceramic Bearings | Steel Bearings |

|---|---|---|

| Friction | Lower | Higher |

| Corrosion Resistance | Excellent | Poor |

| Electrical Insulation | Yes | No |

| Speed Capability | Higher | Lower |

| Cost | Higher | Lower |

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.