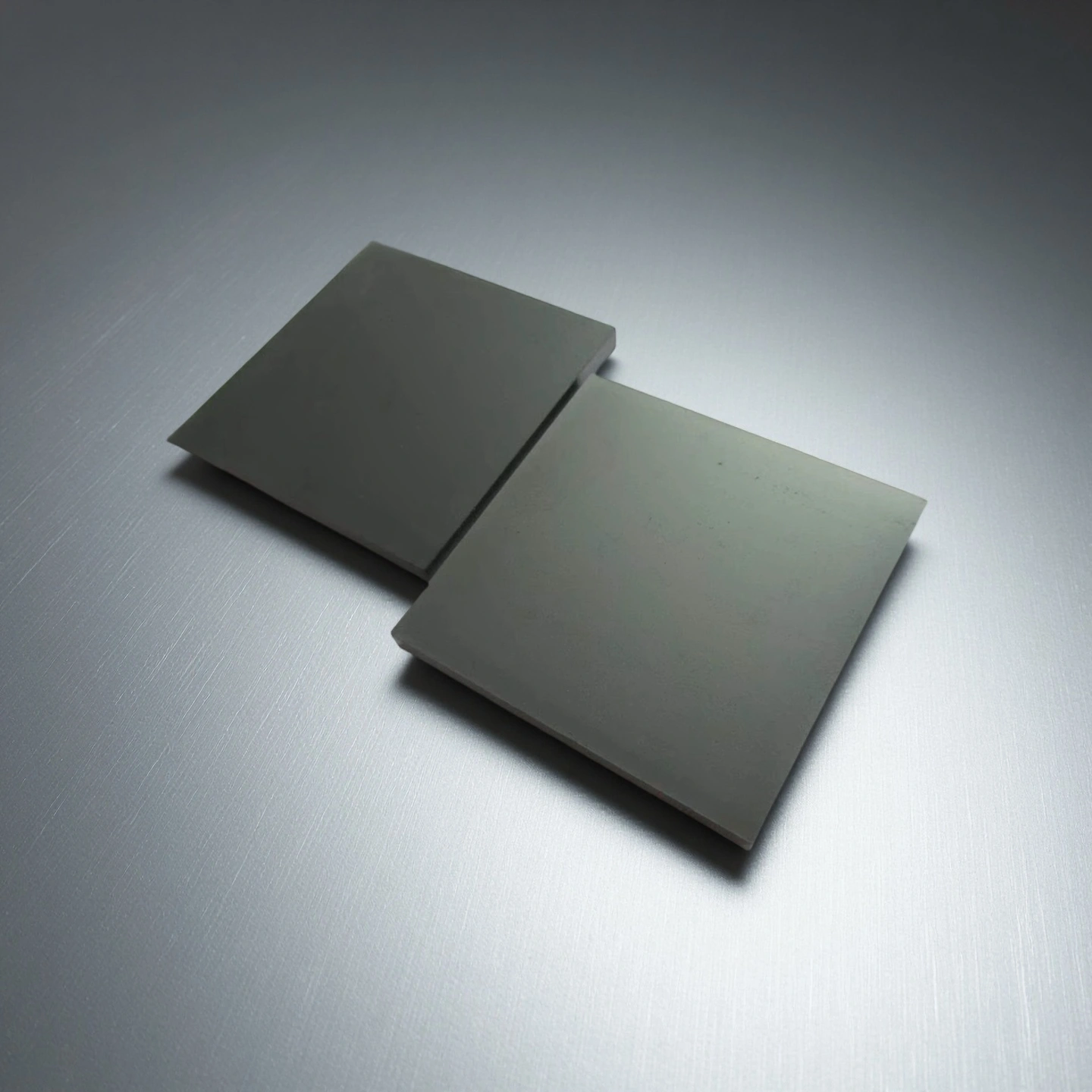

Silicon carbide plates are engineered for stable performance under high thermal loads, offering excellent dimensional stability, oxidation resistance, and mechanical strength. Ideal for industrial kilns, vacuum furnaces, and ceramic sintering lines.

Silicon Carbide Plates Advantages

- High Temperature Resistance: Withstands up to 1600°C continuous operation, suitable for high-temperature kilns and vacuum furnaces.

- Dimensional Stability: Low thermal expansion (≤ 4.5×10⁶⁻⁶/K) prevents cracking during rapid heating and cooling.

- Precise Flatness: Flatness ≤ 0.3 mm/m and tolerances ± 0.2 mm ensure uniform sintering results.

- Reusable Over 50 Cycles: Optimized for long-term use in repeated thermal cycles, reducing replacement costs.

- Multi-industry Compatibility: Used in sintering, heat treatment, catalyst support, and lab-scale thermal processing.

Specifications of Silicon Carbide Plates

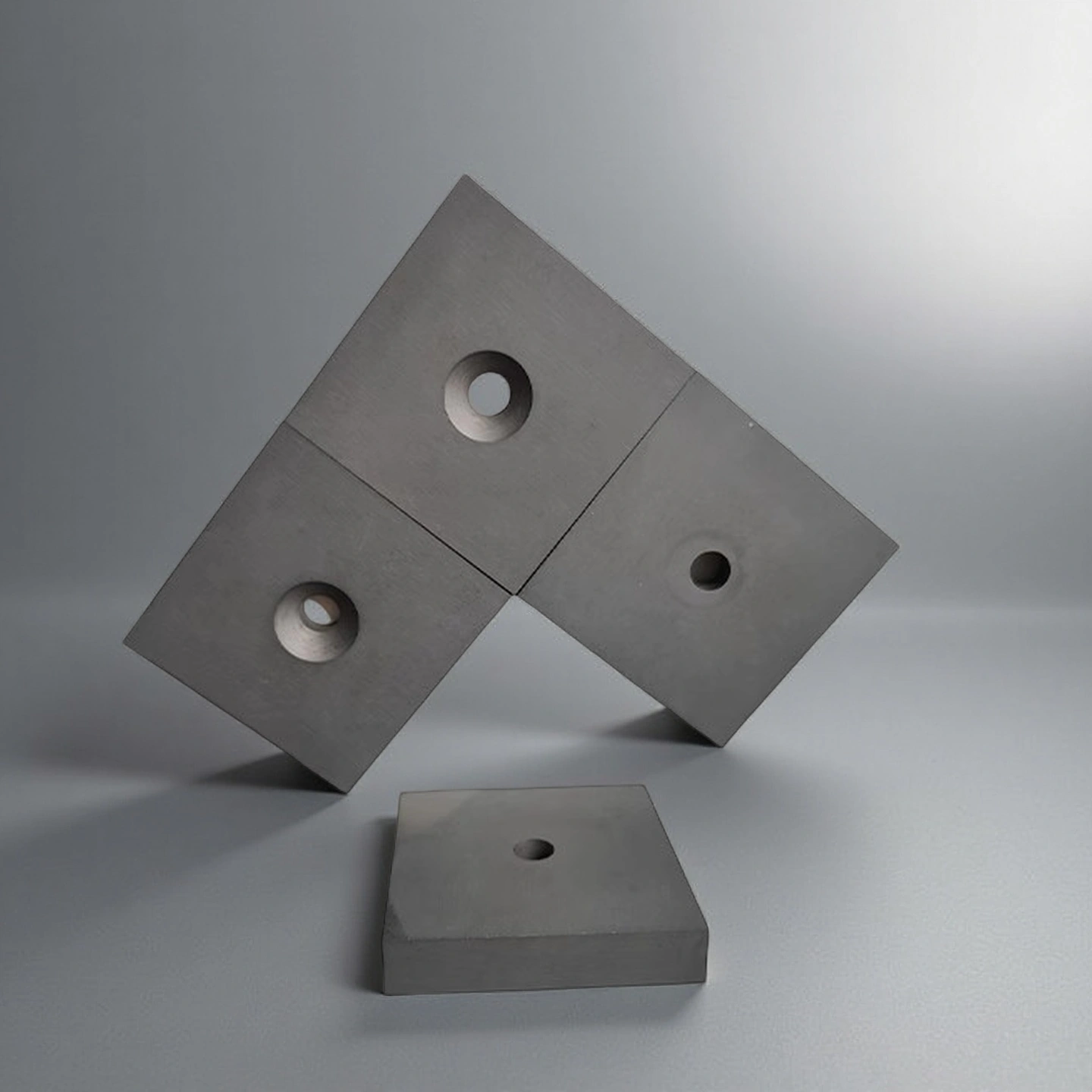

Type 1-Square SIC Plate

| Item | Length(mm) | Width(mm) | Thickness(mm) |

| AT-SIC-P1001 | 5 | 5 | 1 |

| AT-SIC-P1002 | 5 | 5 | 3 |

| AT-SIC-P1003 | 5 | 5 | 5 |

| AT-SIC-P1004 | 10 | 10 | 4 |

| AT-SIC-P1005 | 10 | 10 | 10 |

| AT-SIC-P1006 | 20 | 20 | 3 |

| AT-SIC-P1007 | 25 | 50 | 2 |

| AT-SIC-P1008 | 25 | 50 | 10 |

| AT-SIC-P1009 | 25 | 50 | 5 |

| AT-SIC-P1010 | 25 | 50 | 6 |

| AT-SIC-P1011 | 25 | 50 | 8 |

| AT-SIC-P1012 | 30 | 30 | 10 |

| AT-SIC-P1013 | 40 | 40 | 1 |

| AT-SIC-P1014 | 40 | 40 | 5 |

| AT-SIC-P1015 | 50 | 50 | 1 |

| AT-SIC-P1016 | 50 | 50 | 2 |

| AT-SIC-P1017 | 50 | 50 | 3 |

| AT-SIC-P1018 | 50 | 50 | 4 |

| AT-SIC-P1019 | 50 | 50 | 5 |

| AT-SIC-P1020 | 50 | 50 | 6 |

| AT-SIC-P1021 | 50 | 50 | 8 |

| AT-SIC-P1022 | 50 | 50 | 10 |

| AT-SIC-P1023 | 100 | 100 | 3 |

| AT-SIC-P1024 | 100 | 100 | 4 |

| AT-SIC-P1025 | 100 | 100 | 5 |

| AT-SIC-P1026 | 100 | 100 | 7 |

| AT-SIC-P1027 | 100 | 100 | 10 |

| AT-SIC-P1028 | 100 | 100 | 11 |

| AT-SIC-P1029 | 100 | 100 | 15 |

| AT-SIC-P1030 | 100 | 100 | 20 |

| AT-SIC-P1031 | 150 | 150 | 5 |

| AT-SIC-P1032 | 150 | 150 | 6 |

| AT-SIC-P1033 | 150 | 150 | 8 |

| AT-SIC-P1034 | 150 | 150 | 10 |

Type 2-Round SIC Plate

| Item | Diameter(mm) | Thickness(mm) |

| AT-SIC-P1035 | 10 | 2 |

| AT-SIC-P1036 | 12 | 4 |

| AT-SIC-P1037 | 15 | 3 |

| AT-SIC-P1038 | 20 | 4.3 |

| AT-SIC-P1039 | 30 | 2 |

| AT-SIC-P1040 | 30 | 4 |

| AT-SIC-P1041 | 30 | 6 |

| AT-SIC-P1042 | 50 | 4 |

| AT-SIC-P1043 | 50 | 6 |

| AT-SIC-P1044 | 50 | 8 |

| AT-SIC-P1045 | 100 | 5 |

| AT-SIC-P1046 | 100 | 10 |

Packing

Our Silicon Carbide rods are carefully packaged to ensure safe transit. Custom packaging options are available to meet the specific needs of our customers.