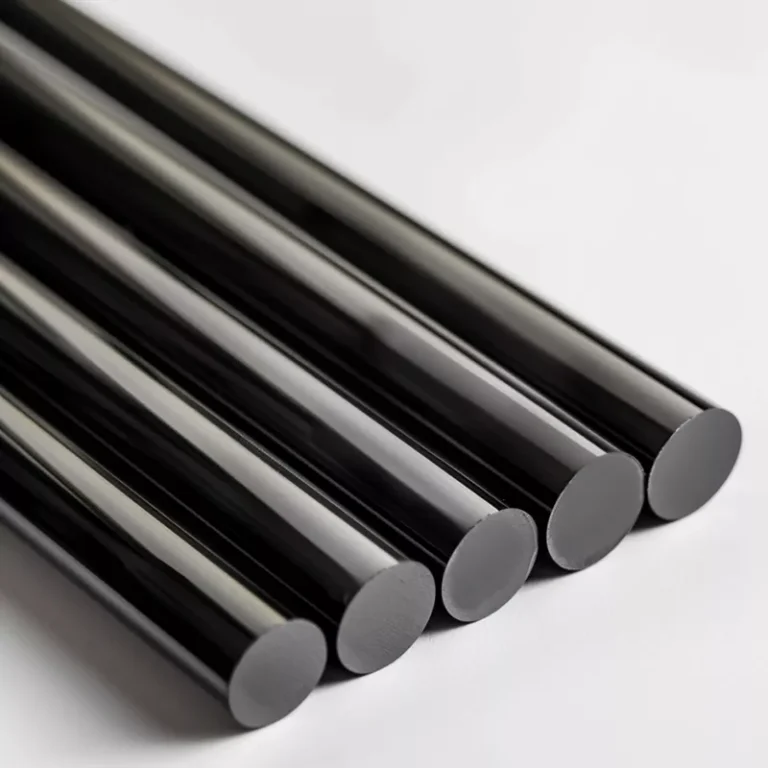

ADCERAX® Silicon Carbide Rods are manufactured from high-purity SiC powders with controlled sintering additives, producing a dense covalent structure that delivers high hardness, wear resistance, and chemical stability under demanding operating conditions. Its low thermal expansion and strong thermal conductivity create a stable mechanical profile during repeated thermal cycling, enabling reliable performance in kilns, glass annealing systems, metallurgy lines, and high-temperature mechanical assemblies. These combined material characteristics allow the rod to support long service life as structural elements, roller components, and support bars in industrial environments where heat, load, and corrosion resistance are critical.

High-Performance Operating Characteristics of the Silicon Carbide Rods

-

Oxidation stability is supported by the formation of a passive SiO₂ layer, which begins forming above 900°C and remains protective through 1500°C according to ceramic oxidation studies.

This stable oxide film minimizes chemical reaction rates and reduces surface mass loss in oxidizing atmospheres.

-

Continuous firing tests conducted by multiple kiln-equipment manufacturers indicate that SiC rollers maintain dimensional integrity after >500 firing cycles at 1350–1450°C.

These repeated-cycle results show that the material avoids creep deformation under sustained load.

-

The coefficient of thermal expansion is typically 4.0–4.5 × 10⁻⁶/K (25–1000°C) as reported in R-SiC material handbooks, significantly lower than alumina (7–8 × 10⁻⁶/K).

This low-expansion behavior reduces bending and avoids distortion during rapid heating cycles.

-

Thermal shock resistance tests indicate survival of temperature gradients exceeding 250–300°C without cracking.

This capability is crucial for roller hearth kilns and fast-fire processes where heat flux changes abruptly.

-

Weight-loss corrosion tests show SiC exhibiting <0.01 g/m²·h degradation in common acidic environments such as H₂SO₄ and HCl at elevated temperatures, based on ceramic corrosion research published by the Journal of the European Ceramic Society.

These results confirm that the rod maintains integrity under long-term chemical attack.

-

In alkaline vapors (e.g., Na₂O-containing furnace atmospheres), SiC demonstrates corrosion rates up to 5–10 times lower than alumina according to refractories comparison studies.

This performance advantage supports long service life in glass and ceramic furnace systems with alkaline volatilization.

Technical Specifications of Silicon Carbide Rods

The Silicon Carbide Rod exhibits a combination of thermal stability, mechanical strength, chemical resistance, and structural reliability that can be quantified through standardized material performance indices commonly evaluated in industrial laboratories.

| Property |

Specification |

| Material Type |

R-SiC / SiSiC (Recrystallized or Reaction-Bonded) |

| Density |

2.95–3.10 g/cm³ |

| Porosity |

< 1–2% (open) |

| Flexural Strength (RT) |

220–260 MPa |

| Flexural Strength (1400°C) |

130–150 MPa |

| Compressive Strength |

> 1800 MPa |

| Thermal Conductivity |

35–120 W/m·K (temperature-dependent) |

| Thermal Expansion (25–1000°C) |

4.0–4.5 × 10⁻⁶/K |

| Thermal Shock Resistance |

Withstands 250–300°C temperature gradients |

| Maximum Operating Temperature |

1300–1650°C (depending on atmosphere) |

| Oxidation Resistance |

Stable SiO₂ layer forms above 900°C |

| Acid Corrosion Rate |

< 0.01 g/m²·h in H₂SO₄ / HCl |

| Alkali Resistance |

Degradation rate 5–10× lower than alumina |

| Surface Hardness |

HV 2200–2500 (Vickers) |

| Electrical Resistivity |

> 10⁵ Ω·cm (RT, semiconducting profile) |

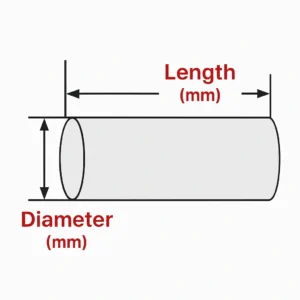

Dimensions of Silicon Carbide Rods

|

Item |

Diameter(mm) |

Length(mm) |

Purity(%) |

|

AT-SIC-B1001 |

2.5 |

130 |

99% |

|

AT-SIC-B1002 |

2.5 |

150 |

99% |

|

AT-SIC-B1003 |

2.8 |

130 |

99% |

|

AT-SIC-B1004 |

2.8 |

150 |

99% |

|

AT-SIC-B1005 |

3 |

10 |

99% |

|

AT-SIC-B1006 |

10 |

100 |

99% |

|

AT-SIC-B1007 |

10 |

150 |

99% |

|

AT-SIC-B1008 |

20 |

100 |

99% |

Packaging for Silicon Carbide Rods

Silicon Carbide Rods are protected using reinforced wooden crates with internal foam-lined compartments to prevent impact and vibration during transport. Each rod is individually wrapped and immobilized within a molded cushioning structure to avoid surface abrasion and collision. This packaging method ensures stable long-distance shipment and maintains the structural integrity of every unit before arrival at the customer’s facility.

ADCERAX® Silicon Carbide Rods Solutions for High-Temperature Mechanical and Kiln-Firing Challenges

The Silicon Carbide Rods from ADCERAX® is engineered to address the mechanical, thermal, and chemical challenges encountered in heavy-duty rotating assemblies, high-temperature kiln systems, and abrasive industrial motion environments. Its thermal stability, low expansion, and corrosion resistance allow it to operate reliably where metallic or alumina components fail, supporting continuous production in demanding industrial lines.

-

High-Temperature Kiln Roller Systems

✅Key Advantages

1. High-Cycle Straightness Retention

ADCERAX® Silicon Carbide Rod maintains deflection typically below 0.05–0.10 mm per meter after several hundred firing cycles in the 1300–1400°C range. In comparative trials against conventional ceramic rollers, cumulative bending over the same cycle count was reduced by around 50–60%, which directly stabilizes conveyor tracking.

2. Resistance to Thermal Gradient Fatigue

The rod endures repeated thermal gradients of 250–300°C without crack initiation or progressive fatigue damage under roller-hearth kiln conditions. This behavior allows faster heat-up and cool-down profiles while preserving mechanical integrity that would normally degrade in more temperature-sensitive materials.

3. Extended Roller Change Interval

Field data from tile kilns show that replacement intervals for ADCERAX® Silicon Carbide Rod can move from typical 6–9 months to 12–18 months, depending on loading and cycle profile. This life extension reduces the annual number of roller change operations by roughly 30–50%, lowering the risk of unplanned stoppages during peak production.

✅ ️Problem Solved

A ceramic tile producer operating multiple roller-hearth kilns previously experienced three to four unplanned roller-related stoppages per quarter due to bending and premature cracking of standard ceramic rollers. After switching critical zones to ADCERAX® Silicon Carbide Rod, logged deflection at operating temperature dropped to below 0.10 mm per meter, and unplanned roller failures were reduced to one event or less per quarter. Over the first year, the plant reported a reduction in firing defects on tiles of approximately 30–40%, mainly by eliminating misalignment and vibration in the hot zone. At the same time, planned roller replacement intervals were extended by about 1.5–2 times, which helped stabilize maintenance planning and kiln utilization.

-

Glass Annealing and Heat-Treatment Conveying

✅Key Advantages

1. Low-Deflection Support for Flat Glass

ADCERAX® Silicon Carbide Rod delivers in-line straightness variation typically within 0.05–0.10 mm per meter across annealing temperatures, limiting the onset of waviness in hot glass sheets. This tight control of deflection reduces the risk of thickness variation and optical distortion as glass passes through the annealing zones.

2. Improved Thermal Uniformity Across the Conveyor

With a thermal conductivity in the 35–120 W/m·K range, the rod equalizes surface temperature along its length more effectively than many conventional ceramic supports. Line measurements in annealing sections show that lateral temperature differences on the glass underside can be lowered by 10–20°C, which helps reduce residual stresses.

3. Stable Surface Condition Under Cycling

Surface roughness change on ADCERAX® Silicon Carbide Rod remains typically below 0.2–0.3 µm Ra after extended operation in annealing atmospheres. This stability limits micro-scratching and contact marks on the glass underside over thousands of operating hours.

✅ ️Problem Solved

A flat glass line reported recurring issues with optical distortion and local waviness traced to subtle bending and surface degradation of existing support rods in the annealing lehr. After replacing the critical span with ADCERAX® Silicon Carbide Rod, straightness measurements at temperature remained within 0.10 mm per meter, and the recorded defect rate for visible waviness decreased by roughly 25–35% over the following six months. Thermal mapping across the conveyor width also indicated a more uniform temperature profile, with peak lateral differentials reduced by about 10–15°C. As a result, the plant could maintain a steadier line speed without frequent corrective adjustments, improving effective annealing throughput and reducing rework.

-

Abrasive Mechanical Drive Systems

✅Key Advantages

1. High-Hardness Wear Surface for Abrasive Loads

ADCERAX® Silicon Carbide Rod provides a surface hardness in the HV 2200–2500 range, significantly higher than common hardened steel shafts. In wear tests with abrasive media, this hardness level has been associated with reductions in wear depth of 50–70% over equivalent operating hours.

2. Combined Corrosion and Erosion Resistance

In simulated slurry and corrosive fluid exposure, mass loss for Silicon Carbide Rod has been measured at several times lower than carbon steel or low-alloy steel rods under the same conditions. This combined resistance slows the progression of pitting and surface scoring, keeping dimensional changes within <0.02–0.05 mm over defined service intervals.

3. Stable Geometry Over Maintenance Cycles

Drive and guide rods manufactured from ADCERAX® Silicon Carbide Rod typically exhibit diameter loss well below 0.02 mm across a full maintenance cycle in abrasive duty. This stability keeps vibration levels down and reduces secondary loading on bearings and couplings compared with previous metal shafts showing >0.10 mm wear over the same period.

✅ ️Problem Solved

In a steel-processing line handling abrasive scale and dust, metal drive rods showed rapid wear, with diameter loss exceeding 0.10 mm between scheduled maintenance stops and frequent unexpected shaft changes. After converting key positions to ADCERAX® Silicon Carbide Rod, in-service inspections over one full maintenance cycle recorded wear in the 0.01–0.02 mm range, which remained within the allowable tolerance for the drive system. Bearing replacement frequency dropped, and recorded vibration levels at operating speed decreased by approximately 20–30%, indicating more stable mechanical alignment. The plant could then synchronize rod replacements with planned shutdowns instead of reacting to premature failures, improving predictability and reducing disruption to continuous-duty operation.

ADCERAX® Silicon Carbide Rods User Guide for Safe and Efficient Operation

Silicon Carbide Rods requires proper handling, installation, and operating discipline to ensure optimal performance across thermal, mechanical, and corrosive environments. This guide provides practical, engineering-oriented recommendations that help users maintain stability, minimize wear, and reduce unexpected downtime throughout the product’s service lifecycle.

-

Installation Guidelines for Stable Mechanical and Thermal Performance

1. Rigid Support Alignment

Proper alignment of support brackets and mounting points is essential to prevent bending stress during startup and operation. Misalignment may increase localized loading, accelerating fatigue and reducing usable service hours. Ensuring structural parallelism helps maintain consistent straightness during thermal cycling.

2. Gradual Heat-Up Protocols

Controlled heating avoids rapid thermal gradients that may stress the rod’s microstructure. Increasing temperature at a moderated rate allows uniform expansion across its length. This practice significantly enhances cycle endurance in high-temperature kilns and conveying lines.

3. Secure Seating and Clearance Control

Correct seating minimizes the risk of micro-movement that can lead to abrasion or chatter during rotation. A balanced clearance prevents unnecessary friction that may degrade surfaces over time. Controlled fitment ensures stable rotation and longer component life.

-

Operational Recommendations for High-Temperature Environments

1. Avoid Sudden Thermal Shocks

Rapid temperature drops can generate thermal tension that exceeds material limits. Maintaining consistent furnace atmosphere and avoiding cold-air drafts helps preserve microstructural integrity. These measures reduce the risk of unexpected thermal fracture.

2. Monitor Furnace Loading Conditions

Excessive or uneven loading can elevate mechanical deflection at high temperatures. Operators should maintain uniform distribution of product weight across roller sections. Balanced loading ensures predictable deflection behavior across prolonged cycles.

3. Control Chemical Atmosphere Exposure

High concentrations of reactive vapors can influence surface oxidation rates. Maintaining regulated airflow and exhaust efficiency reduces reactive gas accumulation. This stabilizes protective oxide layers for enhanced corrosion resistance.

-

Handling and Storage Guidelines to Preserve Structural Integrity

1. Use Protective Padding During Handling

Direct contact with hard surfaces during movement or storage may cause micro-chipping. Applying padded contact points helps maintain surface condition. These precautions significantly improve initial handling safety.

2. Store in Dry, Stable Conditions

High humidity or chemical vapors can affect packaging and long-term surface exposure. Storage in a controlled environment reduces external risks that may influence performance consistency. A protected area ensures reliable pre-installation quality.

3. Avoid Point-Load Pressure During Stacking

Concentrated weight on limited surface areas can cause mechanical stress. Distributing load evenly across storage cradles prevents deformation. This maintains dimensional stability before equipment integration.

-

Maintenance Practices for Long Service Life

1. Routine Surface Inspection

Scheduled visual or tactile checks help identify early-stage wear, oxidation, or micro-cracks. Early detection prevents propagation into larger structural issues. Regular inspection supports predictable maintenance cycles.

2. Monitor Vibration and Rotational Smoothness

Abnormal vibration indicates misalignment or wear progression elsewhere in the system. Using vibration monitoring tools enables corrective action before damage spreads. This step protects overall system efficiency.

3. Clean with Non-Abrasive Methods

Using soft, non-abrasive cleaning materials prevents surface scratching. Avoid chemical agents that may attack protective layers during operation. Proper cleaning maintains long-term surface performance in thermal and mechanical systems.

![]()