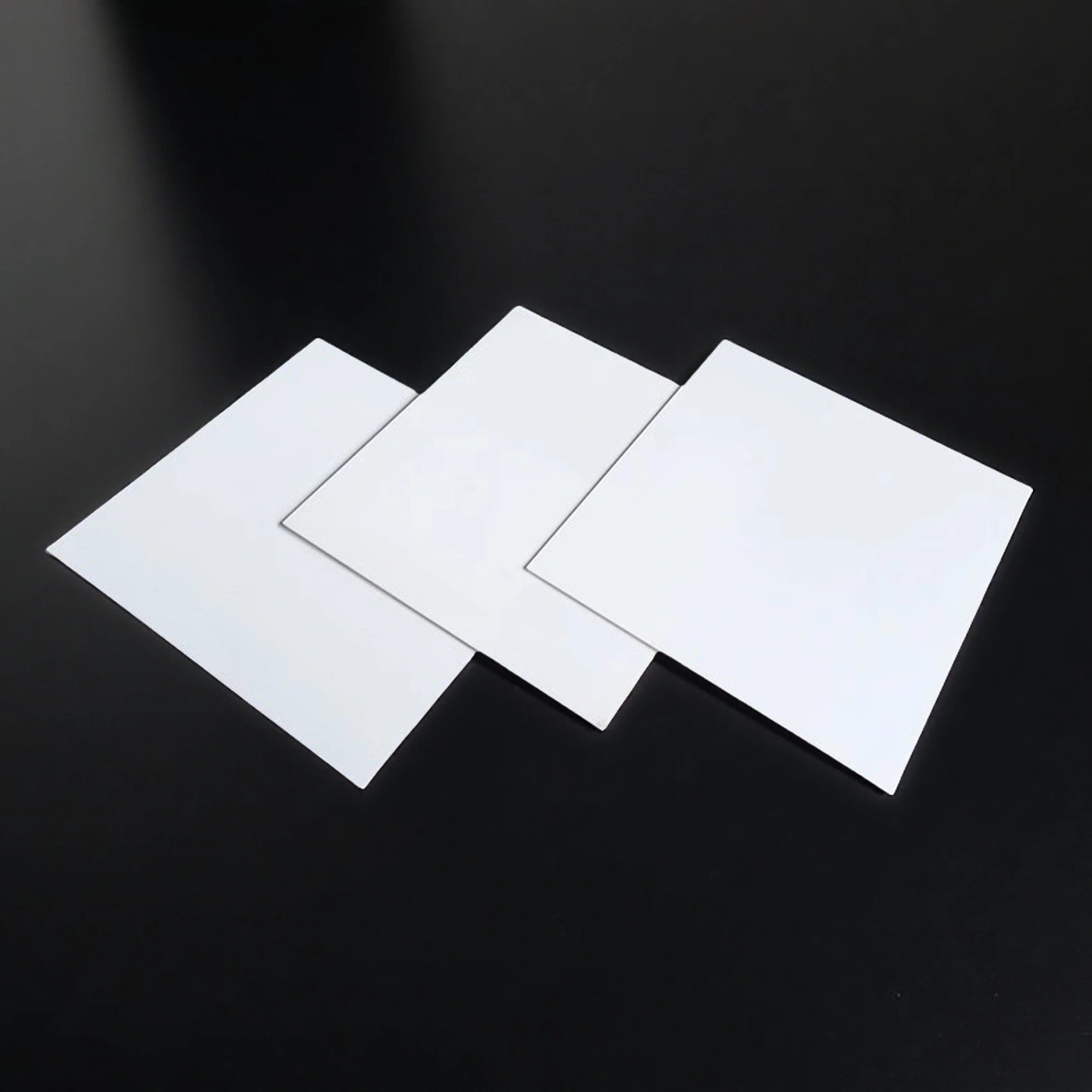

Zirconia-toughened alumina (ZTA) substrates are ceramic insulating base plates made by dispersing fine zirconia (ZrO₂) particles into an alumina (Al₂O₃) matrix. The zirconia phase arrests crack growth and improves edge strength, while alumina provides electrical insulation, chemical stability, and dimensional control. This balance makes ZTA substrates well-suited for laser-drilled vias/slots, lapped surfaces, and repeatable screen printing in heaters, sensors, LED/UV modules, and control electronics.

ZTA Substrates Advantages

- Edge integrity on micro-features — reduced chipping on laser-drilled vias/slots.

- Print-ready surface — controlled Ra and flatness for screen printing and bonding.

- Dimensional stability — consistent thickness and geometry across batches.

- White/reflective option — uniform appearance for optical/LED modules.

- Traceable cleanliness — cleaned, bagged, labeled for immediate line use.

ZTA Ceramic Substrate Properties

| Property | Unit | Alumina (99%) | ZTA (Zirconia Toughened Alumina) | Y-TZP Zirconia |

| Fracture Toughness (KIC) | MPa·m¹⁄² | 5 | 7 – 9 | 6 – 10 |

| Hardness (HV10) | GPa | 8.9 | 9 – 10 (≈ 90 HV) | 12 – 14 |

| Flexural Strength | MPa | 400 | 650 – 800 | 800 – 1200 |

| Density | g/cm³ | 3.9 | 4.0 – 4.3 | 6.0 |

| Relative Wear Rate | — | 1.0 | 0.45 – 0.55 | 0.2 |

| Thermal Expansion Coefficient (RT – 800 °C) | ×10⁻⁶ /K | 8.0 | 8.5 – 9.0 | 10 – 11 |

| Thermal Conductivity (RT) | W/m·K | 25 | 22 – 24 | 2 – 3 |

| Maximum Working Temperature | °C | 1600 | 1450 – 1500 | 1000 – 1200 |

| Dielectric Strength | kV/mm | 12 | 11 – 13 | 9 – 11 |

| Surface Roughness (Ground face) | µm Ra | 0.4 – 1.2 | 0.3 – 0.8 | 0.2 – 0.6 |

| Flatness (after grinding) | mm/300 mm | ≤ 0.4 | ≤ 0.3 | ≤ 0.2 |

Specifications of Zirconia Toughened Alumina Substrates

| Item | Length(mm) | Width(mm) | Thickness(mm) | Purity (Al₂O₃+ZrO₂) |

| AT-ZTA-CS001 | 10 | 10 | 0.5 | 74%+23.5% |

| AT-ZTA-CS002 | 10 | 10 | 1 | 74%+23.5% |

| AT-ZTA-CS003 | 15 | 11 | 1.5 | 74%+23.5% |

| AT-ZTA-CS004 | 18 | 13 | 1.5 | 74%+23.5% |

| AT-ZTA-CS005 | 20 | 20 | 2 | 74%+23.5% |

| AT-ZTA-CS006 | 20 | 20 | 2 | 74%+23.5% |

| AT-ZTA-CS007 | 25 | 25 | 1 | 74%+23.5% |

| AT-ZTA-CS008 | 30 | 30 | 0.5 | 74%+23.5% |

| AT-ZTA-CS009 | 30 | 30 | 1 | 74%+23.5% |

| AT-ZTA-CS010 | 30 | 30 | 2 | 74%+23.5% |

| AT-ZTA-CS011 | 35 | 35 | 1 | 74%+23.5% |

| AT-ZTA-CS012 | 40 | 40 | 1 | 74%+23.5% |

| AT-ZTA-CS013 | 40 | 40 | 3 | 74%+23.5% |

| AT-ZTA-CS014 | 50 | 30 | 0.5 | 74%+23.5% |

| AT-ZTA-CS015 | 50 | 50 | 0.5 | 74%+23.5% |

| AT-ZTA-CS016 | 50 | 50 | 1 | 74%+23.5% |

| AT-ZTA-CS017 | 50 | 50 | 1.5 | 74%+23.5% |

| AT-ZTA-CS018 | 50 | 50 | 2 | 74%+23.5% |

| AT-ZTA-CS019 | 60 | 60 | 1 | 74%+23.5% |

| AT-ZTA-CS020 | 65 | 35 | 0.5 | 74%+23.5% |

| AT-ZTA-CS021 | 65 | 48 | 1 | 74%+23.5% |

| AT-ZTA-CS022 | 70 | 70 | 1.2 | 74%+23.5% |

| AT-ZTA-CS023 | 70 | 70 | 3 | 74%+23.5% |

| AT-ZTA-CS024 | 76.2 | 76.2 | 1.5 | 74%+23.5% |

| AT-ZTA-CS025 | 80 | 80 | 3 | 74%+23.5% |

| AT-ZTA-CS026 | 80 | 80 | 2 | 74%+23.5% |

| AT-ZTA-CS027 | 80 | 70 | 1.5 | 74%+23.5% |

| AT-ZTA-CS028 | 84 | 84 | 0.8 | 74%+23.5% |

| AT-ZTA-CS029 | 100 | 100 | 0.5 | 74%+23.5% |

| AT-ZTA-CS030 | 100 | 100 | 1 | 74%+23.5% |

| AT-ZTA-CS031 | 100 | 100 | 1.2 | 74%+23.5% |

| AT-ZTA-CS032 | 100 | 100 | 1.5 | 74%+23.5% |

| AT-ZTA-CS033 | 100 | 100 | 2 | 74%+23.5% |

| AT-ZTA-CS034 | 100 | 90 | 1.5 | 74%+23.5% |

| AT-ZTA-CS035 | 100 | 80 | 1.8 | 74%+23.5% |

| AT-ZTA-CS036 | 100 | 75 | 2 | 74%+23.5% |

| AT-ZTA-CS037 | 10-400 | 10-400 | 0.5-2.5 | 74%+23.5% |

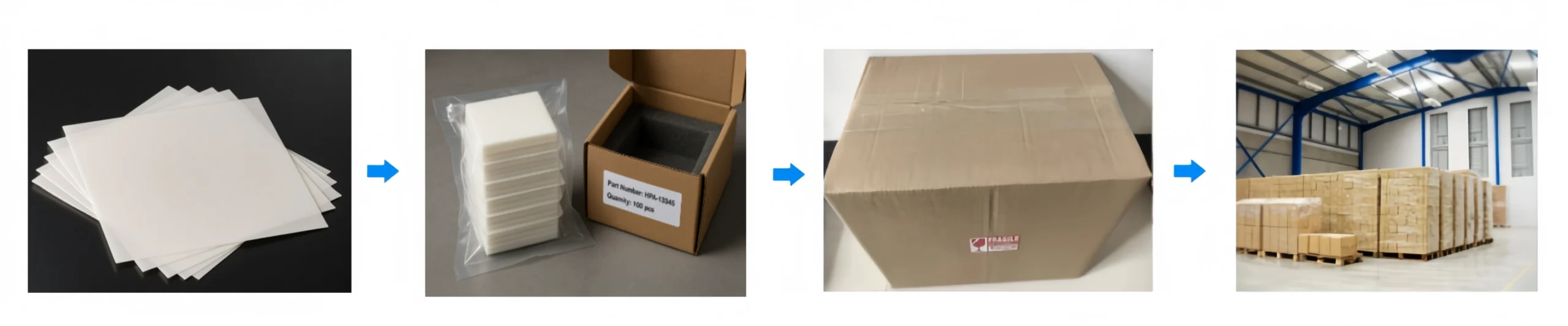

ZTA Ceramic Substrate Packaging

- All ceramic substrates are individually wrapped in anti-static, padded sheets, sealed, and placed in custom-cut foam-lined boxes to ensure maximum protection.