TGA alumina crucible (also called alumina TGA crucible or alumina crucible for TGA) is a small Al₂O₃ cup used to hold samples during thermogravimetric analysis. Compared with metal or glass cups, dense alumina resists high temperatures and common lab reagents, enabling reliable weight-change tracking across heating programs.

Benefits of TGA Alumina Crucible

- Baseline stability: thin-wall options improve thermal response while maintaining cup rigidity, helping reduce baseline drift during programmed ramps.

- Low contamination risk: dense alumina surface minimizes interaction with common polymers, fillers, and inorganic powders, supporting consistent residue analysis.

- Instrument fit & handling: volumes and rim profiles align with common pan holders; optional lids help control local gas exchange for volatile samples.

Alumina Crucible TGA Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Crucible TGA Specifications

| Item NO. | Item name | Capacity | MOQ | Part# | Compatible with |

| AT-ALG-001-1 | Alumina Crucible (Glazed Inside) | 14cc; Purity99.5% | 20PCS | AR9047 For LECO 701 | |

| AT-ALG-001 | Alumina Crucible (Glazed Inside) | 14cc; Purity99.5% | 20PCS | AR9047 For LECO 701 | |

| AT-ALG-002 | Alumina Crucible (Unglazed) | 14cc; Purity99.5% | 20PCS | AR9047 For LECO 701 | |

| AT-018 | LECO Large Al₂O₃Crucible (Glazed Inside) | 20CC; Purity99.5% | 20PCS | 621-331 /529-047 | AR9047 For LECO 701 |

| AT-018-1 | ELTRA Al₂O₃Crucible | 18CC; Purity99.5% | 20PCS | Eltra 26063 | |

| AT-018-4 | LECO Large Al₂O₃Crucible (Yellow, Glazed Inside) | 20CC; Purity99.5% | 20SET | 621-331 /529-047 | AR9047 For LECO 701 |

| AT-018-2 | LECO Large Al₂O₃Crucible (Unglazed) | 20CC; Purity99.5% | 20PCS | 621-331 /529-047 | AR9047 For LECO 701 |

| AT-MY-17 | LECO Small Al₂O₃Crucible (Glazed Inside) | 16CC; Purity99.5% | 20PCS | 529-042 | 529-402 AR9042 For LECO TGA 500/501/601/701; MAC 400/500 |

| AT-MY-17-5 | LECO Small Al₂O₃Crucible (Unglazed) | 16CC; Purity99.5% | 20PCS | 529-042 | 529-402 AR9042 For LECO TGA 500/501/601/701; MAC 400/500 |

| AT-020 | LECO Large Al₂O₃Crucible (Fully Glazed) | 37CC; Purity99.5% | 20PCS | customized product | |

| AT-021 | LECO Small Al₂O₃Crucible (Unglazed) | 10CC; Purity99.5% | 20PCS | customized product | |

| AT-019 | LECO Large Al₂O₃Crucible Lid | OD36.5*H6.5*T1.0mm. Purity99.5% | 20PCS | 529-048 | Alpha AR9043 For TGA 20cc |

| AT-MY-18 | LECO Al₂O₃Crucible Lid | OD34.5*H6.5*T1.0mm Purity99.5% | 20PCS | 529-043 | Alpha AR9043 For TGA 16cc |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

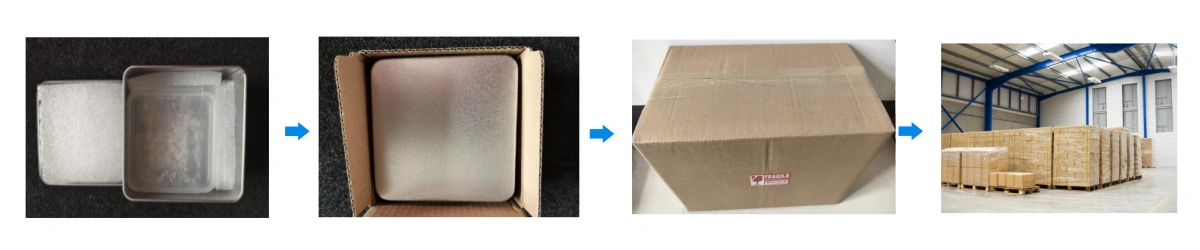

Alumina TGA Crucibles Packaging

- With foam separation, sealed inner sleeve; outer carton with shock protection.