An alumina threaded rod is a ceramic screw-like fastener that combines mechanical strength with insulation and stability, making it a preferred choice where metal fasteners would fail due to heat, electrical conductivity, or chemical attack.

Alumina Threaded Rod Benefits

-

Secure Mechanical Fastening at High Temperatures

Threaded design allows stable fastening and load-bearing in furnaces and lab setups, avoiding loosening where metal screws fail above 1200 °C. -

Precise Alignment and Assembly Compatibility

Machined threads (M2–M18, tolerance ±0.2 mm) enable accurate alignment with alumina nuts and washers, ensuring repeatable installation in analytical instruments and furnace structures. -

Reduced Particle Contamination

Unlike metal fasteners that oxidize or shed particles at high heat, alumina threaded rods maintain surface integrity, protecting sensitive laboratory and semiconductor processes. -

Longer Service Life in Aggressive Environments

The combination of ceramic material and threaded locking function minimizes replacement cycles in corrosive chemical setups and continuous-operation machinery.

Alumina Threaded Rod Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Threaded Rod Specifications

As a professional alumina threaded rod factory in China, we supply both standard stock and custom parts with fast delivery. The following tables are the standard and cutomize sizes:

Type 1:

| Type 1: Alumina Threaded Rod | ||||

| Item No. | Diameter (mm) | Slot width (mm) | Length (mm) | Purity |

| AT-YHL-LWB1001 | 6 | 0.8 | 100-500 | 95% |

| AT-YHL-LWB1002 | 8 | 1 | ||

| AT-YHL-LWB1003 | 10 | 1.5 | ||

| AT-YHL-LWB1004 | 10 | 5 | ||

| AT-YHL-LWB1005 | 12 | 2 | ||

| AT-YHL-LWB1006 | 14 | 2.5 | ||

| AT-YHL-LWB1007 | 16 | 5 | ||

| AT-YHL-LWB1008 | 18 | 5 | ||

Type 2:

| Type 2: Alumina Threaded Rod | ||||

| Item No. | Diameter of Thread (mm) | Length of Thread (mm) | Total Length (mm) | Purity |

| AT-YHL-LWB2001 | M2 | Customize | 100-800 | 99% |

| AT-YHL-LWB2002 | M2.5 | |||

| AT-YHL-LWB2003 | M3 | |||

| AT-YHL-LWB2004 | M3.5 | |||

| AT-YHL-LWB2005 | M4 | 30 | ||

| AT-YHL-LWB2006 | M5 | 30 | ||

| AT-YHL-LWB2007 | M6 | 30 | ||

| AT-YHL-LWB2008 | M8 | 30 | ||

| AT-YHL-LWB2009 | M10 | 30 | ||

| AT-YHL-LWB2010 | M12 | Customize | ||

| AT-YHL-LWB2011 | M14 | |||

| AT-YHL-LWB2012 | M16 | |||

| AT-YHL-LWB2013 | M18 | |||

Type 3:

| Type 3: Alumina Threaded Rod | ||||

| Item No. | Diameter (mm) | Diameter of Thread (mm) | Total Length (mm) | Purity % |

| AT-YHL-LWB3001 | 6 | M4 | 200 | 99 |

| AT-YHL-LWB3002 | 10 | M8 | 450 | 99 |

| AT-YHL-LWB3003 | 12 | M8 | 400 | 99 |

| AT-YHL-LWB3004 | 20 | M12 | 450 | 99 |

| AT-YHL-LWB3005 | 30 | M18 | 360 | 99 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

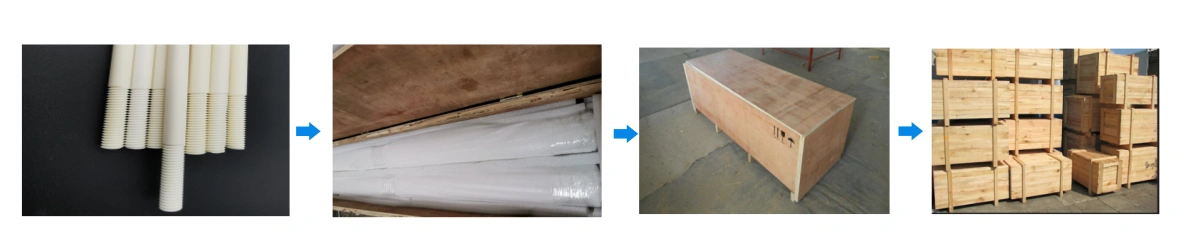

Alumina Threaded Rod Packaging:

-

Individually packed in PE bags to prevent contamination

-

Foam protection inside the carton for safe international shipping

-

Optional ceramic nuts and washers are available as accessories