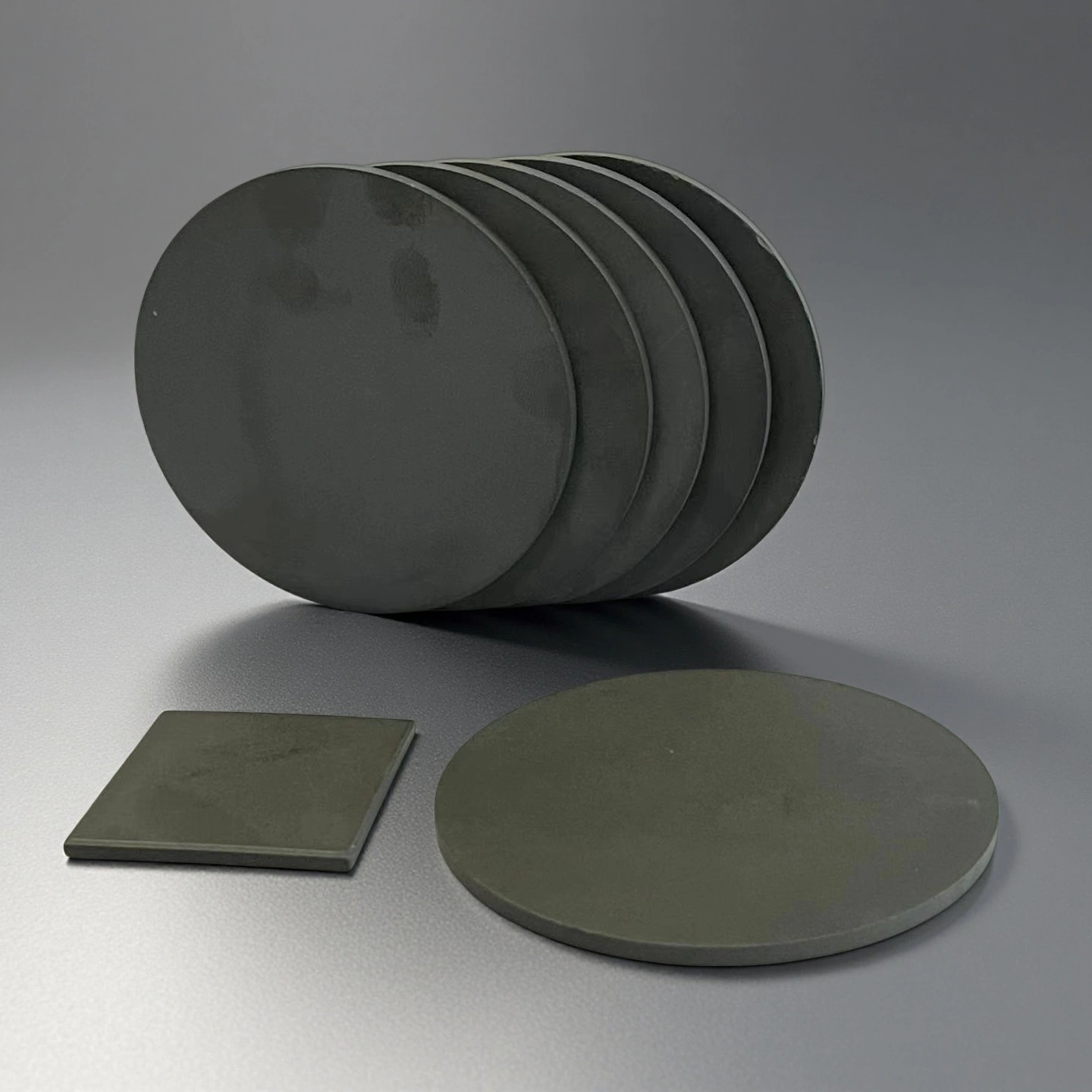

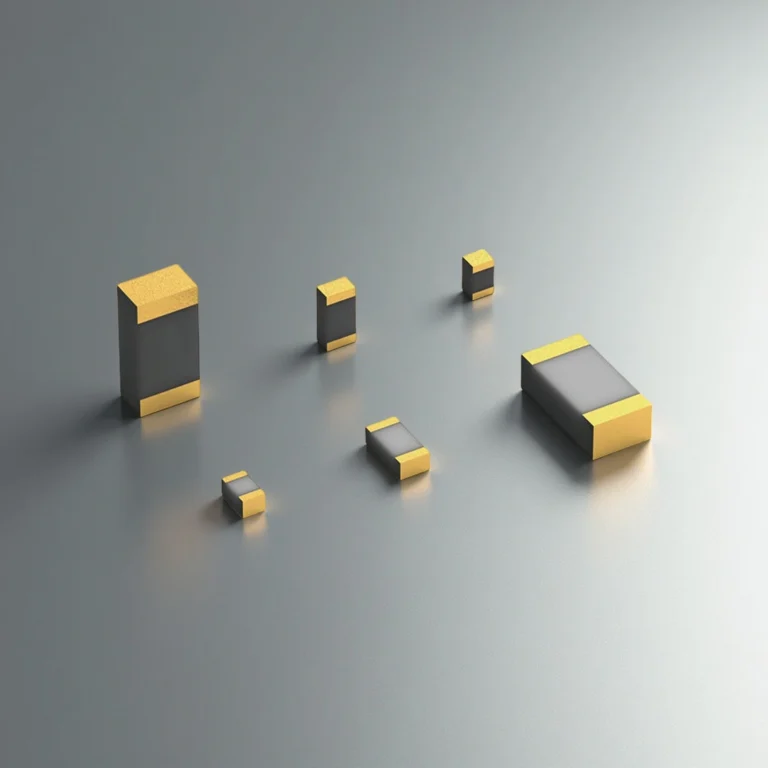

Black Alumina Substrate is a specialized flat sheet or plate made from aluminum oxide (Al₂O₃) ceramic that has been colored black during its manufacturing process. Its primary purpose is to serve as a foundational component in electronic devices, where it simultaneously provides electrical insulation, thermal conductivity (to dissipate heat), and light absorption (to protect sensitive components).

Black Alumina Ceramic Substrate Advantages

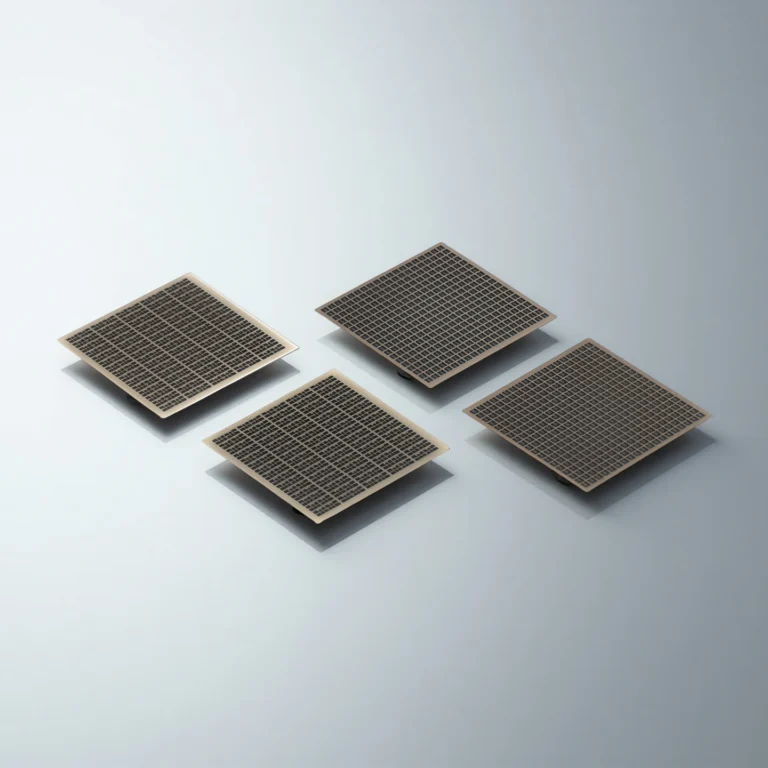

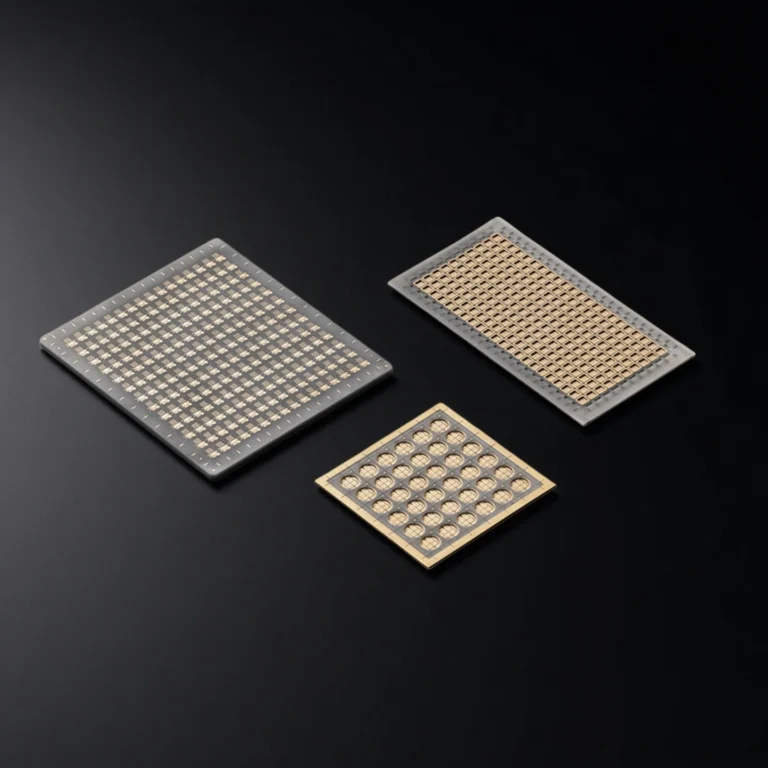

- Light-Absorbing Surface: The inherent black color provides opacity, shielding light-sensitive components from stray light interference. This function is critical for preventing signal noise in optical sensors and photodiode packages.

- High Electrical Insulation: A low dielectric constant and high dielectric strength prevent electrical leakage and short-circuiting in high-density, high-voltage power modules.

- Superior Thermal Stability: The material's high thermal conductivity (up to 29 W/m·K) efficiently dissipates heat from active components like IGBTs and laser diodes, preventing thermal failure and extending device lifespan.

- Dimensional Precision: Manufactured with a low coefficient of thermal expansion and minimal warpage, the substrate maintains its flatness and form during thermal cycling. This dimensional stability is essential for automated assembly and ensures consistent bond-line thickness.

Black Alumina Substrate Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Black Alumina Ceramic Substrate Specifications

| Model | Length x Width | Thickness | Aluminum Oxide Content (%) |

|---|---|---|---|

| AT-AO-J001 | 1-100 | 0.3-10 | 95/99 |

Black Alumina Ceramic Substrate Packaging

- Keep substrates in their original, sealed anti-static packaging until they are ready for the assembly line.