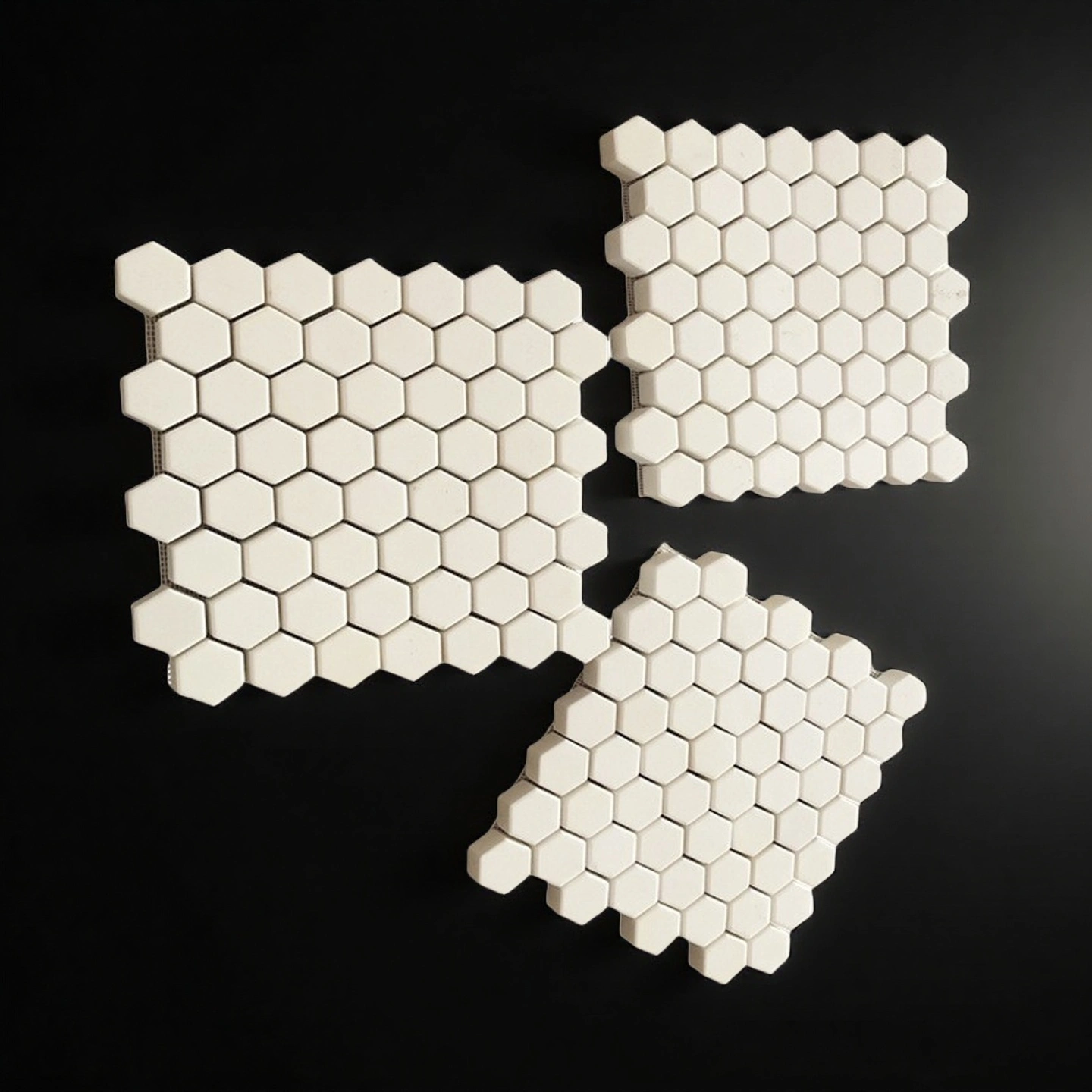

Alumina mosaic plate is a modular ceramic wear lining made from small high-alumina tiles (square or hexagonal) arranged in a mosaic pattern and bonded to a flat, rubber-backed, or steel-backed panel. The dense Al₂O₃ surface provides high hardness and abrasion resistance for chutes, hoppers, transfer points, pipes, and pulley lagging in bulk material handling.

Features & Benefits of Alumina Mosaic Plate

- Mosaic Tile Grid Design

The alumina mosaic plate is built from tightly nested square or hexagonal tiles. This mosaic layout distributes impact forces evenly and minimizes crack propagation, ensuring longer protection in critical wear zones. - Localized Replacement Efficiency

Unlike monolithic liners, alumina mosaic plates allow for sectional replacement. Damaged areas can be swapped out without relining the entire chute or hopper, reducing downtime and maintenance costs during scheduled shutdowns. - Flexible Backing Structures

Customers can choose from:

a. Rubber-backed panels to absorb impact shocks from large ore lumps.

b.Steel-backed plates for bolt-on or stud-welded installations.

c. Flat ceramic sheets for adhesive bonding in lightweight or confined structures.

This adaptability ensures the right match for mining, cement, steel, or port environments. - Optimized Coverage with Hex & Square Patterns

1. Hexagonal alumina ceramic tiles eliminate linear joints, strengthening overall coverage.

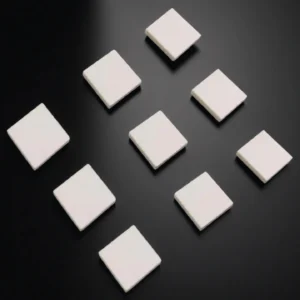

2. Square alumina mosaic plates simplify cutting and fitting for rectangular installations.

Both formats maximize liner surface protection with minimal exposed substrate. - Proven Performance in High-Throughput Lines

Field applications in chutes, hoppers, and pulley lagging confirm that alumina mosaic plates extend liner service life by 2–3 times compared with conventional steel or polymer wear liners, directly improving uptime and reducing operating costs.

Alumina Mosaic Plate Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Mosaic Sheet Specifications

Type 1: Square Alumina Ceramic Mosaic Sheet

| Square Alumina Ceramic Mosaic Sheet | |||

| Item No. | Length (mm) | Width (mm) | Thickness (mm) |

| AT-YHL-MSK001 | 10 | 10 | 3-6 |

| AT-YHL-MSK002 | 17.5 | 17.5 | 3-16 |

| AT-YHL-MSK003 | 20 | 20 | 3-18 |

| AT-YHL-MSK004 | 24 | 24 | 4-10 |

| AT-YHL-MSK005 | 27 | 27 | 5-18 |

| AT-YHL-MSK006 | 38 | 38 | 5-18 |

| AT-YHL-MSK007 | 39 | 39 | 6-18 |

| AT-YHL-MSK008 | 50 | 50 | 5-16 |

Type 2: Hexagon Alumina Ceramic Mosaic Sheet

| Hexagon Alumina Ceramic Mosaic Sheet | |||

| Item No. | Opposite Side Length (mm) | Side Length (mm) | Thickness (mm) |

| AT-YHL-MSK009 | 19.5 | 11.5mm | 3-18 |

| AT-YHL-MSK010 | 20 | 12mm | 3-18 |

| AT-YHL-MSK011 | 21 | 12.5mm | 3-18 |

| AT-YHL-MSK012 | 40 | 23mm | 8-35 |

Type 3: Square Alumina Ceramic Mosaic Sheet with Bumps

| Sqaure Alumina Ceramic Mosaic Sheet with Bumps | |||

| Item No. | Length (mm) | Width (mm) | Thickness (mm) |

| AT-YHL-MSK013 | 20 | 4+1 | 4+1 |

| AT-YHL-MSK014 | 20 | 5+1 | 5+1 |

| AT-YHL-MSK015 | 20 | 6+1 | 6+1 |

| AT-YHL-MSK016 | 20 | 7+1 | 7+1 |

Type 4: Round Alumina Ceramic Mosaic Sheet

| Round Alumina Ceramic Mosaic Sheet | ||

| Item No. | Diameter (mm) | Height (mm) |

| AT-YHL-MSK017 | 16 | 16 |

| AT-YHL-MSK018 | 20 | 20 |

| AT-YHL-MSK019 | 21 | 21 |

| AT-YHL-MSK020 | 20 | 25 |

| AT-YHL-MSK021 | 23.5 | 18 |

| AT-YHL-MSK022 | 23.5 | 20 |

| AT-YHL-MSK023 | 23 | 23 |

| AT-YHL-MSK024 | 23 | 25 |

| AT-YHL-MSK025 | 25 | 25 |

| AT-YHL-MSK026 | 30 | 30 |

| AT-YHL-MSK027 | 31 | 31 |

| AT-YHL-MSK028 | 40 | 40 |

| AT-YHL-MSK029 | 45 | 45 |

| AT-YHL-MSK030 | 50 | 50 |

| AT-YHL-MSK031 | 60 | 60 |

Alumina Mosaic Plate Packaging

- Panel packing: PE wrap → foam corners → export carton → palletized; tile-only kits use partitioned inner boxes.