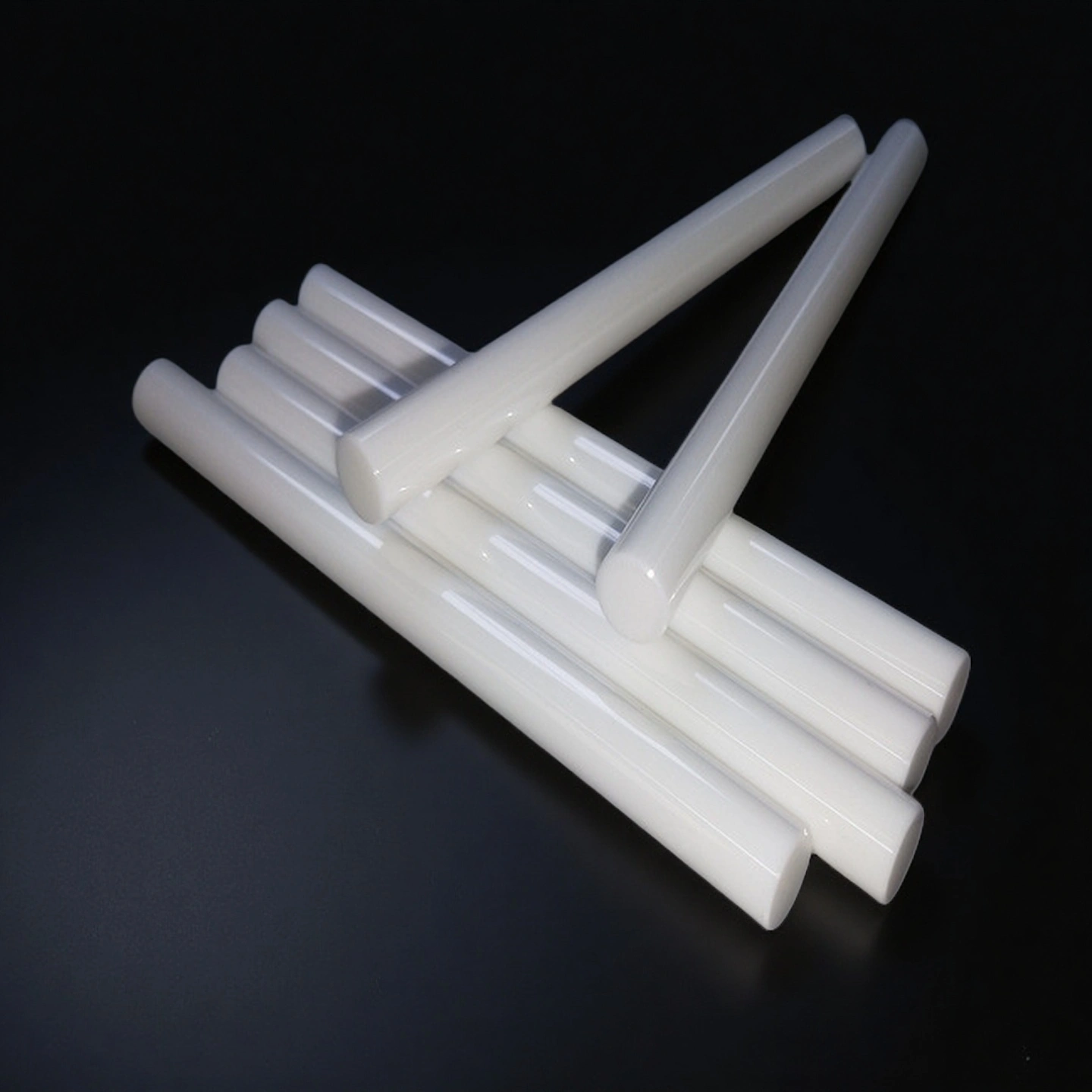

Zirconia Toughened Alumina (ZTA) rod is a structural ceramic made from an alumina (Al₂O₃) matrix dispersed with zirconia (ZrO₂) particles. The zirconia is stabilized (often yttria-stabilized) so that, when microcracks start, zirconia particles transform and expand at the crack tip (transformation toughening). This arrests crack growth and gives the rod higher fracture toughness than pure alumina while keeping high hardness and wear resistance.

Zirconia Toughened Alumina Rod Benefits

- Toughness advantage vs. alumina: ZTA’s KIC ≥5 MPa·m½ reduces edge chipping on pins and shafts under assembly impact.

- Dimensional stability: Ground OD tolerances to ±0.01–0.03 mm and straightness ≤0.02 mm/100 mm support precise bearing fits and linear motion.

- Wear-surface integrity: HV10 ~1,300–1,600 maintains geometry in abrasive slurry or dry sliding environments.

- Thermal capability: Continuous use ~1,400–1,500 °C (load/atmosphere dependent) for furnace fixtures and hot-zone insulators.

- Finish options for sealing/motion: Polishing to Ra ≤0.2 µm lowers friction and mitigates counterface wear.

ZTA Ceramic Rods Properties

| Property | Unit | Alumina (99%) | ZTA (Zirconia Toughened Alumina) | Y-TZP Zirconia |

| Fracture Toughness (KIC) | MPa·m¹⁄² | 5 | 7 – 9 | 6 – 10 |

| Hardness (HV10) | GPa | 8.9 | 9 – 10 (≈ 90 HV) | 12 – 14 |

| Flexural Strength | MPa | 400 | 650 – 800 | 800 – 1200 |

| Density | g/cm³ | 3.9 | 4.0 – 4.3 | 6.0 |

| Relative Wear Rate | — | 1.0 | 0.45 – 0.55 | 0.2 |

| Thermal Expansion Coefficient (RT – 800 °C) | ×10⁻⁶ /K | 8.0 | 8.5 – 9.0 | 10 – 11 |

| Thermal Conductivity (RT) | W/m·K | 25 | 22 – 24 | 2 – 3 |

| Maximum Working Temperature | °C | 1600 | 1450 – 1500 | 1000 – 1200 |

| Dielectric Strength | kV/mm | 12 | 11 – 13 | 9 – 11 |

| Surface Roughness (Ground face) | µm Ra | 0.4 – 1.2 | 0.3 – 0.8 | 0.2 – 0.6 |

| Flatness (after grinding) | mm/300 mm | ≤ 0.4 | ≤ 0.3 | ≤ 0.2 |

Zirconia Toughened Alumina Rods Specifications

| ZTA Rods | ||

| Item No. | Diameter(mm) | Length (mm) |

| AT-ZR-B001 | 1 | 15-1000 |

| AT-ZR-B002 | 2 | 15-1000 |

| AT-ZR-B003 | 3 | 15-1000 |

| AT-ZR-B004 | 4 | 15-1000 |

| AT-ZR-B005 | 5 | 15-1000 |

| AT-ZR-B006 | 6 | 15-1000 |

| AT-ZR-B007 | 7 | 15-1000 |

| AT-ZR-B008 | 8 | 15-1000 |

| AT-ZR-B009 | 9 | 15-1000 |

| AT-ZR-B010 | 10 | 15-1000 |

| AT-ZR-B011 | 11 | 15-1500 |

| AT-ZR-B012 | 12 | 15-1500 |

| AT-ZR-B013 | 13 | 15-1500 |

| AT-ZR-B014 | 14 | 15-1500 |

| AT-ZR-B015 | 15 | 15-1500 |

| AT-ZR-B016 | 16 | 15-1500 |

| AT-ZR-B017 | 17 | 15-1500 |

| AT-ZR-B018 | 18 | 15-1500 |

| AT-ZR-B019 | 19 | 15-1500 |

| AT-ZR-B020 | 20 | 15-1500 |

| AT-ZR-B021 | 21 | 15-1500 |

| AT-ZR-B022 | 22 | 15-1500 |

| AT-ZR-B023 | 23 | 15-1500 |

| AT-ZR-B024 | 24 | 15-1500 |

| AT-ZR-B025 | 25 | 15-1500 |

| AT-ZR-B026 | 26 | 15-1500 |

| AT-ZR-B027 | 27 | 15-1500 |

| AT-ZR-B028 | 28 | 15-1500 |

| AT-ZR-B029 | 29 | 15-1500 |

| AT-ZR-B030 | 30 | 15-1500 |

| AT-ZR-B031 | 31 | 15-1500 |

| AT-ZR-B032 | 32 | 15-1500 |

| AT-ZR-B033 | 33 | 15-1500 |

| AT-ZR-B034 | 34 | 15-1500 |

| AT-ZR-B035 | 35 | 15-1500 |

ZTA Rods Packaging

- Each rod is individually packed in foam cells or vacuum-sealed tubes

- Bundled by diameter or length category