ADCERAX® Cylindrical Zirconia Crucible is designed for demanding high-temperature processes where purity, stability, and durability are critical. With resistance up to 2200 °C, it ensures reliable melting of precious metals and superalloys under aggressive conditions. The dense zirconia structure minimizes contamination, extending service life in continuous operations. Industrial users and research laboratories select the Cylindrical Zirconia Crucible for consistent performance across refining, alloy development, and advanced thermal applications.

Features of Cylindrical Zirconia Crucible

- The Cylindrical Zirconia Crucible withstands continuous service at 2200 °C, ensuring safe use in high-temperature furnaces. This capacity reduces downtime caused by premature failure in conventional crucibles.

- Thermal shock resistance has been tested to endure rapid cycles between room temperature and 1500 °C. This prevents cracking and extends service intervals in demanding operations.

- The Cylindrical Zirconia Crucible contains ≥92% ZrO₂ with Fe₂O₃ and SiO₂ each ≤0.5%. This composition guarantees minimal reaction with molten alloys.

- Low porosity of ≤0.5% limits contamination risks during refining. This specification supports consistent purity in aerospace and jewelry applications.

- With a bulk density of ≥4.5 g/cm³, the Cylindrical Zirconia Crucible maintains structural integrity under heavy load. This enables reliable handling in industrial furnaces.

Technical Properties for Cylindrical Zirconia Crucible

Zirconia Ceramic Tray is designed for demanding sintering environments where performance consistency is critical.

| Property | Specification |

| Chemical Composition | ZrO₂ ≥ 92%, Fe₂O₃ ≤ 0.5%, SiO₂ ≤ 0.5% |

| Bulk Density | ≥ 4.5 g/cm³ |

| Apparent Porosity | ≤ 0.5% |

| Maximum Temperature | Continuous use up to 2200 °C |

| Thermal Shock Resistance | Stable after cycles RT → 1500 °C |

| Hardness | Mohs scale ~ 8.5–9 |

| Mechanical Strength | Fracture toughness ~ 7–10 MPa·m½ |

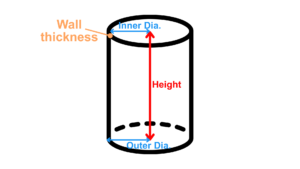

Dimensions of Cylindrical Zirconia Crucible

| Cylindrical ZrO2 Crucible | ||||||

| Item No. | Outer Diamete(mm) | Inner Diameter(mm) | Height(mm) | Wall Thickness(mm) | Volume(ml) | Purity(%) |

| AT-YHG-Y001 | 20.0 | 16.0 | 19.0 | 2.0 | 4 | 95 |

| AT-YHG-Y002 | 24.0 | 20.0 | 50.0 | 2.0 | 15 | 95 |

| AT-YHG-Y003 | 29.5 | 22.7 | 29.6 | 3.4 | 11 | 95 |

| AT-YHG-Y004 | 32.0 | 24.0 | 26.0 | 4.0 | 11 | 95 |

| AT-YHG-Y005 | 32.0 | 23.0 | 30.0 | 4.5 | 12 | 95 |

| AT-YHG-Y006 | 33.5 | 27.0 | 59.0 | 3.3 | 33 | 95 |

| AT-YHG-Y007 | 33.5 | 27.5 | 69.5 | 3.0 | 40 | 95 |

| AT-YHG-Y008 | 35.0 | 28.0 | 31.0 | 3.5 | 18 | 95 |

| AT-YHG-Y009 | 39.0 | 34.0 | 62.0 | 2.5 | 55 | 95 |

| AT-YHG-Y010 | 40.0 | 31.0 | 55.0 | 4.5 | 40 | 95 |

| AT-YHG-Y011 | 42.5 | 34.0 | 59.0 | 4.3 | 52 | 95 |

| AT-YHG-Y012 | 29.5 | 23.0 | 100.0 | 3.3 | 41 | 95 |

| AT-YHG-Y013 | 44.8 | 36.0 | 30.0 | 4.4 | 28 | 95 |

| AT-YHG-Y014 | 45.0 | 37.0 | 103.0 | 4.0 | 109 | 95 |

| AT-YHG-Y015 | 50.0 | 40.0 | 106.0 | 5.0 | 130 | 95 |

| AT-YHG-Y016 | 50.5 | 42.0 | 71.0 | 4.3 | 95 | 95 |

| AT-YHG-Y017 | 51.0 | 42.0 | 84.3 | 4.5 | 114 | 95 |

| AT-YHG-Y018 | 51.0 | 42.0 | 84.0 | 4.5 | 113 | 95 |

| AT-YHG-Y019 | 51.0 | 44.0 | 102.0 | 3.5 | 152 | 95 |

| AT-YHG-Y020 | 59.0 | 51.0 | 91.0 | 4.0 | 182 | 95 |

| AT-YHG-Y021 | 62.0 | 55.0 | 97.0 | 3.5 | 226 | 95 |

| AT-YHG-Y022 | 69.0 | 50.0 | 118.0 | 9.5 | 222 | 95 |

| AT-YHG-Y023 | 70.0 | 50.0 | 200.0 | 10.0 | 383 | 95 |

| AT-YHG-Y024 | 70.0 | 60.0 | 12.0 | 5.0 | 27 | 95 |

| AT-YHG-Y025 | 72.5 | 50.0 | 135.0 | 11.3 | 254 | 95 |

| AT-YHG-Y026 | 77.0 | 69.0 | 85.0 | 4.0 | 310 | 95 |

| AT-YHG-Y027 | 78.0 | 57.0 | 89.0 | 10.5 | 214 | 95 |

| AT-YHG-Y028 | 80.0 | 59.0 | 143.0 | 10.5 | 377 | 95 |

| AT-YHG-Y029 | 85.0 | 75.0 | 109.0 | 5.0 | 471 | 95 |

| AT-YHG-Y030 | 86.0 | 69.0 | 160.0 | 8.5 | 582 | 95 |

| AT-YHG-Y031 | 87.0 | 69.0 | 165.0 | 9.0 | 600 | 95 |

| AT-YHG-Y032 | 107.0 | 82.0 | 128.0 | 12.5 | 643 | 95 |

| AT-YHG-Y033 | 118.0 | 83.0 | 133.0 | 17.5 | 672 | 95 |

| AT-YHG-Y034 | 59.0 | 51.0 | 92.0 | 4.0 | 184 | 95 |

| AT-YHG-Y035 | 23.0 | 18.0 | 94.0 | 2.5 | 24 | 95 |

| AT-YHG-Y036 | 11.5 | 8.8 | 55.6 | 1.4 | 3 | 95 |

| AT-YHG-Y037 | 11.5 | 8.8 | 45.8 | 1.4 | 3 | 95 |

| AT-YHG-Y038 | 16.8 | 9.2 | 9.2 | 3.8 | 2 | 95 |

| AT-YHG-Y039 | 15.0 | 12.0 | 13.0 | 1.5 | 1 | 95 |

| AT-YHG-Y040 | 51.0 | 43.0 | 85.0 | 4.0 | 121 | 95 |

| AT-YHG-Y041 | 40.0 | 35.0 | 32.0 | 2.5 | 30 | 95 |

| AT-YHG-Y042 | 43.0 | 34.0 | 102.0 | 4.5 | 91 | 95 |

| AT-YHG-Y043 | 29.0 | 25.0 | 30.0 | 2.0 | 14 | 95 |

| AT-YHG-Y044 | 42.0 | 35.0 | 102.0 | 3.5 | 96 | 95 |

| AT-YHG-Y045 | 50.0 | 40.0 | 118.0 | 5.0 | 145 | 95 |

| AT-YHG-Y046 | 26.0 | 21.0 | 85.0 | 2.5 | 29 | 95 |

| AT-YHG-Y047 | 41.0 | 35.0 | 58.0 | 3.0 | 54 | 95 |

| AT-YHG-Y048 | 29.0 | 25.0 | 42.0 | 2.0 | 20 | 95 |

| AT-YHG-Y049 | 31.0 | 26.0 | 76.0 | 2.5 | 40 | 95 |

| AT-YHG-Y050 | 32.0 | 23.0 | 30.0 | 4.5 | 12 | 95 |

| AT-YHG-Y051 | 37.0 | 28.0 | 33.0 | 4.5 | 19 | 95 |

| AT-YHG-Y052 | 62.0 | 55.0 | 97.0 | 3.5 | 226 | 95 |

| AT-YHG-Y053 | 85.0 | 76.0 | 110.0 | 4.5 | 489 | 95 |

| AT-YHG-Y054 | 10.5 | 7.7 | 25.0 | 1.4 | 2 | 95 |

| AT-YHG-Y055 | 13.0 | 10.2 | 25.0 | 1.4 | 3 | 95 |

| AT-YHG-Y056 | 18.0 | 16.0 | 26.0 | 1.0 | 5 | 95 |

| AT-YHG-Y057 | 22.0 | 18.8 | 33.0 | 1.6 | 9 | 95 |

| AT-YHG-Y058 | 15.0 | 11.0 | 100.0 | 2.0 | 9 | 95 |

| AT-YHG-Y059 | 50.0 | 44.0 | 80.0 | 3.0 | 120 | 95 |

| AT-YHG-Y060 | 30.0 | 26.0 | 60.0 | 2.0 | 35 | 95 |

| AT-YHG-Y061 | 42.0 | 38.0 | 53.0 | 2.0 | 37 | 95 |

| AT-YHG-Y062 | 57.0 | 53.0 | 65.0 | 2.0 | 100 | 95 |

| AT-YHG-Y063 | 48.0 | 44.0 | 52.0 | 2.0 | 50 | 95 |

| AT-YHG-Y064 | 38.0 | 34.0 | 45.0 | 2.0 | 30 | 95 |

| AT-YHG-Y065 | 9.0 | 6 | 15.0 | 1.5 | 2 | 95 |

| AT-YHG-Y066 | 16.0 | 11.0 | 12.0 | 2.5 | 3 | 95 |

| AT-YHG-Y067 | 16.0 | 11.0 | 95.0 | 2.5 | 10 | 95 |

| AT-YHG-Y068 | 32.0 | 26.0 | 80.0 | 3.0 | 40 | 95 |

| AT-YHG-Y069 | 34.0 | 28.0 | 80.0 | 3.0 | 50 | 95 |

| AT-YHG-Y070 | 36.0 | 30.0 | 80.0 | 3.0 | 60 | 95 |

| AT-YHG-Y071 | 40.0 | 34.2 | 50.0 | 2.9 | 50 | 95 |

| AT-YHG-Y072 | 40.0 | 34.2 | 80.0 | 2.9 | 70 | 95 |

| AT-YHG-Y073 | 45.0 | 39.2 | 50.0 | 2.9 | 50 | 95 |

| AT-YHG-Y074 | 50.0 | 42.0 | 80.0 | 4.0 | 100 | 95 |

| AT-YHG-Y075 | 57.0 | 49.0 | 75.0 | 4.0 | 120 | 95 |

| AT-YHG-Y076 | 66.0 | 59.4 | 66.0 | 3.3 | 120 | 95 |

| AT-YHG-Y077 | 80.0 | 73.0 | 80.0 | 3.5 | 300 | 95 |

Packaging of Cylindrical Zirconia Crucible

Each Cylindrical Zirconia Crucible is carefully wrapped with protective film and cushioned by foam partitions to avoid surface damage during transit. The packed Cylindrical ZrO2 Crucible units are then secured in reinforced wooden cases with clear fragile labels. This packaging method ensures that every Cylindrical Zirconia Ceramic Crucible arrives intact and ready for immediate industrial use.