ADCERAX® Yttria Stabilized Zirconia YSZ Ceramic Substrate delivers stable performance under high temperatures, strong mechanical stress, and chemically demanding conditions. Its combination of high toughness, electrical insulation, and low thermal conductivity supports reliable use in fuel cell systems, heating assemblies, and industrial sensor modules. ADCERAX supplies YSZ ceramic substrates designed for durability and precision in continuous‑duty environments, meeting the requirements of advanced engineering applications worldwide.

Features of Yttria Stabilized Zirconia Ceramic Substrate

- With a melting point of 2715 °C, the substrate withstands extreme thermal environments without cracking or warping.

- Its thermal expansion coefficient of 10.3×10⁻⁶/K aligns with most steel alloys, reducing thermal stress in hybrid assemblies.

- Low thermal conductivity of ~2.5 W/m·K ensures efficient insulation in high-temperature fuel cell modules.

- YSZ Ceramic offers fracture toughness ≥8 MPa·m¹/², which is significantly higher than alumina or mullite substrates.

- Proven in tests to exhibit 15× higher wear resistance than standard alumina ceramics under dry sliding conditions.

- YSZ Ceramic Substrate resists corrosion from strong acids and bases in chemically reactive zones.

- Its non-magnetic, chemically inert structure remains stable in H₂, O₂, N₂, and CO atmospheres at elevated temperatures.

- Ionic conductivity between 600–1000 °C enables its use in SOFC oxygen transport and solid-state sensing layers.

- Surface hardness reaches ≥1300 HV, extending wear resistance in mechanical interfaces under repetitive stress.

Technical Properties for Yttria Stabilized Zirconia Ceramic Substrate

Yttria Stabilized Zirconia Ceramic Substrate exhibits a dense microstructure, excellent thermal insulation, and reliable electrochemical behavior under high-temperature industrial conditions. Its performance characteristics make it suitable for integration into demanding energy, sensor, and thermal control systems.

| Property | Specification |

|---|---|

| Material Composition | ZrO₂ + 3–8 mol% Y₂O₃ |

| Density | 5.95 – 6.05 g/cm³ |

| Melting Point | ~2715 °C |

| Flexural Strength | >700 MPa |

| Fracture Toughness | ≥8 MPa·m¹/² |

| Vickers Hardness | ≥1300 HV |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K |

| Thermal Conductivity | ~2.5 W/m·K @ 1000 °C |

| Max Working Temperature (Air) | 1000–1200 °C (short-term to 1350 °C) |

| Electrical Resistivity (RT) | >10¹² Ω·cm |

| Ionic Conductivity | High (600–1000 °C range) |

| Corrosion Resistance | Acid & alkali resistant |

| Magnetic Properties | Non-magnetic |

| Surface Finish (Polished) | Ra ≤ 0.1 µm |

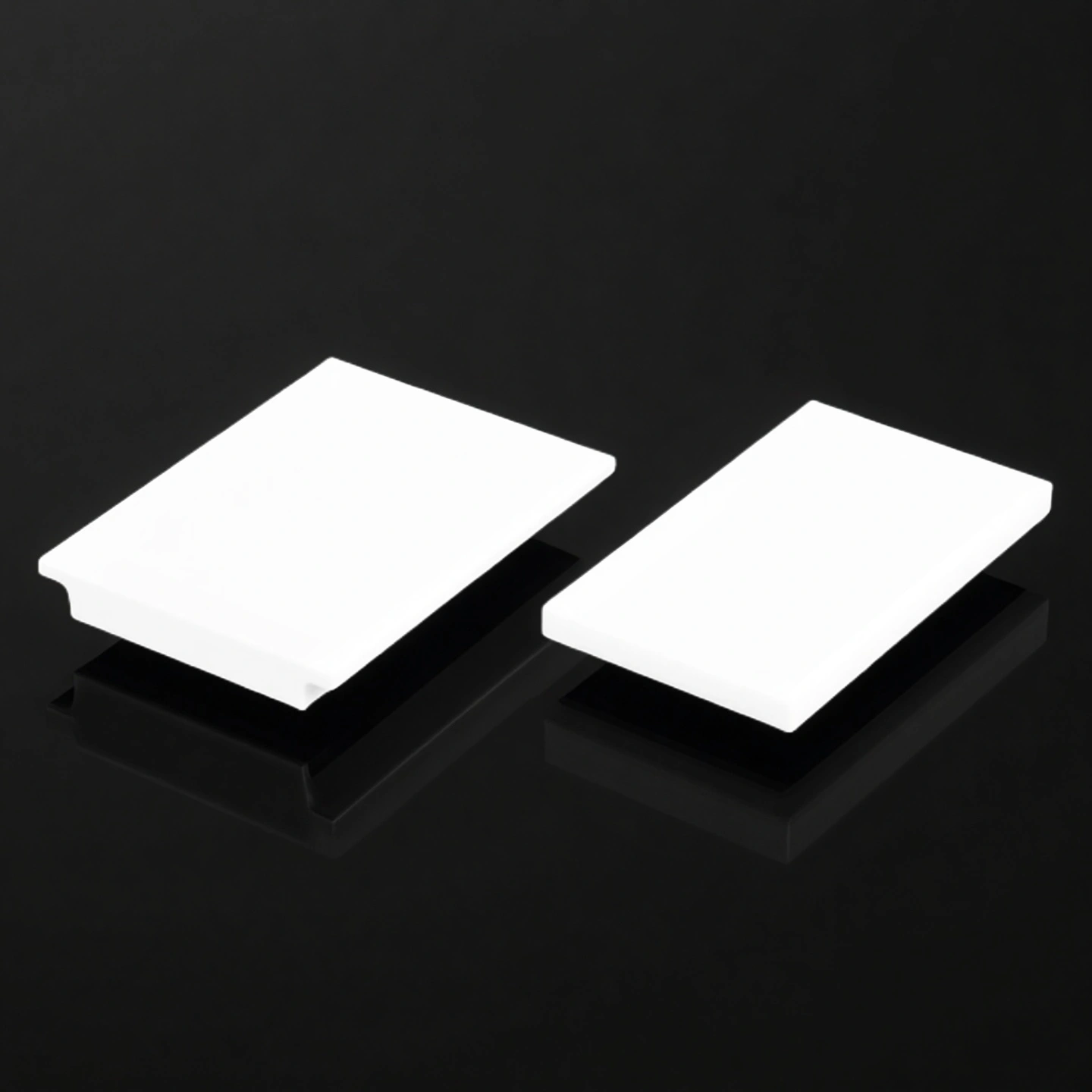

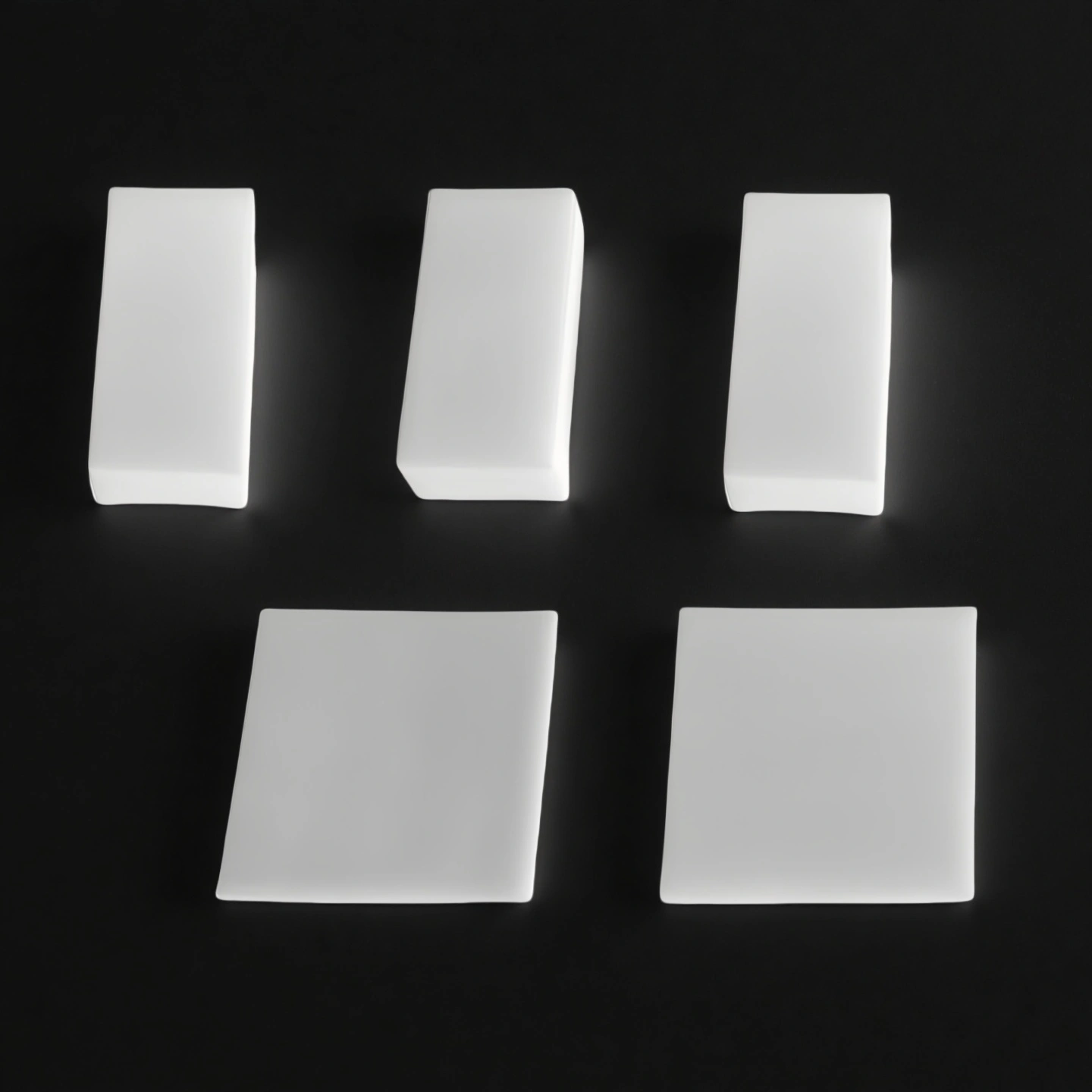

| Color | White to light gray |

Specifications of Yttria Stabilized Zirconia Ceramic Substrate

| Round Zirconia Plates | |||

| Item No. | Outer diameter(mm) | Thickness (mm) | Purity(%) |

| AT-YHG-B2001 | 6 | 0.25 | 95% |

| AT-YHG-B2002 | 8 | 0.25 | 95% |

| AT-YHG-B2003 | 10 | 0.25 | 95% |

| AT-YHG-B2004 | 12 | 0.25 | 95% |

| AT-YHG-B2005 | 16 | 0.25 | 95% |

| AT-YHG-B2006 | 20 | 0.25 | 95% |

| AT-YHG-B2007 | 6 | 0.5 | 95% |

| AT-YHG-B2008 | 8 | 0.5 | 95% |

| AT-YHG-B2009 | 10 | 0.5 | 95% |

| AT-YHG-B2010 | 12 | 0.5 | 95% |

| AT-YHG-B2011 | 16 | 0.5 | 95% |

| AT-YHG-B2012 | 18 | 0.5 | 95% |

| AT-YHG-B2013 | 20 | 0.5 | 95% |

| AT-YHG-B2014 | 25 | 0.5 | 95% |

| AT-YHG-B2015 | 30 | 0.5 | 95% |

| AT-YHG-B2016 | 50 | 0.5 | 95% |

| AT-YHG-B2017 | 55 | 0.5 | 95% |

| AT-YHG-B2018 | 65 | 0.5 | 95% |

| AT-YHG-B2019 | 100 | 0.5 | 95% |

| AT-YHG-B2020 | 6 | 0.635 | 95% |

| AT-YHG-B2021 | 8 | 0.635 | 95% |

| AT-YHG-B2022 | 10 | 0.635 | 95% |

| AT-YHG-B2023 | 12 | 0.635 | 95% |

| AT-YHG-B2024 | 16 | 0.635 | 95% |

| AT-YHG-B2025 | 18 | 0.635 | 95% |

| AT-YHG-B2026 | 20 | 0.635 | 95% |

| AT-YHG-B2027 | 30 | 0.635 | 95% |

| AT-YHG-B2028 | 50 | 0.635 | 95% |

| AT-YHG-B2029 | 100 | 0.635 | 95% |

| AT-YHG-B2030 | 3.5 | 1 | 95% |

| AT-YHG-B2031 | 5 | 1 | 95% |

| AT-YHG-B2032 | 6 | 1 | 95% |

| AT-YHG-B2033 | 8 | 1 | 95% |

| AT-YHG-B2034 | 10 | 1 | 95% |

| AT-YHG-B2035 | 12 | 1 | 95% |

| AT-YHG-B2036 | 16 | 1 | 95% |

| AT-YHG-B2037 | 18 | 1 | 95% |

| AT-YHG-B2038 | 20 | 1 | 95% |

| AT-YHG-B2039 | 25 | 1 | 95% |

| AT-YHG-B2040 | 30 | 1 | 95% |

| AT-YHG-B2041 | 33 | 1 | 95% |

| AT-YHG-B2042 | 35 | 1 | 95% |

| AT-YHG-B2043 | 40 | 1 | 95% |

| AT-YHG-B2044 | 50 | 1 | 95% |

| AT-YHG-B2045 | 75 | 1 | 95% |

| AT-YHG-B2046 | 100 | 1 | 95% |

| AT-YHG-B2047 | 40 | 1.5 | 95% |

| AT-YHG-B2048 | 50 | 2 | 95% |

| AT-YHG-B2049 | 120 | 2 | 95% |

| AT-YHG-B2050 | 36 | 4 | 95% |

| AT-YHG-B2051 | 125 | 6 | 95% |

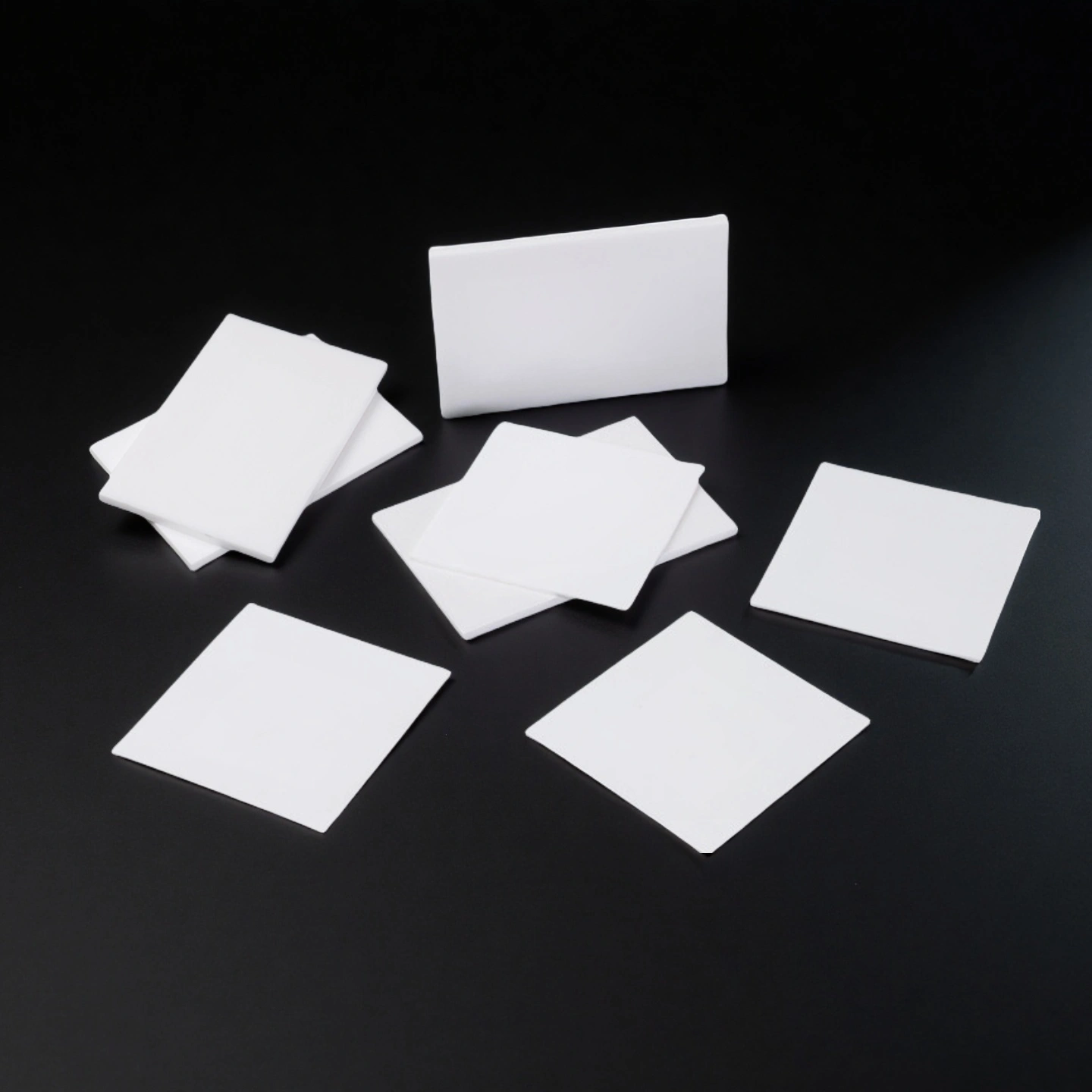

| Square Zirconia Plates | ||||

| Item No. | Length(mm) | Width (mm) | Thickness (mm) | Purity(%) |

| AT-YHG-B3001 | 115 | 115 | 0.12 | 95% |

| AT-YHG-B3002 | 115 | 115 | 0.12 | 95% |

| AT-YHG-B3003 | 65 | 74 | 0.2 | 95% |

| AT-YHG-B3004 | 10 | 10 | 0.25 | 95% |

| AT-YHG-B3005 | 120 | 120 | 0.25 | 95% |

| AT-YHG-B3006 | 138 | 190 | 0.25 | 95% |

| AT-YHG-B3007 | 100 | 100 | 0.25 | 95% |

| AT-YHG-B3008 | 100 | 100 | 0.25 | 95% |

| AT-YHG-B3009 | 120 | 120 | 0.25 | 95% |

| AT-YHG-B3010 | 65 | 74 | 0.28 | 95% |

| AT-YHG-B3011 | 100 | 100 | 0.3 | 95% |

| AT-YHG-B3012 | 138 | 190 | 0.32 | 95% |

| AT-YHG-B3013 | 100 | 100 | 0.35 | 95% |

| AT-YHG-B3014 | 120 | 120 | 0.38 | 95% |

| AT-YHG-B3015 | 114 | 114 | 0.38 | 95% |

| AT-YHG-B3016 | 138 | 190 | 0.38 | 95% |

| AT-YHG-B3017 | 138 | 190 | 0.38 | 95% |

| AT-YHG-B3018 | 100 | 100 | 0.5 | 95% |

| AT-YHG-B3019 | 10 | 10 | 0.5 | 95% |

| AT-YHG-B3020 | 50 | 50 | 0.5 | 95% |

| AT-YHG-B3021 | 100 | 100 | 0.5 | 95% |

| AT-YHG-B3022 | 120 | 120 | 0.5 | 95% |

| AT-YHG-B3023 | 138 | 190 | 0.5 | 95% |

| AT-YHG-B3024 | 114 | 114 | 0.5 | 95% |

| AT-YHG-B3025 | 138 | 190 | 0.5 | 95% |

| AT-YHG-B3026 | 100 | 100 | 0.5 | 95% |

| AT-YHG-B3027 | 100 | 100 | 0.6 | 95% |

| AT-YHG-B3028 | 10 | 10 | 0.635 | 95% |

| AT-YHG-B3029 | 30 | 30 | 0.635 | 95% |

| AT-YHG-B3030 | 50 | 50 | 0.635 | 95% |

| AT-YHG-B3031 | 100 | 100 | 0.635 | 95% |

| AT-YHG-B3032 | 120 | 120 | 0.635 | 95% |

| AT-YHG-B3033 | 152 | 152 | 0.635 | 95% |

| AT-YHG-B3034 | 138 | 190 | 0.635 | 95% |

| AT-YHG-B3035 | 114 | 114 | 0.65 | 95% |

| AT-YHG-B3036 | 138 | 190 | 0.65 | 95% |

| AT-YHG-B3037 | 100 | 100 | 0.7 | 95% |

| AT-YHG-B3038 | 76.2 | 76.2 | 0.75 | 95% |

| AT-YHG-B3039 | 84 | 84 | 0.8 | 95% |

| AT-YHG-B3040 | 120 | 120 | 0.8 | 95% |

| AT-YHG-B3041 | 138 | 190 | 0.8 | 95% |

| AT-YHG-B3042 | 100 | 100 | 1 | 95% |

| AT-YHG-B3043 | 10 | 10 | 1 | 95% |

| AT-YHG-B3044 | 20 | 20 | 1 | 95% |

| AT-YHG-B3045 | 25 | 25 | 1 | 95% |

| AT-YHG-B3046 | 30 | 30 | 1 | 95% |

| AT-YHG-B3047 | 35 | 35 | 1 | 95% |

| AT-YHG-B3048 | 40 | 40 | 1 | 95% |

| AT-YHG-B3049 | 50 | 50 | 1 | 95% |

| AT-YHG-B3050 | 56 | 90 | 1 | 95% |

| AT-YHG-B3051 | 60 | 60 | 1 | 95% |

| AT-YHG-B3052 | 100 | 100 | 1 | 95% |

| AT-YHG-B3053 | 109 | 109 | 1 | 95% |

| AT-YHG-B3054 | 114 | 114 | 1 | 95% |

| AT-YHG-B3055 | 127 | 127 | 1 | 95% |

| AT-YHG-B3056 | 150 | 150 | 1 | 95% |

| AT-YHG-B3057 | 100 | 100 | 1 | 95% |

| AT-YHG-B3058 | 138 | 190 | 1 | 95% |

| AT-YHG-B3059 | 138 | 190 | 1 | 95% |

| AT-YHG-B3060 | 120 | 120 | 1 | 95% |

| AT-YHG-B3061 | 150 | 150 | 1 | 95% |

| AT-YHG-B3062 | 100 | 100 | 1.5 | 95% |

| AT-YHG-B3063 | 127 | 127 | 1.5 | 95% |

| AT-YHG-B3064 | 100 | 100 | 1.5 | 95% |

| AT-YHG-B3065 | 150 | 150 | 1.5 | 95% |

| AT-YHG-B3066 | 20 | 20 | 2 | 95% |

| AT-YHG-B3067 | 30 | 30 | 2 | 95% |

| AT-YHG-B3068 | 70 | 70 | 2 | 95% |

| AT-YHG-B3069 | 100 | 100 | 2 | 95% |

| AT-YHG-B3070 | 125 | 125 | 2 | 95% |

| AT-YHG-B3071 | 100 | 100 | 2 | 95% |

| AT-YHG-B3072 | 150 | 150 | 2 | 95% |

| AT-YHG-B3073 | 180 | 180 | 2 | 95% |

| AT-YHG-B3074 | 200 | 200 | 2 | 95% |

| AT-YHG-B3075 | 220 | 220 | 2 | 95% |

| AT-YHG-B3076 | 100 | 100 | 2.5 | 95% |

| AT-YHG-B3077 | 100 | 100 | 2.5 | 95% |

| AT-YHG-B3078 | 160 | 170 | 2.5 | 95% |

| AT-YHG-B3079 | 70 | 70 | 3 | 95% |

| AT-YHG-B3080 | 100 | 100 | 3 | 95% |

| AT-YHG-B3081 | 80 | 80 | 3 | 95% |

| AT-YHG-B3082 | 100 | 100 | 3 | 95% |

| AT-YHG-B3083 | 120 | 120 | 3 | 95% |

| AT-YHG-B3084 | 150 | 150 | 3 | 95% |

| AT-YHG-B3085 | 180 | 180 | 3 | 95% |

| AT-YHG-B3086 | 200 | 200 | 3 | 95% |

| AT-YHG-B3087 | 100 | 100 | 3.5 | 95% |

| AT-YHG-B3088 | 100 | 100 | 4 | 95% |

| AT-YHG-B3089 | 40 | 40 | 5 | 95% |

| AT-YHG-B3090 | 50 | 50 | 5 | 95% |

| AT-YHG-B3091 | 80 | 80 | 5 | 95% |

| AT-YHG-B3092 | 80 | 110 | 5 | 95% |

| AT-YHG-B3093 | 100 | 100 | 5 | 95% |

| AT-YHG-B3094 | 110 | 110 | 5 | 95% |

| AT-YHG-B3095 | 150 | 150 | 5 | 95% |

| AT-YHG-B3096 | 180 | 180 | 5 | 95% |

| AT-YHG-B3097 | 200 | 200 | 5 | 95% |

| AT-YHG-B3098 | 50 | 50 | 6 | 95% |

| AT-YHG-B3099 | 50 | 50 | 7 | 95% |

| AT-YHG-B3100 | 50 | 50 | 8 | 95% |

| AT-YHG-B3101 | 100 | 100 | 8 | 95% |

| AT-YHG-B3102 | 150 | 150 | 8 | 95% |

| AT-YHG-B3103 | 50 | 50 | 10 | 95% |

| AT-YHG-B3104 | 100 | 100 | 10 | 95% |

| AT-YHG-B3105 | 100 | 100 | 12 | 95% |

| AT-YHG-B3106 | 50 | 50 | 15 | 95% |

| AT-YHG-B3107 | 100 | 100 | 15 | 95% |

| AT-YHG-B3108 | 100 | 100 | 20 | 95% |

Packaging of Yttria Stabilized Zirconia Ceramic Substrate

Yttria Stabilized Zirconia Ceramic Substrate is securely packed with layered protection, including foam-lined cartons, reinforced wooden cases, and export-grade crating. Each unit is labeled for traceability and stability during international transit. Shock warning labels and moisture-resistant sealing ensure safe delivery to industrial facilities.