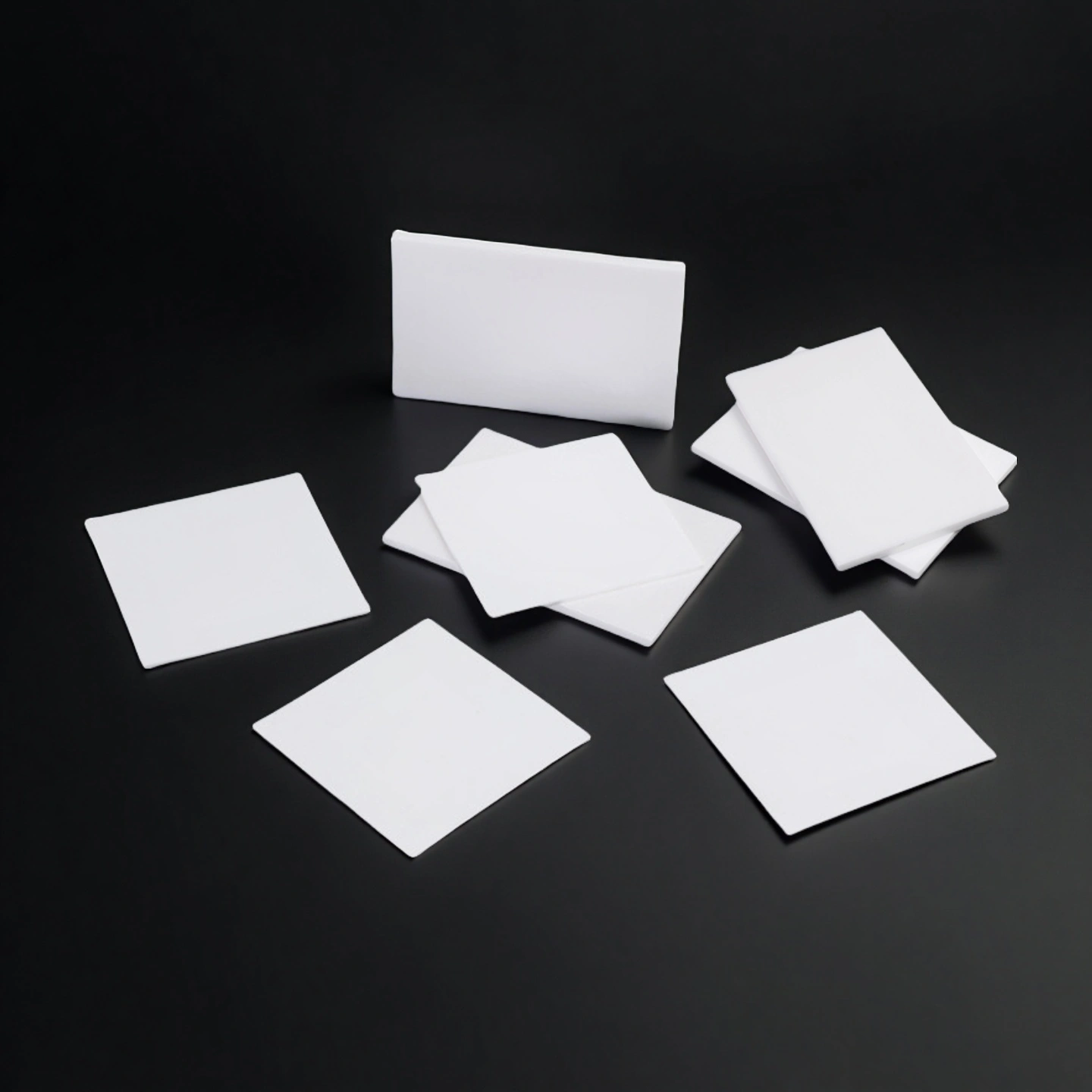

Zirconia ceramic sheets are widely used in high-temperature and insulating components that require strength and precision. It suits applications including laser welding equipment, vacuum furnaces, and insulation layers.

Zirconia Ceramic Sheet Benefits

- High-density YSZ material (≥5.9 g/cm³) for structural stability

- Electrically insulating (>14 kV/mm) and thermally stable up to 2200°C

- Excellent resistance to wear, chemical corrosion, and cracking

- Tolerance control down to ±0.05mm for critical alignment usage

- Machinable surfaces allow design integration in OEM equipment

Zirconia Ceramic Sheet Specifications

| Zirconia Ceramic Sheet | ||||

| Item no. | Length(mm) | Width(mm) | Thickness(mm) | ZrO2's Purity(mm) |

| AT-YHG-GB1001 | 50 | 25 | 5 | 95 |

| AT-YHG-GB1002 | 50 | 25 | 10 | 95 |

| AT-YHG-GB1003 | 50 | 50 | 5 | 95 |

| AT-YHG-GB1004 | 74 | 52 | 5 | 95 |

| AT-YHG-GB1005 | 80 | 60 | 6 | 95 |

| AT-YHG-GB1006 | 100 | 100 | 5 | 95 |

| AT-YHG-GB1007 | 100 | 10 | 20 | 95 |

| AT-YHG-GB1008 | 150 | 90 | 5 | 95 |

| AT-YHG-GB1009 | 150 | 150 | 10 | 95 |

| AT-YHG-GB1010 | 150 | 150 | 12 | 95 |

| AT-YHG-GB1011 | 180 | 100 | 5 | 95 |

| AT-YHG-GB1012 | 180 | 100 | 10 | 95 |

| AT-YHG-GB1013 | 180 | 120 | 20 | 95 |

| AT-YHG-GB1014 | 200 | 150 | 5 | 95 |

| AT-YHG-GB1015 | 200 | 150 | 10 | 95 |

| AT-YHG-GB1016 | 200 | 150 | 20 | 95 |

| AT-YHG-GB1017 | 280 | 120 | 10 | 95 |

| AT-YHG-GB1018 | 380 | 120 | 10 | 95 |

Packing:

- Multi-layer foam trays, sealed shrink bags, and shock-proof export cartons.