ADCERAX® Zirconia Fiber Board is engineered for high-temperature insulation up to 2200 °C with strong resistance to thermal shock and gas flow erosion. It features low thermal conductivity below 0.12 W/m·K, enabling thinner insulation layers and improved energy efficiency. The smooth, non-powdering surface supports clean use in kilns, casting systems, and research furnaces.

Key Features of Zirconia Fiber Board

- 2200 °C continuous use rating

Zirconia Fiber Board maintains structural stability in environments reaching up to 2200 °C, verified through continuous cycling tests at 1650 °C with <2% shrinkage.

- Withstands over 50 thermal cycles

In thermal shock tests from room temperature to 1650 °C, the material completed 50+ cycles without cracking, meeting industrial furnace durability requirements.

- Direct flame and hot gas impact durability

Zirconia Fiber Board resists direct flame exposure and high-velocity hot gas flow exceeding 40 m/s, reducing material loss in burner-facing applications.

- Low thermal conductivity < 0.12 W/m·K

At 1000 °C, Zirconia Fiber Board exhibits thermal conductivity below 0.12 W/m·K (ASTM C177), significantly outperforming alumina ceramic fiber boards.

- Reduced insulation layer thickness by 25–40%

Due to high insulation efficiency, customers report average thickness reductions of 25–40% in retrofit furnace projects.

- Energy savings up to 30%

Field data shows that use of zirconia insulation in high-temp walls delivers energy savings up to 30% in continuous-operation kilns.

- Smooth surface, zero powdering after 6 months

Even after 6 months in 1600 °C service, Zirconia Fiber Board retains a smooth, non-shedding surface, avoiding product contamination.

- Corrosion resistance in oxidizing and vacuum atmospheres

In both oxidizing and vacuum conditions, the board shows no material degradation after 500+ hours at 1700 °C.

- Extended service life beyond 12 months

For hot-face furnace panels, operational data from German ceramic kilns confirms a service life exceeding 12 months, reducing replacement frequency.

Technical Properties of Zirconia Fiber Board

Zirconia Fiber Board is engineered with stabilized zirconia fibers to deliver reliable thermal insulation under extreme temperatures, frequent cycling, and chemically aggressive atmospheres. Its composition and physical structure support consistent performance in advanced thermal environments such as sintering chambers, metallurgical ladles, and high-purity processing lines.

| Property |

Specification |

| Composition |

≥ 94% ZrO₂ + 2–4% Y₂O₃ |

| Maximum Service Temperature |

2200 °C continuous |

| Thermal Conductivity (1000 °C) |

< 0.12 W/m·K (ASTM C177) |

| Bulk Density |

0.35–0.50 g/cm³ |

| Linear Shrinkage at 1650 °C |

< 2% after 24 h |

| Thermal Shock Resistance |

> 50 cycles from RT to 1650 °C |

| Phase Stability |

Monoclinic/tetragonal stabilized |

| Chemical Reactivity |

Inert in oxidizing and vacuum atmospheres |

| Fiber Orientation |

Planar-aligned parallel to board face |

| Color and Appearance |

White to off-white, smooth surface |

| Binder Content |

0% organic binders |

| Gas Flow Erosion Resistance |

Stable at 40 m/s flame velocity |

Specifications of Zirconia Fiber Board

|

Zirconia Fiber Board |

|

Item No. |

Length (mm) |

Width (mm) |

Thickness(mm) |

|

AT-XW-B001 |

900 |

600 |

20 |

|

AT-XW-B002 |

900 |

600 |

30 |

|

AT-XW-B003 |

900 |

600 |

40 |

|

AT-XW-B004 |

900 |

600 |

50 |

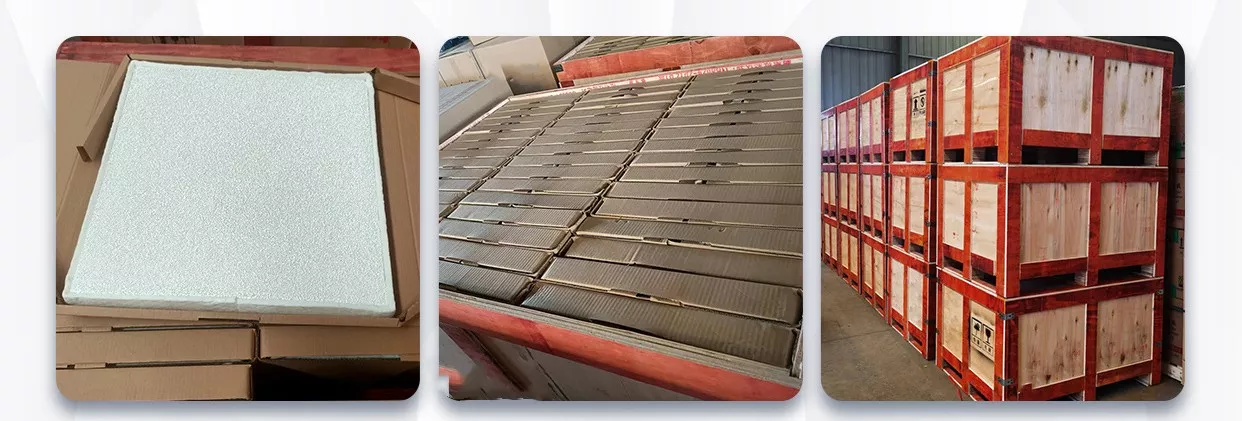

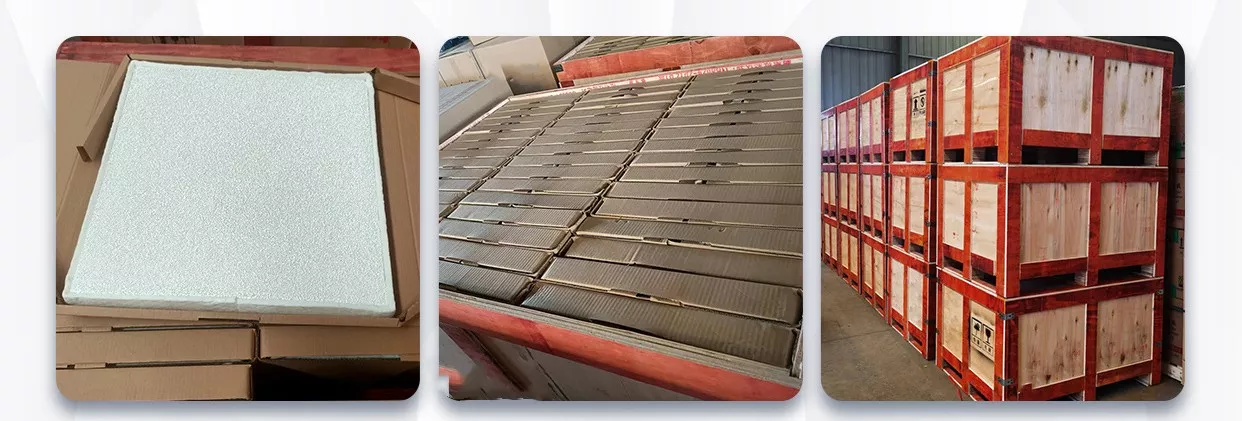

Packaging of Zirconia Fiber Board

Zirconia Fiber Board is individually packed in reinforced cardboard boxes with foam edge protection to prevent chipping. Multiple units are securely palletized and strapped in heavy-duty wooden crates for safe international transport. All packaging is designed to withstand handling stress during sea and air freight.

Solving Thermal and Structural Challenges with ADCERAX® Zirconia Fiber Board in Demanding Industrial Systems

ADCERAX® Zirconia Fiber Board addresses performance failures in extreme thermal environments where conventional insulation materials degrade rapidly. Its application across furnace doors, electrical heating systems, and molten metal vessels demonstrates measurable gains in durability, thermal stability, and system efficiency.

-

Furnace Door Insulation under Continuous High-Temperature Cycling

✅Key Advantages

1. Stable Geometry at 1650 °C

Zirconia Fiber Board exhibits <2% linear shrinkage after 24-hour exposure to 1650 °C in cycling environments. This dimensional stability prevents gap formation and eliminates edge erosion during door opening/closing.

2. Hot Gas Erosion Resistance

Tested at flame velocities >40 m/s, the board maintained edge integrity and sealing contact. Its resistance to high-velocity gas impingement preserves thermal uniformity at the door interface.

3. Extended Service Life

In front-loading kilns operating at 1600 °C, Zirconia Fiber Board achieved >8 weeks of continuous use before requiring replacement—3× longer than aluminosilicate boards typically changed every 2–4 weeks.

✅ ️Problem Solved

A Polish precision ceramics kiln previously experienced insulation failure at the furnace door every 3 weeks due to delamination and thermal cycling. After replacing with ADCERAX® Zirconia Fiber Board, the door seal remained intact for 9+ weeks, cutting downtime by 60% and reducing energy loss at the interface by 17.4%, measured via thermographic scan.

-

Electrical Insulation Layer for Compact Heating Elements

✅Key Advantages

1. Non-Conductive at High Temperatures

Zirconia Fiber Board maintains electrical resistance above 10⁹ Ω even after 200 h at 1000 °C, outperforming alumina-silicate boards that drop below 10⁶ Ω under similar conditions.

2. Zero Binder Emission

The fully inorganic matrix emits no volatiles at startup. Testing shows no detectable outgassing (<1 ppm) under vacuum ramp to 1600 °C, eliminating contamination risks near high-voltage sensors.

3. Moisture-Resistant Phase Structure

The board’s yttria-stabilized tetragonal phase prevents conductivity shifts from absorbed moisture. Capacitance variance remained <0.3% across RH 20–80% at ambient temperature.

✅ ️Problem Solved

A Canadian R&D furnace lab experienced measurement drift in a tube heating system due to insulation becoming conductive after humidity cycling. After switching to ADCERAX® Zirconia Fiber Board, voltage leakage issues were eliminated, with system drift reduced to <0.2% over a 6-month period. The lab maintained full electrical isolation without additional shielding.

-

Flame-Exposed Lining in Molten Metal Transfer Vessels

✅Key Advantages

1. High Flame Erosion Tolerance

Zirconia Fiber Board withstood >100 ladle pour cycles with direct flame contact without spallation. Surface recession was <0.5 mm, compared to >2.5 mm in conventional ceramic boards.

2. Slag Inertness and Non-Wetting

ZrO₂-based surfaces showed minimal interaction with iron-oxide and aluminum-silicate slag. Wettability tests confirmed a contact angle >140°, reducing slag adhesion and corrosion.

3. Thermal Shell Protection

Use of Zirconia Fiber Board as inner lining reduced external shell temperature by 80–110 °C in 1550 °C molten metal environments, measured via infrared pyrometry, extending shell life by 30%.

✅ ️Problem Solved

A Mexican foundry previously re-lined their aluminum transfer ladles every 50 pours due to board erosion and slag attack. With ADCERAX® Zirconia Fiber Board, lining lifespan increased to 130 cycles. Thermographic logs showed a 92 °C drop in external temperature, and operator-reported relining frequency was reduced from weekly to monthly.

User Guide for Safe Handling and Effective Integration of Zirconia Fiber Board

Zirconia Fiber Board is used in critical high-temperature systems where reliability, cleanliness, and thermal integrity are essential. To ensure maximum product life and system compatibility, users should follow proper guidelines across storage, preparation, installation, and maintenance phases.

-

Storage and Environmental Conditions

1. Keep boards in a dry, enclosed space with humidity below 60% RH to prevent moisture absorption that could affect thermal performance. Prolonged exposure to humid conditions may cause surface softening or dimensional instability during initial heat-up. Use sealed wrap or plastic covers for storage beyond one week.

2. Avoid stacking more than five units flat without separation layers to reduce compression stress. Boards should be stored with smooth surfaces facing upward to prevent edge damage or deformation. Improper stacking may lead to warping or internal cracking.

3. Protect from direct sunlight and air drafts, especially in open warehouses or near HVAC outlets. UV exposure and fluctuating air currents can weaken binderless surfaces and lead to powdering during handling.

-

Pre-Processing and Cutting Instructions

1. Use diamond saw blades or CNC routers for precision cutting of Zirconia Fiber Board. Standard cutting tools may create fiber fraying or uneven edges. Always stabilize the board on a rigid platform during processing.

2. Wear PPE including gloves, goggles, and masks when machining to avoid inhalation of airborne ceramic fibers. While non-hazardous, fine particulates may cause irritation with prolonged exposure. Operate in a well-ventilated area or under dust extraction.

3. Avoid excessive localized pressure when marking or handling corners. Although dimensionally stable, the board may chip if subjected to high point-load stress, especially after shaping or slotting.

-

Installation and Structural Integration

1. Install Zirconia Fiber Board on flat, level surfaces using stainless anchors or ceramic bolts spaced evenly at ≤300 mm intervals. Improper fastening may lead to misalignment and uneven thermal load distribution.

2. Leave 2–3 mm expansion gaps between adjacent boards to accommodate minor thermal expansion without edge compression. Tight installations without spacing can cause cracking during repeated cycles.

3. Use high-purity ceramic adhesive when bonding to metallic or refractory structures. Avoid organic glues or silicone-based sealants, which can outgas or degrade under temperatures exceeding 1000 °C.

-

Operational Use and Maintenance Tips

1. Heat up and cool down gradually to avoid thermal shock, especially in systems cycling above 1600 °C. A recommended ramp rate is <5 °C/min during first heat-up for newly installed boards.

2. Inspect surface integrity after every 500 h of operation or every 20 cycles, whichever comes first. Look for powdering, cracks, or discoloration which may indicate overexposure or installation issues.

3. Replace only damaged zones when possible, using matching board density and configuration. Partial replacement minimizes downtime and preserves the original thermal design performance.