ADCERAX® Zirconia Ceramic Sleeve is engineered for high-performance applications involving corrosive fluids, abrasive slurries, and elevated temperatures. It serves as a protective barrier in industrial pumps, valves, and rotating equipment used in chemical, metallurgical, and energy sectors.

With high fracture toughness and thermal stability, Zirconia Ceramic Sleeve helps reduce maintenance frequency and extend system uptime. Its material integrity remains stable in aggressive media environments where metal or polymer sleeves degrade rapidly.

Performance Features of Zirconia Ceramic Sleeve in Harsh Industrial Environments

- The sleeve maintains chemical stability across pH 1–14, enabling deployment in sulfuric, nitric, and hydrochloric acid processes.

- In simulated alkali exposure tests, weight loss after 72 hours remained below 0.01%, confirming suitability for caustic pipelines.

- Chloride-rich and fluorine-based applications report no structural degradation up to 1000 °C, outperforming stainless steel and aluminum oxide alternatives.

- The material exhibits Vickers hardness above 1200 HV0.5, making it highly resistant to abrasive slurry and particle-laden flow.

- Laboratory tribology tests show wear rate under 10⁻⁶ mm³/N·m, ensuring sleeve longevity even in mineral slurry systems.

- Field reports in metallurgical equipment confirm 2–4× service life extension compared to high-chrome steel sleeves under identical loading.

- Maximum working temperature reaches up to 1300 °C, maintaining strength and surface finish beyond typical ceramic limits.

- Coefficient of thermal expansion is controlled at 9.5 × 10⁻⁶ /°C, minimizing mismatch with metal assemblies during thermal cycling.

- After 100 thermal shock cycles between 25–1000 °C, no visible cracks or strength loss were detected, confirming long-term thermal reliability.

Technical Properties of Zirconia Ceramic Sleeve

Zirconia Ceramic Sleeve exhibits high mechanical strength, thermal reliability, and chemical inertness under demanding industrial conditions. Its engineered microstructure ensures consistent performance in aggressive media, high-pressure flow systems, and elevated temperatures where conventional materials degrade.

| Property |

Specification |

| Material Type |

Stabilized Zirconia (Y‑TZP / Mg‑PSZ) |

| Density |

≥ 6.0 g/cm³ |

| Flexural Strength |

700–900 MPa |

| Compressive Strength |

≥ 2000 MPa |

| Fracture Toughness (K_IC) |

6–9 MPa·m¹/² |

| Vickers Hardness |

> 1200 HV0.5 |

| Thermal Expansion Coefficient |

9.5 × 10⁻⁶/°C (20–1000 °C) |

| Maximum Operating Temperature |

Up to 1300 °C |

| Thermal Conductivity |

2.2–3.0 W/m·K |

| Acid Resistance |

Weight loss < 0.01% (72h, pH 1–2) |

| Alkali Resistance |

Stable in NaOH/KOH solutions |

| Surface Roughness (Inner) |

Ra < 0.2 µm |

Specifications of Zirconia Ceramic Sleeve

|

Zirconia Ceramic Sleeve |

|

Item NO. |

Diameter (mm) |

Width(mm) |

|

AT-YHG-CT1001 |

Customize |

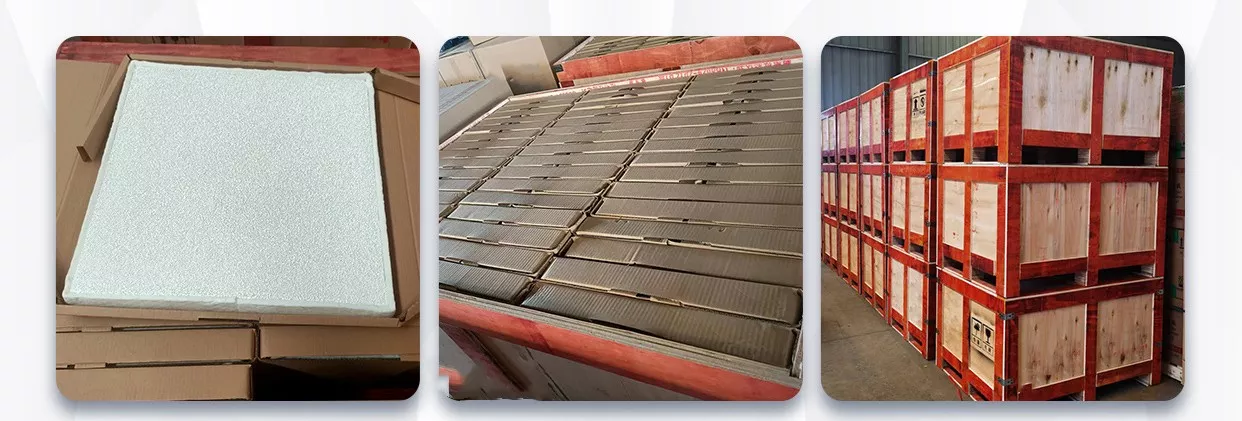

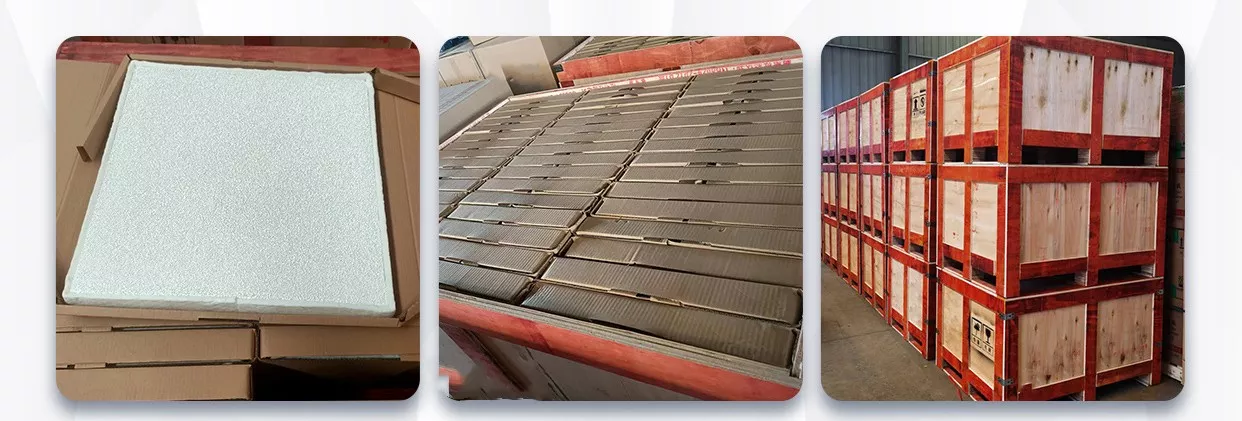

Packaging of Zirconia Ceramic Sleeve

Zirconia Ceramic Sleeve is packed using high-density foam inserts and shock-resistant cardboard compartments to ensure zero movement during transit. Each unit is further secured in reinforced wooden crates designed for export-grade logistics. This multi-layered packaging system minimizes risk of fracture, abrasion, or chemical contamination.

How ADCERAX® Zirconia Ceramic Sleeve Resolves Failure Points in Fluid Handling and Corrosive Process Equipment

ADCERAX® Zirconia Ceramic Sleeve is deployed in targeted industrial systems where chemical reactivity, particulate abrasion, or thermal shock leads to premature failure of traditional sleeve components. Its material properties directly address the operational pain points in specific flow control and high-purity applications.

-

Zirconia Ceramic Sleeve in Acidic Slurry Pumps for Flue Gas Desulfurization (FGD)

✅Key Advantages

1. Acidic Media Stability – The ADCERAX® Zirconia Ceramic Sleeve demonstrates weight loss below 0.01% after 72-hour immersion in pH < 2 sulfuric slurry. Its stable crystal lattice resists acid corrosion and prevents ionic leaching that weakens metal sleeves.

2. Dual Resistance to Abrasion and Scaling – Laboratory slurry testing shows wear rate under 10⁻⁶ mm³/N·m, maintaining inner surface polish and reducing gypsum scaling over 2,000 h of cyclic operation.

3. Thermal Durability in Continuous Operation – The sleeve retains >90% of its flexural strength at 1000 °C, avoiding microcracks from hot–cold slurry transitions common in FGD recirculation loops.

✅ ️Problem Solved

A European power plant replaced stainless-steel sleeves in FGD pumps that corroded within 45 days due to acidic slurry. After switching to ADCERAX® Zirconia Ceramic Sleeve, the pump maintained stable discharge pressure for over 12 months without measurable dimensional loss. Maintenance downtime dropped by 60%, and acid consumption for corrosion compensation decreased by 15%, proving strong cost reduction under emission control compliance.

-

Zirconia Ceramic Sleeve in High-Precision Metering Pumps for Chemical Dosing Skids

✅Key Advantages

1. Dimensional Stability under CIP Thermal Cycles – ADCERAX® Zirconia Ceramic Sleeve maintains dimensional change below 0.005% during repetitive heating–cooling between 25–120 °C, ensuring repeatable metering volume.

2. Superior Surface Finish for Flow Accuracy – Precision polished bore achieves Ra < 0.2 µm, minimizing frictional drag and preventing micro-bubble retention that alters dosing calibration.

3. Chemical Inertness to Reactive Reagents – The zirconia matrix remains unaffected by H₂O₂ and NaOH exposure after 500 h, providing material consistency for aggressive reagent handling.

✅ ️Problem Solved

An American fine chemical producer experienced ±4% dosing drift due to thermal distortion of polymer sleeves during CIP. After adopting ADCERAX® Zirconia Ceramic Sleeve, flow deviation dropped below ±0.5%, maintaining precise volumetric delivery through 1000 operating hours. Pump recalibration frequency decreased from biweekly to quarterly, improving line throughput stability and reducing maintenance labor by 40%.

-

Zirconia Ceramic Sleeve in Seawater Intake Valves for Coastal Power Plants

✅Key Advantages

1. Chloride Corrosion Immunity – In 3.5% NaCl immersion at 90 °C, ADCERAX® Zirconia Ceramic Sleeve exhibited no measurable pitting or mass loss after 1000 h, unlike bronze and duplex steel counterparts.

2. Biofouling Resistance through Dense Surface Microstructure – The material’s fine-grained surface limits biological attachment by over 80% compared to metal sleeves, reducing marine growth accumulation.

3. Galvanic Isolation from Metal Housings – Electrical resistivity above 10¹² Ω·cm prevents galvanic coupling in mixed-metal assemblies, eliminating localized corrosion at interfaces.

✅ ️Problem Solved

A coastal thermal power station in Korea reported severe pitting and scaling in seawater valve guides every 6 months. After implementing ADCERAX® Zirconia Ceramic Sleeve, no corrosion or biofouling was detected during an 18‑month maintenance cycle. Valve movement remained smooth, seal leakage incidents dropped to zero, and cleaning shutdown intervals were extended by 50%, confirming its long-term corrosion and fouling resistance under saline operation.

Operational Guidance for Zirconia Ceramic Sleeve Installation and Handling

Zirconia Ceramic Sleeve must be correctly handled, installed, and maintained to achieve optimal performance and prevent avoidable failure in demanding industrial conditions. This guide outlines practical precautions and key usage considerations across critical stages of deployment, helping users maximize the service life of Zirconia Ceramic Sleeve in fluid-facing systems.

-

Pre-Installation Checklist

1. Inspect for Visible Surface Defects

Examine all Zirconia Ceramic Sleeves for cracks, chips, or surface irregularities before use. Even minor defects can propagate under thermal or mechanical stress. Reject any components with visual non-conformities.

2. Ensure Clean and Dry Fitment Environment

Prevent dust, oil, and moisture contamination in mating areas to avoid stress points or misalignment during installation. Use lint-free wipes and compressed air when cleaning interfaces.

3. Verify Alignment and Sleeve Orientation

Match sleeve bore and length orientation with flow direction or mechanical axis. Misaligned placement can induce torsional stress or restrict flow, leading to early failure.

-

Assembly and Integration

1. Avoid Excessive Mechanical Force

Use press-fitting tools with controlled pressure and guided motion. Do not strike or hammer Zirconia Ceramic Sleeve directly, as this can cause microfractures invisible to the naked eye.

2. Use Support Rings or Dampers Where Applicable

In dynamic or rotating assemblies, consider soft-mounting options. Vibration isolation helps extend fatigue life, especially under cyclic loading or pulsed flows.

3. Torque Fasteners Evenly Around Ceramic Interfaces

Uneven torque distribution can cause asymmetric stress. Follow recommended torque sequences, especially in flanged or sealed sleeve assemblies.

-

Operational Best Practices

1. Avoid Sudden Thermal Transients

Rapid heating or cooling can create thermal shock. Ramp temperature changes below 10 °C/min where process control permits to preserve material integrity.

2. Monitor Fluid Cleanliness and pH Stability

Highly abrasive or unstable chemical fluids accelerate wear. Install inline filters or neutralization controls when using Zirconia Ceramic Sleeve in unbuffered or slurry-rich environments.

3. Document Service Cycles and Replace Predictively

Logging operational hours and peak condition cycles aids preventive maintenance. Set replacement thresholds based on wear trends, not just visible degradation.

-

Handling and Storage

1. Store in Original Packaging Until Use

The foam-layered packaging is designed to prevent impact and surface damage. Keep sleeves in protective crates until final assembly.

2. Avoid Stacking Without Isolation Padding

Direct contact between sleeves can result in surface abrasion or chipping. Use foam layers or cardboard sheets between stacked units.

3. Label and Rotate Inventory by Lot Number

Implement first-in, first-out (FIFO) handling for traceability. Record lot numbers on system logs to track performance trends.